Introduction

Understanding the vital role of forward curve blowers in various industries – ranging from HVAC systems to medical equipment – highlights their significance. These specialized fans are engineered for high airflow at low pressures, enhancing operational efficiency while ensuring clean air movement in sensitive environments. However, the selection and maintenance of the right blower can present challenges for engineers and technicians. What essential design principles and maintenance practices can help maximize the effectiveness of forward curve blowers?

By addressing these challenges, we can unlock the full potential of these critical components.

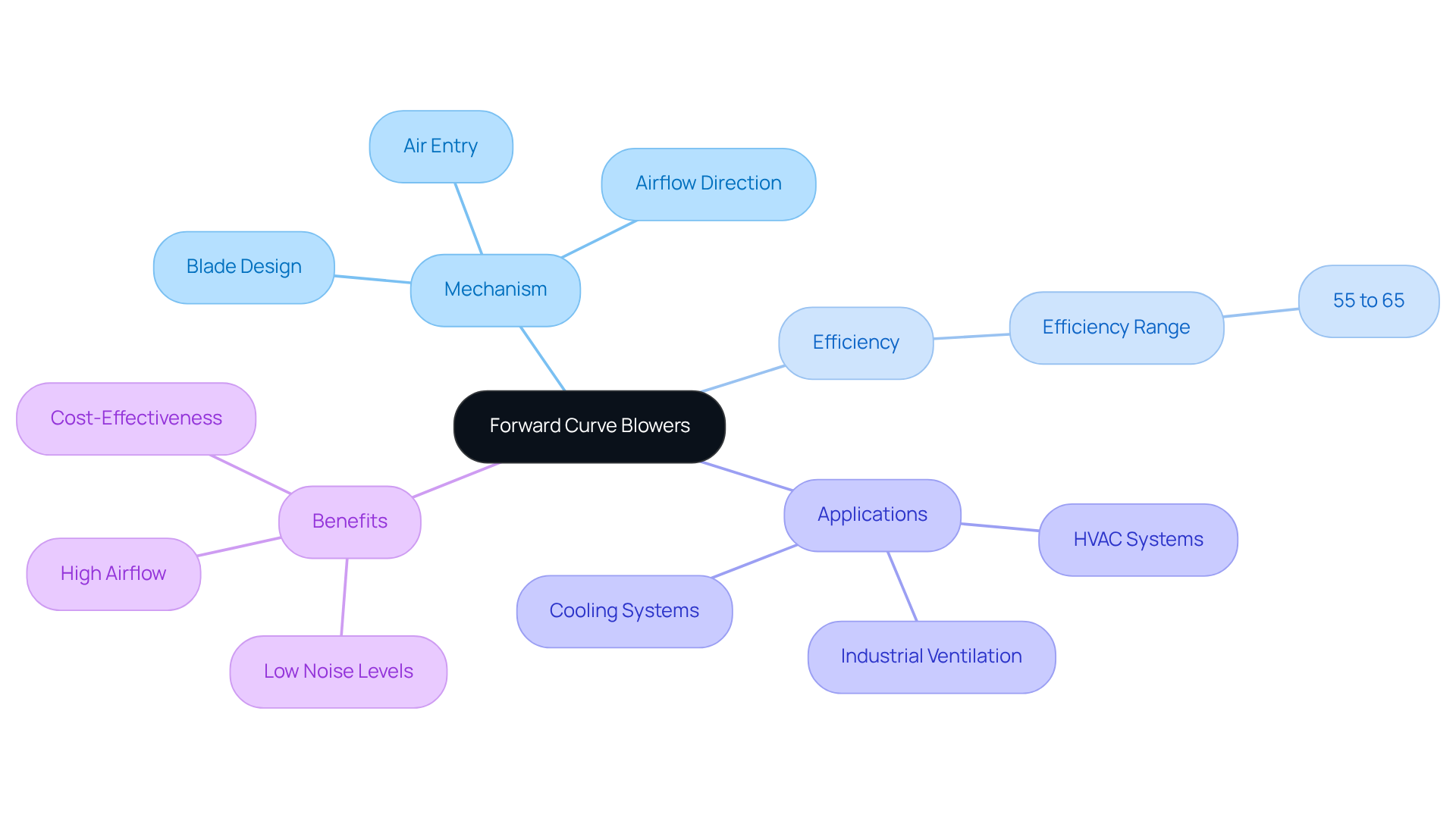

Define Forward Curve Blowers and Their Mechanism

Forward curve blowers, also known as forward curved centrifugal units, feature blades that bend in the direction of rotation. This design enables them to effectively transport large volumes of air at comparatively low pressures with a forward curve blower. By drawing air into the center of the impeller and propelling it radially outward, these fans achieve a high airflow rate. This characteristic makes the forward curve blower particularly suitable for applications requiring efficient air movement, such as HVAC systems and industrial ventilation. Notably, forward curved fans typically operate with an efficiency range of 55% to 65%. This efficiency is a critical factor for engineers when selecting fans for specific applications.

Gagner-Toomey Associates stands as the globe’s largest producer of standard and custom air-movers, offering a diverse range of DC input forward fan units optimized for effectiveness, efficiency, and low noise. The integration of a double inlet fan scroll housing significantly enhances performance by allowing air entry from both sides, thereby maximizing airflow efficiency. This mechanism is essential for optimizing their use in cooling systems, where maintaining consistent airflow is vital.

As highlighted, forward curve blowers are better for quiet, clean, and low-pressure rooms, making them ideal for environments that demand silent operation and clean air movement, such as homes and offices. Understanding the operational principles and benefits of forward fans, along with their efficiency and suitability for various applications, is crucial for engineers aiming to implement effective cooling solutions.

