Overview

Static pressure in HVAC systems signifies the resistance to airflow within ductwork when air is at rest, playing a vital role in ensuring efficient climate control and energy usage. Optimal static pressure, typically around 0.5 inches of water column, is essential for achieving balanced airflow. Deviations from this standard can result in increased energy consumption and system inefficiencies.

Therefore, it is imperative to prioritize regular maintenance to mitigate common issues such as:

- Blocked filters

- Improperly sized ducts

By addressing these factors, one can enhance system performance and sustainability.

Introduction

Understanding static pressure is crucial for professionals engaged in HVAC systems, as it has a direct effect on airflow and energy efficiency. By comprehending the concept of static pressure—essentially the resistance to airflow within ductwork—one can reveal the underlying factors that influence heating and cooling systems.

However, many encounter difficulties due to incorrect measurements or inadequate maintenance, resulting in inefficiencies and discomfort.

What are the primary challenges associated with static pressure, and how can these be effectively addressed to improve HVAC performance and enhance indoor comfort?

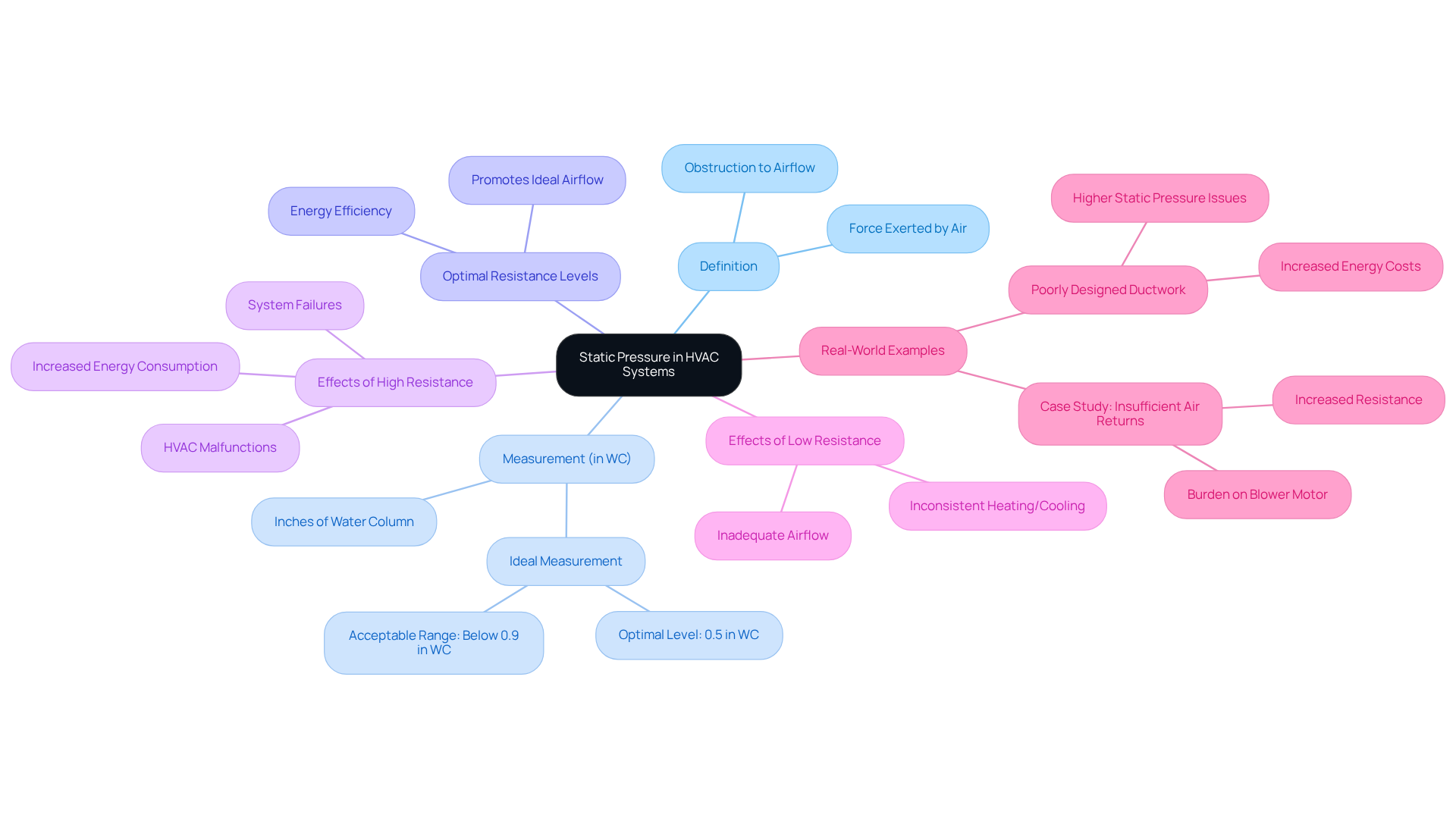

Define Static Pressure in HVAC Systems

What is static pressure? It is defined in as the obstruction to airflow within ducting and associated components when air remains motionless. This force, exerted by air against the walls of ducts, fittings, and other elements, is typically measured in inches of water column (in. WC).

