Overview

The article emphasizes crucial heat pipe design techniques that engineers must consider to optimize thermal management solutions across diverse applications. It underscores vital design principles, various types of heat pipes, and technological advancements, highlighting the necessity of selecting suitable materials and configurations. This selection is essential to enhance efficiency and performance, particularly in high-performance electronics and other industries. By addressing these critical aspects, engineers can significantly improve thermal management outcomes.

Introduction

The demand for efficient thermal management solutions has reached unprecedented levels, particularly as electronic systems grow increasingly compact and powerful. Engineers are persistently exploring innovative techniques to optimize heat pipe design, a vital component in sustaining performance and reliability across a multitude of applications.

However, with an array of design options at their disposal, how can engineers effectively navigate the complexities of heat pipe technology to achieve superior thermal performance? This article explores ten essential heat pipe design techniques that not only enhance cooling efficiency but also address the unique challenges encountered in diverse industries, ranging from aerospace to consumer electronics.

Gagner-Toomey Associates: Pioneering Cooling Solutions for Heat Pipe Applications

Gagner-Toomey Associates stands at the forefront of innovative cooling solutions that utilize heat pipe design tailored for thermal conduction applications. Collaborating with a diverse array of manufacturers, the company empowers engineers with access to state-of-the-art technologies, particularly in heat pipe design, that significantly improve heat management across various electronic systems.

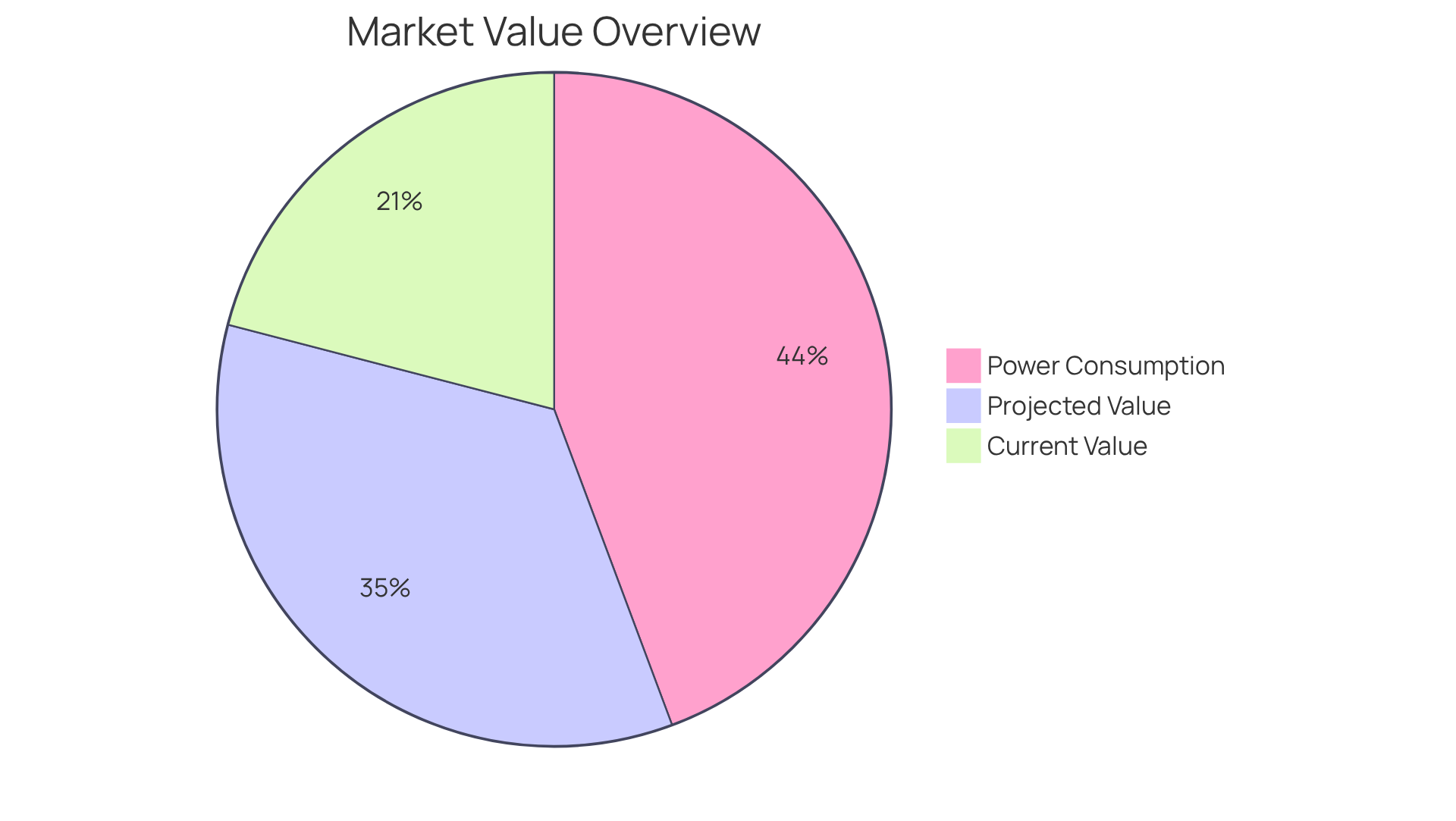

In 2023, the thermal conduit market was valued at approximately USD 3.5 billion, with projections indicating growth to USD 5.8 billion by 2032, translating to a compound annual growth rate (CAGR) of 12.4% from 2025 to 2032. This expansion is fueled by the rising demand for efficient cooling solutions in high-performance electronics, particularly as data centers consumed 7.4 Gigawatts of power in 2023—a remarkable 55% increase from the previous year.

