Overview

The article delves into essential techniques for effective semiconductor cooling, emphasizing various innovative methods such as:

- Jet impingement cooling

- Electroluminescent cooling

- Immersion cooling

These methods are underpinned by robust evidence demonstrating their efficiency in managing heat dissipation—a critical factor for enhancing the performance and reliability of electronic components in high-density environments.

Introduction

As the demand for advanced electronics surges, the significance of effective cooling solutions for semiconductors has reached unprecedented levels. Innovative techniques are emerging to address the challenges posed by escalating heat generation in high-performance devices, thereby presenting engineers with a myriad of opportunities to enhance both reliability and performance. However, amidst the plethora of cooling methods available, which techniques stand out as truly essential for the future of semiconductor technology?

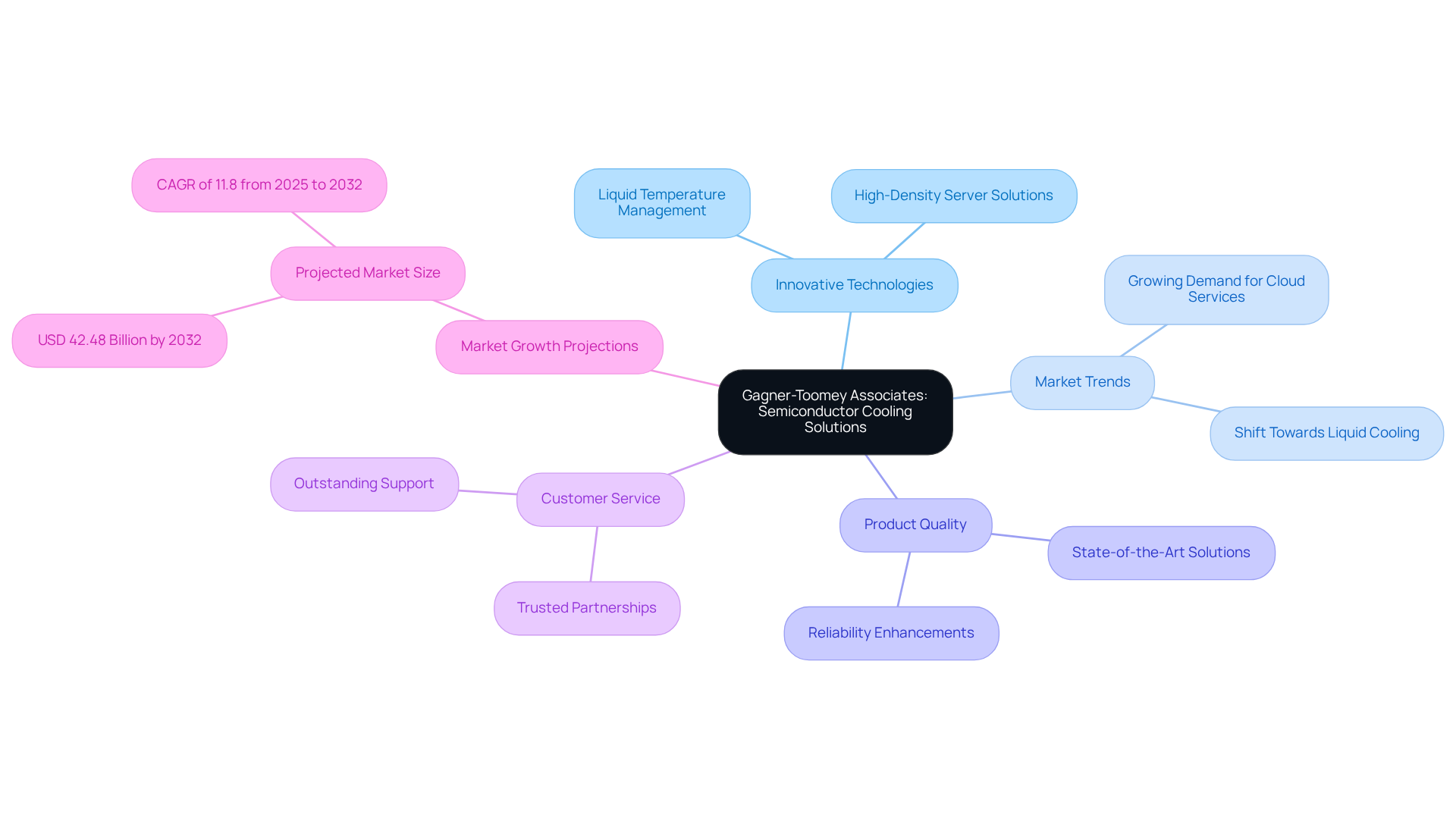

Gagner-Toomey Associates: Leading Provider of Semiconductor Cooling Solutions

Gagner-Toomey Associates stands out as a premier supplier of semiconductor cooling solutions, focusing on innovative technologies that address the unique challenges engineers face in the electronics industry. By collaborating with a diverse array of manufacturers, Gagner-Toomey delivers state-of-the-art temperature control solutions that significantly enhance the performance and reliability of electronic components. Their commitment to excellence is reflected not only in the high quality of the products they represent but also in their outstanding customer service, solidifying their position as a trusted partner for engineers seeking effective thermal management solutions.