Industry standards suggest that an optimal resistance level is around 0.5 in WC, which promotes ideal within the system. However, increased can lead to significant inefficiencies, compelling climate control systems to consume more energy as fans exert additional effort to push air through the ducts.

Notably, can precipitate or premature failures if not diligently monitored. Conversely, low fixed air resistance may result in inadequate airflow, causing inconsistent heating or cooling across different areas of a residence.

Real-world examples illustrate how can exacerbate flow challenges, culminating in higher energy costs and potential system failures. For instance, a case study highlights the complications that arise from insufficient air returns, which can burden the blower motor, increase resistance, and lead to inefficiencies.

Therefore, and performing of it are crucial for ensuring effective climate control performance and enhancing overall indoor comfort.

Explain the Importance of Static Pressure for HVAC Performance

Understanding what , as it serves as a fundamental element in the performance of heating, ventilation, and air conditioning systems, playing a critical role in determining and overall efficiency. A properly balanced air tension ensures uniform air distribution throughout a structure, which is vital for maintaining stable temperatures and optimal .

When static force is excessively high—often due to issues like —fans and blowers must work harder, leading to , potentially up to 30% more electricity, and accelerated wear on components. Conversely, a reduction in atmospheric force can lead to insufficient airflow, creating uncomfortable warm or cool spots and diminishing air quality.

Notably, approximately half of heating and cooling systems are improperly sized, frequently resulting in uneven airflow that exacerbates these issues. Therefore, , typically around 0.5 inches of water column (in. Wc), is crucial for achieving peak and .

Regular oversight and maintenance, such as duct cleaning and filter changes at least biannually, are essential strategies to prevent airflow complications and ensure the longevity of heating and cooling units.