Gagner-Toomey’s commitment to excellence is evident in its proactive strategies for addressing the intricate challenges engineers encounter, especially in the effective and efficient heat pipe design for cooling high-performance components. As the electronics sector evolves, the integration of advanced cooling technologies, such as variable conductance heat conduits, positions Gagner-Toomey as a pivotal player in heat pipe design and heat management.

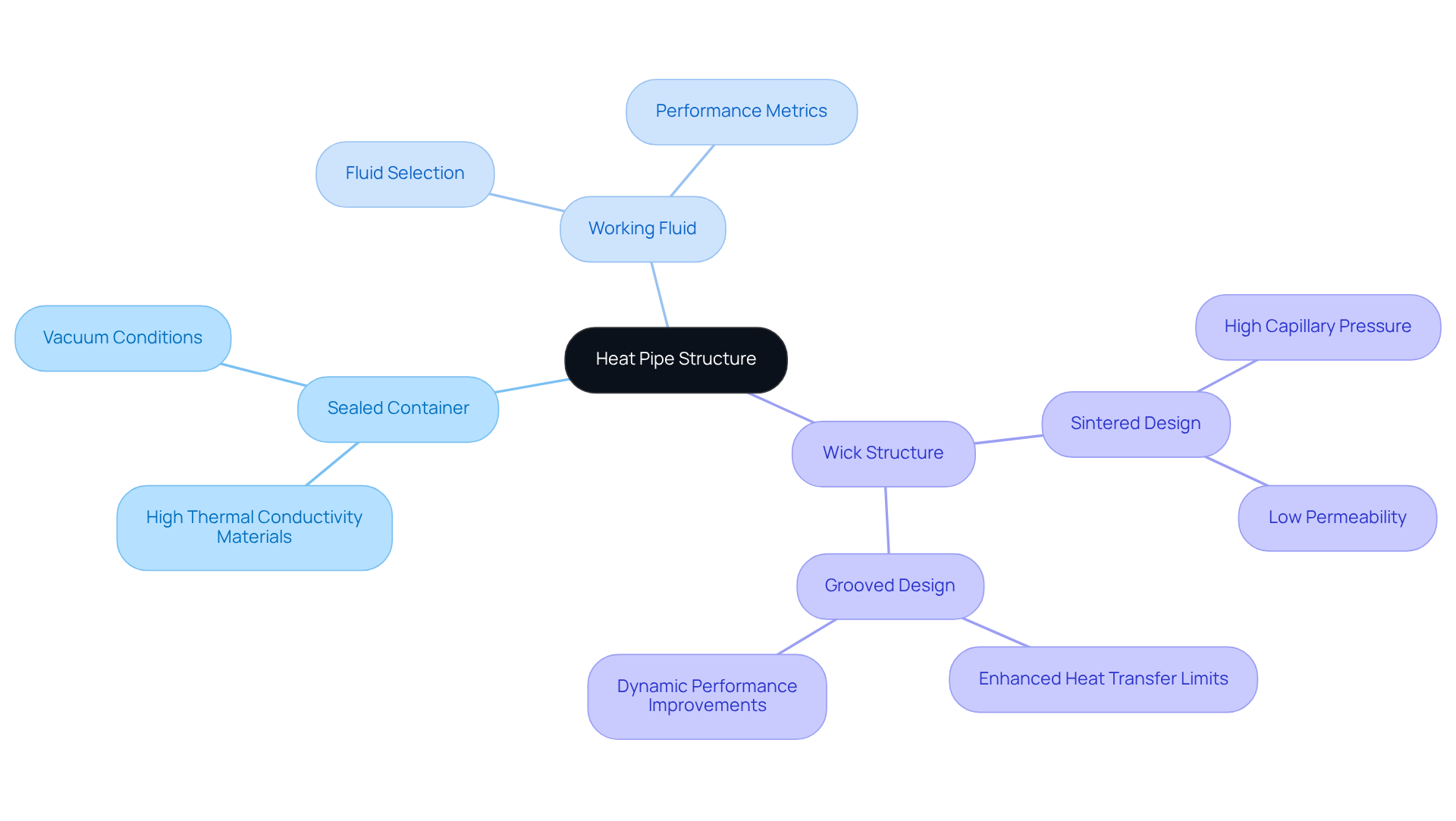

Understanding Heat Pipe Structure: Key Design Principles

Heat pipes are comprised of three essential components: a sealed container, a working fluid, and a wick structure. The container, typically made from materials with high thermal conductivity, houses the working fluid under vacuum conditions. The wick structure plays a critical role in facilitating the capillary action required for the fluid’s movement between the evaporator and condenser sections.

Recent advancements in wick designs, including sintered and grooved configurations, have demonstrated significant improvements in heat performance, especially under dynamic conditions. Research indicates that grooved thermal conduits can achieve resistance values as low as 0.04 K/W at elevated energy inputs, underscoring their effectiveness in temperature control applications.

Experts in temperature management emphasize the importance of selecting an appropriate wick design tailored to specific operational requirements, as this choice profoundly influences the overall efficiency of the system. Understanding these design principles and current trends in thermal transfer technology is vital for engineers aiming to optimize performance in their projects, thereby ensuring effective management solutions.

