Introduction

Understanding the importance of LED cooling fans is crucial for anyone engaged in electronics. These devices are vital for ensuring optimal performance and extending the lifespan of LED components. This article will explore the fundamentals of LED cooling fans, including their design, technical specifications, and best practices for implementation and maintenance.

With a variety of models available and potential issues that may arise, how can you ensure you select the right fan and troubleshoot effectively?

Explore the Fundamentals of LED Cooling Fans

LED ventilation devices, such as a led cooling fan, play a crucial role in dispersing heat generated by LED components. If this heat is not effectively managed, it can lead to performance decline and a shortened lifespan of the devices. These ventilation systems utilize a led cooling fan that operates on the principle of forced convection, actively directing airflow across heat sinks to enhance heat dissipation. Key components include:

- Fan Blades: Designed to maximize airflow while minimizing noise, these blades ensure efficient cooling without disruptive sound levels. Gagner-Toomey Associates provides a comprehensive range of DC input Tube Axial fans, optimized for performance and efficiency, available in sizes from 15 to 280mm, with IP protection available upon request.

- Motor Type: Brushless DC motors are preferred for their efficiency and longevity, delivering reliable performance over extended periods.

- Control Mechanisms: PWM (Pulse Width Modulation) control allows for variable speed operation, optimizing temperature management based on thermal load, which is essential for maintaining optimal LED performance.

As we look ahead to 2026, effective refrigeration solutions are becoming increasingly vital due to the rising demand for energy-efficient electronics. Engineers stress that the principles of forced convection are essential for effective thermal management, noting that heat transfer occurs through conduction, convection, and radiation. Case studies highlight the successful application of forced convection in LED thermal management, showcasing significant advancements in temperature control and component lifespan. Furthermore, a mere 10°C increase in heat can drastically reduce the lifespan of electronic components, emphasizing the necessity of proper maintenance and operation of the led cooling fan. Operating a fan for just eight hours daily can significantly extend its lifespan, underscoring the importance of careful fan selection and upkeep. Gagner-Toomey’s extensive portfolio of temperature regulation solutions, including standard and custom designs, as well as miniature blower/fan options for consumer applications, ensures that engineers can find the right fan for specific uses, ultimately enhancing thermal management in electronic systems.

