Overview

The article addresses the critical factors engineers must evaluate when choosing the appropriate electronic cooling fan for their applications. It underscores the necessity of assessing:

- Airflow requirements

- Energy efficiency

- Noise levels

- Compatibility with existing systems

These considerations are backed by specific examples and statistics that illustrate their significant influence on overall performance and reliability in electronic cooling solutions.

Introduction

Choosing the right electronic cooling fan is a critical decision that can significantly impact the performance and reliability of electronic devices. As the complexity of modern electronics continues to grow, understanding the nuances of cooling fan technology becomes increasingly vital. This article explores seven key factors that engineers must consider when selecting cooling fans—ranging from energy efficiency to fan type—thereby ensuring optimal thermal management across various applications.

How can engineers effectively navigate the myriad options available to make informed choices that enhance both performance and longevity?

Gagner-Toomey Associates: Leading Provider of Electronic Cooling Solutions

Gagner-Toomey Associates stands out as a leading provider of , committed to empowering engineers in overcoming the intricate challenges of the electronics sector. By focusing on cutting-edge , the company presents a diverse portfolio of manufacturers, guaranteeing clients access to that significantly elevate performance and efficiency.

Recent statistics reveal that is exceptionally high, underscoring the company’s unwavering commitment to excellence in customer service and product representation.

As industry leaders increasingly advocate for , Gagner-Toomey remains at the forefront, adeptly adapting to the latest trends in electronic temperature management for 2025 and beyond. Their expertise establishes them as a in search of .

Electric Cooling Fans: Essential Components for Electronics Cooling

s play a crucial role in the thermal regulation of electronic devices. They use an to facilitate the removal of heat generated by electronic components, ensuring that devices operate within safe temperature limits. By improving airflow, these units, which include an electronic cooling fan, help maintain and of electronic equipment. The design and efficiency of electronic cooling fans have a direct impact on the overall performance of refrigeration units, making them indispensable across a wide range of applications, from consumer electronics to industrial machinery. The is projected to be valued at approximately USD 8.125 billion in 2024, underscoring the critical importance of these components within the industry.

Engineers emphasize that , which can be accomplished with an electronic cooling fan, is vital for preventing overheating, thereby avoiding system failures and reduced functionality. Recent innovations in electric fan technology include the incorporation of smart features such as Wi-Fi connectivity and voice control, enabling real-time monitoring and management of fan performance. Aarti Bagekari, a Research Associate at Cognitive Market Research, notes that “the fan market is experiencing significant growth, primarily fueled by technological advancements in the automotive sector.” These innovations, such as the electronic cooling fan, are particularly advantageous in high-performance applications, where precise is essential.

Case studies illustrate the impact of electronic cooling fans on thermal management. For instance, in data centers, that incorporate electronic cooling fans have been shown to enhance airflow and reduce noise, . Moreover, Tesla’s advancements in temperature regulation systems for new electric vehicle models, which incorporate electronic cooling fans, are designed to improve battery efficiency and vehicle performance, reflecting the growing demand for effective thermal management systems across various sectors. As the market continues to evolve, the focus on and innovative designs will further solidify the importance of electronic cooling fans as electric ventilation devices in modern electronics.

Understanding Electric Cooling Fan Operation and Mechanisms

Electric ventilation devices operate by converting electrical energy into mechanical energy through a motor. This motor propels the electronic fan blades, generating airflow that effectively dissipates heat from electronic components. The design of these blades is crucial, as variations in shape and size can optimize both airflow and pressure. Understanding these operational principles is vital for engineers, influencing their based on specific and environmental considerations.

Notably, s account for approximately 16% of electricity consumed in commercial buildings, highlighting the critical need for choosing to lower operational costs. Case studies illustrate that opting for a fan with a high can lead to substantial ; for instance, a more efficient 20 horsepower fan in a commercial heating and ventilation context could save over $1,000 annually in energy expenses. This underscores the necessity for and efficiency of the electronic cooling fan in their temperature control strategies.

Furthermore, the (CFE) index serves as a valuable metric for assessing fan performance, empowering engineers to make informed decisions that enhance both cooling effectiveness and energy efficiency.

PWM Fans: Superior Efficiency and Performance in Cooling Systems

leverage Pulse Width Modulation (PWM) technology to optimize , enabling precise adjustments in voltage supplied to the motor. This capability allows PWM devices to operate at various speeds, significantly .