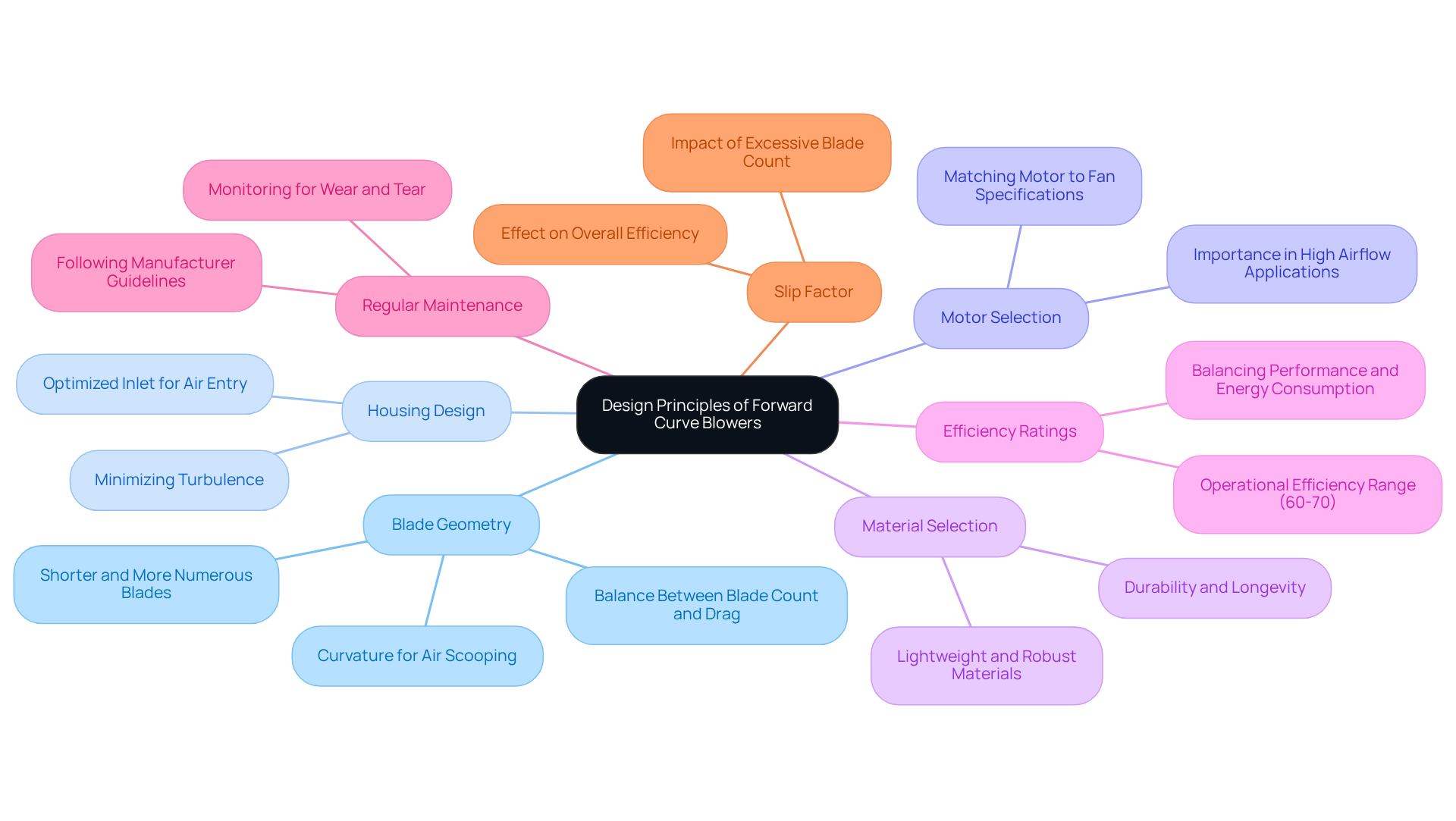

Explore Design Principles of Forward Curve Blowers

The design of forward curve blowers is grounded in several key principles that optimize their performance:

-

Blade Geometry: Forward curve blowers feature blades that are typically shorter and more numerous than those found in backward-curved fans. This design choice enhances airflow efficiency significantly. The curvature of the blades is meticulously crafted to scoop air effectively, thereby increasing velocity. Moreover, the number of blades plays a crucial role in efficiency; while more blades can create smoother airflow, they may also increase drag if not properly optimized.

-

Housing Design: The casing of the fan is engineered to minimize turbulence and maximize airflow. A well-designed scroll directs air smoothly, which reduces energy losses. Additionally, an optimized inlet can further enhance these characteristics, ensuring ideal air entry conditions.

-

Motor Selection: Selecting the appropriate motor is vital for achieving desired performance outcomes. Motors must be matched to the fan’s specifications to ensure optimal operation, especially in applications that demand high airflow at low pressure.

-

Material Selection: The choice of materials in construction is critical; they must endure operational stresses and environmental conditions to ensure durability and longevity. Utilizing lightweight yet robust materials can enhance efficiency while reducing energy consumption.

-