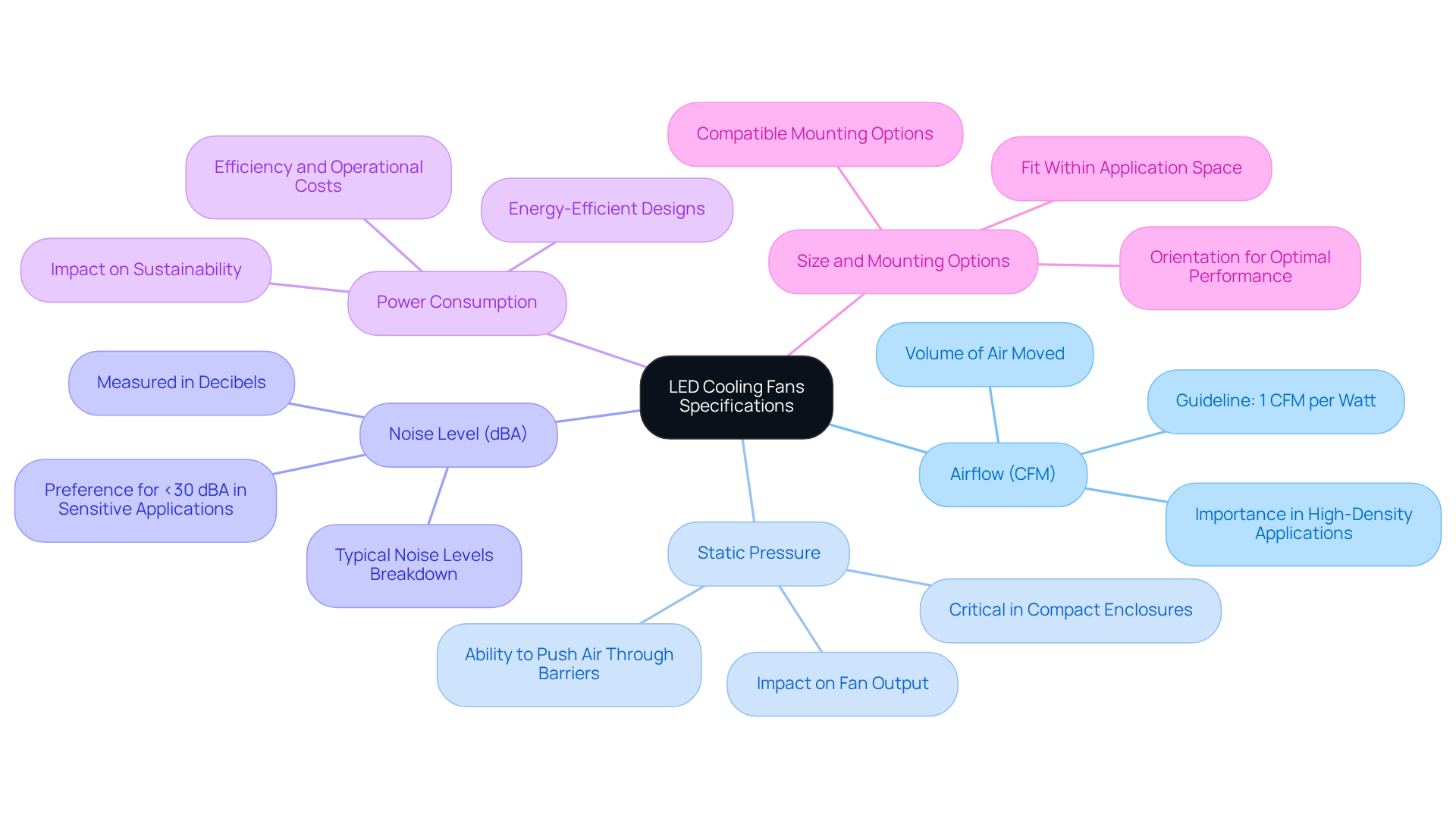

Analyze Technical Specifications and Features

When selecting LED cooling fans, understanding the technical specifications is crucial for optimal performance:

-

Airflow (CFM): Airflow, measured in cubic feet per minute, indicates the volume of air the fan can move. A higher CFM rating is essential for effective cooling, particularly in high-density applications where heat generation is significant.

-

Static Pressure: This specification is vital for blowers operating in restrictive environments. It assesses the fan’s ability to push air through barriers like heat sinks and filters. In scenarios with high static pressure, such as compact enclosures, it’s imperative to choose devices designed to maintain airflow under pressure to prevent overheating.

-

Noise Level (dBA): Noise levels, measured in decibels, reflect how loud the fan operates. For noise-sensitive applications, lower dBA ratings are preferable. Engineers often seek fans that operate below 30 dBA to ensure a quiet environment, especially in consumer electronics.

-

Power Consumption: Efficiency is key; look for fans that provide high airflow while minimizing power usage. Energy-efficient designs not only reduce operational costs but also enhance the sustainability of electronic devices.

-

Size and Mounting Options: Ensure the fan fits within your application space and has compatible mounting options. Proper orientation and secure mounting are essential for optimal performance and reliability.

By comprehending these specifications, you can select the right fan tailored to your specific temperature regulation needs, ultimately improving system efficiency and extending lifespan.