As the landscape of chip temperature regulation evolves, trends indicate a growing shift toward liquid temperature management technologies, anticipated to experience the highest growth rates due to their efficiency in addressing high-density server environments. The global module market for electronic components is projected to reach USD 42.48 billion by 2032, reflecting a robust CAGR of 11.8% from 2025 to 2032. This growth is driven by increasing data production and the rising demand for cloud services, necessitating that can effectively manage the heat generated by advanced electronic applications.

Gagner-Toomey Associates is at the forefront of these advancements, equipping engineers with the tools they need to navigate the complexities of modern electronic component temperature regulation. Their strategic emphasis on innovative technologies positions them as a pivotal player in the industry, prepared to address the evolving demands of the electronics market.

Jet Impingement Cooling: Efficient Heat Management for High-Power Semiconductors

Jet impingement cooling is a method that enhances semiconductor cooling by addressing the critical challenge of heat dissipation in electronic systems through high-speed jets of coolant directed at electronic surfaces, significantly improving thermal transfer efficiency. This method proves particularly advantageous for high-power semiconductors, especially in semiconductor cooling, as it can reduce resistance to temperature changes by as much as 80%.

Research substantiates this claim, revealing a maximum transfer improvement of 80% when employing SiO nanoparticles at a concentration of 8.5 vol%. By meticulously adjusting jet parameters—including velocity, angle, and spacing—engineers can optimize performance, achieving fluxes that exceed 897 W/cm² at a flow rate of 320 mL/min in practical applications.

This technique is increasingly preferred in environments where , particularly semiconductor cooling, is paramount, such as in cutting-edge electronic devices and photovoltaic systems. Furthermore, recent studies highlight that jet impingement refrigeration not only enhances efficiency but also extends the lifespan and reliability of electronic components.

It is noteworthy that nearly 50% of device failures stem from excessive heat or temperature-related issues. Additionally, the extensive thermal coefficient is sensitive to variations in the hole diameter-to-impingement spacing ratio, providing engineers with crucial insights for refining thermal designs.

![]()

