Overview

Vapor chamber cooling represents a cutting-edge thermal management technique that leverages phase change principles to efficiently dissipate heat. This method proves particularly effective for high-heat flux applications, including CPUs, GPUs, and electric vehicles. The operational mechanisms of vapor chambers are intricate, yet they provide significant advantages over traditional thermal pipes, particularly in achieving uniform heat distribution. As electronic devices continue to evolve, the importance of vapor chambers grows, underscoring their critical role in addressing the demands of modern technology.

Introduction

In the realm of modern electronics, the effective management of heat has emerged as a paramount concern as devices become increasingly powerful and compact. Vapor chamber cooling technology stands at the forefront of thermal management solutions, utilizing innovative phase change principles to ensure optimal performance across a diverse array of applications.

From high-performance CPUs and GPUs to electric vehicles, vapor chambers provide unparalleled heat dissipation capabilities, which are crucial for maintaining the reliability and efficiency of advanced electronic systems. This article delves into the principles underlying vapor chamber cooling, compares its performance with traditional heat pipes, explores its varied applications, and analyzes the design considerations essential for successful integration into electronic devices.

As the demand for efficient thermal solutions continues to escalate, a comprehensive understanding of the intricacies of vapor chamber technology is vital for engineers and manufacturers alike.

Define Vapor Chamber Cooling: Principles and Mechanisms

Vapor chamber cooling is a cutting-edge thermal management technique that utilizes phase change principles for effective energy transfer. A steam compartment acts as a sealed vessel filled with a working liquid, typically water, and incorporates a wick design that enhances capillary action. Upon the application of warmth to one side of the chamber, the liquid transitions into gas, dispersing throughout the chamber and absorbing heat. This gas subsequently transforms back into liquid on the cooler side, establishing a continuous cycle of evaporation and condensation that facilitates rapid energy dissipation. This mechanism proves particularly advantageous in high-heat flux applications, such as CPUs and GPUs, where vapor chamber cooling is essential for efficient heat management.

Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers for cooling, delivers innovative solutions that ensure even heat distribution across a broader surface area, significantly reducing hotspots and enhancing overall heat management. Their extensive collection includes integrated cooling solutions that combine gas-filled compartments with other heat management technologies, such as extruded aluminum heatsinks and liquid cooling systems. Additionally, Gagner-Toomey offers a diverse range of DC input Tube Axial fans and Centrifugal Blowers, available in sizes from 15 to 280mm, further augmenting their cooling system offerings.

A comparative analysis titled ‘Comparative Study of Vapor Systems Designs’ demonstrated that configurations featuring machined posts and vent designs consistently achieved superior thermal performance metrics, including the highest power dissipation and lowest thermal resistance, with a measured thermal resistance of 0.05 K/W at 420 W, underscoring the efficiency of vapor chamber cooling systems in effectively managing heat.

As the sector evolves, future studies should explore various heating methods to enhance the input power capabilities of heat exchangers. The recommended liquid charging accuracy in this context was approximately ±2 L, underscoring the importance of precision in thermal management design. This ongoing advancement by Gagner-Toomey Associates is vital for meeting the increasing demands of modern electronics, confirming that vapor chamber cooling systems remain a crucial component in sophisticated heat management solutions.

