Overview

The article centers on essential concepts and integration techniques pertaining to automotive motors, underscoring their critical role in vehicle performance and functionality. It delves into various types of motors, including:

- DC motors

- AC motors

- Brushless DC motors

It also discusses their applications, market trends, control techniques, and challenges in integration. Understanding these elements is pivotal for engineers aiming to enhance vehicle efficiency and adhere to industry standards.

Introduction

In the dynamic landscape of the automotive industry, motors play a pivotal role in transforming electrical energy into the mechanical power that drives vehicle functionality. From the familiar DC motors powering everyday features like power windows to the advanced brushless DC motors revolutionizing electric vehicles, understanding the various types of automotive motors and their applications is essential for engineers and manufacturers alike.

As the demand for efficiency and performance escalates, innovations in motor control techniques and integration strategies become crucial for addressing the challenges posed by modern vehicle design.

This article delves into the fundamentals of automotive motors, explores their diverse applications, and addresses the complexities of integrating these vital components into today’s vehicles, thereby highlighting the continuous evolution of technology in this field.

Explore the Fundamentals of Automotive Motors

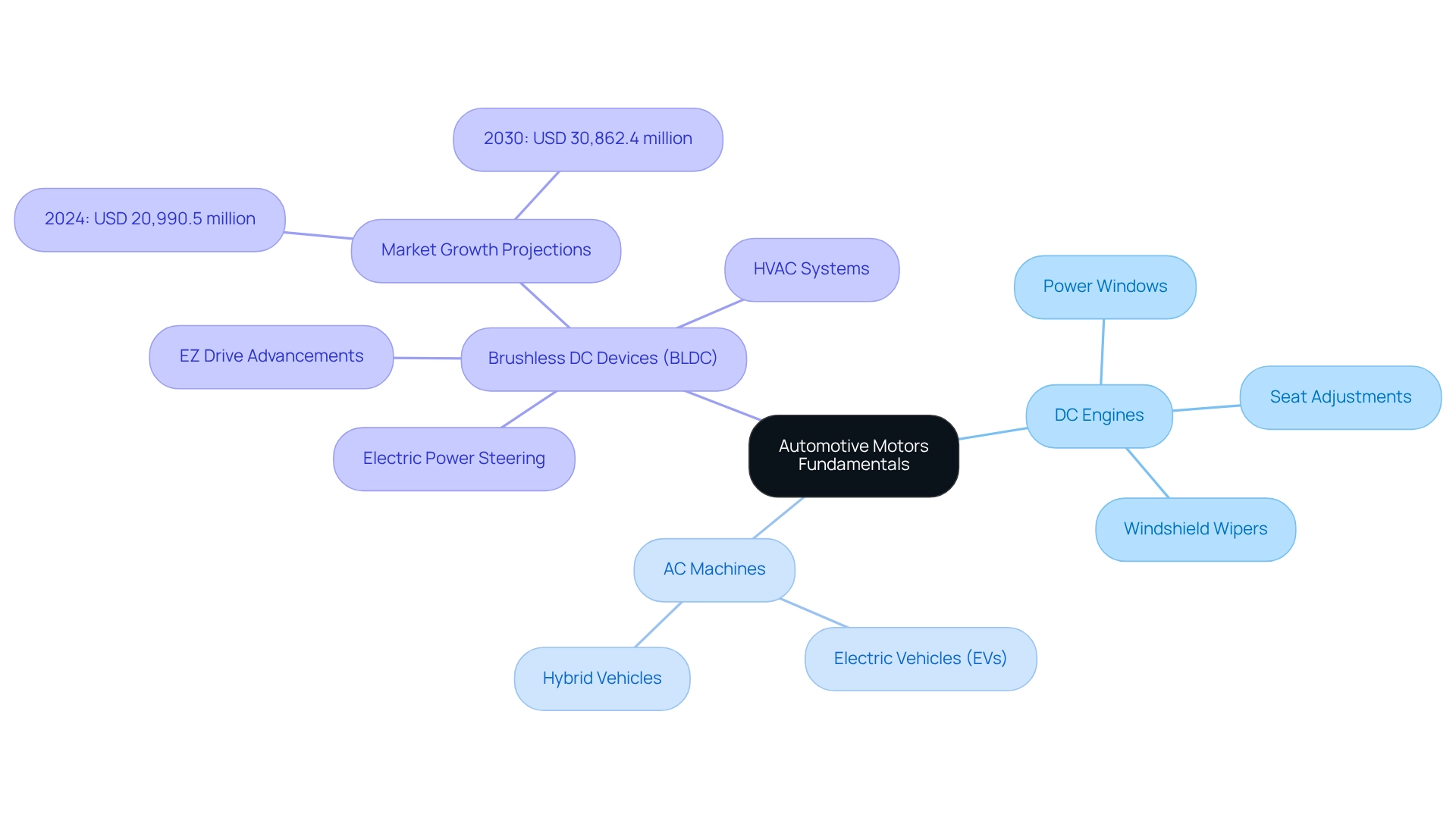

Automotive motors are essential components that convert electrical energy into mechanical energy, enabling a variety of functions within automobiles. The main categories of engines used in automotive functions comprise:

- DC Engines: These devices are commonly used in functions that require variable speed and torque, such as power windows, seat adjustments, and windshield wipers. Their flexibility makes them crucial for numerous automotive motor features.

- AC Machines: Predominantly found in electric vehicles (EVs) and hybrid vehicles, AC machines are renowned for their efficiency and dependability. They play a vital role in driving the propulsion system of the vehicle, contributing to overall energy conservation and performance.

- Brushless DC Devices (BLDC): Known for their high efficiency and minimal maintenance requirements, BLDC devices are increasingly favored in applications like electric power steering and HVAC systems. Their design minimizes energy loss, making them ideal for contemporary vehicle applications.

