Overview

The article delineates four essential steps to optimize bladed fans for maximum efficiency. It emphasizes the importance of:

- Understanding fan components

- Designing efficient blades

- Selecting appropriate motors and controls

- Implementing seasonal adjustments

Each step is bolstered by specific strategies, such as:

- Choosing blade shapes that minimize drag

- Utilizing brushless DC motors for enhanced energy savings

These strategies ensure that fans operate effectively throughout the year, providing a comprehensive approach to achieving optimal performance.

Introduction

Understanding the intricacies of bladed fans is crucial for unlocking significant potential for energy savings and enhanced performance. By delving into essential components—such as blades, motors, housings, and control systems—users can discover effective strategies to optimize their fans. However, navigating the complex relationship between design choices and operational efficiency presents a challenge.

To ensure that these fans operate at peak performance throughout the year, specific steps must be taken.

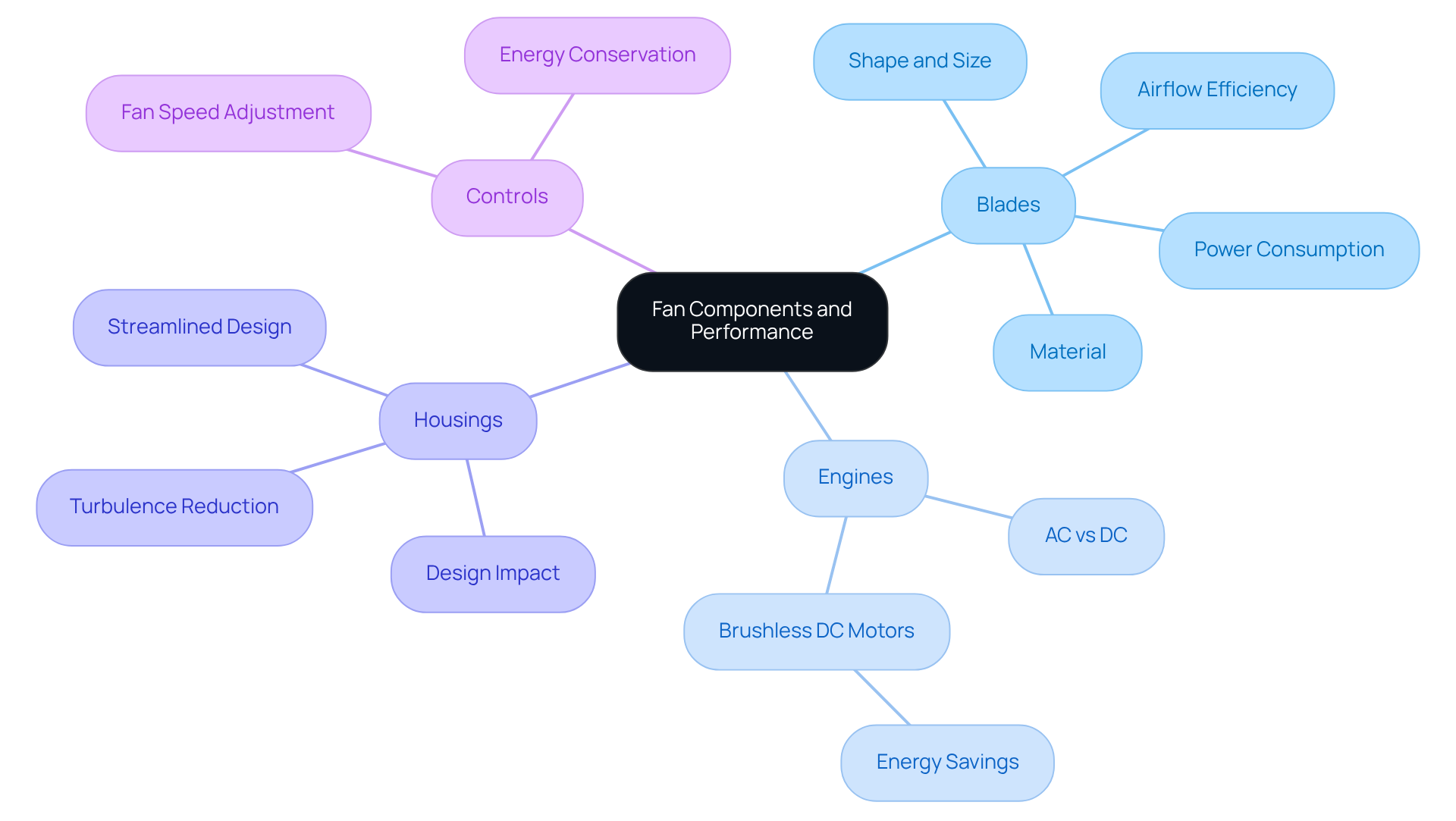

Understand Fan Components and Their Impact on Performance

To enhance the performance of bladed fans, it is essential to familiarize yourself with the : blades, engines, housings, and controls. Each of these elements significantly influences the airflow, energy consumption, and noise levels of bladed fans.