Real-world applications illustrate that these devices can reduce by up to 60% when functioning at lower speeds, while also achieving a noise reduction of approximately 6 dB with a 25% decrease in speed. Notably, by 25% results in a corresponding 25% decline in airflow, highlighting the trade-offs involved in temperature regulation.

Such efficiency makes PWM devices, like the , particularly advantageous in environments such as data centers and high-performance computing, where effective and energy savings are critical.

Industry leaders recognize that not only improves airflow efficiency but also extends the lifespan of fans; as Chi Xu states, “this adaptability makes PWM devices superior to conventional thermal solutions in terms of both effectiveness and efficiency.”

Furthermore, ensuring compatibility with the motherboard is crucial when selecting PWM units, as not all setups are equipped with the necessary connections. The integration of advanced features, such as optimized blade angles and stators, further of PWM devices, making an electronic cooling fan a premier choice in electronic heat management.

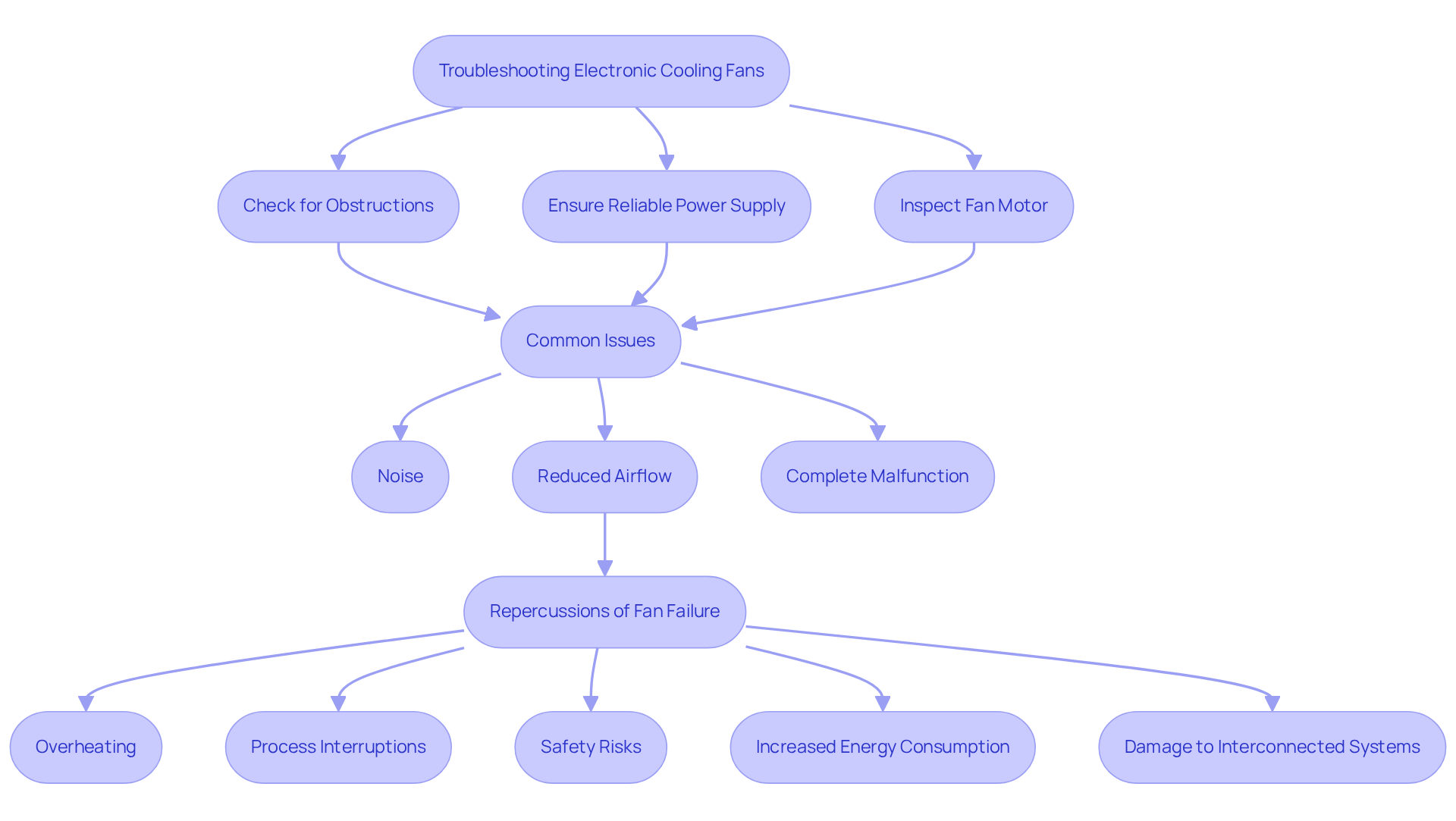

Common Issues with Electric Cooling Fans and Troubleshooting Tips

s are critical components in electronic setups, yet they often encounter various issues, including noise, , and complete malfunction. The initial step in troubleshooting these devices involves:

- Checking for obstructions

- Ensuring a reliable power supply

- Inspecting the fan motor for signs of wear

Notably, statistics reveal that , frequently attributed to lubrication issues and misalignment, occurring at a rate of 4:1 compared to motor insulation breakdown failures. , such as:

- Removing dust buildup

- Verifying electrical connections

can . For instance, , as imbalances are responsible for 15-20% of , enabling corrective actions before substantial damage occurs. By promptly addressing these issues, and reliability of the electronic cooling fan, ultimately ensuring . As Qiang Miao aptly stated, ‘The electronic cooling fan is essential for ensuring the reliability of electronic devices.’ Additionally, the repercussions of fan failure can include:

- Reduced airflow

- Overheating

- Process interruptions

- Safety risks

- Increased energy consumption

- Damage to interconnected systems

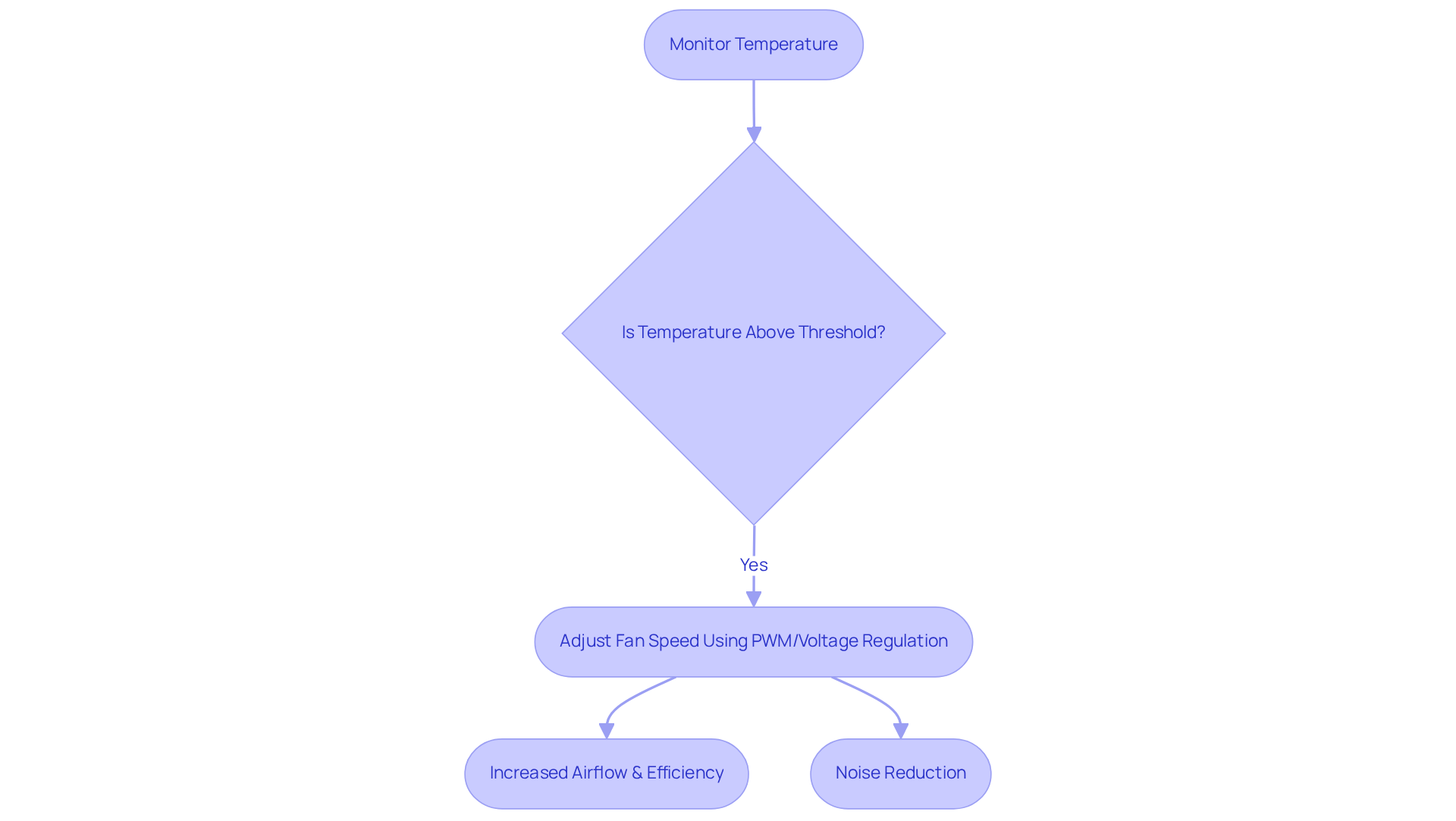

Fan Speed Control: Key to Effective Thermal Management

Regulating the speed of the is essential for the efficient of electronic devices. By dynamically adjusting the speed of ventilation fans according to real-time temperature readings, engineers significantly enhance airflow and efficiency. Techniques such as (PWM) and voltage regulation enable these adjustments, allowing devices to respond swiftly to fluctuating thermal conditions.

For instance, data centers that implement have reported , as evidenced by studies involving specific server configurations that optimize thermal management. Engineers emphasize the importance of these , noting that they not only improve but also reduce . A 25% reduction in rotor speed can lead to a noise decrease of approximately 6 dB, and systems that utilize PWM devices can achieve up to a 30% reduction in sound output compared to traditional thermal management systems.

As John Doe, an industry leader, asserts, “The integration of is transforming thermal management solutions, making them more efficient and reliable than ever before.” As the electronics industry evolves, mastering these techniques for controlling the speed of the electronic cooling fan will be vital for optimizing thermal management solutions.

Furthermore, the anticipated growth of the PWM secondary side controllers market, projected to expand at a CAGR of 8.9% from 2024 to 2031, underscores the increasing significance of these technologies within the industry.

