Introduction

Industrial DC fans play a crucial role in a wide range of applications, delivering exceptional energy efficiency and performance that surpasses traditional AC units. Understanding their fundamentals allows engineers to optimize cooling and ventilation systems, leading to significant reductions in operational costs. However, the real challenge lies in effectively implementing best practices for installation, usage, and maintenance to fully realize these benefits.

To ensure these systems operate at peak efficiency and reliability, engineers can adopt several strategies:

- It is essential to conduct thorough assessments of the specific cooling needs of each application. This involves analyzing factors such as airflow requirements and environmental conditions.

- Proper installation techniques must be employed to maximize performance. This includes ensuring correct alignment and securing all connections to prevent energy loss.

- Regular maintenance is vital. Engineers should establish a routine inspection schedule to identify and address potential issues before they escalate.

By leveraging these strategies, engineers can harness the full potential of industrial DC fans, ensuring they contribute effectively to energy savings and operational efficiency.

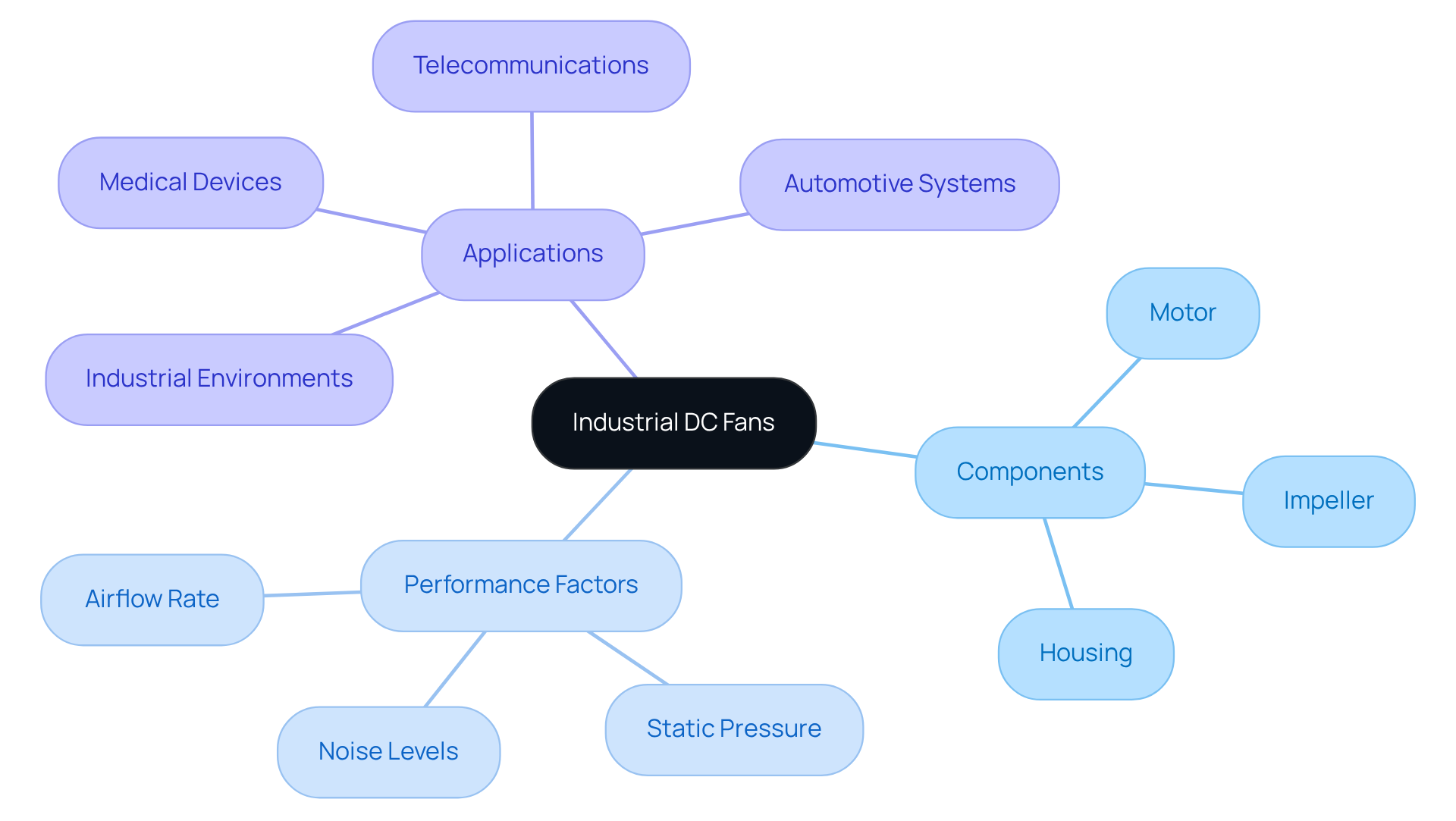

Understand the Fundamentals of Industrial DC Fans

Industrial DC fans play a pivotal role in numerous applications, delivering effective cooling and ventilation through direct current (DC) electricity. This approach significantly enhances energy efficiency compared to traditional AC units. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of both standard and custom air-movers, provides an extensive product line of industrial DC fans, featuring DC input Tube Axial fans in sizes ranging from 15 to 280mm, along with a comprehensive portfolio of DC input Centrifugal Blowers, from 15 to 225mm.

Key components – motor, impeller, and housing – are essential in generating air movement. Understanding critical factors such as airflow rate, static pressure, and noise levels is crucial for selecting the appropriate fan for specific applications. For example, Gagner-Toomey’s industrial DC fan devices are meticulously engineered to operate reliably under extreme conditions, with operational temperature ranges spanning from -40°C to 85°C. This versatility makes the industrial DC fan suitable for a variety of industrial environments.

Familiarity with these fundamentals empowers engineers to optimize fan selection and integration, ensuring effective thermal management within their systems. As noted by industry specialists, the performance and adaptability of Gagner-Toomey’s industrial DC fan units are vital in meeting the demands of modern engineering applications.