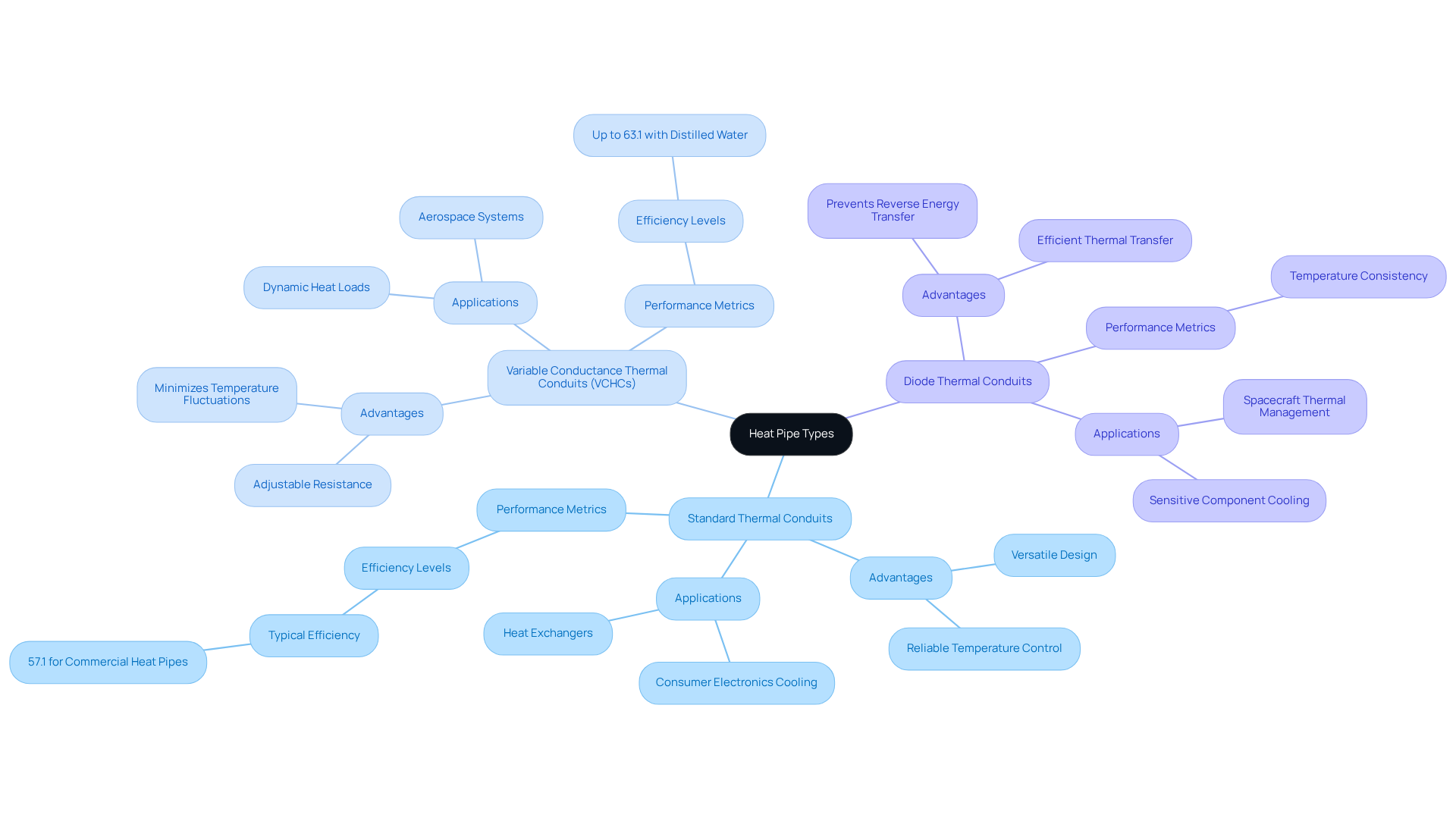

Exploring Different Heat Pipe Types: Selection Criteria for Engineers

When selecting thermal conduits, engineers must evaluate several critical factors, including the working fluid, usage specifications, and desired temperature performance. The most common types of thermal conduits include:

- Standard thermal conduits

- Variable conductance thermal conduits (VCHCs)

- Diode thermal conduits

Each type is tailored for specific operational requirements.

Standard heat pipe design is versatile and widely employed across various applications, providing reliable temperature control. VCHPs are particularly advantageous in systems with fluctuating heat loads, as they adjust their resistance based on ambient temperature and power input. This flexibility reduces temperature fluctuations at the evaporator, thereby enhancing overall system efficiency. Recent advancements in VCHPs have significantly boosted their performance, with research indicating that they can achieve efficiency levels of up to 63.1% when using distilled water as a working fluid, making them increasingly relevant in 2025 for applications requiring precise temperature regulation.

Diode heat exchangers, designed to prevent reverse energy transfer, play a crucial role in spacecraft applications where maintaining temperature consistency is essential. Their unique design facilitates efficient thermal transfer in a single direction, ensuring that sensitive components remain within optimal temperature ranges.

Statistics indicate that engineers prioritize temperature efficiency, reliability, and adaptability when selecting conduction tubes. A recent survey revealed that:

- 78% of engineers consider energy efficiency the primary criterion

- 65% closely follow the ability to manage varying heat loads

Real-world examples illustrate the effectiveness of these heat transfer types: the heat pipe design in standard models is frequently utilized in consumer electronics for efficient cooling, while VCHPs are increasingly adopted in aerospace sectors to manage temperature loads during flight. Diode cooling devices have proven indispensable in satellite systems, where they maintain temperature balance despite extreme environmental conditions. By understanding these types and their characteristics, engineers can make informed decisions that enhance the performance and reliability of their heat management systems.