- Blades: The shape, size, and material of the blades are pivotal in determining how effectively air is moved. For example, wider blades can push more air but may necessitate increased power consumption.

- Engines: The type of engine utilized—AC versus DC—can markedly affect performance. Brushless DC motors, in particular, are often more efficient than traditional AC motors, offering superior energy savings.

- Housings: The design of the enclosure for the bladed fans also plays a crucial role; a poorly designed enclosure can create turbulence, thereby diminishing performance. A streamlined design is vital for bladed fans as it minimizes resistance and enhances airflow efficiency.

- Controls: Advanced control systems are instrumental in adjusting fan speed according to demand, thereby promoting energy conservation.

By comprehensively understanding these components, you empower yourself to make informed decisions in the subsequent steps of the optimization process.

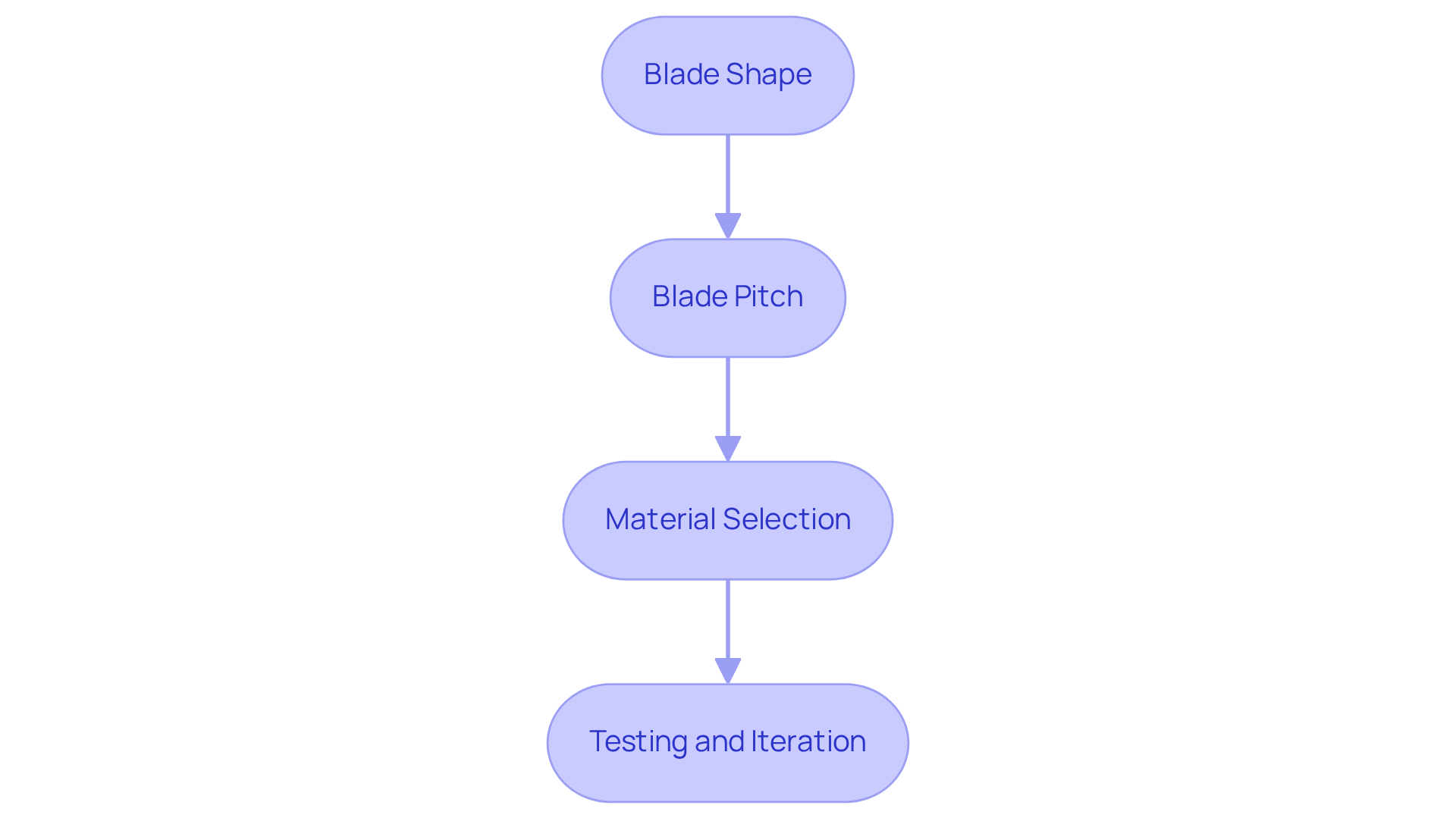

Design Blades for Optimal Airflow and Energy Efficiency

To design blades that maximize airflow and energy efficiency, follow these essential steps:

- Blade Shape: Select an airfoil shape to minimize drag and enhance lift. This design promotes optimal airflow while reducing energy consumption.

- Blade Pitch: Modify the angle of the blades (pitch) to fine-tune airflow for specific applications. A higher pitch can boost airflow but may necessitate increased power.

- Material Selection: Choose lightweight materials such as composite plastics or aluminum to lower the overall weight of the fan, thereby enhancing performance.

- Testing and Iteration: Employ computational fluid dynamics (CFD) simulations to evaluate various blade designs prior to physical prototyping. This approach conserves time and resources by identifying the most efficient designs early in the process.

By concentrating on these critical design elements, you can engineer bladed fans that substantially elevate their performance.