Recent advancements in vehicle engine technology, such as the introduction of the ‘EZ Drive’ for BLDC engines, underscore the industry’s commitment to enhancing efficiency and user-friendliness. The brushless DC engine market, significantly propelled by the automotive motors sector, is projected to grow from USD 20,990.5 million in 2024 to USD 30,862.4 million by 2030. Furthermore, the Asia Pacific region is expected to dominate the global vehicle engine market throughout the forecast period from 2025 to 2034. Understanding these fundamentals is crucial for engineers, as the demand for skilled technicians is elevating operational costs, emphasizing the importance of integrating engines into transportation systems. This knowledge not only facilitates the incorporation of automotive motors into automotive systems but also highlights their impact on performance and energy efficiency.

Identify Different Types of Automotive Motors and Their Applications

Automotive motors play vital roles in enhancing performance and functionality, with each type crafted for specific uses. Understanding these drives is essential for making informed design decisions and creating effective integration strategies in vehicle engineering. Here are the main types of drives and their applications:

- Brushed DC Drives: These drives are preferred for their simplicity and affordability, making them suitable for applications such as windshield wipers and electric seats. Their straightforward design facilitates easy maintenance and replacement, contributing to their widespread use in various transportation systems. The global brushed direct current engine market was valued at USD 10.27 billion in 2021, and it is anticipated to reach USD 17.65 billion by 2029, indicating substantial growth potential.

- Brushless DC Engines (BLDC): Increasingly common in electric transportation, BLDC engines are crucial for traction and are employed in high-efficiency applications like cooling fans and pumps. Their capacity for precise speed regulation and reduced noise enhances overall performance, making them a favored choice in contemporary automotive motor design. Notably, forecasts suggest that by 2025, a significant proportion of electric vehicles will utilize brushless DC engines, underscoring their growing importance in the sector. Furthermore, the Asia Pacific region is anticipated to lead the brushless DC machinery market from 2023 to 2028, emphasizing the geographical significance of this technology.