Efficiency Ratings: Familiarity with the efficiency ratings of various designs is essential for selecting the right fan for specific applications. This balance between performance and energy consumption is crucial. Forward curve blowers typically operate within an efficiency range of 60-70%, making them suitable for a variety of engineering applications.

-

Regular Maintenance: Consistent maintenance is key to the longevity and efficiency of centrifugal fans. This includes monitoring for signs of wear, ensuring proper lubrication, and following manufacturer guidelines to maintain optimal functionality.

-

Slip Factor: The slip factor can negatively impact overall effectiveness when an excessive number of blades are used, thereby affecting the fan’s efficiency.

By adhering to these design principles, engineers can create forward curve blowers that not only meet stringent industry standards but also provide exceptional performance across diverse applications.

Identify Applications of Forward Curve Blowers in Industry

Forward fans are essential in various sectors due to their ability to deliver high airflow at low pressures. Their applications are critical in enhancing operational efficiency across multiple industries:

- HVAC systems rely on forward curve blowers, which are integral to heating, ventilation, and air conditioning, ensuring efficient air circulation that optimizes indoor environments.

- Industrial Processes: In manufacturing, forward curve blowers are vital for drying, cooling, and material handling processes, where consistent airflow is crucial for productivity.

- Food Processing: The forward curve blower plays a key role in maintaining air quality and temperature regulation in food processing facilities, which is essential for ensuring product safety and quality.