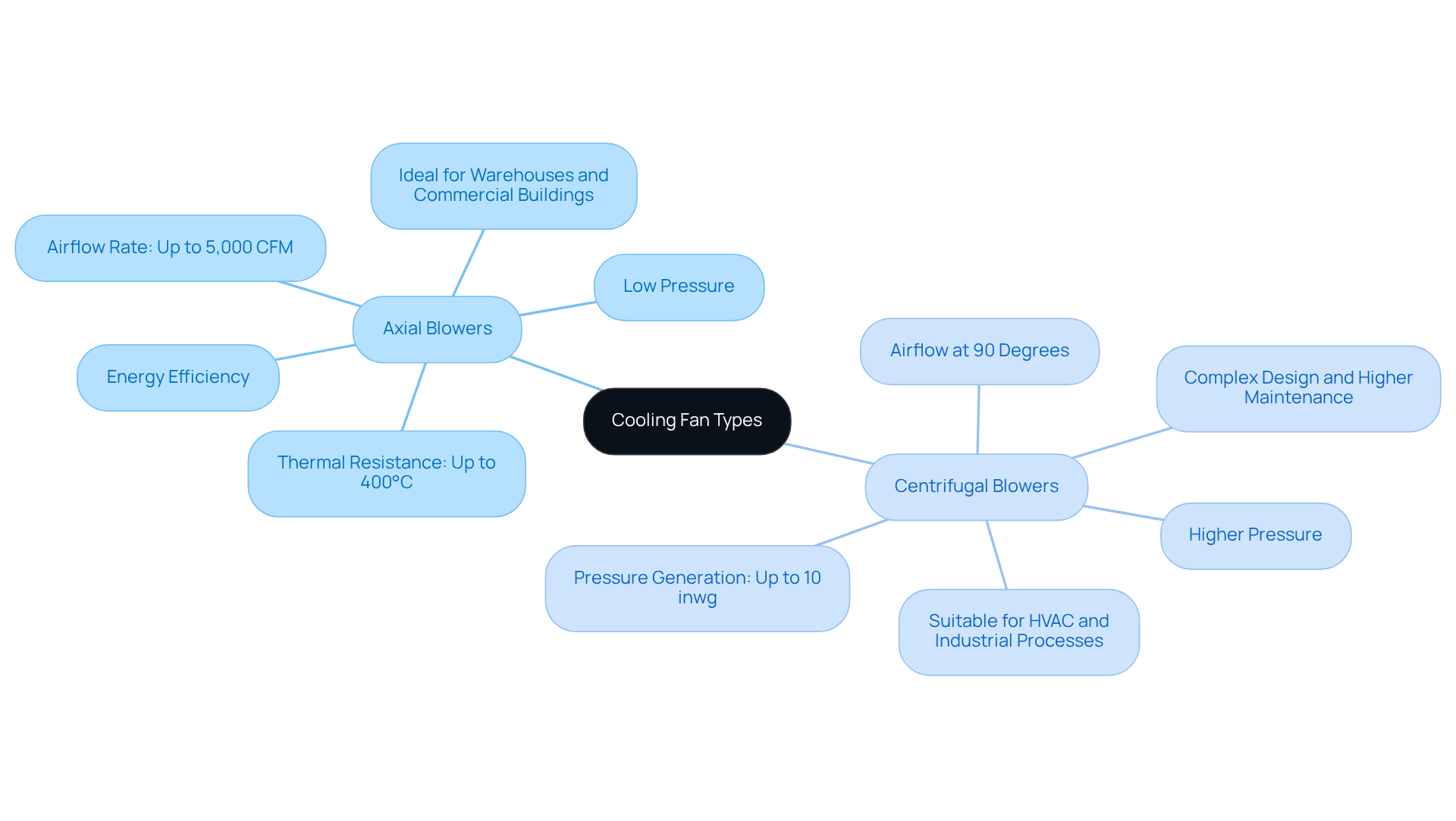

Comparing Cooling Fan Types: Axial, Centrifugal, and More

Cooling devices are essential elements in numerous applications, with each variety designed to meet specific requirements. at low pressure, making them ideal for general ventilation tasks in environments such as warehouses and commercial structures. Their energy efficiency and straightforward design facilitate regular maintenance, which is crucial for continuous operation. Furthermore, axial blowers, including , are thermal-resistant up to 400°C, underscoring their suitability for high-temperature environments often encountered in electronics cooling. Conversely, are engineered to produce greater pressure, rendering them appropriate for applications that necessitate concentrated airflow, such as HVAC systems and industrial processes. These devices expel air at a 90-degree angle, enabling effective airflow management in ducted systems and high-resistance settings. Due to their design that enhances air pressure, centrifugal blowers are particularly suitable for , capable of generating pressures up to 10 inwg.

Statistics reveal that axial blowers can achieve airflow rates of up to 5,000 CFM with a static pressure of 0.5 inwg. This efficiency makes centrifugal blowers particularly advantageous in scenarios demanding robust airflow against resistance, such as air filtration and temperature regulation towers.

Engineers emphasize the importance of . For instance, axial units are typically preferred in low-pressure environments due to their ability to deliver , whereas where directed airflow is critical. Understanding these distinctions is essential for optimizing and ensuring the reliability of the setup.

In practical terms, the decision between axial and centrifugal blowers hinges on factors such as , space constraints, and noise considerations. As one engineer aptly stated, ‘Your decision to use one or the other will simply come down to meeting the requirements of your system.’ Additionally, it is crucial to recognize that both centrifugal blowers and axial devices generate audible and electromagnetic noise, with centrifugal models being slightly noisier than their axial counterparts. This insight underscores the necessity of evaluating each electronic cooling fan’s strengths and weaknesses to achieve optimal temperature regulation solutions in electronic applications. When selecting between axial and centrifugal units, consider , space limitations, noise factors, budget, and maintenance requirements.

Cooling Fans in Data Centers: Ensuring Optimal Performance

In data centers, are essential for maintaining for servers and networking equipment. As the concentration of electronic components increases, an becomes crucial for efficient to prevent overheating and ensure reliability.

often integrate a combination of , temperature monitoring, and the use of an electronic cooling fan technology, enhancing efficiency while minimizing .

Establishing robust ventilation fan setups is vital for and in these critical environments.