Electroluminescent Semiconductor Cooling: A Cutting-Edge Approach

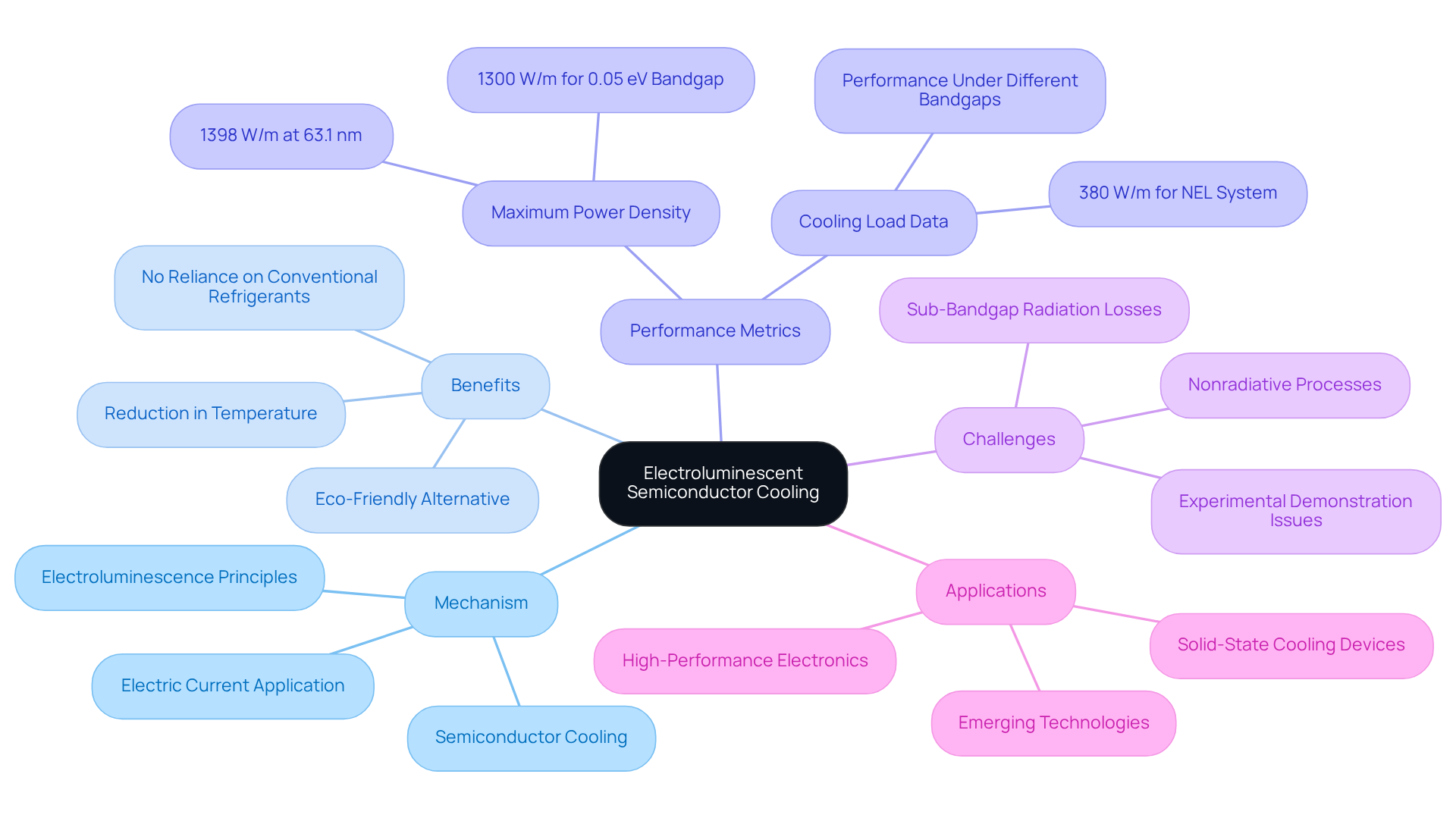

Electroluminescent materials introduce a groundbreaking method that leverages the principles of electroluminescence for effective temperature regulation. This technology utilizes by applying an electric current to specialized semiconductor materials, which efficiently absorbs heat from devices, leading to a substantial reduction in temperature. Notably, this approach enhances temperature regulation efficiency while eliminating reliance on conventional refrigerants, positioning it as an eco-friendly alternative.

Research demonstrates that the thermal load for electroluminescent systems can achieve remarkable levels, with maximum power densities reported at 1398 W/m under optimal conditions at a gap of 63.1 nm. Furthermore, for a semiconductor with a bandgap of 0.05 eV, the thermal load approximates 1300 W/m, underscoring the performance capabilities of this technology.

As advancements continue, semiconductor cooling technologies are poised to transform heat management in high-performance electronics, offering sustainable solutions that align with modern environmental standards. Nevertheless, challenges persist in the experimental demonstration of these systems, necessitating resolution to fully unlock their potential.

Real-world applications are already emerging, highlighting this technology’s promise across various electronic devices and paving the way for a future in which semiconductor cooling becomes standard for efficient and eco-friendly cooling.