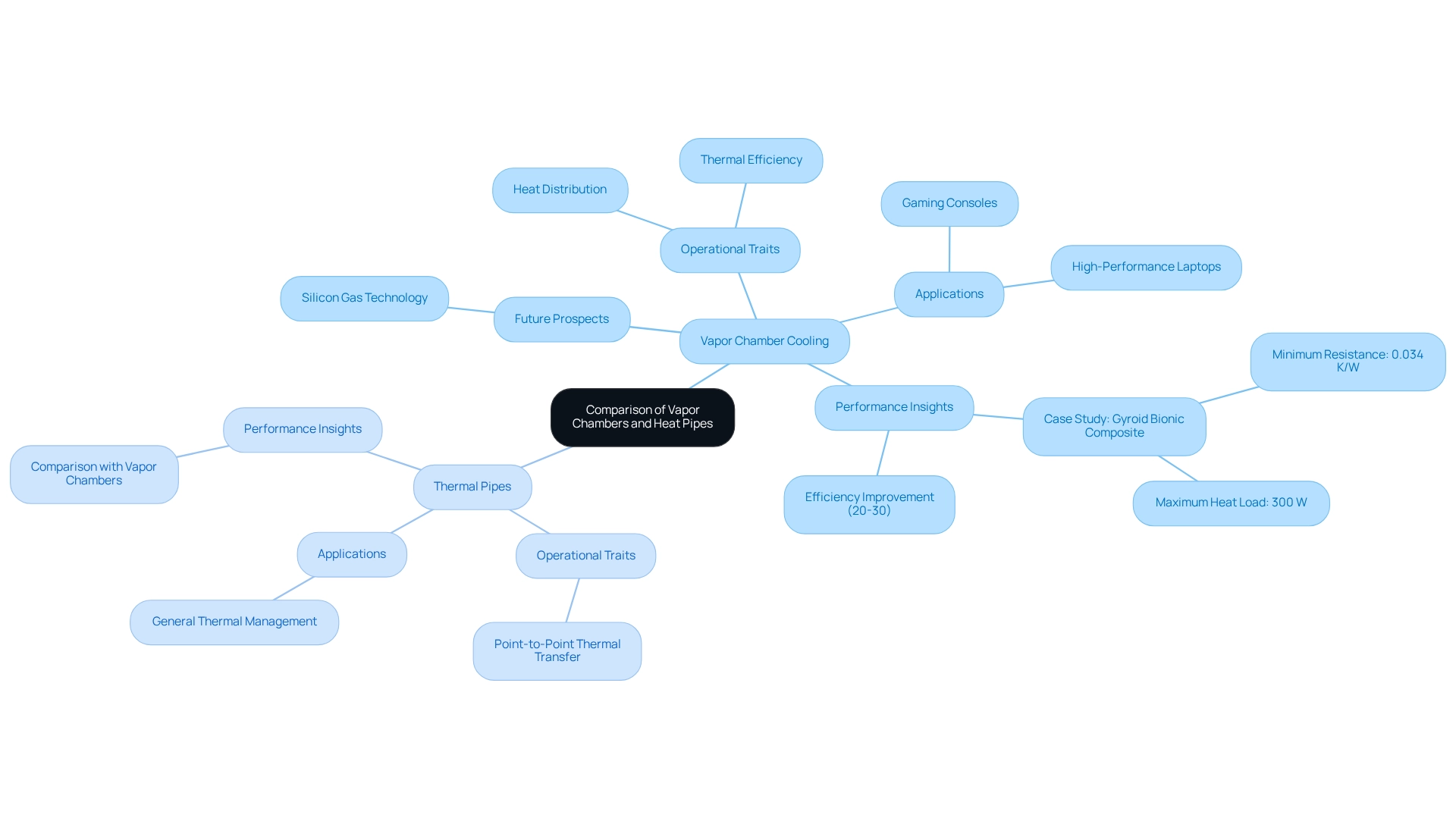

Compare Vapor Chambers and Heat Pipes: Performance Insights

Vapor chamber cooling systems and thermal tubes serve as critical temperature control solutions, each with unique operational traits tailored for specific applications. Thermal pipes function by transferring heat in a linear manner, leveraging the vaporization and condensation of a working fluid within a cylindrical structure. In contrast, flat enclosures utilize their design to distribute heat across two dimensions, facilitating more uniform thermal dissipation with the help of vapor chamber cooling. This configuration enables thermal units to manage larger thermal loads while delivering exceptional thermal efficiency in constrained environments, especially through vapor chamber cooling.

