Overview

This article highlights four essential practices for selecting commercial fans in electronics, underscoring the critical need to understand specifications, evaluate application requirements, choose suitable fan types, and implement optimal installation and maintenance practices.

Key factors such as:

- Airflow rate

- Static pressure

- Noise levels

- Adherence to environmental conditions

are discussed in detail, collectively ensuring peak performance and efficiency in electronic cooling applications. By grasping these elements, professionals can make informed decisions that enhance the effectiveness of their cooling solutions.

Introduction

In the realm of electronics cooling, the selection of the right commercial fan stands as a pivotal decision that can profoundly influence both performance and efficiency. Engineers face a myriad of specifications to consider—airflow rates, static pressure, noise levels, and power consumption—navigating a complex landscape to identify the optimal solution tailored to their specific applications. As industries evolve and the demand for reliable cooling solutions intensifies, grasping the nuances of fan selection becomes essential.

This article explores the critical specifications, application requirements, and best practices for selecting and maintaining commercial fans, offering valuable insights for engineers dedicated to enhancing system reliability and operational effectiveness.

Understand Key Specifications of Commercial Fans

Choosing the appropriate commercial fan for electronics applications necessitates a comprehensive grasp of various essential specifications that affect efficiency. Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers a comprehensive portfolio of cooling solutions optimized for performance, efficiency, and low noise, establishing them as a leading provider in the industry. Understanding these specifications is crucial:

- Airflow Rate (CFM): The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air a fan can move. Elevated CFM ratings are essential for applications requiring substantial cooling. Current trends show that numerous commercial fans, including those from Gagner-Toomey, are designed to meet the rising air movement rate requirements, reflecting the increasing demand for efficient cooling solutions in the electronics industry. The significance of flow rate CFM cannot be overstated, as it directly influences cooling efficiency across various applications.

- Static Pressure: This specification assesses the resistance a fan can overcome to sustain air movement, making it essential for systems with ductwork or filters that may impede air circulation. Recent insights reveal that the installation of accessories, such as filters, can significantly impact static pressure performance. Johann Tang, a Product Specialist, notes, “The filter causes the most significant pressure loss, while the finger guard causes little loss.” For instance, the MU1225S-21 fan exemplifies how accessory integration can alter airflow characteristics, underscoring the importance of considering static pressure in fan selection.

- Noise Level (dBA): The noise produced by a fan, measured in decibels (dBA), is a crucial factor in environments where sound levels are a concern. Opting for devices with lower dBA ratings can help preserve a quieter workspace, which is increasingly essential in . Gagner-Toomey’s products are specifically designed with low noise levels in mind, catering to this growing need.

- Power Consumption: Understanding the wattage and efficiency ratings of these devices is crucial for selecting energy-efficient alternatives that reduce operational expenses. As energy efficiency becomes a priority in the electronics sector, devices that offer reduced power usage without sacrificing performance, such as those from Gagner-Toomey, are gaining popularity.

- Size and Mounting Options: The physical dimensions and mounting configurations of the devices must align with the intended installation space. Gagner-Toomey provides a broad product line that includes a commercial fan selection of and Centrifugal Blowers, available in sizes from 15 to 280mm, ensuring compatibility with various systems for effective integration. Additionally, custom designs starting from 15x3mm sizes are available, along with IP protection options in most models upon request.

- Common Pitfalls: Engineers should be aware of frequent errors in fan selection, such as neglecting the influence of accessories on efficiency or failing to take into account the particular cooling requirements of their applications. These oversights can lead to suboptimal fan efficiency and increased operational costs.

By focusing on these specifications, engineers can make informed choices that guarantee optimal fan operation in their specific applications. This approach not only enhances cooling efficiency but also contributes to the overall reliability of electronic systems. Ultimately, concentrating on these key specifications will lead to improved product outcomes and operational effectiveness.