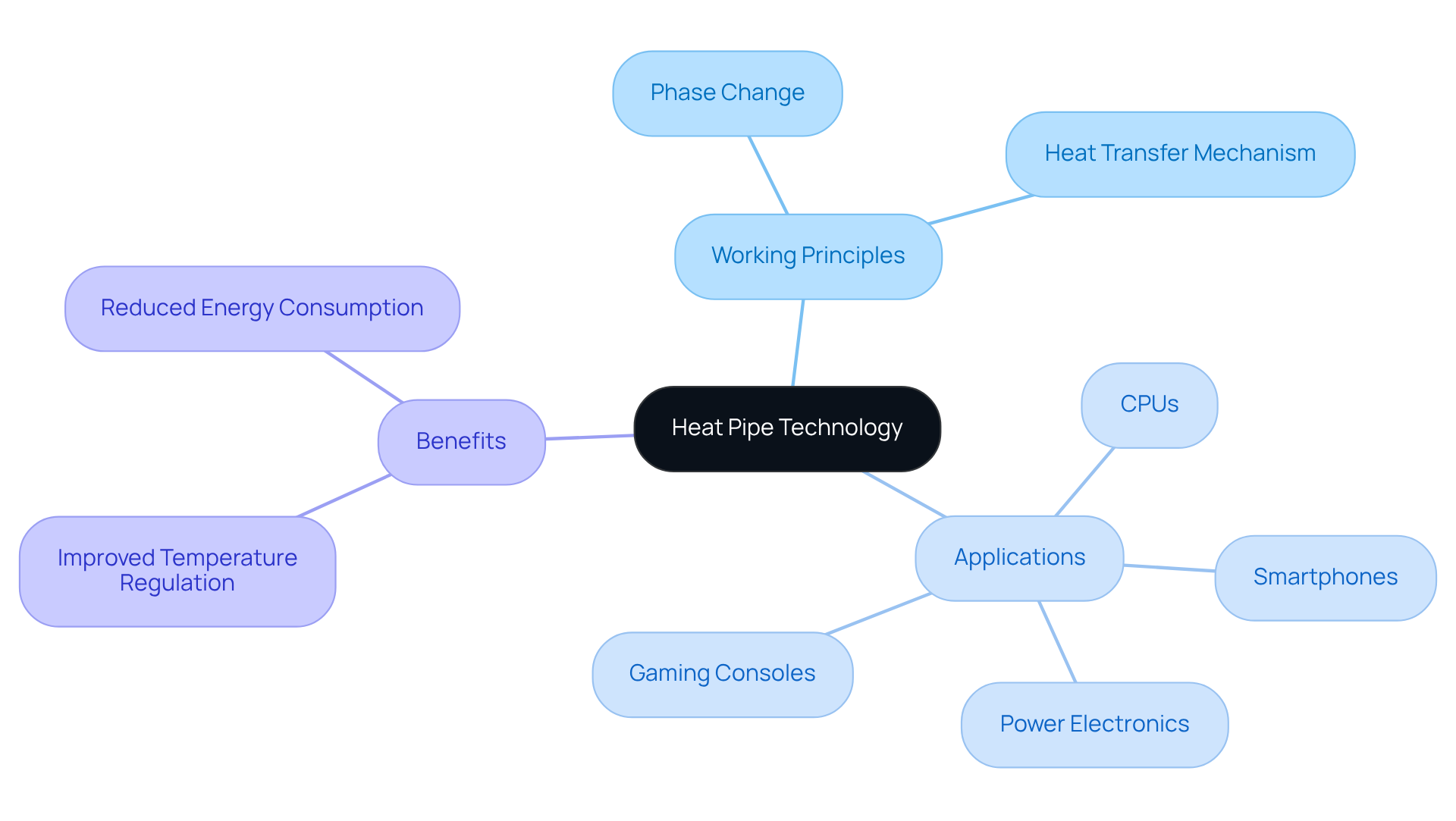

Heat Pipe Technology: Proven Thermal Management for Semiconductor Devices

Heat transfer pipe technology stands out as a remarkably efficient passive temperature management solution for semiconductor devices, particularly in semiconductor cooling by adeptly transferring heat away from critical components. Utilizing phase change principles, operate through a working fluid that evaporates at elevated temperatures and condenses in cooler regions, thereby facilitating effective thermal movement. This technology is prevalent in applications such as CPUs and power electronics, where high thermal conductivity and reliability are paramount.

In 2023, the active temperature regulation segment, which includes semiconductor cooling and thermal pipes, dominated the management market, highlighting the increasing dependence on semiconductor cooling technology for optimal performance. Engineers can leverage thermal tubes to enhance the thermal efficiency of their designs while minimizing size and weight, positioning them as an ideal choice for modern electronic applications.

Effective implementations of semiconductor cooling involve their integration into high-performance computer processors and graphics cards, where they significantly boost thermal efficiency and extend component lifespan. Moreover, thermal pipes are increasingly utilized in consumer electronics, including smartphones and gaming consoles, to manage excess heat and enhance overall performance. The benefits of conduits, such as improved temperature regulation and reduced energy consumption, further underscore their critical role in temperature management strategies.

Single-Phase Liquid Cooling: Reliable Cooling for Semiconductor Applications

Single-phase liquid cooling systems utilize a coolant, typically a mixture of water and glycol, to effectively absorb heat from electronic components. This method is lauded for its reliability and efficiency, making it particularly suitable for applications in data centers and .

By optimizing coolant flow rates and maintaining appropriate temperatures, engineers can significantly enhance heat management through semiconductor cooling, which is crucial for the durability and performance of electronic components. Notably, studies indicate that effective coolant flow rates in semiconductor cooling can lead to improved performance, thereby reducing the risk of thermal throttling and operational failures.

As the demand for reliable temperature control escalates in 2025, single-phase liquid temperature regulation emerges as a robust option, adeptly managing high-density workloads while extending the lifespan of critical hardware. Furthermore, single-phase immersion temperature regulation technology can reduce initial data center costs by 60% and power consumption for temperature management by 95%, underscoring its financial advantages.

The immersion refrigeration market is projected to grow from USD 0.57 billion in 2025 to USD 2.60 billion by 2032, at a CAGR of 24.2%, highlighting the increasing significance of these systems. As GRC states, “Immersion refrigeration provides a sustainable, space-efficient solution capable of managing increased thermal loads while reducing energy use and footprint.