For example, while thermal pipes are adept at point-to-point thermal transfer, vapor chamber cooling demonstrates superior efficiency in scenarios necessitating consistent warmth distribution, such as in high-performance laptops and gaming consoles. Research indicates that vapor chamber cooling systems can improve cooling efficiency by 20-30% compared to conventional pipes under similar conditions. A notable case study on the Gyroid Bionic Composite Porous Wick Heat Exchange Unit revealed a minimum resistance of 0.034 K/W and a maximum heat load of 300 W, underscoring the potential of advanced heat exchange designs in high-demand applications.

Furthermore, the measurement precision of T-type thermocouples, with an accuracy of ±0.5 °C, is crucial for evaluating the effectiveness of these temperature control solutions. Tanya Liu from the Department of Mechanical Engineering at Stanford University notes, ‘Water is easy to work with in a laboratory environment and has a relatively high capillary merit number,’ highlighting the importance of material selection in thermal management technology.

Looking ahead, the future prospects of silicon gas technology present exciting potential applications that could further enhance heat management solutions. Nonetheless, engineers must carefully weigh the balance between performance and cost when selecting heat management solutions. In conclusion, the choice between vapor chamber cooling systems and thermal conduits hinges on the specific management requirements of the application, with vapor chamber cooling providing distinct advantages where uniform temperature distribution is paramount.