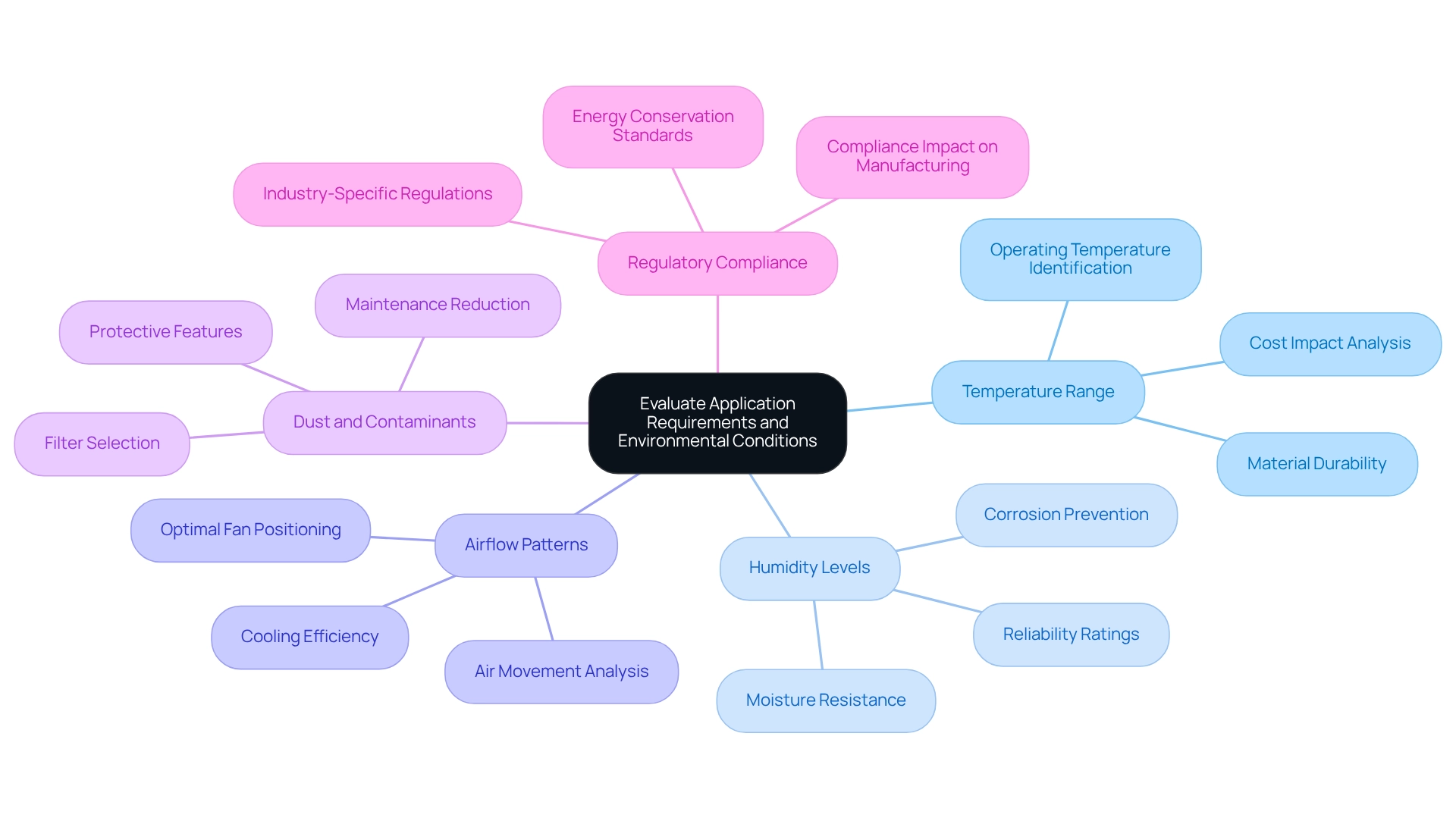

Evaluate Application Requirements and Environmental Conditions

Selecting the right commercial fan requires a comprehensive evaluation of specific application requirements and environmental conditions. To facilitate this process, consider the following key factors:

- Temperature Range: Begin by identifying the operating temperature range of the environment. In high-temperature settings, fans may require specialized materials to ensure durability and optimal performance. Real-world case studies indicate that a phased approach to evaluating temperature range requirements can significantly influence manufacturing costs and operational effectiveness, particularly for small business manufacturers.