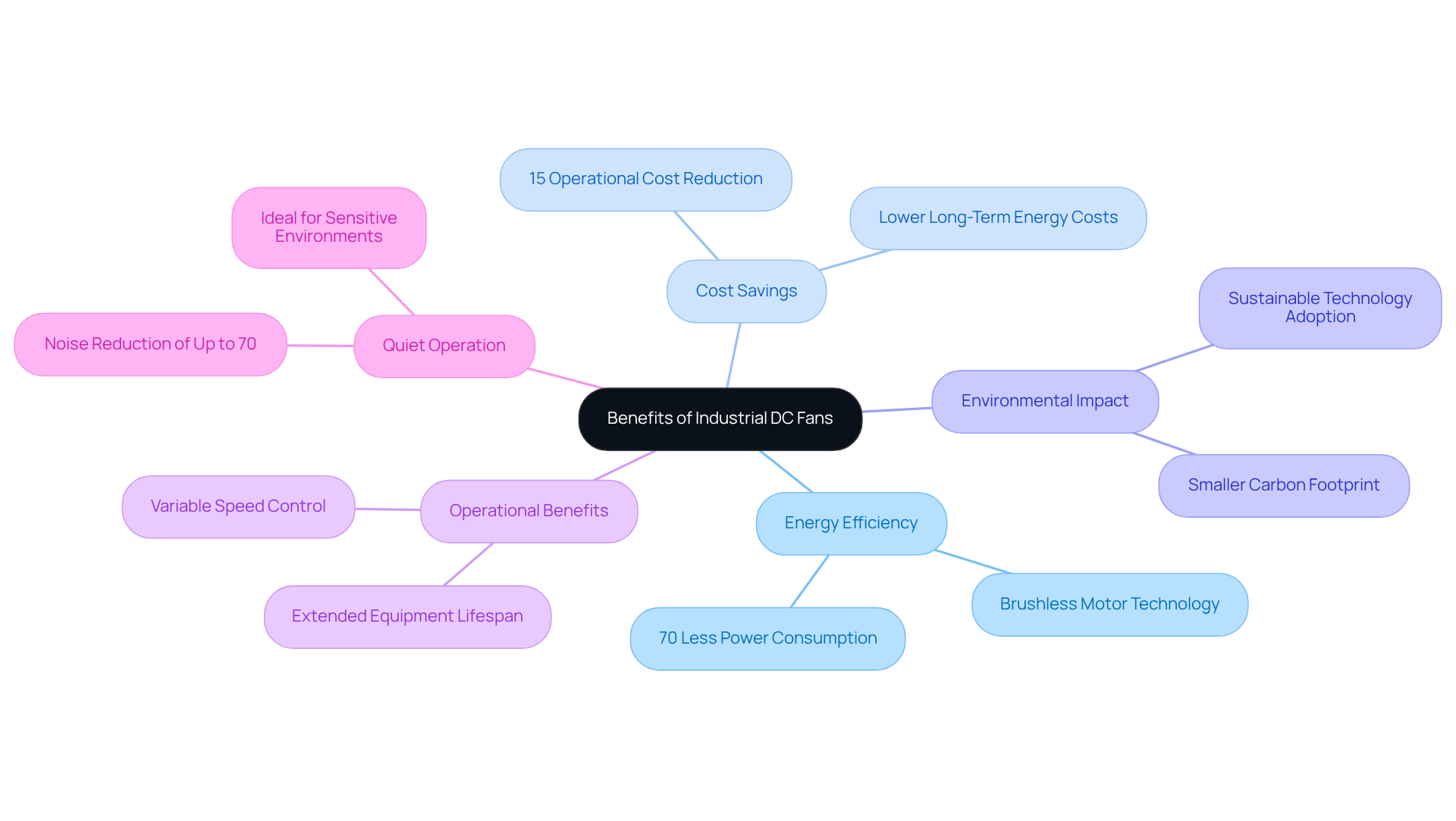

Leverage the Benefits of Industrial DC Fans in Design

Incorporating industrial DC fans into design processes presents significant advantages that cannot be overlooked. These devices are recognized for their exceptional energy efficiency, consuming up to 70% less power than traditional alternating current (AC) units. This remarkable reduction translates into substantial decreases in operating expenses and a smaller carbon footprint, making DC blowers an attractive option for environmentally conscious organizations.

Moreover, industrial DC fans provide the same ventilation capabilities as AC motors while utilizing considerably less energy, reinforcing their efficiency claims. The integration of variable speed control in DC units allows for precise airflow management tailored to real-time cooling requirements, which is particularly beneficial in environments with fluctuating temperatures. For example, in a manufacturing facility, strategically deploying direct current blowers can help maintain optimal temperatures for machinery, thereby extending equipment lifespan and boosting overall productivity.

Real-world applications further illustrate the financial benefits of this technology. Companies that have adopted DC units report operational cost reductions of up to 15%, underscoring the economic advantages of transitioning to this advanced technology. Additionally, the quiet operation of DC units makes them ideal for sensitive environments, such as medical facilities and telecommunications equipment.

Engineers and designers should prioritize these compelling advantages in their projects to fully harness the capabilities of industrial DC fan technology. By doing so, they not only enhance operational efficiency but also contribute to a more sustainable future.