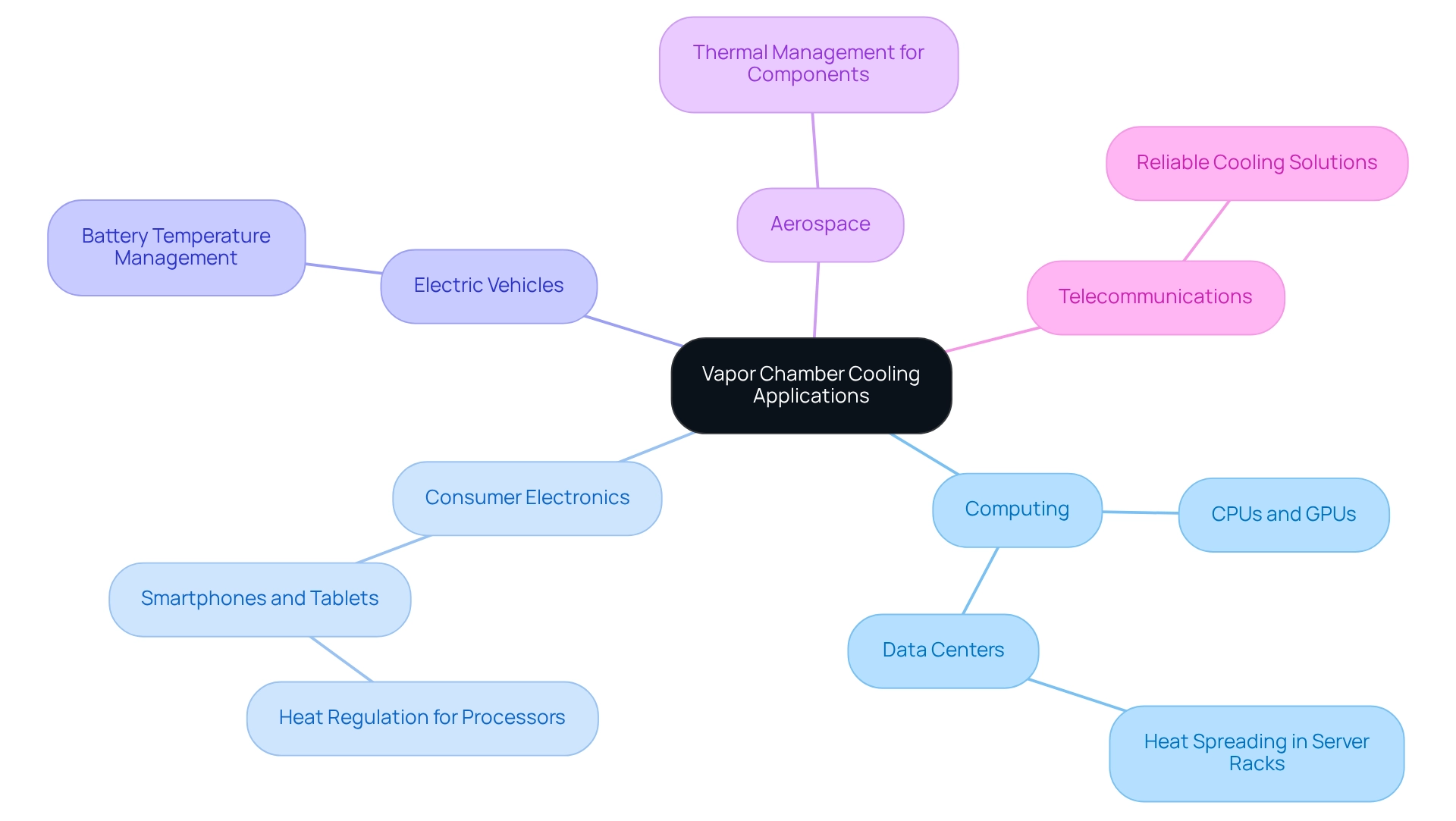

Explore Applications of Vapor Chambers in Electronics: From CPUs to EVs

Devices utilizing vapor chamber cooling are increasingly recognized for their exceptional thermal management capabilities across a variety of electronic applications. In computing, vapor chamber cooling plays a crucial role in high-performance CPUs and GPUs by effectively maintaining optimal operating temperatures during intensive processing tasks. This technology, vapor chamber cooling, is also prevalent in smartphones and tablets, where it regulates heat generated by powerful processors while enabling sleek designs. Beyond consumer electronics, thermal management devices such as vapor chamber cooling are vital in electric vehicles (EVs), where they manage battery temperatures to ensure both safety and efficiency. Their capacity to handle high thermal fluxes makes them particularly suitable for aerospace and telecommunications applications, where reliable vapor chamber cooling is essential for performance and longevity.

Research indicates that:

- Copper foam wicks exhibit outstanding thermal transfer capabilities and adaptability to cooling water temperatures, underscoring their efficiency in diverse environments.

- CPVCs with fine-particle powders demonstrate superior performance compared to those with coarse-particle powders, emphasizing the significance of material selection in optimizing effectiveness.

As illustrated in the case study ‘Effective Cooling in Data Centers,’ gas-filled spaces facilitate heat distribution within server racks, reducing the reliance on active cooling methods such as fans or liquid cooling.

As the electronics sector evolves in 2025, the demand for cooling systems is expected to rise, driven by the increasing necessity for effective heat management in high-density applications.

Analyze Design Considerations for Vapor Chamber Integration: Challenges and Solutions

Incorporating heat dissipation units into electronic systems presents several essential design factors. A key challenge is the selection of suitable interface materials (TIMs), which are critical for optimizing heat transfer between the heat source and the condensation area. Recent performance data indicates that high-performance TIMs can significantly reduce heat resistance, thereby enhancing overall system efficiency. Additionally, the design of the gas container must be meticulously optimized to promote effective capillary action and fluid movement, both of which are vital for efficient heat management.

Manufacturing methods significantly impact the effectiveness of heat exchangers. Precision in crafting the wick structure and maintaining vacuum integrity is essential; any deviation can lead to suboptimal performance. Furthermore, minimizing the overall heat resistance of the system is imperative for boosting efficiency.

To tackle these challenges, engineers can employ advanced manufacturing techniques, such as additive manufacturing, which facilitates the creation of custom designs tailored to specific applications. Moreover, selecting high-performance TIMs capable of withstanding operational conditions is crucial for ensuring reliable performance.