- Medical Equipment: In hospitals, forward curve blowers are utilized in ventilation systems to provide clean air in surgical and patient care settings, safeguarding health.

- Electronics Cooling: These fans are critical for cooling electronic components, preventing overheating and ensuring optimal functionality in devices.

- Forward curve blowers are effective in dust collection systems, helping maintain clean and safe working environments.

Understanding these applications allows engineers to tailor their designs to meet specific industry needs, ultimately enhancing overall system performance.

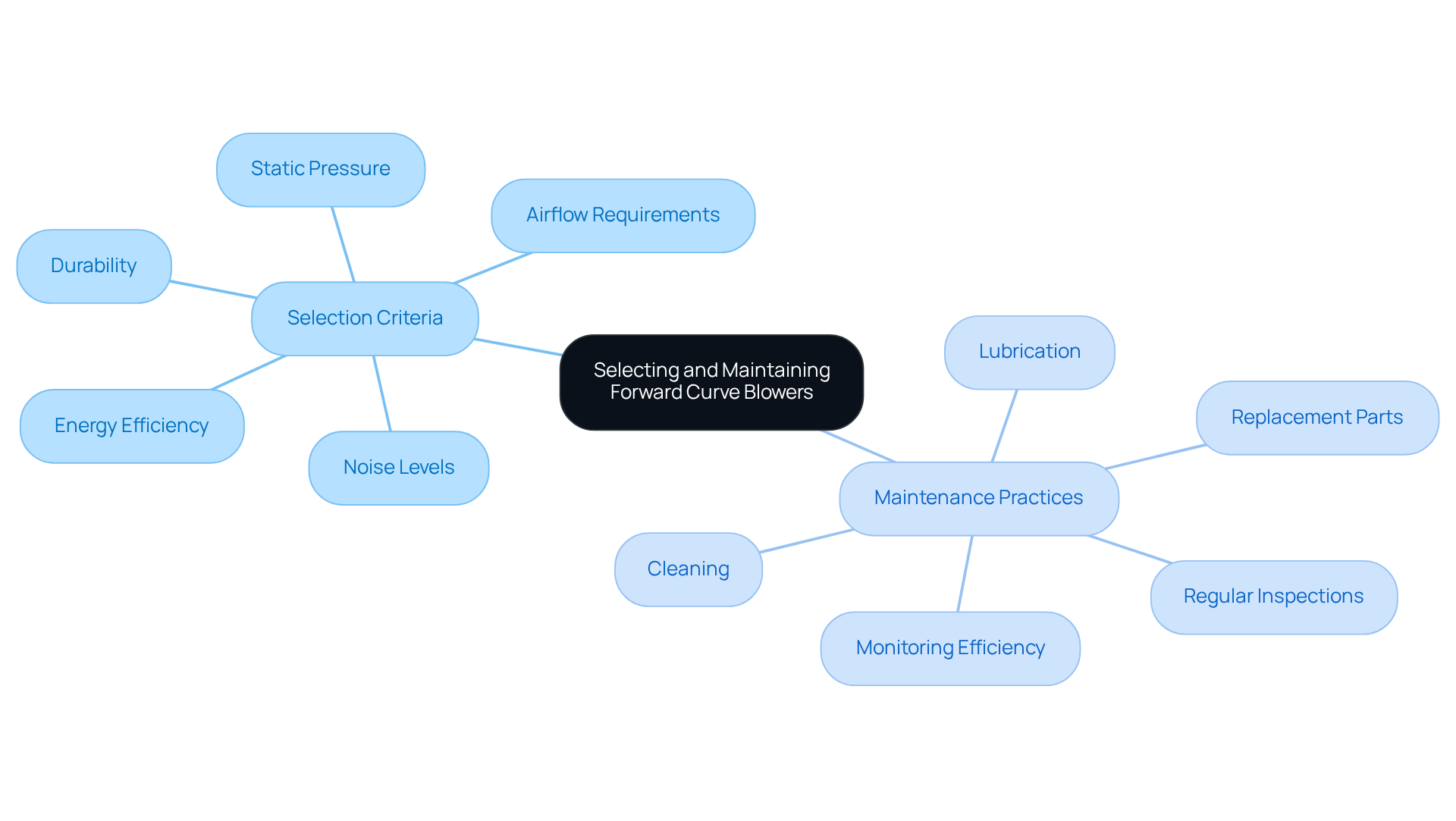

Guide on Selecting and Maintaining Forward Curve Blowers

Selecting and maintaining a forward curve blower is essential for optimal performance and longevity. Here’s how to ensure you make the right choices:

Selection Criteria

- Airflow Requirements: Start by determining the required airflow (CFM) for your specific application. This is crucial for ensuring the blower meets operational demands.