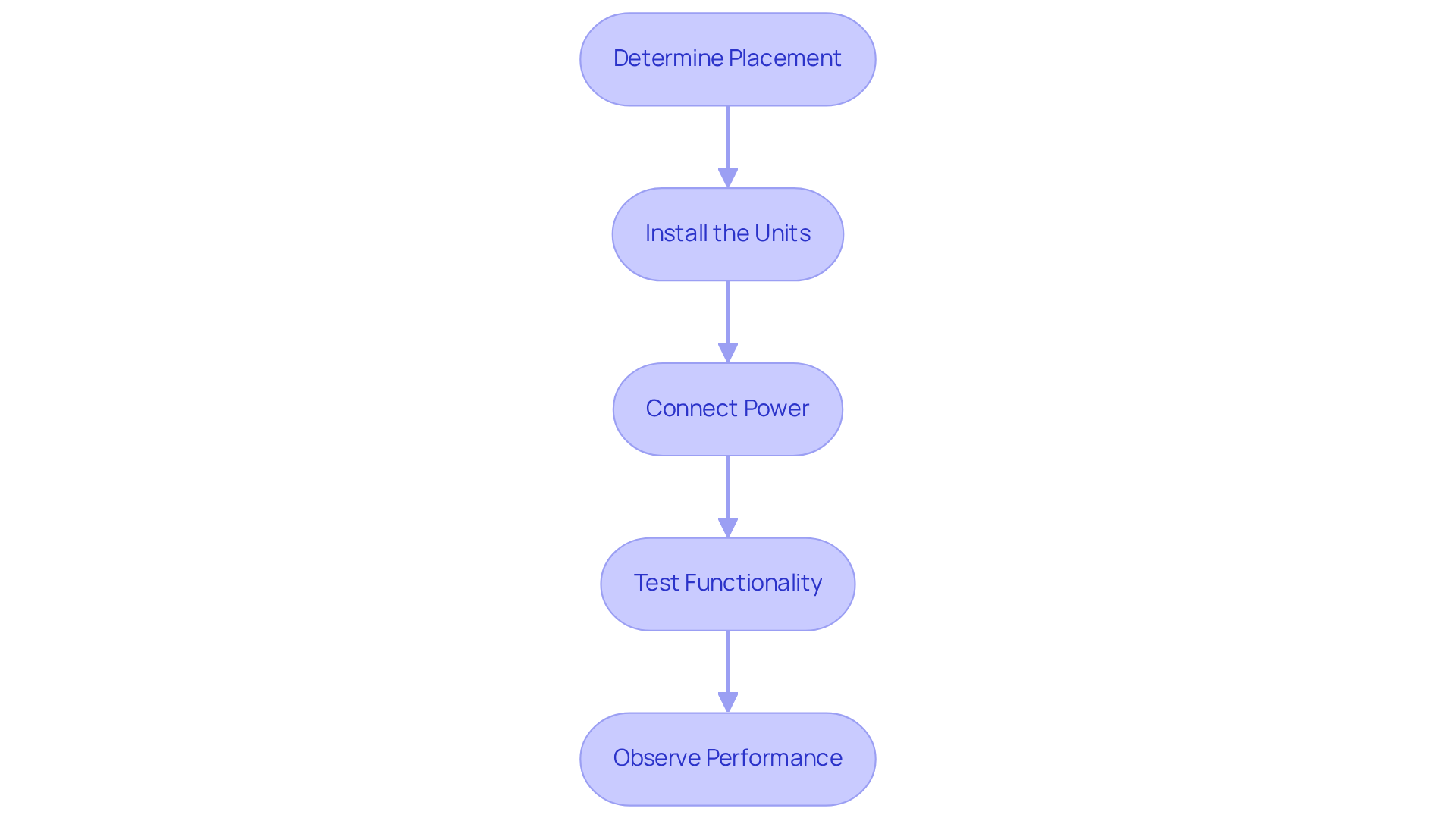

Implement LED Cooling Fans in Electronic Systems

To implement LED cooling fans effectively, follow these essential steps:

-

Determine Placement: Start by identifying the optimal locations for the devices. This ensures effective airflow across heat-generating components, which is crucial for maintaining system performance.

-

Install the Units: Secure the units using appropriate screws or brackets. Position them strategically to draw in cool air or exhaust hot air, maximizing their cooling efficiency.

-

Connect Power: Connect the fan to the power supply, ensuring compatibility with the voltage and current ratings. If available, utilize PWM connectors for precise speed control, enhancing operational flexibility.