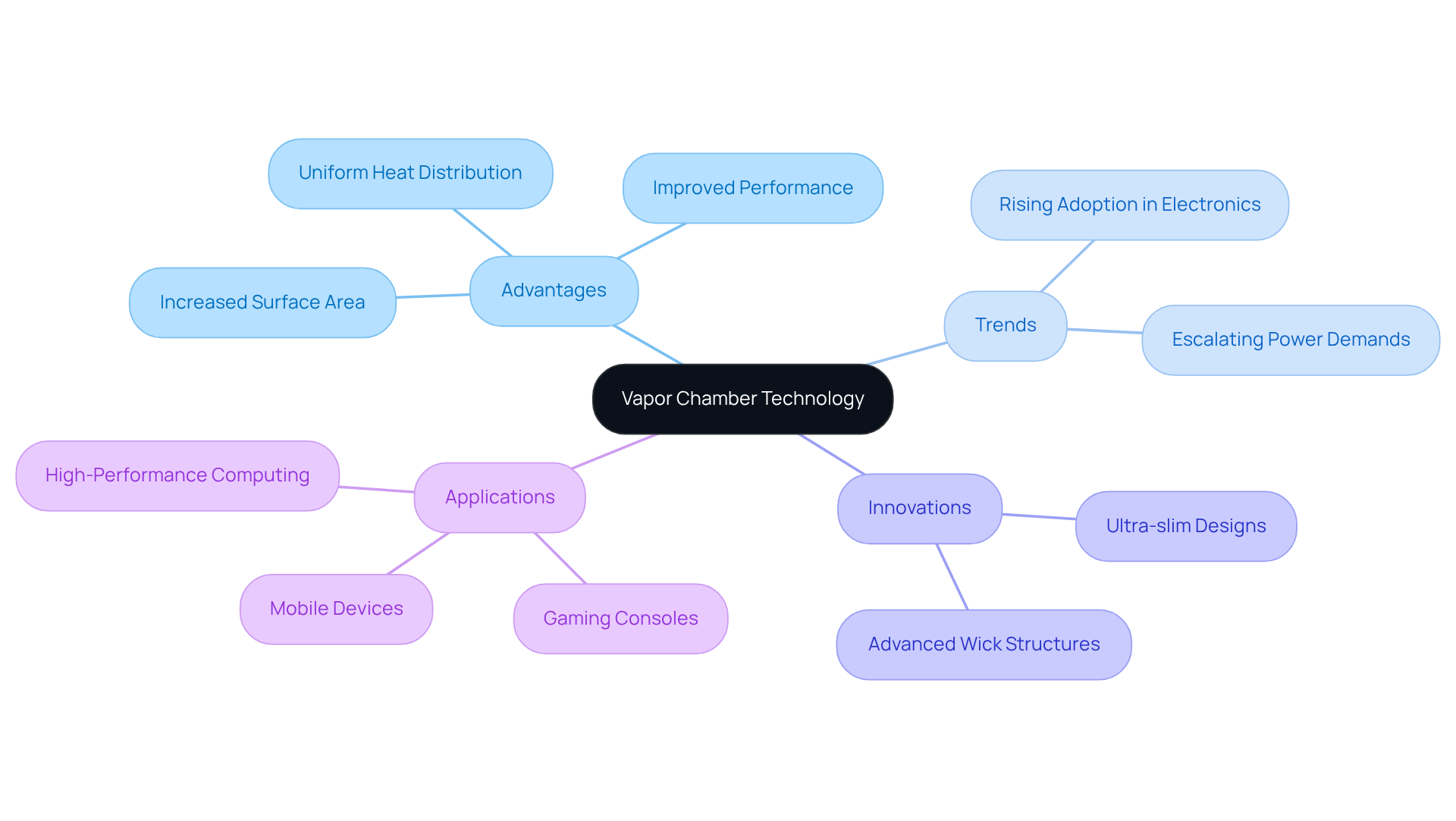

Utilizing Vapor Chamber Technology: Enhancing Thermal Performance

Vapor chambers represent a significant advancement in thermal management technology, employing the same principles as traditional thermal pipes but achieving superior thermal performance. Their increased surface area and ability to distribute heat uniformly make them particularly effective in high thermal flux environments, such as CPUs and GPUs. By evenly dispersing heat across their surfaces, vapor chambers are essential in sustaining optimal operating temperatures, thereby preventing hotspots that could jeopardize the reliability and longevity of electronic components.

As we look towards 2025, trends indicate a rising adoption of vapor chamber technology within the electronics sector, propelled by the escalating power demands of contemporary devices. Engineers have noted that vapor chambers not only enhance temperature distribution but also contribute to improved performance in compact designs, making them ideal for high-density applications. Innovations in vapor chamber design, including advanced wick structures and materials, are further elevating their efficiency and effectiveness in thermal energy management.

For instance, vapor chambers are increasingly integrated into high-performance CPUs, where they facilitate superior temperature control by dispersing heat more effectively than traditional cooling methods. This capability is critical as electronic components continue to evolve, generating higher thermal outputs. The latest innovations also include ultra-slim vapor chambers that address the spatial constraints of modern electronics while maintaining excellent heat conductivity.

Applications of vapor chambers can be observed in scenarios demanding substantial heat dissipation, such as gaming consoles and high-performance computing systems, where they manage heat fluxes that can exceed 300 W/cm. With the growing demand for efficient cooling solutions, heat pipe design is poised to become an integral component in the heat management strategies of advanced electronic systems.

Implementing Variable Conductance Heat Pipes: Adaptive Thermal Solutions

The heat pipe design of Variable Conductance Heat Pipes (VCHPs) is engineered to dynamically adjust their heat conductance in response to fluctuating operational conditions. By utilizing a non-condensable gas reservoir, these systems effectively regulate transfer rates, maintaining stable evaporator temperatures even amidst variable power loads. This capability is particularly crucial in aerospace applications, where maintaining temperature balance is essential for the functionality of sensitive electronic components.

Recent advancements in heat pipe design have significantly improved the performance of VCHPs, enabling them to proficiently manage heat dissipation in high-performance computing systems and other compact devices. For instance, VCHPs are increasingly integrated into spacecraft temperature regulation systems, demonstrating their capacity to adapt to extreme heat loads encountered during missions.

Market projections indicate that the VCHP market is valued at approximately $284.9 million in 2025, with a projected CAGR of around 3.4%, reflecting a growing demand for these solutions. Engineers must meticulously evaluate the specific temperature control requirements of their projects to fully leverage the advantages of VCHPs, ensuring optimal performance and reliability across diverse environments. Aerospace engineers emphasize that the flexibility of VCHPs significantly enhances the reliability of heat pipe design in critical applications.