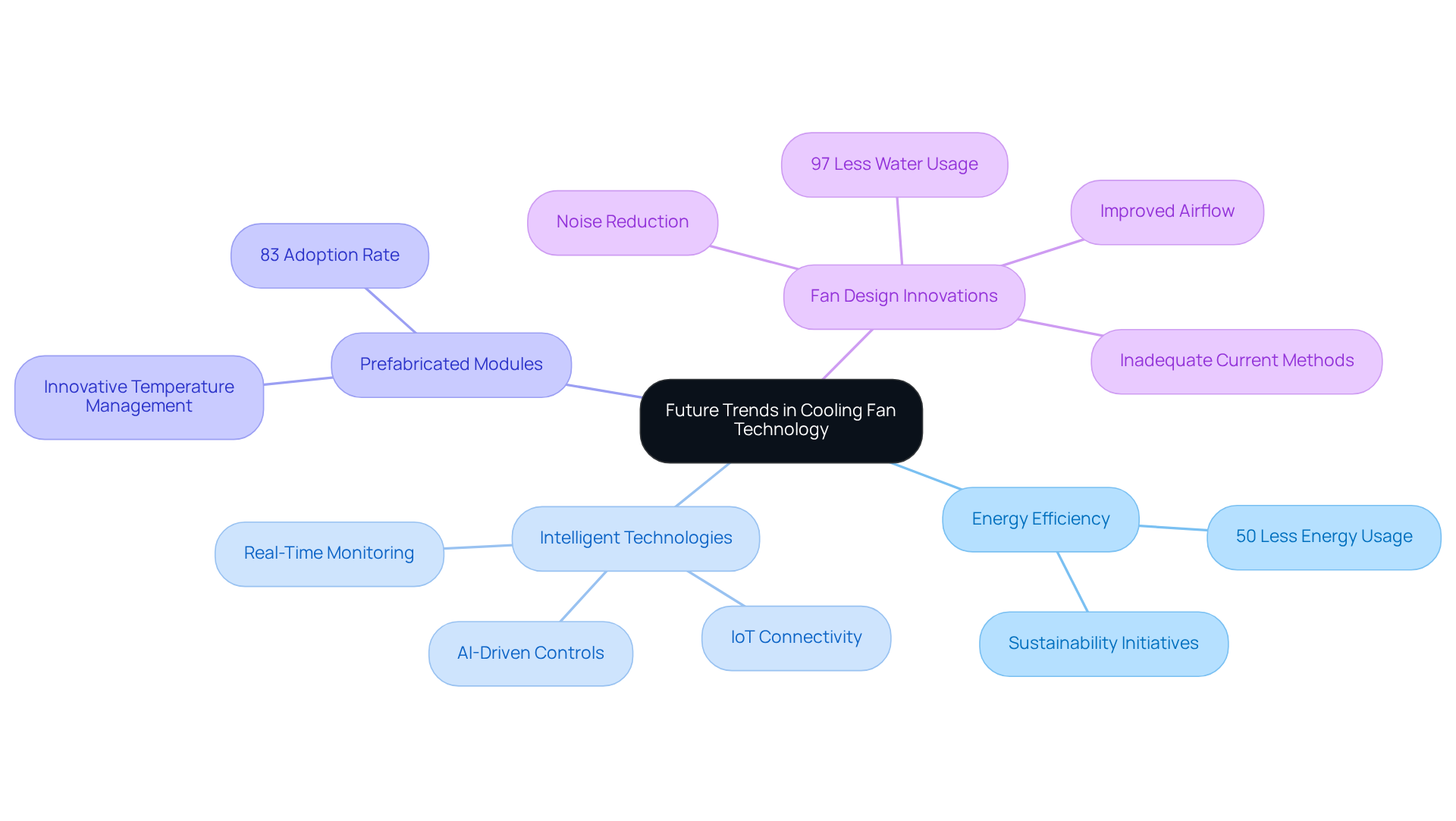

Future Trends in Cooling Fan Technology: What Engineers Should Anticipate

The future of fan technology is poised for remarkable advancements, driven by the imperative for enhanced and performance. Emerging trends highlight the integration of , including IoT connectivity and AI-driven controls, which enable and optimization of . Notably, studies indicate that 83% of temperature regulation modules, signaling a transition towards innovative .

Furthermore, , exemplified by Shumate Engineering’s Hybrid Abatic Fluid Cooler, which utilizes 50% less energy and 97% less water than conventional systems, are anticipated to improve airflow and diminish noise levels. With 34% of data centers reporting their current as inadequate, engineers should anticipate these innovations to leverage . Staying abreast of these developments is essential for ensuring optimal performance and sustainability in their applications.