- Humidity Levels: In moist environments, it is crucial to select ventilators that offer moisture resistance to prevent corrosion and prolong their lifespan. Humidity resistance ratings are essential for ensuring reliability under such conditions.

- Airflow Patterns: A thorough understanding of airflow dynamics within the space is vital. Analyzing air movement can inform optimal fan positioning, thereby enhancing efficiency and cooling effectiveness.

- Dust and Contaminants: In areas with high dust concentrations, it is advisable to select devices equipped with protective features or filters. This choice helps maintain performance and reduces maintenance requirements.

- Regulatory Compliance: It is imperative to confirm that the selected units comply with industry-specific regulations, especially in sensitive environments such as data centers or laboratories. Compliance with is increasingly critical, as highlighted by the projected need to remodel 75 percent of GFB shipments within the next five years. This urgency underscores the necessity for engineers to consider compliance factors when selecting a commercial fan.

By meticulously evaluating these elements, engineers can ensure that the chosen commercial fan not only fulfills operational standards but also enhances the overall reliability and efficiency of the system. As noted by AMCA, gaining insights through confidential interviews with fan manufacturers can further enrich the selection process, offering valuable perspectives on industry standards and practices. Furthermore, seeking expert advice on assessing software requirements can guide engineers in making informed decisions.

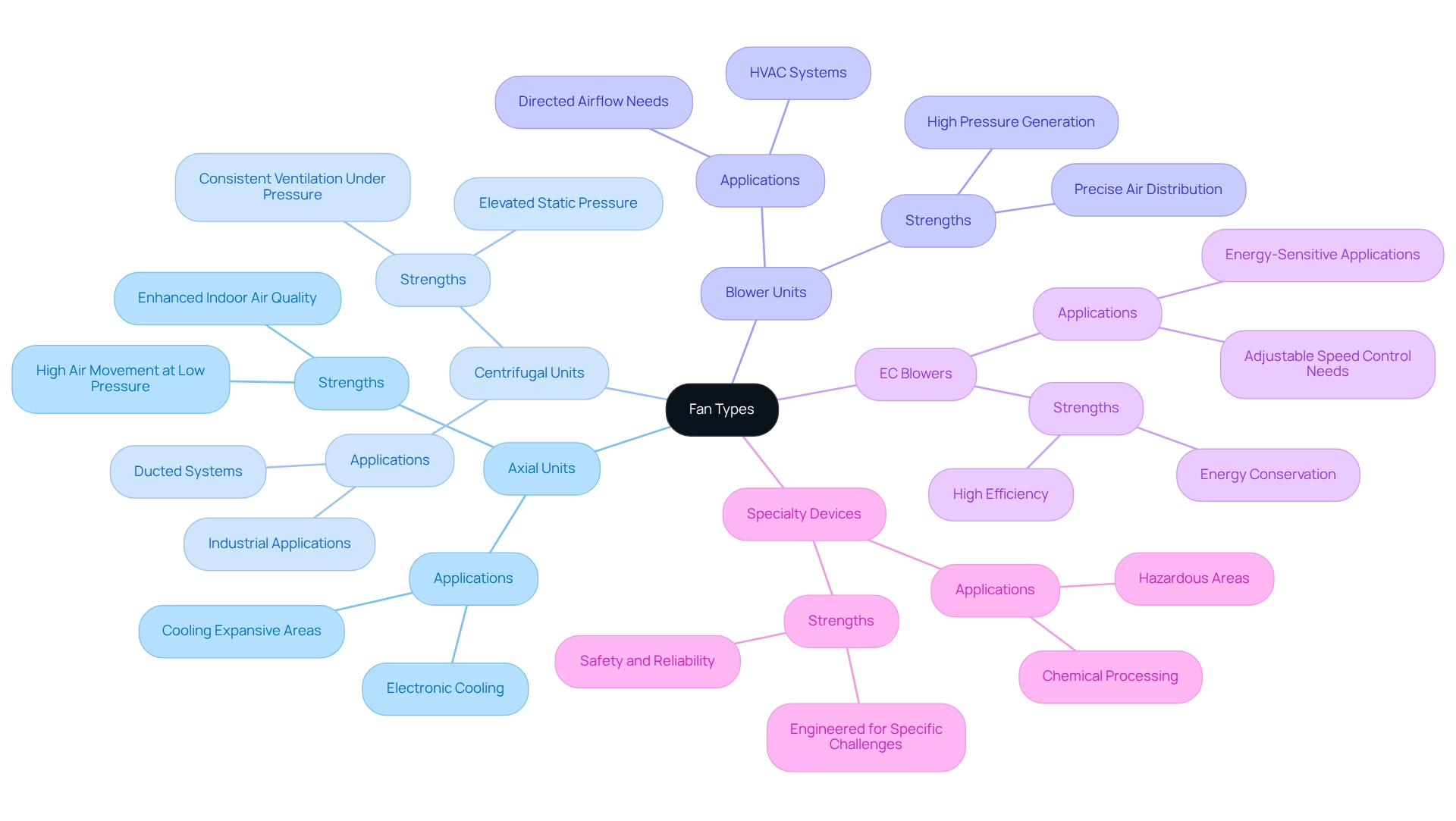

Select Appropriate Fan Types Based on Performance Metrics

Selecting the appropriate commercial fan type is essential for optimizing performance metrics across various contexts. Here is an overview of typical ventilator types and their specific applications:

- Axial Units: These devices excel in delivering high air movement at low pressure, making them ideal for cooling expansive areas or equipment within confined spaces. Their design facilitates efficient air movement, crucial for electronic cooling applications. Notably, Rosenberg’s axial devices have significantly enhanced indoor air quality in environments such as schools and hospitals, underscoring their effectiveness in high-volume applications.

- Centrifugal Units: Designed for scenarios requiring elevated static pressure, centrifugal units are frequently utilized in ducted systems where resistance to airflow is a critical factor. Their ability to maintain consistent ventilation under pressure makes them suitable for various industrial applications. Including static pressure data can further illustrate their effectiveness in these environments.

- Blower Units: Known for generating high pressure, blower units are particularly efficient in situations that demand directed airflow, such as HVAC systems. Their performance is especially beneficial in settings where precise air distribution is paramount.

- EC Blowers: Electronically commutated blowers are characterized by their high efficiency and , making them particularly advantageous in energy-sensitive applications. Rosenberg emphasizes the benefits of EC technology, highlighting energy conservation and improved functionality, which are crucial in contemporary electronic cooling solutions.

- Specialty Devices: In specific applications, specialized devices such as explosion-proof models for hazardous areas or corrosion-resistant options for chemical processing are vital. These devices, such as the commercial fan, are engineered to tackle specific operational challenges, ensuring safety and reliability. Understanding the strengths and limitations of each fan type, including the commercial fan, enables engineers to select the most effective solution tailored to their cooling requirements. The latest advancements in axial and centrifugal fan technologies continue to enhance efficiency metrics, providing engineers with innovative options for their projects.