However, it is imperative to address challenges such as high development and manufacturing costs, which may hinder the adoption of VCHPs in cost-sensitive industries.

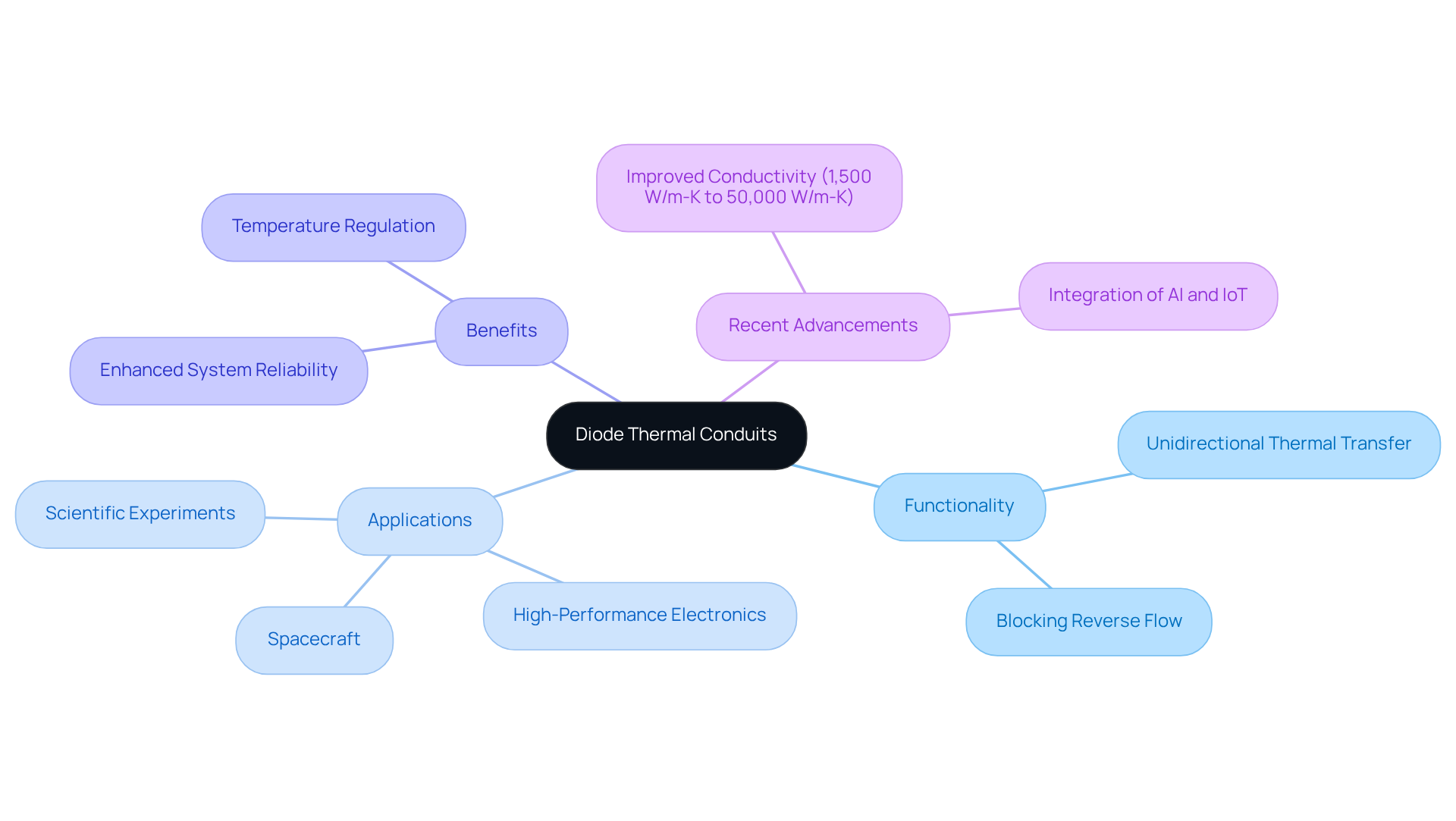

Incorporating Diode Heat Pipes: Specialized Applications and Benefits

Diode thermal conduits are meticulously crafted to enable unidirectional thermal transfer while effectively blocking reverse flow. This capability is crucial in applications where maintaining precise temperature gradients is essential, particularly in spacecraft temperature control. By preventing warmth from returning to sensitive components, diode thermal conductors significantly enhance system reliability and performance.

Recent advancements in diode energy transfer technology have led to improved conductivity, with effective conductivities ranging from 1,500 W/m-K to 50,000 W/m-K, ensuring optimal energy transfer even in compact spaces. In practical applications, these thermal conductors are indispensable in high-performance electronics, where they manage thermal loads from CPUs and GPUs, preventing overheating and thermal throttling. They also prove beneficial in high-stakes scientific experiments and advanced computing systems that demand accurate temperature regulation.

Thermal management experts emphasize the importance of diode thermal conduits in directing thermal flow, a critical factor for maintaining operational integrity in demanding environments. Furthermore, emerging trends in heat exchange technology, including advancements in material engineering and the integration of AI and IoT for dynamic temperature load adjustments, underscore the evolving landscape of energy management solutions.

Engineers should prioritize diode thermal conduits in their designs to achieve exceptional thermal control and ensure the longevity of electronic components.