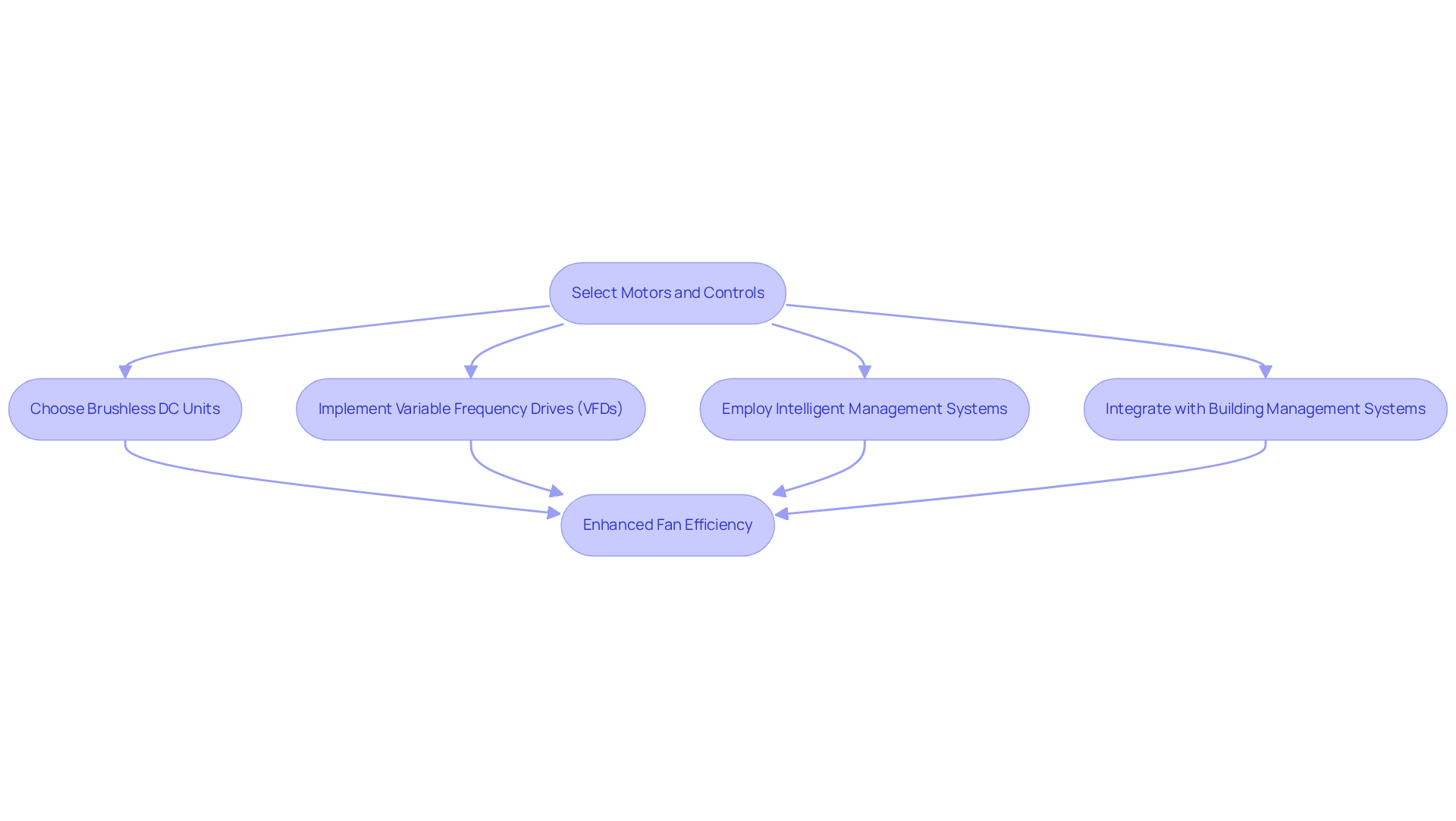

Select Motors and Controls for Enhanced Fan Efficiency

Selecting the appropriate motors and controls is critical for optimizing performance and efficiency. To begin with, consider the type of drive; brushless DC units should be selected due to their compared to conventional AC units. These units also provide improved speed management, which is essential for various applications.

Next, implement Variable Frequency Drives (VFDs) to adjust motor speed based on real-time demand. This adjustment can lead to significant energy savings, making it a practical choice for energy-conscious operations.

Moreover, employ intelligent management systems that can observe and modify fan functioning according to environmental factors. This capability ensures that peak performance is consistently maintained, adapting to changing conditions effectively.

If applicable, integrate fan operations with existing building management systems. This integration allows for centralized monitoring and management, thereby enhancing overall effectiveness and operational efficiency.

By thoughtfully selecting motors and controls, you can significantly enhance the performance of your bladed fans, resulting in improved operational outcomes and energy efficiency.