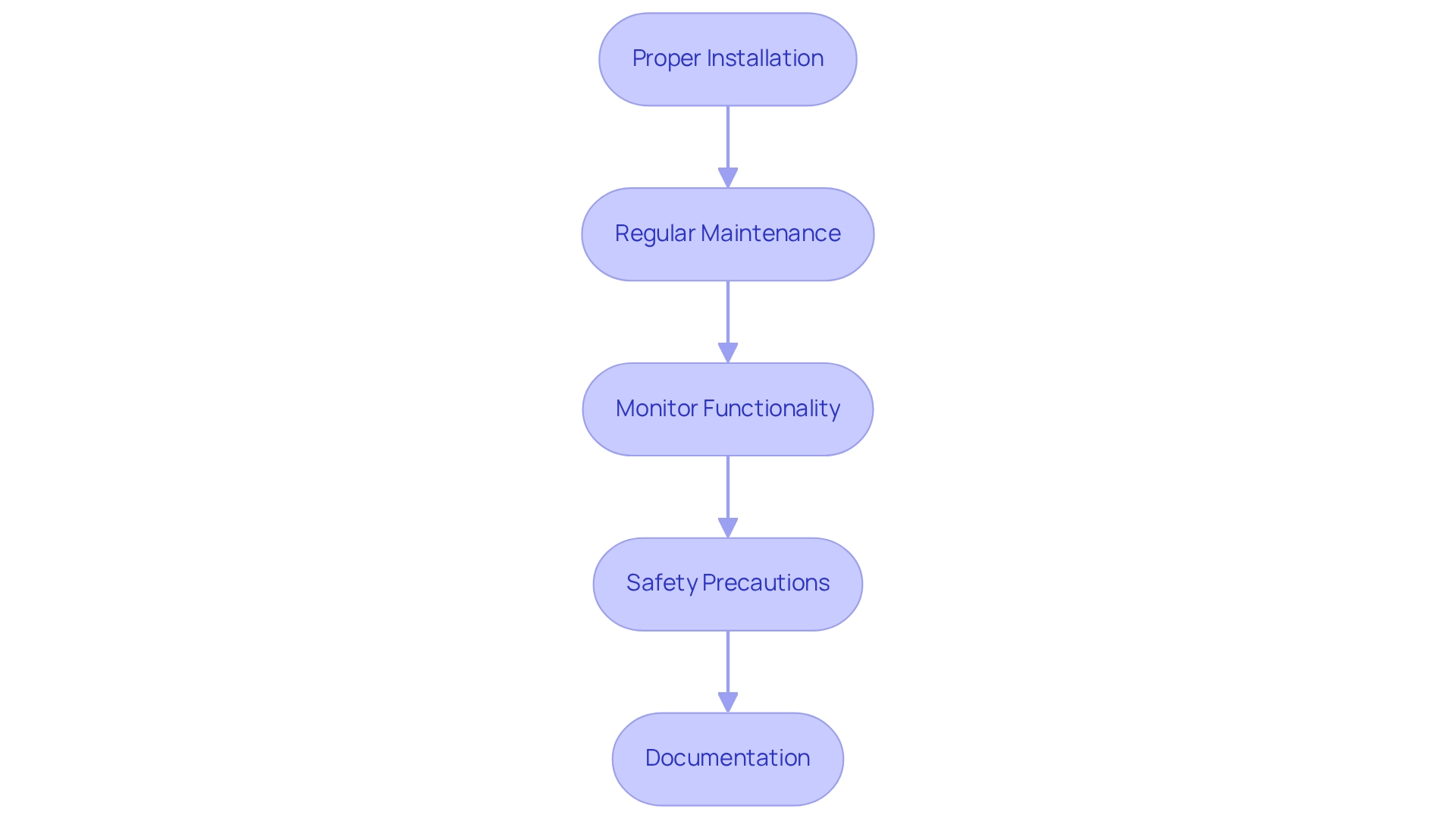

Implement Best Practices for Installation and Maintenance

To enhance the efficiency and longevity of commercial ventilation units, it is crucial to adhere to the following best practices for installation and upkeep:

- Proper Installation: Install ventilation units in accordance with manufacturer specifications, ensuring correct mounting, alignment, and secure electrical connections. This minimizes installation errors, which can lead to significant operational inefficiencies. Common pitfalls, such as improper voltage supply and loose connections, can result in motor malfunctions.

- Regular Maintenance: Implement a routine inspection schedule to check for dust buildup, wear and tear, and overall functionality. Cleaning fan blades and housings can enhance efficiency by up to 20%. are vital, as they help detect overheating issues early, preventing costly repairs. Proper storage of industrial ceiling fans during the off-season also prevents damage and ensures preparedness for the next cycle of use.

