Overview

The article underscores the vital importance of mastering CFM (Cubic Feet per Minute) for electronics engineers, highlighting its essential role in fan selection and overall system efficiency. By elucidating the concept of CFM, the article enables engineers to ascertain the precise fan specifications necessary to enhance cooling performance in electronic devices. This is supported by detailed calculations and practical examples that illustrate how airflow measurement directly influences system design and energy efficiency.

Introduction

Understanding airflow is essential in the field of electronics engineering, especially regarding the selection of appropriate fans for cooling systems.

- Cubic Feet per Minute (CFM) is a critical metric that not only defines a fan’s air-moving capacity but also significantly impacts the overall efficiency and effectiveness of electronic cooling solutions.

- As engineers aim to optimize performance while reducing noise and energy consumption, the challenge lies in mastering the complexities of CFM calculations and their implications for fan design.

- How can engineers ensure they make informed decisions that effectively balance airflow requirements with system constraints?

Define CFM: Understanding Airflow Measurement

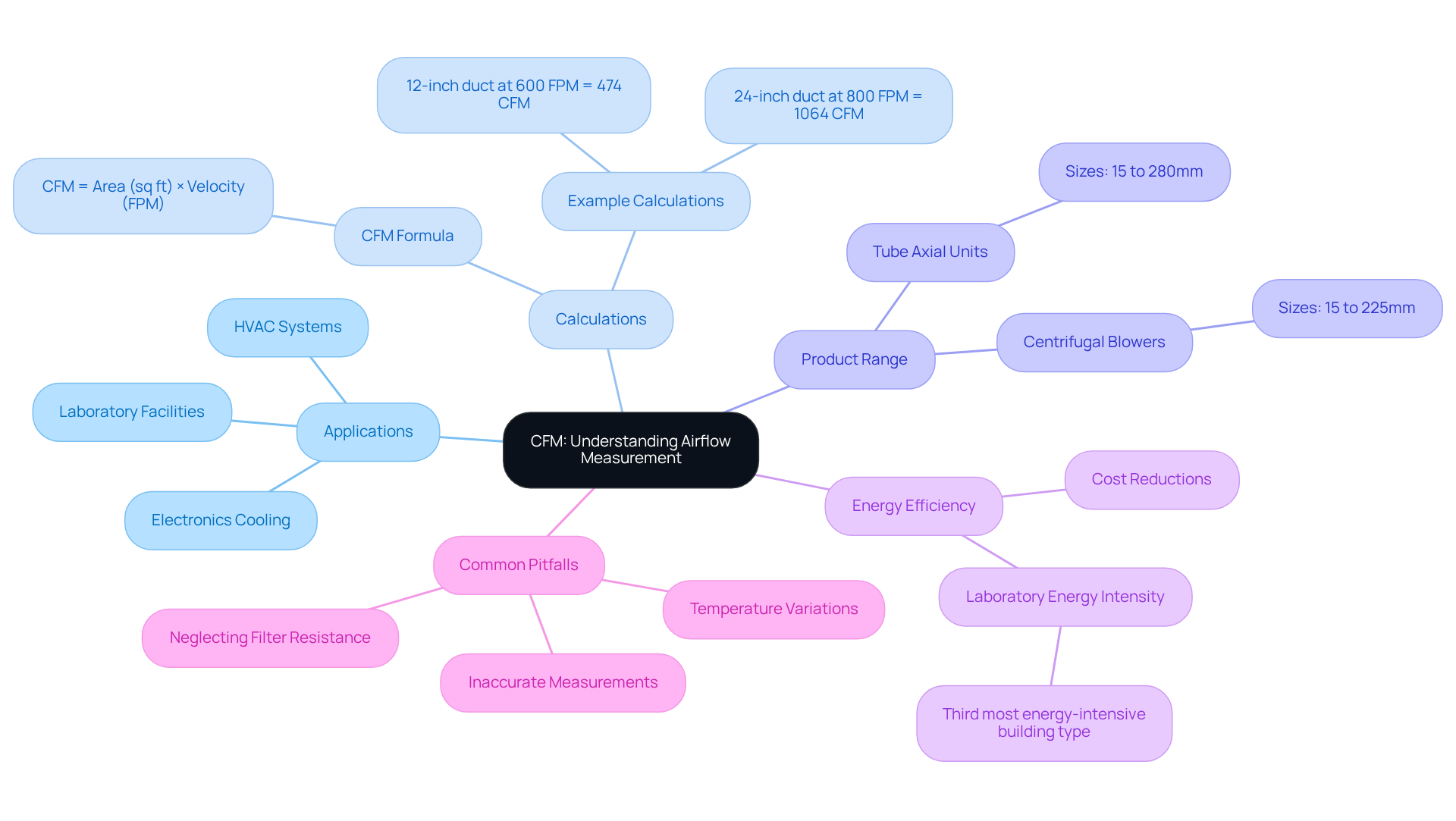

The CFM on fans, or Cubic Feet per Minute, quantifies the volume of air a fan can move in one minute, making it an essential metric in fan design and selection for various applications, particularly in electronics cooling and HVAC systems.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a comprehensive range of DC input Tube Axial units and Centrifugal Blowers, meticulously optimized for performance, efficiency, and low noise. Their product lineup includes sizes from 15 to 280mm for Tube Axial units and 15 to 225mm for Centrifugal Blowers, with IP protection available upon request.