![]()

Two-Phase Liquid Cooling: Advanced Solutions for High Heat Flux

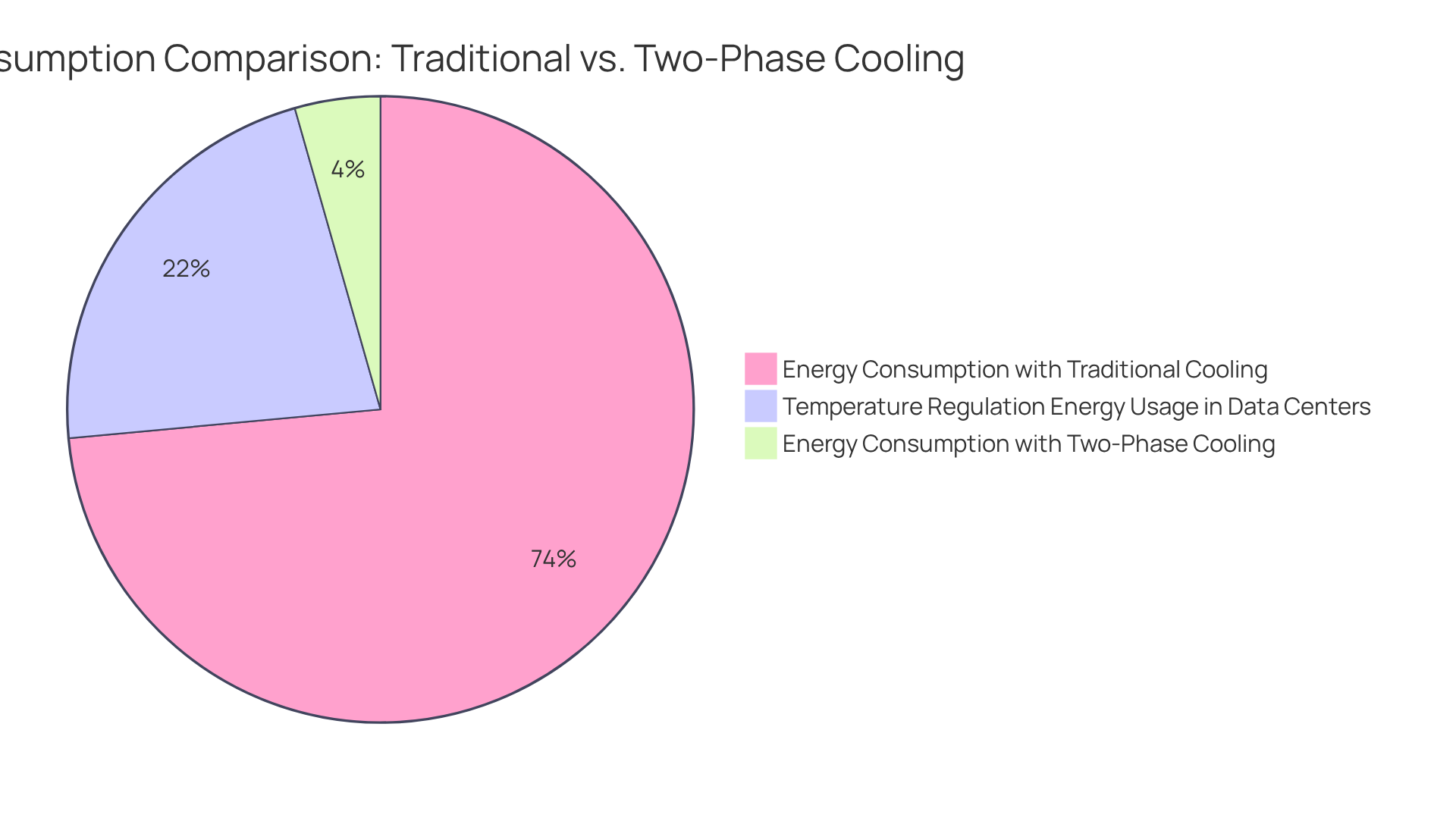

Two-phase liquid temperature regulation effectively addresses the critical challenge of heat management in semiconductor devices, incorporating by leveraging the phase change of a working fluid to absorb and dissipate energy efficiently. As the liquid coolant absorbs heat, it vaporizes, enabling superior heat transfer even in scenarios with high heat flux. This method proves particularly advantageous for applications such as GPUs and high-density data centers, where semiconductor cooling solutions often struggle.

Implementing two-phase temperature control systems can lead to substantial enhancements in thermal performance, achieving energy consumption reductions of up to 94% compared to traditional methods. Given that temperature regulation systems account for 30-50% of the overall energy usage in data centers, this reduction is exceptionally significant. Furthermore, these systems can minimize the overall footprint of temperature regulation infrastructure, as evidenced by the statistic that the introduction of liquid temperature management has resulted in a 10.2% decrease in total data center power consumption.