-

Test Functionality: Turn on the device and confirm that the cooling units function properly. Pay attention to any unusual noises or vibrations, as these may indicate improper installation that needs addressing.

-

Observe Performance: After installation, monitor the temperatures closely. Ensure the vents provide sufficient temperature regulation. Adjust fan speeds as necessary based on the thermal load to optimize performance.

By following these steps, you will ensure that your electronic setups effectively integrate the LED cooling fan into your LED ventilation systems, enhancing their reliability and efficiency.

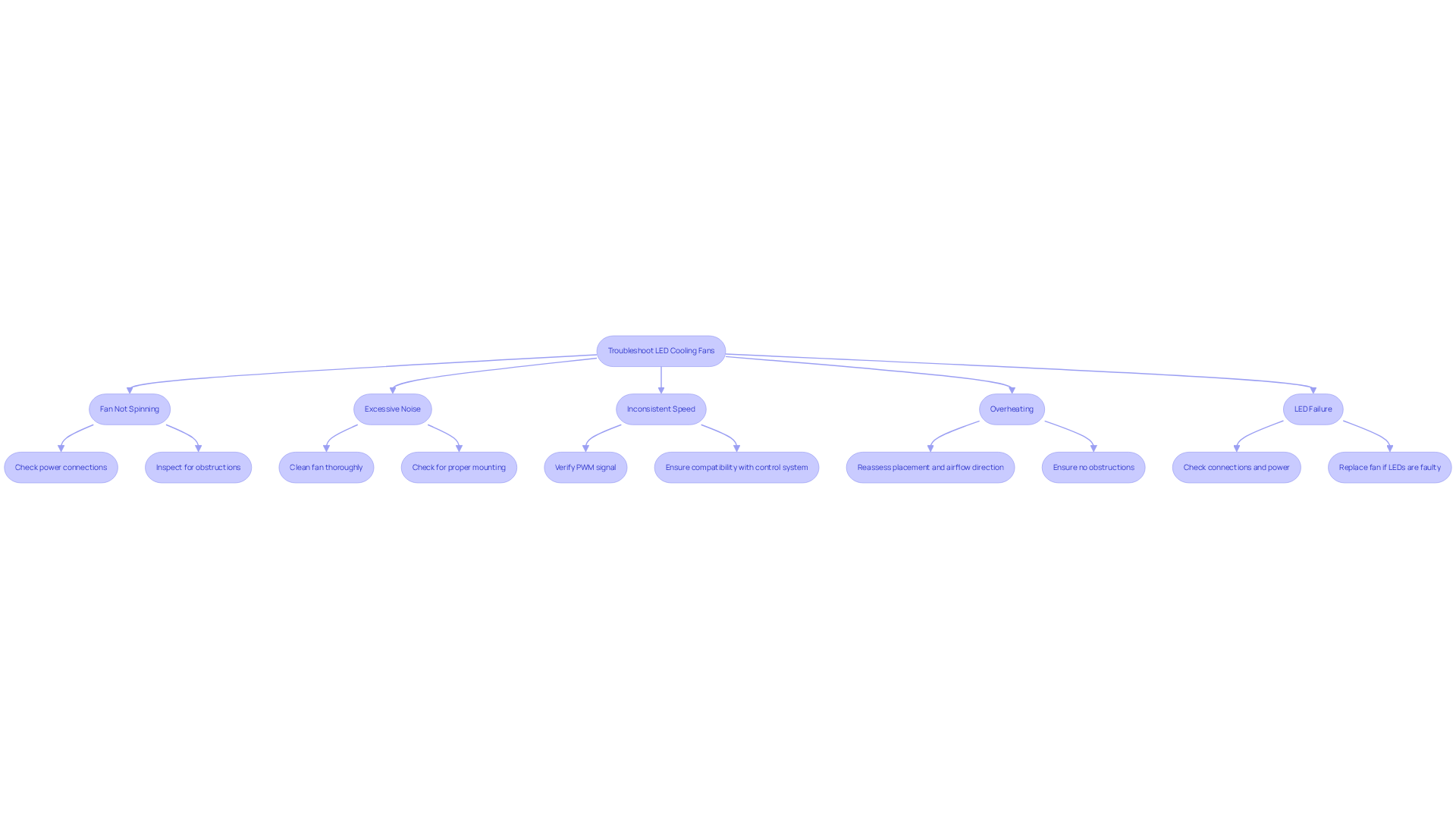

Troubleshoot Common Issues with LED Cooling Fans

Common issues with LED cooling fans include:

-

Fan Not Spinning: First, check the power connections to ensure the fan is receiving adequate voltage. Inspect for any obstructions that may prevent movement, as these can significantly hinder performance.

-

Excessive Noise: A noisy fan often indicates bearing failure or debris caught in the blades. Clean the fan thoroughly and check for proper mounting to mitigate this issue.

-

Inconsistent Speed: If you notice fluctuations in fan speed, verify the PWM signal and ensure the fan is compatible with the control system. Compatibility is crucial for consistent operation.

-

Overheating: If the fan is not delivering sufficient ventilation, reassess its placement and airflow direction. Ensure that the fan is not obstructed by other components, as this can lead to overheating and reduced efficiency.

-

LED Failure: If the fan’s LEDs are not functioning, check the connections and ensure the fan is powered correctly. If the LEDs are faulty, replacing the fan may be necessary.

By understanding these common issues and their solutions, you can ensure the optimal performance of your LED cooling fan. Regular maintenance practices, such as lubricating the fan bearings at least once a year, are crucial to ensure smooth operation and prevent issues that could reduce production capacity by as much as 20%.

Conclusion

Mastering LED cooling fans is crucial for ensuring the longevity and performance of LED systems. By grasping the fundamentals – like airflow dynamics, motor types, and control mechanisms – engineers and technicians gain the expertise needed to select and implement optimal cooling solutions. Effectively managing heat through robust thermal management not only boosts device efficiency but also significantly prolongs component lifespan.

Key insights from this article underscore the necessity of choosing the right fan based on specifications such as airflow, static pressure, noise levels, and power consumption. The step-by-step guide for installation and troubleshooting common issues empowers users to maintain peak functionality. By adhering to these best practices, you can ensure that LED cooling fans operate effectively, preventing overheating and performance degradation.

Given the pivotal role that LED cooling fans play in electronic systems, prioritizing their selection, installation, and maintenance is imperative. As the demand for energy-efficient electronics continues to grow, investing in high-quality cooling solutions will yield better performance and reliability. Embrace the knowledge shared in this article to make informed decisions that will enhance your LED systems and contribute to a more efficient future in technology.

Frequently Asked Questions

What is the role of LED cooling fans?

LED cooling fans are crucial for dispersing heat generated by LED components, helping to prevent performance decline and extending the lifespan of the devices.

How do LED cooling fans work?

They operate on the principle of forced convection, actively directing airflow across heat sinks to enhance heat dissipation.

What are the key components of a LED cooling fan?

Key components include fan blades designed for efficient airflow and minimal noise, brushless DC motors for reliability and efficiency, and PWM (Pulse Width Modulation) control for variable speed operation.

Why are brushless DC motors preferred in LED cooling fans?

Brushless DC motors are preferred for their efficiency and longevity, providing reliable performance over extended periods.

What is the significance of PWM control in LED cooling fans?

PWM control allows for variable speed operation, optimizing temperature management based on thermal load, which is essential for maintaining optimal LED performance.

What impact does heat have on electronic components?

A mere 10°C increase in heat can drastically reduce the lifespan of electronic components, highlighting the need for effective thermal management.

How can operating a fan affect its lifespan?

Operating a fan for just eight hours daily can significantly extend its lifespan, emphasizing the importance of careful fan selection and maintenance.

What solutions does Gagner-Toomey Associates offer for LED cooling fans?

Gagner-Toomey offers a comprehensive range of DC input Tube Axial fans in various sizes, along with standard and custom designs, and miniature blower/fan options for specific applications to enhance thermal management in electronic systems.