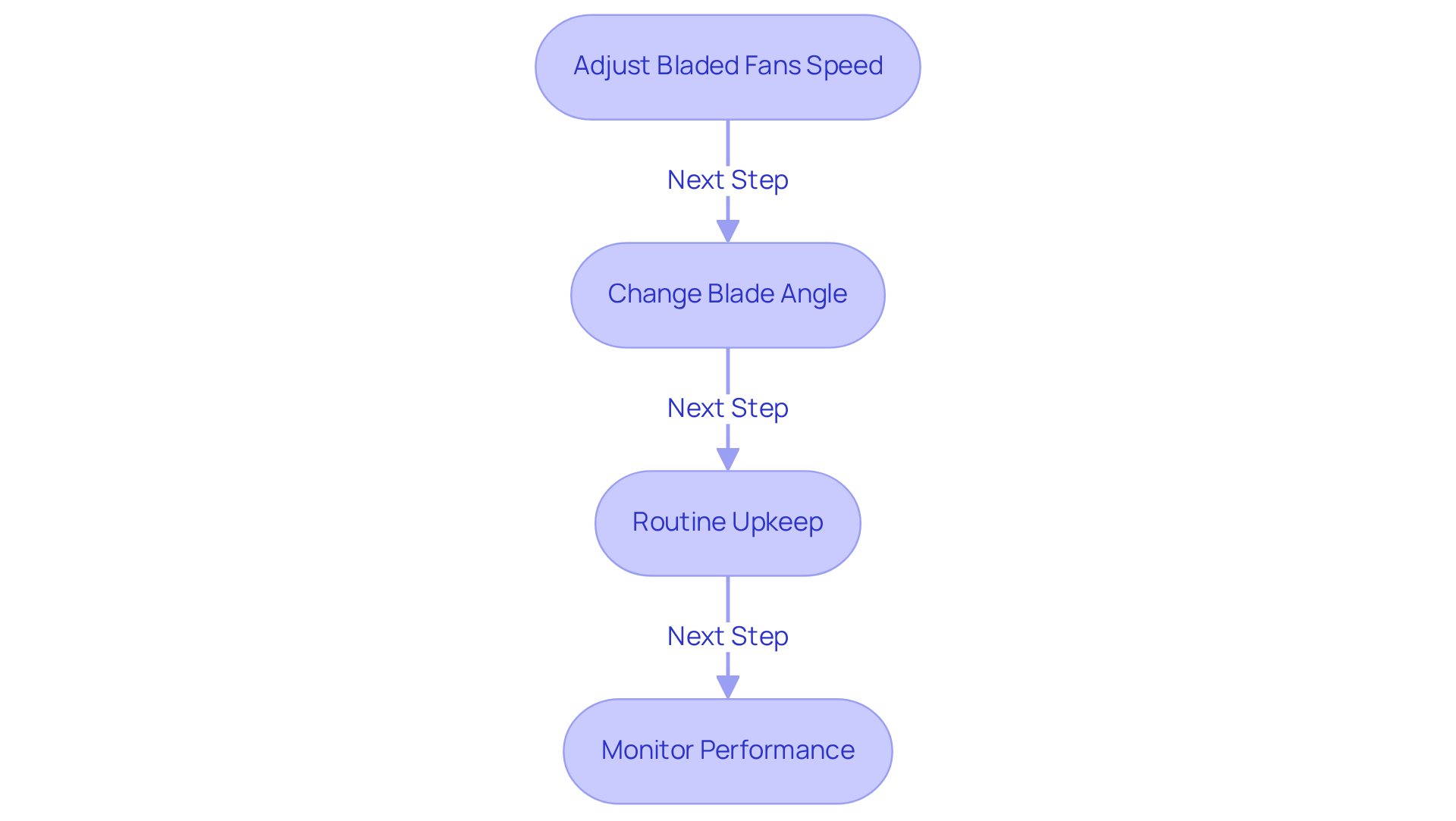

Implement Seasonal Adjustments for Year-Round Efficiency

To ensure year-round efficiency, it is essential to implement the following seasonal adjustments:

- Adjust Bladed Fans Speed: During warmer months, increase the speed of bladed fans to enhance cooling performance, while reducing their speed in cooler months to conserve energy. The US Department of Energy indicates that optimizing fan performance can reduce energy consumption by up to 50% in some cases.

- Change Blade Angle: If feasible, adjust the blade pitch seasonally to optimize airflow for either heating or cooling requirements. This adjustment can significantly impact by maximizing performance based on the season.

- Routine Upkeep: Schedule maintenance inspections at the start of every season to clean blades, assess motor performance, and confirm that mechanisms are functioning properly. This ensures durability and effectiveness.

- Monitor Performance: Utilize advanced control systems and sensors to track fan performance and adjust settings based on real-time data. This allows for optimal operation throughout the year.

By implementing these adjustments, you can effectively adapt your bladed fans to seasonal demands while maintaining maximum efficiency and enhancing overall energy savings.

Conclusion

Optimizing bladed fans for maximum efficiency is a multifaceted process that hinges on understanding the critical components involved, including blades, engines, housings, and controls. Each of these elements plays a vital role in influencing airflow, energy consumption, and overall performance, making it essential to approach optimization with a comprehensive strategy.

Key steps to enhance fan efficiency include:

- Designing blades that promote optimal airflow and energy savings

- Selecting the right motors and controls for superior performance

- Implementing seasonal adjustments to ensure year-round efficiency