Successful implementations of two-phase temperature regulation have demonstrated the capability to manage thermal loads exceeding 100 kW per cabinet, particularly when using semiconductor cooling, which outperforms air-cooled cabinets that typically handle only 10-15 kW. As the sector continues to evolve, the adoption of two-phase temperature regulation technologies is becoming increasingly essential for overcoming the heat management challenges posed by advanced electronic components.

Immersion Cooling: Revolutionary Method for Semiconductor Thermal Management

Immersion refrigeration, a revolutionary approach to thermal management, utilizes semiconductor cooling by submerging semiconductor devices in a dielectric liquid. This method facilitates semiconductor cooling by enabling direct thermal transfer from the components to the coolant, significantly enhancing by reducing thermal resistance and effectively managing high heat loads. This is particularly beneficial in data centers and high-performance computing environments, where traditional air temperature management techniques frequently fall short of providing adequate semiconductor cooling.

As the demand for advanced temperature control solutions escalates, immersion refrigeration technologies are set to witness substantial market growth, with the AI data center sector alone projected to reach a value of $13.62 billion by 2024. Notable implementations, such as Microsoft’s testing of Wiwynn’s two-phase immersion temperature regulation technology, have demonstrated power usage reductions of 5% to 15%, underscoring the efficiency of this innovative method.

Furthermore, semiconductor cooling not only enhances heat management but also accommodates the increasing power densities of modern AI servers, which can generate up to 1.5 kilowatts of heat per chip. As this technology progresses, it offers exciting opportunities for engineers to refine thermal management in their designs, ultimately paving the way for more efficient and sustainable data center operations.

![]()