A thorough understanding of CFM on fans enables engineers to determine the appropriate fan size and type necessary to achieve desired airflow rates, thereby ensuring optimal performance and efficiency in electronic systems. For instance, a fan with a CFM on fans rating of 100 can effectively move 100 cubic feet of air each minute, which is crucial for meeting specific cooling requirements in electronic devices or environments.

The calculation of CFM on fans can be expressed with the formula:

CFM = Area (sq ft) × Velocity (FPM)

In practical applications, a duct size of 12 inches with a velocity of 600 FPM results in a CFM on fans of 474, illustrating how precise calculations can inform the design of effective HVAC systems.

Additionally, in laboratory settings, where energy efficiency is paramount—given that laboratory facilities rank as the third most energy-intensive building type—accurate measurements of CFM on fans can lead to significant operational cost reductions and improved indoor air quality.

As the demand for efficient cooling solutions continues to grow in 2025, mastering CFM on fans will be vital for engineers aiming to optimize HVAC system performance across diverse environments. Gagner-Toomey’s extensive portfolio, which includes integrated cooling solutions and custom designs, supports engineers in achieving these objectives.

However, engineers must also be vigilant regarding common pitfalls in measuring CFM on fans, such as neglecting to account for temperature variations that affect air density. Utilizing resources like the can further aid in precise calculations of CFM on fans.