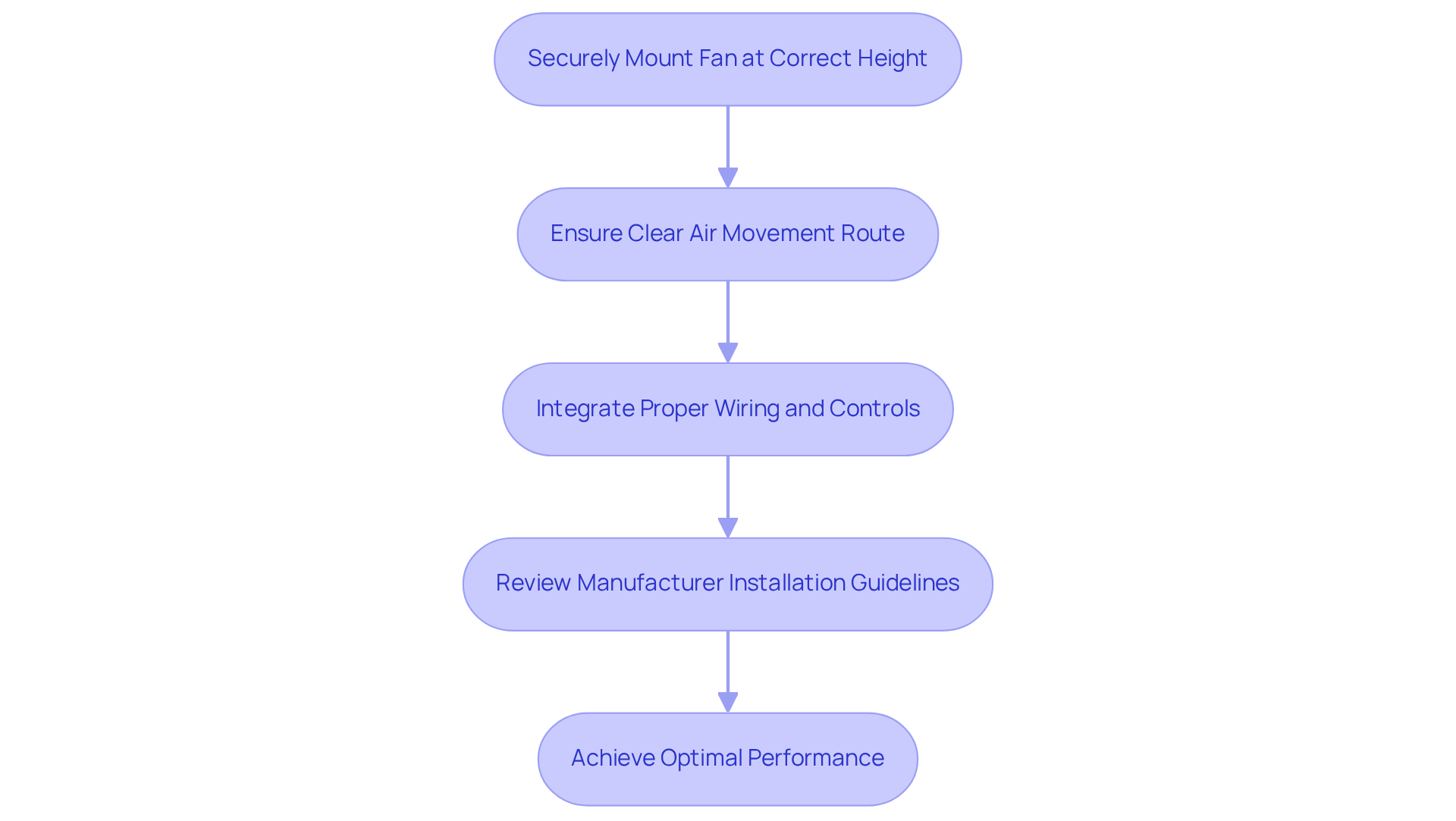

Implement Effective Installation Techniques for Optimal Performance

To achieve optimal performance from industrial DC fans, it is crucial to focus on installation techniques.

- Ensure that the fan is mounted securely and at the correct height to optimize circulation. For instance, devices should typically be installed 20-30 feet above the floor in large areas to promote effective air circulation.

- Maintaining a clear route for air movement is essential; any barriers can significantly diminish fan performance.