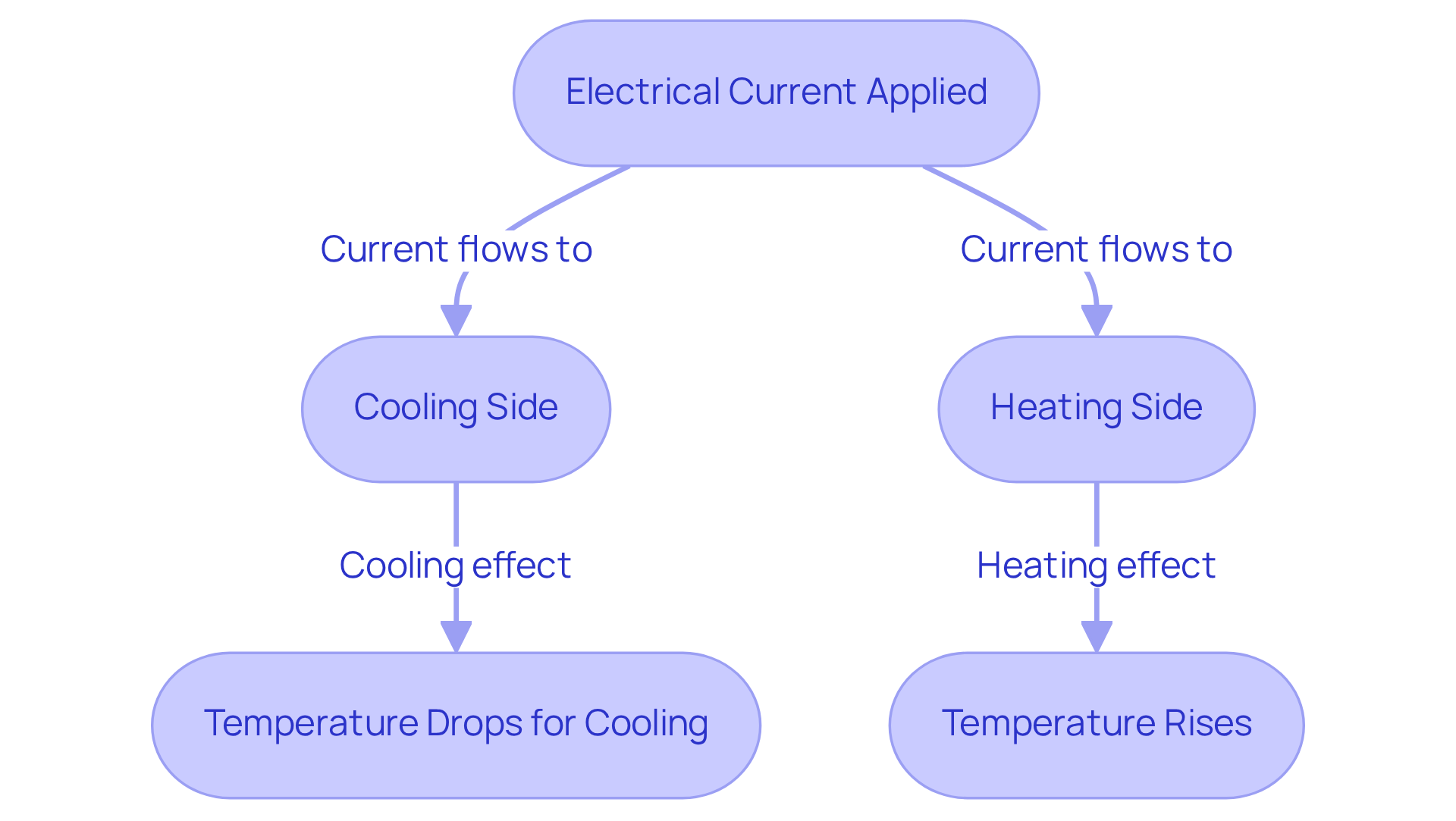

Thermoelectric Modules: Harnessing the Peltier Effect for Cooling

Thermoelectric modules, commonly known as Peltier devices, harness the Peltier effect to create a temperature differential between two surfaces of a conductive material. By applying an electrical current, one side of the module cools, while the opposite side heats up, thus facilitating precise temperature regulation for semiconductor cooling in devices. This technology proves particularly advantageous in applications that demand , such as in portable electronics and laser diodes.

As advancements in thermoelectric materials progress, the efficiency and effectiveness of these modules are anticipated to improve, positioning them as a valuable option for engineers seeking innovative cooling strategies.