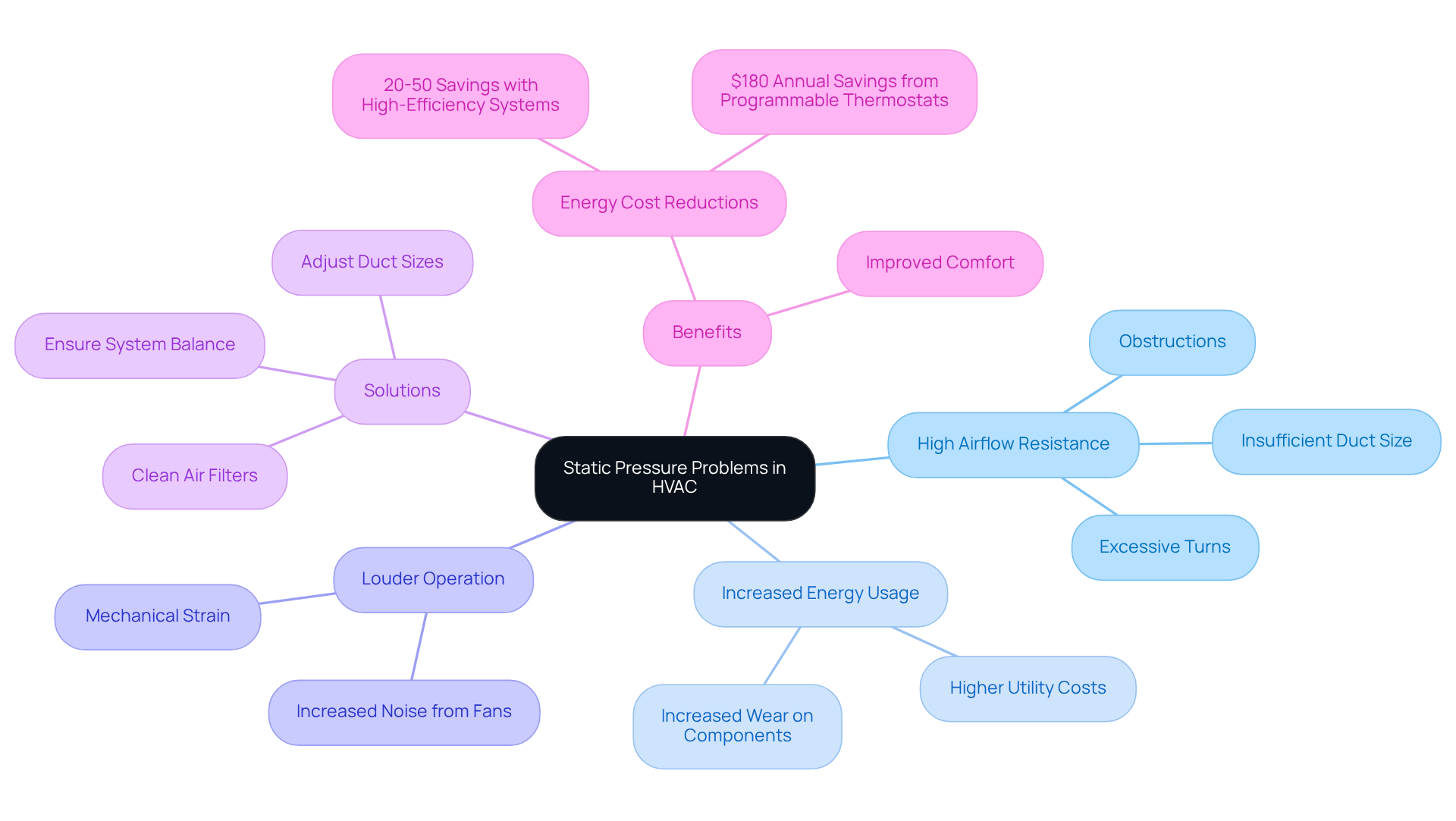

Identify Common Static Pressure Problems and Solutions

High in heating and cooling setups often stems from insufficient duct size, obstructions, or excessive turns. This leads to increased energy usage, higher utility costs, and louder operation. For instance, due to these inefficiencies, with of overall household in average New Jersey residences. Moreover, heating units can represent as much as 42% of monthly energy consumption during winter, underscoring the importance of addressing airflow challenges in the colder season.

To mitigate elevated air resistance, it is essential to:

- Adjust duct sizes to appropriate measurements

- Routinely clean or change air filters

- Ensure proper system balance

Implementing these measures can lead to of 20 to 50% when upgrading to . Additionally, utilizing programmable thermostats can further decrease heating and cooling costs by 10%, translating to savings of approximately $180 annually.

Routine maintenance is crucial; checking ductwork for leaks and ensuring vents remain unobstructed can help maintain optimal airflow levels. Regular inspections and adjustments of are also necessary for the efficient operation of , contributing to equipment longevity. can cut heating and cooling costs by up to 20%. By proactively addressing these common issues, HVAC systems can achieve enhanced efficiency, improved comfort, and reduced energy expenses.

Conclusion

Understanding static pressure is vital for maintaining the efficiency and performance of HVAC systems. It represents the resistance to airflow within ductwork, impacting energy consumption, temperature stability, and indoor air quality. By recognizing its significance and ensuring optimal levels, homeowners can enhance their climate control systems and achieve greater comfort.

Key points throughout the article highlight:

- The definition of static pressure

- Its importance in HVAC performance

- Common issues that arise from improper management

The ideal static pressure level, typically around 0.5 inches of water column, is essential for preventing inefficiencies that can lead to increased energy costs and system failures. Strategies for mitigating high static pressure include:

- Adjusting duct sizes

- Conducting regular maintenance

- Utilizing programmable thermostats

In light of these insights, proactive measures are crucial for optimal HVAC performance. Regular maintenance and monitoring of static pressure contribute not only to energy savings but also to enhanced overall indoor comfort and air quality. By addressing static pressure issues, homeowners can ensure their HVAC systems operate efficiently, ultimately leading to a more sustainable and comfortable living environment.

Frequently Asked Questions

What is static pressure in HVAC systems?

Static pressure is defined as the obstruction to airflow within ducting and associated components when air remains motionless. It is the force exerted by air against the walls of ducts, fittings, and other elements.

How is static pressure measured?

Static pressure is typically measured in inches of water column (in. WC).

What is the optimal level of static pressure for HVAC systems?

Industry standards suggest that an optimal resistance level is around 0.5 in WC, which promotes ideal airflow and efficiency within the system.

What are the consequences of increased air resistance in HVAC systems?

Increased air resistance can lead to significant inefficiencies, causing climate control systems to consume more energy as fans exert additional effort to push air through the ducts.

What can happen if static pressure is not monitored diligently?

Elevated atmospheric force can lead to HVAC malfunctions or premature failures if not monitored, while low fixed air resistance may result in inadequate airflow, causing inconsistent heating or cooling.

How can poorly designed ductwork affect static pressure?

Poorly designed or inadequately sized ductwork can exacerbate flow challenges, leading to higher energy costs and potential system failures, such as those arising from insufficient air returns.

Why is it important to understand static pressure in HVAC systems?

Understanding static pressure and performing routine observation and maintenance are crucial for ensuring effective climate control performance and enhancing overall indoor comfort.