- Proper wiring and control integration are vital, as they ensure that the fan operates smoothly and responds to system demands.

- Regularly reviewing installation guidelines from manufacturers can help engineers adhere to best practices and avoid common installation errors.

By following these recommendations, you can enhance the efficiency and reliability of your DC units.

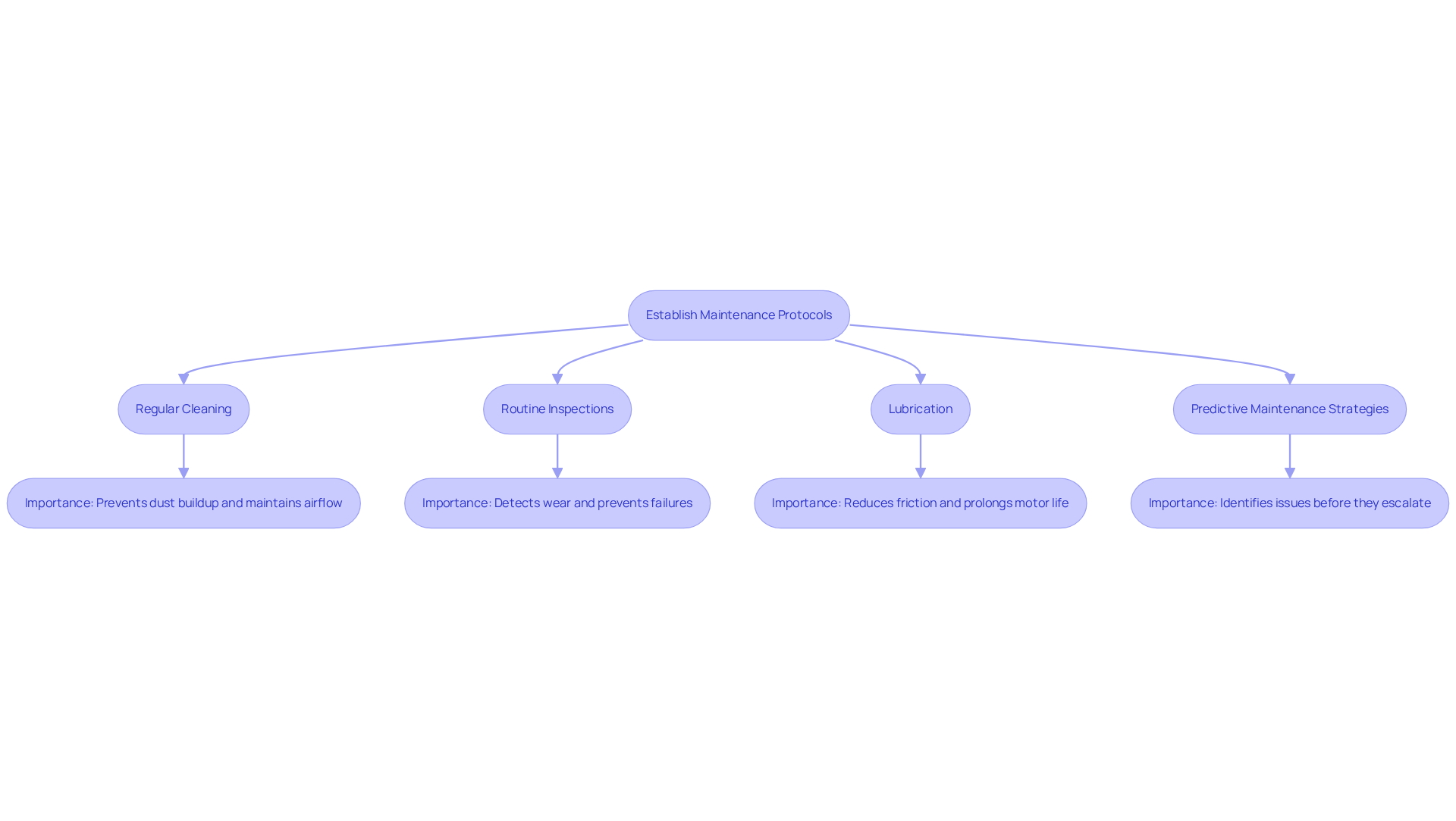

Establish Maintenance Protocols for Longevity and Efficiency

To ensure the performance and durability of industrial DC fans, it is essential to establish a robust maintenance protocol. Regular cleaning of fan blades and housing is vital to prevent dust and debris buildup, which can obstruct airflow and elevate energy consumption. Maintenance professionals advocate for routine inspections to detect signs of wear, particularly in motor components and bearings. As Marc Cousineau, Senior Content Marketing Manager, emphasizes, “Regular maintenance not only saves money by avoiding costly repairs but also contributes to a safer and more efficient work environment.”

Lubrication should adhere to manufacturer guidelines to reduce friction and prolong motor life. Implementing predictive maintenance strategies, as exemplified by Oneida County’s predictive asset management, enables organizations to identify potential issues before they escalate into failures, significantly minimizing unplanned downtime. By following these best practices, including a recommended cleaning frequency of monthly to quarterly, organizations can optimize the performance of their DC fans, thereby enhancing overall system reliability and efficiency.

Conclusion

Industrial DC fans play a crucial role in enhancing energy efficiency and improving thermal management across various applications. Understanding their fundamental components and operational capabilities empowers engineers to make informed decisions, leading to effective cooling and ventilation solutions. The benefits of these fans extend beyond functionality; they provide significant energy savings and reduce environmental impact, making them a preferred choice in today’s industrial landscape.

To utilize industrial DC fans effectively, several best practices should be highlighted:

- Proper installation techniques are vital for maximizing performance.

- Maintenance protocols ensure longevity and efficiency.

- The economic advantages realized through their integration into design processes cannot be overlooked.