A case study titled ‘Thermal Budget Considerations for Vapor Chamber Cooling’ emphasizes the importance of calculating maximum allowable temperature differences to ensure effective vapor chamber cooling. The findings from this case study demonstrate that adhering to thermal budget guidelines can significantly enhance the design process for electronic cooling solutions, enabling engineers to ascertain the appropriate application of heat exchange devices based on distinct thermal requirements.

As the vapor chamber cooling market continues to intersect with various industries, including telecommunications and automotive, it is essential for engineers to remain informed about these design considerations to implement innovative vapor chamber cooling solutions in 2025. The upcoming EDS 2025 event, scheduled for May 19 to May 23, 2025, in Las Vegas, NV, will offer further insights and networking opportunities for engineers to discuss these challenges and solutions. As Ralf Hug, Global Head of Product Management & Marketing, remarked, “Their expertise allows us to make data-driven, strategic decisions and ensures we remain aligned with the latest trends and opportunities in the market.

Conclusion

The exploration of vapor chamber cooling technology underscores its pivotal role in modern thermal management solutions. By harnessing innovative phase change principles, vapor chambers adeptly tackle the escalating challenges of heat dissipation in increasingly compact and powerful electronic devices. Their capability to distribute heat uniformly across surfaces positions vapor chambers as superior to traditional heat pipes, particularly in high-heat flux applications such as CPUs, GPUs, and electric vehicles.

Comparative analyses reveal that vapor chambers not only enhance cooling performance but also exhibit versatility across a range of applications, including consumer electronics and aerospace. The successful integration of these systems necessitates meticulous attention to design elements such as thermal interface materials and manufacturing precision, both critical for optimizing performance and reliability.

With the demand for advanced thermal solutions on the rise, a comprehensive understanding of vapor chamber technology becomes essential for engineers and manufacturers. The future of electronics increasingly hinges on efficient thermal management, and vapor chambers are poised to lead this evolution. Embracing these innovative solutions will be crucial to ensuring the performance, safety, and longevity of next-generation electronic devices.

Frequently Asked Questions

What is vapor chamber cooling?

Vapor chamber cooling is a thermal management technique that uses phase change principles for effective energy transfer, involving a sealed vessel filled with a working liquid, typically water, that facilitates rapid energy dissipation through a cycle of evaporation and condensation.

How does vapor chamber cooling work?

When warmth is applied to one side of the chamber, the liquid turns into gas, which spreads throughout the chamber and absorbs heat. The gas then transforms back into liquid on the cooler side, creating a continuous cycle that effectively manages heat.

In what applications is vapor chamber cooling particularly beneficial?

Vapor chamber cooling is especially advantageous in high-heat flux applications, such as CPUs and GPUs, where efficient heat management is crucial.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers for cooling, providing innovative solutions for even heat distribution, including integrated cooling solutions that combine gas-filled compartments with other heat management technologies.

What products does Gagner-Toomey offer?

Gagner-Toomey offers a range of products, including DC input Tube Axial fans and Centrifugal Blowers in sizes from 15 to 280mm, as well as extruded aluminum heatsinks and liquid cooling systems.

What did the comparative analysis titled ‘Comparative Study of Vapor Systems Designs’ reveal?

The analysis showed that configurations with machined posts and vent designs achieved superior thermal performance, including the highest power dissipation and lowest thermal resistance, with a measured thermal resistance of 0.05 K/W at 420 W.

What future studies are suggested for vapor chamber cooling?

Future studies should explore various heating methods to enhance the input power capabilities of heat exchangers, emphasizing the importance of precision in thermal management design, with a recommended liquid charging accuracy of approximately ±2 L.

Why are vapor chamber cooling systems important in modern electronics?

Vapor chamber cooling systems are crucial for meeting the increasing demands of modern electronics, confirming their role as essential components in sophisticated heat management solutions.