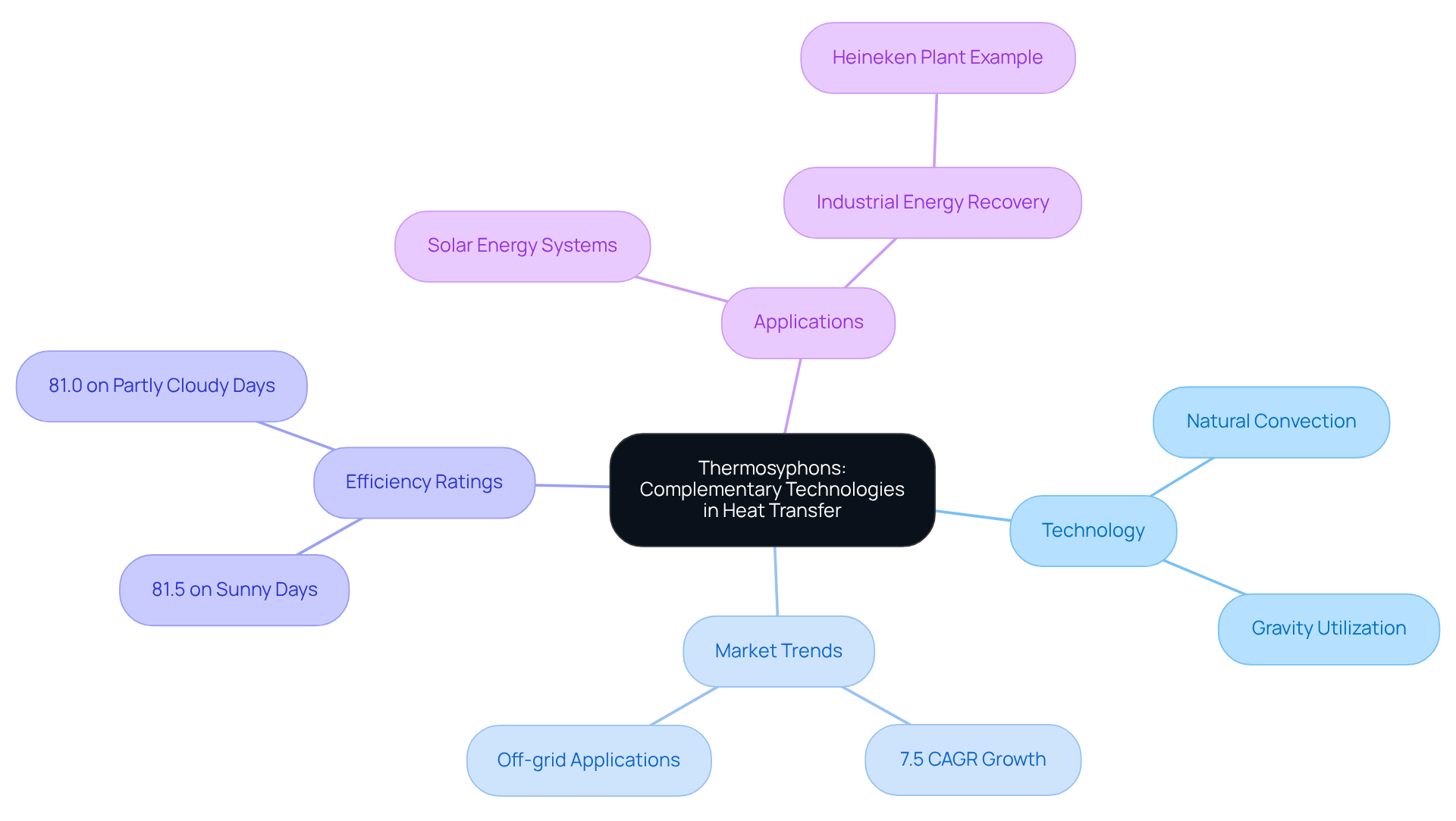

Leveraging Thermosyphons: Complementary Technologies in Heat Transfer

Thermosyphons represent a cutting-edge solution in passive temperature transfer technology, harnessing natural convection to circulate a working fluid between energy sources and sinks. Unlike thermal pipes that rely on capillary action, thermosyphons utilize gravity to return the liquid to the evaporator, making them ideal for applications where orientation is not a constraint. Engineers can leverage thermosyphons in systems that prioritize simplicity and reliability, particularly in solar thermal applications and industrial energy recovery systems.

Current market trends reveal a burgeoning interest in passive heat transfer devices, propelled by their efficiency and minimal maintenance needs. Notably, the thermosyphon segment is anticipated to expand at a 7.5% CAGR from 2025 to 2034, bolstered by their straightforward installation and low upkeep, indicative of their rising adoption in off-grid and rural settings.

Recent advancements underscore the adaptability of thermosyphons within solar energy systems, significantly enhancing energy efficiency. A pertinent study on thermosyphon solar water heating systems demonstrated their capability to meet hot water demands in commercial settings, achieving efficiency ratings of up to 81.5% on clear sunny days and 81.0% on partly cloudy days.

In the realm of industrial energy recovery, thermosyphons are increasingly utilized to optimize energy consumption, showcasing their efficacy across various sectors. A prime example is the solar heat system implemented at the Heineken plant, which exemplifies the practical application of thermosyphons in promoting energy efficiency and sustainability goals. As engineers continue to explore passive thermal transfer technologies, the integration of thermosyphons into energy systems is expected to play a pivotal role in achieving sustainability targets.

Adopting Loop Heat Pipes: Efficiency in Thermal Management

Loop heat conduits (LHCs) represent a significant advancement in heat pipe design for temperature management technology, leveraging capillary action to efficiently transfer warmth over extensive distances. Unlike conventional thermal pipes, the heat pipe design of loop heat pipes (LHPs) excels in environments where gravity poses challenges, such as in spacecraft and large electronic systems. Their ability to operate effectively in these demanding conditions is bolstered by high thermal efficiency in their heat pipe design, making them a preferred choice for engineers focused on reliable transfer solutions.

Recent advancements in heat pipe design technology have highlighted their applicability across various sectors, notably aerospace and high-performance computing. For instance, the heat pipe design is utilized in spacecraft to manage thermal dissipation from powerful systems, ensuring optimal performance without the need for mechanical pumps. This passive operation not only simplifies heat pipe design but also enhances reliability.