- Static Pressure: Evaluate the static pressure requirements. A fan that can’t handle the necessary pressure won’t function effectively in your system.

- Noise Levels: Consider the acceptable noise levels for your environment. Some fans operate more quietly than others, which can be a significant factor in sensitive settings.

- Energy Efficiency: Look for fans with high efficiency ratings. This not only reduces operational costs but also contributes to a more sustainable operation.

- Durability: Choose materials that can withstand the specific environmental conditions of your application. This ensures longevity and reliability.

Maintenance Practices

- Regular Inspections: Conduct routine checks for wear and tear. Ensuring all components function correctly is vital for maintaining efficiency.

- Lubrication: Regularly lubricate bearings and moving parts. This minimizes friction and wear, extending the blower’s lifespan.

- Cleaning: Keep the blower and its parts clean. Dust accumulation can impede functionality, so regular cleaning is essential.

- Monitoring Efficiency: Track airflow and pressure consistently. Identifying drops in efficiency early can indicate maintenance needs before they escalate.

- Replacement Parts: Always use manufacturer-recommended parts for replacements. This maintains compatibility and performance, ensuring your blower operates as intended.

By adhering to these guidelines, users can ensure that their forward curve blowers function efficiently and have a long service life. This proactive approach not only enhances performance but also contributes significantly to the success of your applications.

Conclusion

Forward curve blowers are essential components in various engineering applications, expertly designed to move air efficiently at low pressures while achieving high airflow rates. Their distinctive blade geometry and housing design optimize performance, making them crucial in environments that demand quiet and clean air movement, such as HVAC systems and industrial settings.

This article explores the fundamental design principles that enhance the efficiency of these blowers, including blade geometry, housing design, and material selection. It highlights their diverse applications across industries – from food processing to medical equipment – underscoring their vital role in maintaining air quality and operational efficiency. Furthermore, it offers practical guidance on selecting and maintaining forward curve blowers, emphasizing the necessity of regular inspections and proper lubrication to ensure longevity and optimal performance.

In conclusion, grasping the intricacies of forward curve blowers equips engineers with the knowledge to select the right equipment for specific applications. It also reinforces the importance of maintenance practices in achieving sustained efficiency. By embracing these insights, professionals can enhance performance, reduce operational costs, and improve environmental conditions across various sectors.

Frequently Asked Questions

What are forward curve blowers?

Forward curve blowers, also known as forward curved centrifugal units, are fans that feature blades bending in the direction of rotation, allowing them to transport large volumes of air at low pressures.

How do forward curve blowers work?

These blowers draw air into the center of the impeller and propel it radially outward, achieving a high airflow rate suitable for efficient air movement.

What is the efficiency range of forward curve blowers?

Forward curve blowers typically operate with an efficiency range of 55% to 65%.

What applications are forward curve blowers suitable for?

They are particularly suitable for applications requiring efficient air movement, such as HVAC systems and industrial ventilation, as well as environments that demand silent operation and clean air movement.

Who is a major producer of forward curve blowers?

Gagner-Toomey Associates is the globe’s largest producer of standard and custom air-movers, offering a diverse range of DC input forward fan units.

How does the design of the double inlet fan scroll housing enhance performance?

The double inlet fan scroll housing allows air entry from both sides, maximizing airflow efficiency and making it essential for optimizing use in cooling systems.

Why are forward curve blowers preferred for quiet and clean environments?

They are better suited for quiet, clean, and low-pressure rooms, making them ideal for homes and offices that require silent operation and effective air movement.