Explore CFM’s Role in Fan Selection and Efficiency

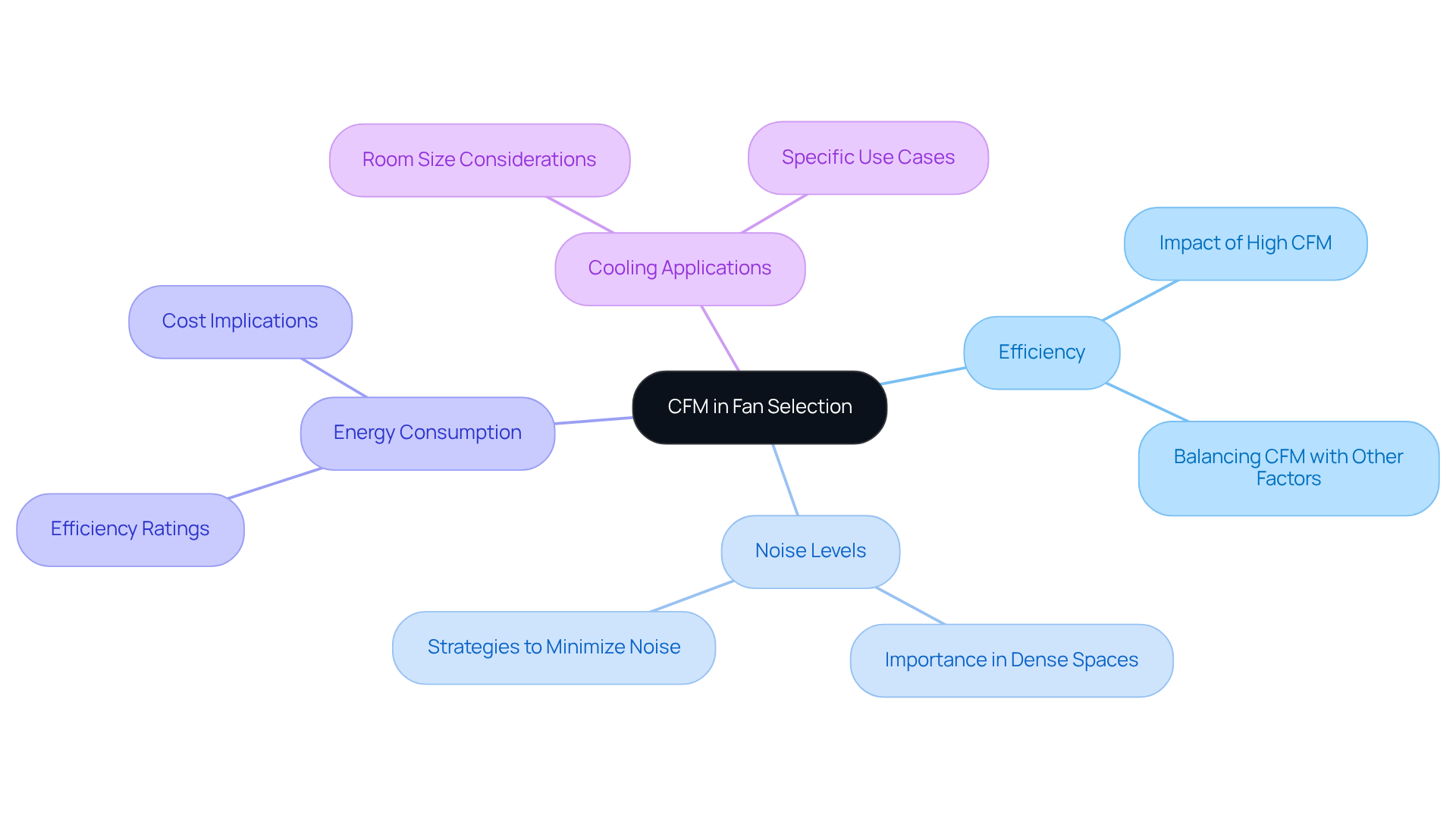

The metric known as CFM on fans, or Cubic Feet per Minute, is critical in fan selection and profoundly impacts the efficiency and effectiveness of cooling systems. Engineers are tasked with determining the required CFM on fans tailored to specific applications, whether for cooling electronic components or ensuring adequate ventilation within a space. A fan boasting a higher CFM on fans rating has the capability to move more air effectively; for instance, 4-speed fan models can exceed 5,000 CFM on fans, rendering them suitable for cooling a 300 sq ft room.

However, it is imperative to balance CFM with other vital factors, including noise levels, energy consumption, and fixed resistance. In densely packed electronic enclosures, for example, selecting a fan with the correct CFM on fans is crucial to ensure optimal cooling without generating excessive noise or wasting energy.

As Casey Zangaro aptly noted, “When choosing new or substitute fans, it is essential that you assess the flowrate requirement at the static force you will be operating.” This balance not only enhances system performance but also contributes to , underscoring the necessity for engineers to consider these dynamics when designing cooling solutions.

As the industry advances, mastering the optimization of CFM on fans while minimizing noise and energy consumption will become increasingly vital for achieving effective cooling in electronics.