Engineers have noted that the heat pipe design of LHPs can transport larger volumes of thermal energy compared to traditional copper/water thermal conduits, which can transfer energy over greater distances. This characteristic renders them particularly suitable for large electronic systems where heat pipe design is essential for efficient thermal management. The unique wicking properties of materials used in heat pipe design, such as those developed by Mott Corp, facilitate seamless energy transfer, even in intricate configurations.

As the industry progresses, the incorporation of additive manufacturing techniques, including 3D printing, has further optimized the heat pipe design of LHPs. Although 3D printed LHPs may exhibit diminished thermal transport capabilities relative to conventional methods, this innovation in heat pipe design allows for rapid design iterations and the production of complex components that traditional techniques struggle to achieve. Consequently, the heat pipe design is not only becoming more accessible but also more efficient, with engineers increasingly recognizing its significance in contemporary heat management applications. As Mott articulates, ‘A heat pipe design is a sophisticated energy transfer apparatus utilized to convey energy across extended distances without requiring mechanical pumps.

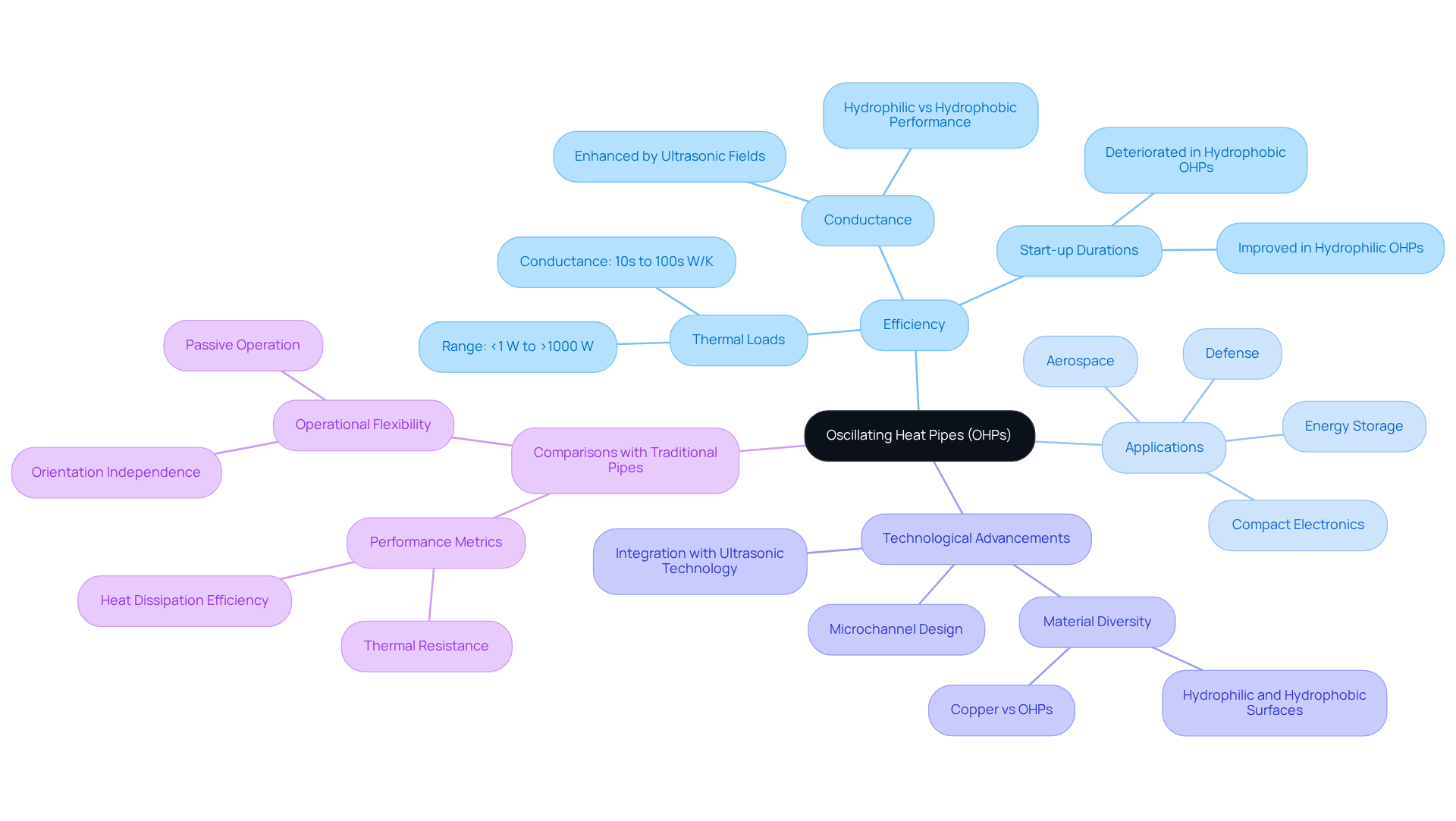

Exploring Oscillating Heat Pipes: Innovative Approaches to Heat Transfer

Oscillating heat pipes (OHPs) represent a cutting-edge solution in temperature management, leveraging a pulsating motion of the working fluid to enhance energy transfer. This unique mechanism empowers OHPs to operate efficiently across various orientations and under diverse heat loads. Particularly advantageous in compact electronic devices, where space constraints are prevalent, OHPs ensure effective heat dissipation is achieved. Engineers should seriously consider OHPs for applications demanding high heat performance within a limited footprint.