Selecting the Right Cooling Fan: Key Considerations for Engineers

necessitates a thorough assessment of several critical factors. Engineers must prioritize , ensuring that the fan’s capacity exceeds the calculated needs, particularly when accounting for backpressure. For example, if the airflow requirement is 50 CFM at zero backpressure, it is advisable to choose a fan with a capacity of 75-100 CFM to maintain efficiency under operational conditions. Additionally, noise levels are a vital consideration; fans such as the Fractal Design Aspect 12 operate at a of just 18.3 dBA, making them ideal for noise-sensitive environments.

is paramount, especially in continuous-use setups. Fans certified by Energy Star can significantly reduce power consumption without compromising effectiveness, which is essential for long-term operational cost savings. Moreover, systems employing can achieve of up to 30% compared to conventional fan designs, further enhancing efficiency. Compatibility with existing frameworks must also be evaluated, including the fan’s size, speed, and control options. Common sizes range from 40mm to 120mm, with customizable options available to suit specific applications.

Engineers should consider the in these devices, as this directly impacts durability and functionality. For instance, ball bearings offer over 60,000 hours of lifecycle, making them ideal for high-speed applications, while sleeve bearings are suitable for lower-speed environments, with a lifecycle of approximately 30,000 hours. Understanding these specifications and their implications for functionality will empower engineers to make informed choices that enhance and efficiency. Furthermore, is crucial to ensure quality and reliability in performance.

Conclusion

Selecting the right electronic cooling fan represents a pivotal decision that significantly influences the performance and reliability of electronic devices. Understanding the various factors that impact fan selection enables engineers to ensure optimal thermal management and extend the lifespan of their equipment. The significance of airflow capacity, energy efficiency, noise levels, and compatibility with existing systems cannot be overstated, as these elements directly contribute to the effectiveness of cooling solutions.

This article has provided key insights into the operation and mechanisms of electric cooling fans, underscoring the importance of advanced technologies such as PWM for enhancing efficiency and performance. The comparison between different fan types, including axial and centrifugal fans, illustrates how specific applications dictate the best choice for effective cooling. Furthermore, troubleshooting common issues and implementing regular maintenance practices can greatly enhance fan reliability and performance.

As the electronics industry continues to evolve, it is essential to stay informed about emerging trends and innovations in cooling fan technology. Embracing advancements in IoT connectivity, AI-driven controls, and energy-efficient designs will empower engineers to optimize their cooling strategies. By prioritizing these considerations, engineers can not only enhance the performance of their systems but also contribute to a more sustainable and efficient future in electronic temperature management.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is a leading provider of electronic temperature management solutions, helping engineers tackle challenges in the electronics sector with advanced temperature management technologies.

How does Gagner-Toomey Associates ensure customer satisfaction?

The company has a high level of customer satisfaction in electronic temperature control services, reflecting its commitment to excellence in customer service and product representation.

What role do electric cooling fans play in electronics cooling?

Electric cooling fans are essential for thermal regulation in electronic devices, helping to remove heat generated by components to maintain safe operating temperatures and extend equipment lifespan.

What is the projected market value for electric ventilation fans by 2024?

The electric ventilation fans market is projected to be valued at approximately USD 8.125 billion in 2024.

What recent innovations have been made in electric fan technology?

Recent innovations include smart features such as Wi-Fi connectivity and voice control, allowing for real-time monitoring and management of fan performance.

Why is effective temperature regulation important in electronics?

Effective temperature regulation prevents overheating, which can lead to system failures and reduced functionality, making it crucial for maintaining optimal performance.

How do electric cooling fans operate?

Electric cooling fans convert electrical energy into mechanical energy through a motor, which propels the fan blades to generate airflow that dissipates heat from electronic components.

What percentage of electricity do electronic cooling fans consume in commercial buildings?

Electronic cooling fans account for approximately 16% of electricity consumed in commercial buildings.

What is the Fan Energy Index (FEI) and why is it important?

The Fan Energy Index (FEI) is a metric for assessing fan performance, helping engineers choose energy-efficient models that can lead to significant energy savings.

How can engineers benefit from understanding cooling fan efficiency metrics?

By using metrics like the Cooling-Fan Efficiency (CFE) index, engineers can make informed decisions that enhance cooling effectiveness and energy efficiency in their temperature control strategies.