- Stepper Motors: Renowned for their precision, stepper motors are utilized in applications requiring exact positioning, such as throttle control in hybrid vehicles. Their ability to move in discrete steps enables precise control, which is essential for enhancing engine performance and efficiency.

- Induction Machines: Known for their durability and efficiency, induction machines are commonly employed in electric vehicles, particularly for traction applications. Their resilience and ability to operate under varying conditions render them well-suited for the demanding environments of modern vehicle systems.

As the market for brushed direct current devices is projected to reach USD 17.65 billion by 2029, driven by significant uptake in sectors such as automotive motors and vehicle production, the relevance of these technologies continues to rise. Additionally, the implementation of brushless DC devices in electric cooling systems has proven to enhance mechanical and electrical performance, optimizing cooling efficiency and improving fuel economy.

Understand Automotive Motor Control Techniques and Technologies

Control techniques play a critical role in optimizing the efficiency and reliability of automotive motors. Among the most significant methods are:

- Pulse Width Modulation (PWM): This technique modulates the width of pulses in a signal to effectively control the speed of direct current devices. Recent studies indicate that the Random PWM technique minimizes harmonic distortions while maximizing efficiency, making it a preferred choice in modern applications. Furthermore, the effectiveness of the inverter is greatest when utilizing the DPWM method, demonstrating an enhancement ranging from a minimum of 0.35% to a maximum of 2.23% in comparison to SVPWM.

- Field-Oriented Control (FOC): Commonly employed for Brushless DC (BLDC) devices, FOC allows for precise regulation of torque and speed. Research indicates that applying advanced control strategies, such as those relying on decoupling back EMF voltage, significantly enhances dynamic response and overall performance.

- Sensorless Control: These methods estimate position without requiring physical sensors, thereby minimizing complexity and cost. The effectiveness of sensorless methods has been validated through various simulations and experiments, demonstrating their viability in automotive motors.

- Closed-Loop Control Systems: These systems continuously monitor engine performance and adjust inputs to maintain desired outputs, thereby enhancing efficiency and responsiveness. The latest advancements in control techniques have shown improvements in static and dynamic performance, particularly in BLDC machines.

Recent case studies underscore the importance of PWM in vehicle power control. For instance, an NVH performance assessment of different PWM techniques revealed that while SVPWM serves as a reliable baseline, the Random PWM technique offers comparable noise and vibration performance with reduced harmonic distortion. Furthermore, the Whale Optimization Algorithm has been shown to significantly enhance the regulation of BLDC devices, surpassing conventional techniques as confirmed by statistical evaluations conducted using SPSS.

Understanding these regulation methods is essential for engineers aiming to enhance device performance in the automotive sector, especially as automotive motors evolve with emerging technologies and methodologies.

Address Challenges in Automotive Motor Integration and Compliance

Integrating automotive motors into vehicle systems involves navigating several critical challenges:

- Space Constraints: The average trip for a conventional internal combustion engine (ICE) vehicle spans 400 miles, necessitating two stops averaging 20 minutes each. Consequently, the design of automotive motors must accommodate limited space while delivering optimal performance. Creative design solutions, including advanced solenoid pumps and rotary boost pumps, are essential to optimize efficiency within these constraints, especially in electronic applications. Gagner-Toomey Associates provides over 100 standard parts ready for shipment, ensuring compliance and product availability for these innovative solutions.

- Thermal Management: Effective thermal management is vital to prevent overheating, particularly in high-performance applications. Current challenges in this domain include the development of advanced cooling solutions capable of maintaining optimal operating temperatures under varying conditions. Case studies indicate that the commercial transport segment, projected to capture a significant share of the automotive thermal management market, increasingly emphasizes safety features, underscoring the necessity for robust thermal solutions. For instance, the integration of advanced rotary boost pumps has demonstrated enhanced cooling efficiency in real-world applications.