- By leveraging variable speed controls and adhering to manufacturer guidelines, organizations can optimize airflow management, reduce operational costs, and maintain a quieter working environment.

Ultimately, the effective use of industrial DC fans transcends immediate performance; it fosters a sustainable and efficient future in industrial operations. By prioritizing these best practices, engineers and designers not only enhance system reliability but also contribute to a greener planet. Embracing the capabilities of industrial DC fans is a significant step toward achieving both operational excellence and environmental stewardship.

Frequently Asked Questions

What are industrial DC fans used for?

Industrial DC fans are used for effective cooling and ventilation in various applications, utilizing direct current (DC) electricity to enhance energy efficiency compared to traditional AC units.

Who is Gagner-Toomey Associates?

Gagner-Toomey Associates is recognized as the world’s largest manufacturer of both standard and custom air-movers, offering an extensive product line of industrial DC fans.

What types of industrial DC fans does Gagner-Toomey offer?

Gagner-Toomey offers DC input Tube Axial fans in sizes ranging from 15 to 280mm and DC input Centrifugal Blowers from 15 to 225mm.

What are the key components of industrial DC fans?

The key components of industrial DC fans include the motor, impeller, and housing, which are essential for generating air movement.

What factors should be considered when selecting an industrial DC fan?

Important factors to consider include airflow rate, static pressure, and noise levels to ensure the appropriate fan is selected for specific applications.

What is the operational temperature range for Gagner-Toomey’s industrial DC fans?

Gagner-Toomey’s industrial DC fans are engineered to operate reliably under extreme conditions, with an operational temperature range from -40°C to 85°C.

Why is understanding the fundamentals of industrial DC fans important for engineers?

Familiarity with the fundamentals helps engineers optimize fan selection and integration, ensuring effective thermal management within their systems.

What makes Gagner-Toomey’s industrial DC fan units suitable for modern engineering applications?

The performance and adaptability of Gagner-Toomey’s industrial DC fan units are vital in meeting the demands of modern engineering applications.