Since 2009, OHPs have collaborated with U.S. government agencies to drive solutions innovation related to heat, underscoring their credibility in the field. Recent advancements reveal that OHPs can accommodate thermal loads ranging from less than 1 W to over 1000 W, with conductances reaching tens to hundreds of W/K. Notably, hydrophilic OHPs have demonstrated significant enhancements in thermal performance, resulting in reduced start-up durations and minimized temperature variations compared to traditional copper pipes. However, it is essential to acknowledge that the global thermal transfer performance of hydrophobic PHPs has diminished relative to copper PHPs, indicating certain limitations of the technology.

OHPs exhibit remarkable adaptability, available in various materials, forms, and dimensions, making them suitable for a wide array of applications, including aerospace and defense. The internal microchannel design of OHPs facilitates efficient thermal transfer, further amplifying their effectiveness. Experts in heat management emphasize that heat pipe design not only provides compact and reliable solutions but also enables high power capabilities across multiple applications. As the demand for innovative energy transfer technologies escalates, OHPs stand at the forefront, equipping engineers with a powerful tool for achieving superior performance in constrained environments.

Identifying Heat Pipe Applications: From Electronics to Aerospace

Heat conduits play a pivotal role in diverse industries, including electronics, aerospace, automotive, and renewable energy. In the electronics sector, they are indispensable for cooling high-performance components such as CPUs and GPUs, which ensures optimal operation and longevity. The aerospace industry relies on temperature conduits to maintain precise temperature regulation in spacecraft, where effective energy management is crucial for mission success. Their unique ability to transfer heat efficiently, even with minimal temperature differences, makes thermal conduits vital in applications that require reliable thermal solutions. As engineers design systems, they must recognize the innovative potential of heat pipe design to enhance performance and reliability across various applications.

Current trends indicate a growing adoption of thermal conduits within the automotive industry, particularly for electric vehicles, where they are essential for regulating battery temperatures, thereby improving efficiency and safety. In 2023, the automotive sector accounted for 35% of the temperature regulation market, underscoring its significant role in heat management. Moreover, advancements in temperature transfer technology, particularly the heat pipe design and the development of loop systems, are paving the way for more efficient energy management solutions in renewable energy frameworks, such as solar energy applications. The temperature transfer market is projected to grow at a CAGR of 10% over the next five years, reflecting the escalating demand for effective energy management solutions. By harnessing these technologies, engineers can markedly enhance the thermal performance of their designs, addressing the increasing requirements for energy efficiency and sustainability. Leading companies like Aavid Thermalloy LLC and Furukawa Electric Co., Ltd. are at the forefront of innovative heat pipe solutions, further propelling advancements in this domain.

Conclusion

The exploration of heat pipe design techniques underscores the pivotal role these systems play in optimizing thermal management across diverse industries. By delving into the complexities of heat pipe construction—from the careful selection of working fluids to the implementation of advanced designs such as variable conductance and diode heat pipes—engineers can markedly enhance the efficiency and reliability of their thermal management solutions.

This article provides critical insights into various heat pipe types, including:

- Standard thermal conduits

- Vapor chambers

- Oscillating heat pipes

Each type is specifically engineered to address distinct operational requirements. The discussion extends to emerging technologies, such as:

- Thermosyphons

- Loop heat pipes

These highlight the relentless innovation within this field. As the demand for efficient cooling solutions escalates, particularly in sectors like electronics and aerospace, the strategic application of these techniques becomes increasingly vital for engineers.

In conclusion, advancements in heat pipe design not only bolster thermal performance but also promote the sustainability and efficiency of contemporary systems. Engineers are urged to remain abreast of the latest developments and to integrate these innovative techniques into their projects to tackle the mounting challenges of thermal management. By embracing these essential heat pipe design strategies, engineers will undoubtedly pave the way for more effective and reliable cooling solutions in the future.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for pioneering innovative cooling solutions using heat pipe design tailored for thermal conduction applications, collaborating with various manufacturers to enhance heat management in electronic systems.

What is the current market value of the thermal conduit market?

In 2023, the thermal conduit market was valued at approximately USD 3.5 billion, with projections indicating it will grow to USD 5.8 billion by 2032.

What is the projected compound annual growth rate (CAGR) for the thermal conduit market?

The projected CAGR for the thermal conduit market is 12.4% from 2025 to 2032.

What factors are driving the growth of the thermal conduit market?

The growth is primarily driven by the rising demand for efficient cooling solutions in high-performance electronics, particularly due to increased power consumption in data centers.

What are the main components of a heat pipe?

Heat pipes consist of three essential components: a sealed container, a working fluid, and a wick structure.

How does the wick structure in a heat pipe function?

The wick structure facilitates capillary action, allowing the working fluid to move between the evaporator and condenser sections of the heat pipe.

What are the recent advancements in wick designs for heat pipes?

Recent advancements include sintered and grooved wick designs, which have shown significant improvements in heat performance, particularly under dynamic conditions.

What types of thermal conduits are commonly used by engineers?

The common types of thermal conduits include standard thermal conduits, variable conductance thermal conduits (VCHCs), and diode thermal conduits.

What are the advantages of variable conductance thermal conduits (VCHPs)?

VCHPs are advantageous in systems with fluctuating heat loads as they adjust their resistance based on ambient temperature and power input, enhancing overall system efficiency.

What is the efficiency level that VCHPs can achieve using distilled water as a working fluid?

VCHPs can achieve efficiency levels of up to 63.1% when using distilled water as a working fluid.

What role do diode thermal conduits play in spacecraft applications?

Diode thermal conduits prevent reverse energy transfer, ensuring that sensitive components maintain optimal temperature ranges in spacecraft.

What criteria do engineers prioritize when selecting thermal conduits?

Engineers prioritize energy efficiency, the ability to manage varying heat loads, and reliability when selecting thermal conduits.

Can you provide examples of applications for different types of heat pipes?

Standard heat pipe designs are often used in consumer electronics, VCHPs are increasingly adopted in aerospace for managing temperature loads during flight, and diode cooling devices are essential in satellite systems for maintaining temperature balance.