By focusing on blade design, utilizing advanced motor technology, and making timely adjustments based on environmental conditions, significant improvements in operational outcomes and energy efficiency can be achieved.

Ultimately, the journey toward maximizing the efficiency of bladed fans is not just about immediate gains but also about fostering a sustainable approach to energy use. By applying these strategies, individuals and organizations can contribute to a more energy-conscious future, reducing costs and environmental impact while enjoying the benefits of enhanced performance. Taking action today can lead to a more efficient tomorrow, making the optimization of bladed fans a worthwhile endeavor.

Frequently Asked Questions

What are the main components of bladed fans that impact their performance?

The main components are blades, engines, housings, and controls. Each of these elements significantly influences airflow, energy consumption, and noise levels.

How do the blades of a fan affect its performance?

The shape, size, and material of the blades are crucial for air movement. Wider blades can push more air but may require increased power consumption.

What types of engines are used in bladed fans, and how do they affect performance?

Bladed fans typically use AC or DC engines. Brushless DC motors are often more efficient than traditional AC motors, offering better energy savings.

Why is the housing design important for the performance of bladed fans?

The design of the enclosure is important because a poorly designed housing can create turbulence, reducing performance. A streamlined design minimizes resistance and enhances airflow efficiency.

How do control systems contribute to the efficiency of bladed fans?

Advanced control systems allow for adjusting fan speed based on demand, which promotes energy conservation and improves overall efficiency.

Why is it important to understand the components of bladed fans?

Understanding these components empowers individuals to make informed decisions during the optimization process for better performance.