- Monitor Functionality: Utilize metrics such as airflow and noise levels to evaluate fan operation. Significant deviations from standard operation may indicate the need for maintenance or replacement, helping to avoid expensive downtime. Addressing common issues promptly through regular checks can improve fan efficiency and durability, as shown in various case studies.

- Safety Precautions: Adhere to all safety guidelines during installation and maintenance. This includes disconnecting power before servicing and using appropriate personal protective equipment (PPE) to ensure a safe working environment.

- Documentation: Maintain detailed records of installation dates, maintenance activities, and repairs. This documentation assists in diagnosing issues and organizing upcoming maintenance, thereby enhancing the durability and dependability of the devices. Thorough documentation is essential for effective maintenance planning, as noted by maintenance professionals.

By following these best practices, organizations can ensure that their commercial fans operate efficiently and effectively throughout their lifespan, ultimately enhancing performance and reducing operational costs.

Conclusion

Selecting the right commercial fan is essential for achieving optimal performance and efficiency in electronic cooling applications. Understanding key specifications—such as airflow rate, static pressure, noise level, power consumption, and size—empowers engineers to make informed decisions that bolster system reliability. Furthermore, evaluating application requirements and environmental conditions, including temperature, humidity, and airflow patterns, guarantees that the selected fan meets specific operational demands.

Different fan types serve distinct purposes. For instance, axial fans excel in high airflow applications, while centrifugal fans are designed for environments requiring higher static pressure. Grasping these performance metrics enables tailored solutions that maximize cooling effectiveness. Additionally, adhering to best practices for installation and maintenance can significantly prolong the lifespan of commercial fans. Regular inspections, proper installation techniques, and thorough documentation are crucial for maintaining optimal functionality.

In conclusion, the process of selecting and maintaining commercial fans is multifaceted, necessitating a comprehensive understanding of specifications, application needs, and best practices. As industries evolve, prioritizing these factors will not only enhance cooling efficiency but also drive operational effectiveness in electronic systems. By adopting a strategic approach to fan selection and maintenance, engineers can ensure that their cooling solutions remain reliable and efficient in an increasingly demanding landscape.

Frequently Asked Questions

What is the significance of the airflow rate (CFM) in commercial fans for electronics applications?

The airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air a fan can move. Elevated CFM ratings are essential for applications requiring substantial cooling, directly influencing cooling efficiency across various applications.

How does static pressure affect fan performance?

Static pressure assesses the resistance a fan can overcome to sustain air movement, which is crucial for systems with ductwork or filters that may impede air circulation. Accessories like filters can significantly impact static pressure performance, affecting airflow characteristics.

Why is noise level (dBA) an important consideration when selecting a fan?

The noise produced by a fan, measured in decibels (dBA), is crucial in environments where sound levels are a concern. Choosing devices with lower dBA ratings helps maintain a quieter workspace, which is increasingly important in contemporary electronic applications.

What role does power consumption play in fan selection?

Understanding the wattage and efficiency ratings is essential for selecting energy-efficient alternatives that reduce operational expenses. Devices that offer reduced power usage without sacrificing performance are becoming increasingly popular in the electronics sector.

How do size and mounting options influence fan selection?

The physical dimensions and mounting configurations of the fans must align with the intended installation space. Gagner-Toomey offers a wide range of sizes and custom designs to ensure compatibility with various systems for effective integration.

What are common pitfalls engineers should avoid when selecting fans?

Engineers should be cautious of frequent errors, such as neglecting the influence of accessories on efficiency or failing to consider specific cooling requirements. These oversights can lead to suboptimal fan efficiency and increased operational costs.

How can focusing on these specifications improve fan operation?

By concentrating on key specifications like airflow rate, static pressure, noise level, power consumption, and size, engineers can make informed choices that enhance cooling efficiency and contribute to the overall reliability of electronic systems.