Calculate CFM Requirements: A Step-by-Step Guide

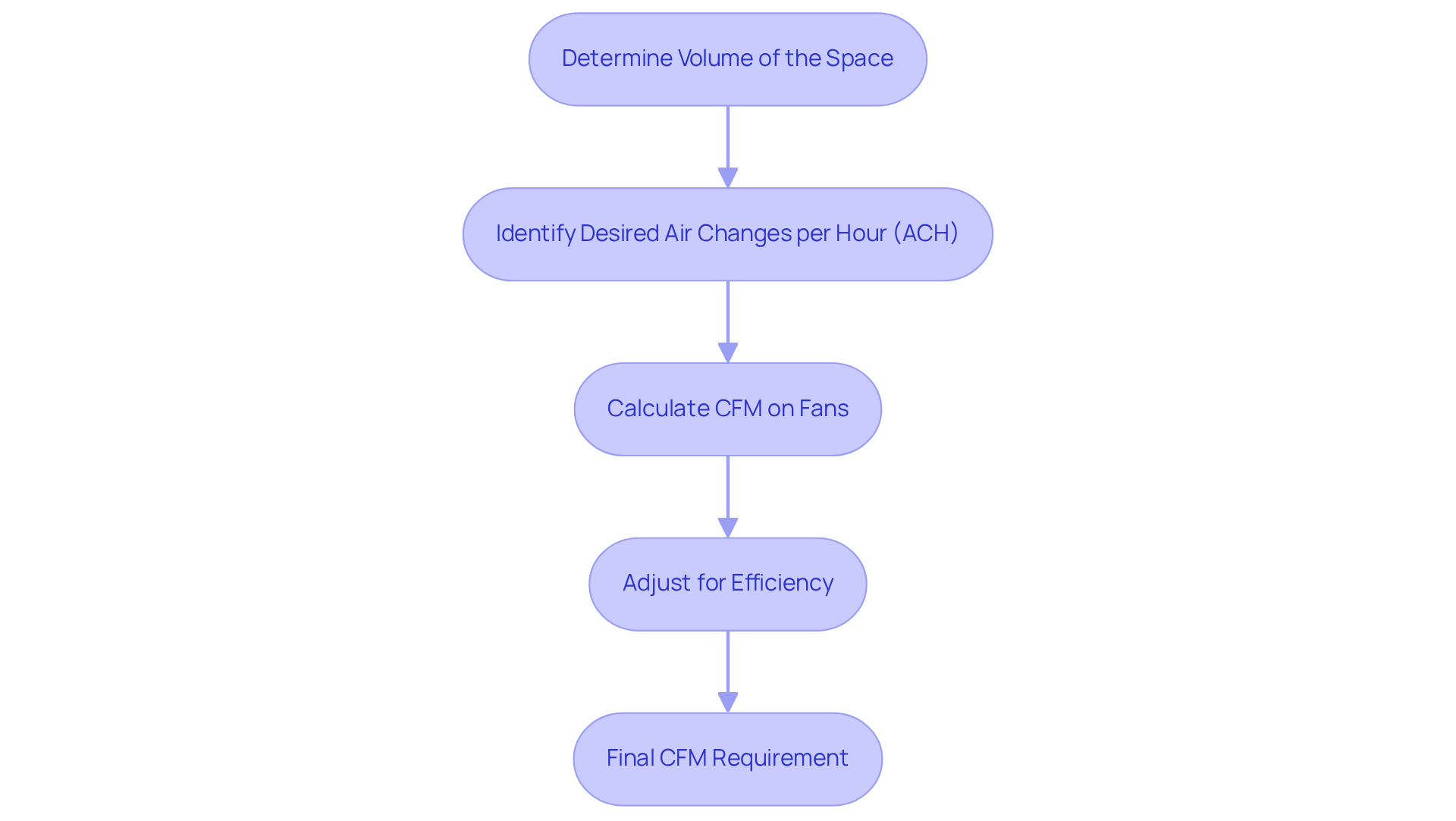

To calculate the CFM requirements for a specific application, follow these steps:

- Determine the Volume of the Space: Measure the length, width, and height of the area in feet. Multiply these dimensions to find the volume in cubic feet (Volume = Length × Width × Height).

- Identify the Desired Air Changes per Hour (ACH): Establish how many times you want the air in the space to be replaced in one hour. This value varies based on the application; for instance, general ventilation typically requires 4-6 ACH.

- [Calculate CFM on Fans](https://workaci.com/resources/blog/calculating-cfm): To calculate CFM on fans, use the formula:

CFM = (Volume × ACH) / 60. This converts the volume of air needed per hour into a per-minute measurement. - Adjust for Efficiency: Factor in the efficiency of the fan and any potential losses due to ductwork or filters. It may be necessary to increase the calculated CFM to account for these factors.