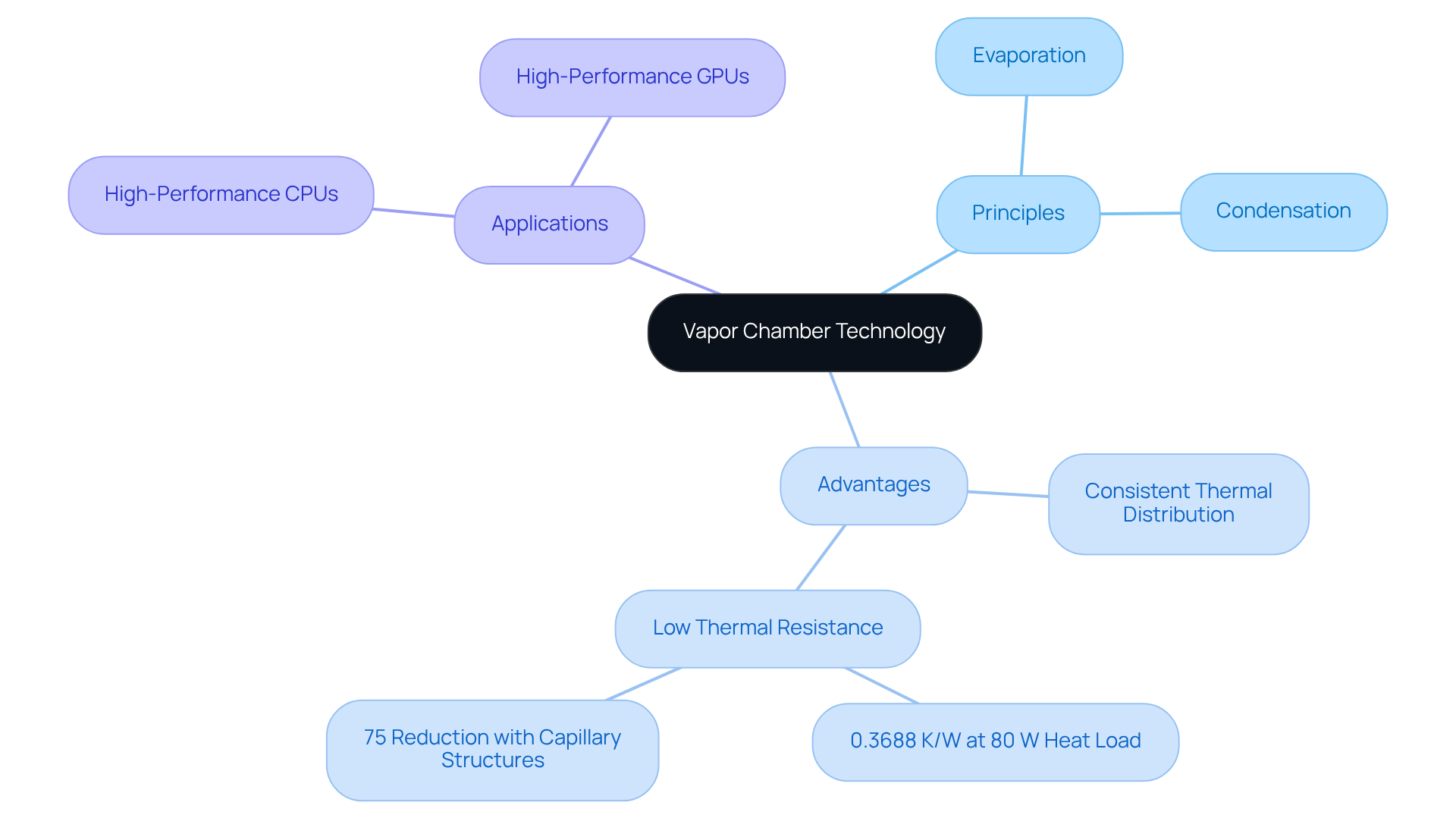

Vapor Chamber Technology: Enhanced Heat Spreading for Semiconductors

Vapor chamber technology represents a cutting-edge two-phase that excels in distributing heat across extensive surface areas. By harnessing the principles of evaporation and condensation of a working fluid within a sealed chamber, vapor chambers proficiently facilitate semiconductor cooling by transferring energy away from localized hot spots in semiconductor devices.

This technology proves particularly advantageous in scenarios demanding consistent thermal distribution, such as in high-performance CPUs and GPUs. For instance, vapor chambers can achieve thermal resistance as low as 0.3688 K/W at an 80 W heat load, significantly enhancing performance.

Successful applications in high-performance CPUs illustrate their capability to sustain optimal operating conditions, thereby bolstering reliability and efficiency in demanding applications. Engineers can leverage this innovative solution for semiconductor cooling to ensure superior thermal management, ultimately leading to enhanced performance and longevity of semiconductor devices.

Conclusion

The landscape of semiconductor cooling is undergoing rapid transformation, propelled by the escalating demands for efficiency and reliability in electronic components. Innovative techniques such as jet impingement cooling, electroluminescent cooling, and immersion refrigeration are leading this evolution, equipping engineers with effective solutions to address the challenges of heat management in high-performance applications. Gagner-Toomey Associates stands at the forefront of this industry, delivering cutting-edge technologies that enhance thermal management while aligning with sustainability objectives.

This article has explored key techniques, highlighting their distinct advantages and applications. Jet impingement cooling is notable for its exceptional thermal transfer efficiency, while electroluminescent cooling offers an eco-friendly alternative to conventional methods. Furthermore, immersion cooling and two-phase liquid cooling exemplify how advanced technologies are revolutionizing temperature regulation in data centers and high-density environments. Each method plays a vital role in improving the performance and longevity of semiconductor devices, effectively addressing the critical issue of heat dissipation.

As the semiconductor industry continues to expand, the adoption of these innovative cooling solutions becomes imperative for sustaining optimal performance and reliability. Engineers and manufacturers must remain vigilant about the latest advancements and trends in semiconductor cooling technologies to meet the growing demands of modern electronics. By prioritizing effective thermal management, the industry can pave the way for the development of more efficient, sustainable, and high-performing electronic devices.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leading provider of semiconductor cooling solutions, focusing on innovative technologies that address the challenges faced by engineers in the electronics industry.

How does Gagner-Toomey Associates enhance the performance of electronic components?

They collaborate with various manufacturers to deliver state-of-the-art temperature control solutions, which significantly improve the performance and reliability of electronic components.

What trends are emerging in semiconductor cooling technologies?

There is a growing shift toward liquid temperature management technologies, which are expected to experience high growth rates due to their efficiency in high-density server environments.

What is the projected growth of the global module market for electronic components?

The global module market is projected to reach USD 42.48 billion by 2032, with a robust compound annual growth rate (CAGR) of 11.8% from 2025 to 2032.

What is jet impingement cooling?

Jet impingement cooling is a method that enhances semiconductor cooling by using high-speed jets of coolant directed at electronic surfaces to improve thermal transfer efficiency.

How effective is jet impingement cooling in reducing temperature resistance?

Jet impingement cooling can reduce resistance to temperature changes by as much as 80%, especially when using SiO nanoparticles.

What parameters can engineers adjust to optimize jet impingement cooling performance?

Engineers can optimize performance by adjusting jet parameters such as velocity, angle, and spacing.

What percentage of device failures are related to excessive heat?

Nearly 50% of device failures stem from excessive heat or temperature-related issues.

What is electroluminescent semiconductor cooling?

Electroluminescent semiconductor cooling is a method that uses electroluminescent materials to absorb heat from devices by applying an electric current, leading to significant temperature reduction.

What are the advantages of electroluminescent semiconductor cooling?

This technology enhances temperature regulation efficiency and eliminates the reliance on conventional refrigerants, making it an eco-friendly alternative.

What challenges do electroluminescent systems face?

There are challenges in the experimental demonstration of these systems that need to be resolved to fully unlock their potential.

Where are real-world applications of electroluminescent cooling emerging?

Real-world applications are emerging across various electronic devices, indicating the promise of this technology for efficient and eco-friendly cooling solutions.