- Compliance with Standards: Automotive motors must comply with stringent industry standards for safety and performance. This encompasses adherence to the Automotive Standard SAE and VDA, alongside quality management certifications like IATF 16969. Comprehensive testing and validation procedures are critical to ensuring that all components, including advanced solenoid and rotary boost pumps, meet regulatory standards, which may complicate the integration process.

- Interference with Other Systems: Motors can generate electromagnetic interference (EMI) that disrupts other electronic components within the transport. Addressing this challenge necessitates careful design considerations and effective shielding techniques to minimize interference and ensure seamless operation of all systems. The incorporation of EMI suppression circuits in advanced pump designs can significantly mitigate these issues, as evidenced in various vehicle applications.

- Shift Towards Electric Vehicles: In 2022, the number of battery electric cars registered in Europe reached 1,126,682, reflecting a 28.35% increase compared to the previous year. This transition towards electric vehicles demands a reevaluation of automotive motors integration strategies to accommodate new technologies and performance requirements. Effectively addressing these challenges is crucial for the successful integration of automotive motors and compliance with automotive regulations, ultimately contributing to the development of safer and more efficient vehicles.

Conclusion

The automotive industry is experiencing a profound transformation, with motors leading this evolution. A comprehensive understanding of various motor types—such as DC, AC, brushless DC, and induction motors—highlights their critical roles in enhancing vehicle functionality and performance. Each motor type offers distinct advantages tailored to specific automotive applications, from powering essential features to driving electric vehicles.

Moreover, advancements in motor control techniques, including Pulse Width Modulation and Field-Oriented Control, emphasize the necessity of optimizing efficiency and responsiveness. These technologies not only enhance motor performance but also meet the increasing demands for energy efficiency in modern vehicles. As the industry evolves, integrating these motors into vehicle systems presents challenges that require innovative solutions. Key issues such as space constraints, thermal management, adherence to stringent standards, and the transition to electric vehicles necessitate a thorough understanding of motor integration strategies.

Ultimately, the ongoing evolution of automotive motors and their associated technologies underscores their pivotal role in shaping the future of transportation. As engineers and manufacturers navigate these complexities, a focus on efficiency, performance, and compliance will propel the development of safer and more sustainable vehicles. Grasping these dynamics is essential for all stakeholders in the automotive sector, as the integration of advanced motor technologies will be vital in addressing the challenges of tomorrow’s automotive landscape.

Frequently Asked Questions

What are automotive motors and their primary function?

Automotive motors are essential components that convert electrical energy into mechanical energy, enabling various functions within automobiles.

What are the main categories of engines used in automotive functions?

The main categories of engines are DC Engines, AC Machines, and Brushless DC Devices (BLDC).

What are the applications of DC Engines in automobiles?

DC Engines are commonly used in functions that require variable speed and torque, such as power windows, seat adjustments, and windshield wipers.

Where are AC Machines primarily found, and what are their benefits?

AC Machines are predominantly found in electric vehicles (EVs) and hybrid vehicles, known for their efficiency and dependability, playing a vital role in driving the vehicle’s propulsion system.

What advantages do Brushless DC Devices (BLDC) offer?

BLDC devices are known for their high efficiency and minimal maintenance requirements, making them ideal for applications like electric power steering and HVAC systems.

What recent advancements have been made in vehicle engine technology?

Recent advancements include the introduction of the ‘EZ Drive’ for BLDC engines, aimed at enhancing efficiency and user-friendliness.

What is the projected growth of the brushless DC engine market?

The brushless DC engine market is projected to grow from USD 20,990.5 million in 2024 to USD 30,862.4 million by 2030.

Which region is expected to dominate the global vehicle engine market from 2025 to 2034?

The Asia Pacific region is expected to dominate the global vehicle engine market throughout the forecast period from 2025 to 2034.

Why is understanding automotive motors important for engineers?

Understanding automotive motors is crucial for engineers as the demand for skilled technicians is elevating operational costs, emphasizing the importance of integrating engines into transportation systems and their impact on performance and energy efficiency.