For example, consider a room measuring 10 feet long, 10 feet wide, and 8 feet high, resulting in a volume of 800 cubic feet. If the desired air changes per hour is 5, the calculation would be:

CFM = (800 × 5) / 60 = 66.67 CFM

Therefore, a fan capable of delivering at least 67 CFM would be suitable for this application.

In practical applications, understanding air changes per hour is crucial for effective cooling in electronics. In environments where electronics are housed, maintaining optimal temperatures often requires specific ACH rates to ensure reliability and performance. Furthermore, considering the flow velocity of 2,686 Feet Per Minute (FPM) and the velocity measurement recorded at 0.45 inches W.C. can provide additional insights into airflow dynamics. The case study titled ‘Calculating Air Flow Volume with Differential Force Transmitters‘ illustrates how to determine CFM using a differential force transmitter, which is particularly relevant for electronics engineers. Additionally, the duct cross-sectional area, calculated as 1.07 square feet, is essential for applying the CFM formula in real-world HVAC scenarios.

We invite you to , comments, or topic ideas to enhance our discussion on this important subject.

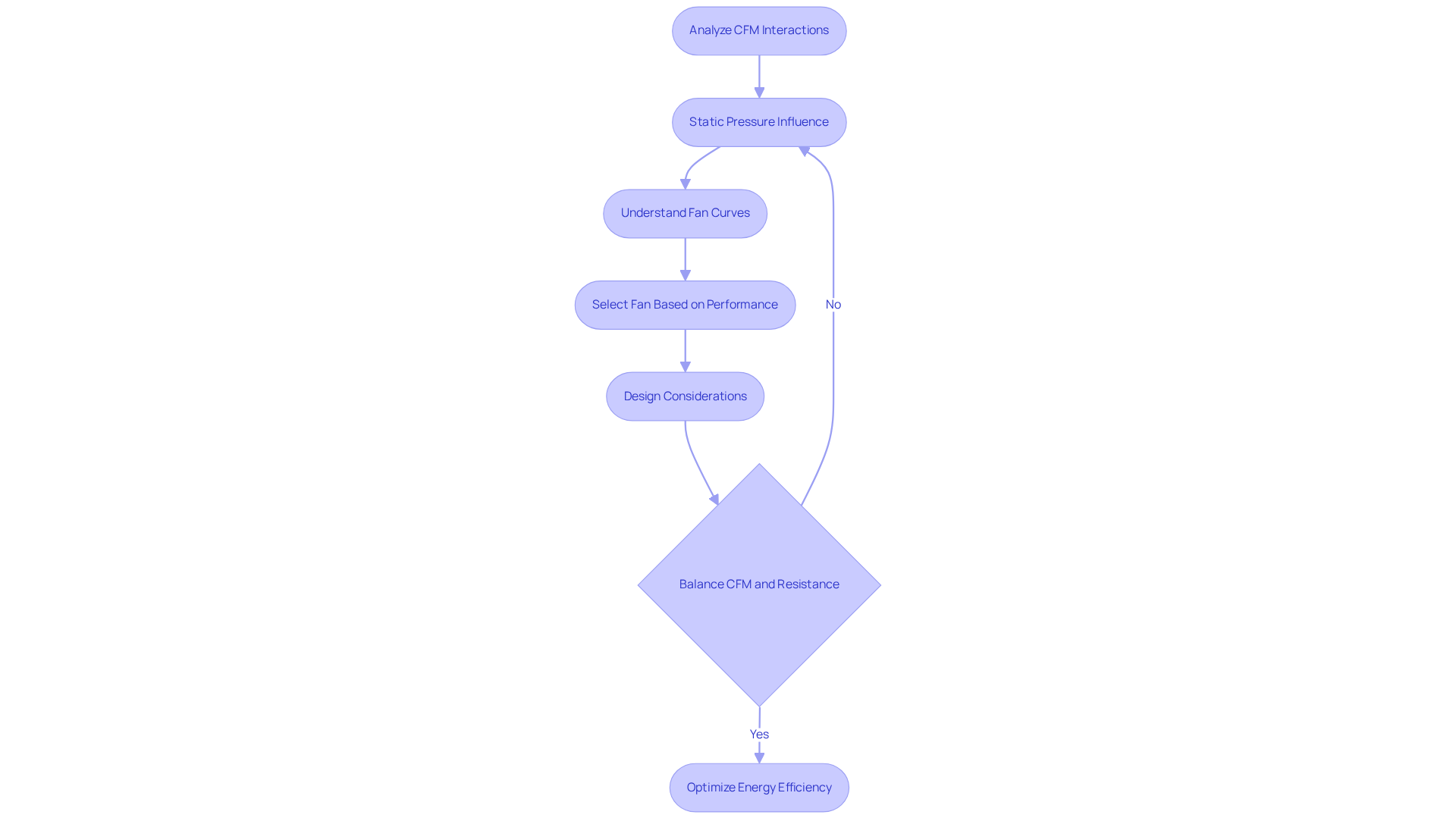

Analyze CFM Interactions: Static Pressure and Fan Design

The interaction of CFM on fans and fixed force is essential in fan design and performance. Static force, defined as the resistance to airflow within a system, significantly influences the CFM on fans. As ambient force increases, the CFM generally decreases, necessitating that blowers are designed to operate efficiently under expected condition levels.

Understanding Fan Curves: Fan performance is graphically illustrated on fan curves, which depict the connection between CFM on fans and atmospheric resistance. These curves are invaluable for engineers, enabling them to select fans that deliver optimal performance tailored to specific applications. For instance, a fan functioning at a constant force of 0.5 inches w.g. may reach a CFM of 10,000 while requiring only 1.6 horsepower, whereas at 1 inch w.g., the same fan would necessitate 2.5 horsepower, demonstrating the direct effect of resistance on energy use. Gagner-Toomey Associates offers a broad product line of DC input Tube Axial fans and Centrifugal Blowers, optimized for performance, efficiency, low noise, and IP protection, which can be selected based on these curves.

Design Considerations: Engineers must consider the fixed force created by ductwork, filters, and other system elements during the design phase. In situations where airflow resistance is significant, such as systems with large ductwork or high-efficiency filters, choosing a fan that can manage increased resistance becomes essential. Gagner-Toomey’s fixed airflow fans are engineered to efficiently handle elevated forces, typically producing ratings near 3.0 inches w.g., which is crucial for preserving airflow in constrained settings.

Balancing CFM on fans and static resistance: Achieving a balance between the desired CFM on fans and the resistance requirements of the system is crucial. Selecting a fan that can maintain sufficient airflow while overcoming resistance ensures effective operation, avoiding overheating or potential system failures. In practical applications, such as computer cooling, if a fan is placed in a confined enclosure, it must be rated for increased resistance to maintain the required CFM on fans, thereby ensuring that essential components remain sufficiently cooled. Moreover, recognizing that a 10% reduction in RPM leads to a 19% decline in resting force further illustrates how fan efficiency can be influenced by variations in RPM.

Understanding these dynamics not only aids in selecting the right fan but also plays a vital role in and operational costs across various applications, as increased static pressure leads to higher energy usage and costs. Gagner-Toomey Associates provides a complete portfolio of innovative cooling solutions, including custom designs and integrated cooling systems, to meet the diverse needs of electronics engineers.

Conclusion

Mastering the concept of CFM, or Cubic Feet per Minute, is crucial for engineers involved in fan design and selection, particularly within the realms of electronics cooling and HVAC systems. Understanding how to accurately measure and apply CFM not only enhances the efficiency and effectiveness of cooling solutions but also ensures that electronic components operate within safe temperature ranges.

Key insights underscore the importance of CFM in selecting the appropriate fan size and type, detailing the calculations necessary to determine CFM requirements for specific applications, and exploring the intricate relationship between CFM and static pressure in fan performance. Engineers must balance CFM with factors such as noise levels and energy consumption to achieve optimal results in their designs. Practical examples illustrate how precise calculations and an understanding of airflow dynamics can lead to significant improvements in system performance and energy efficiency.

In conclusion, engineers are encouraged to delve deeper into mastering CFM to refine their designs and enhance the performance of cooling systems across various applications. By leveraging resources and tools available, such as the HVAC Estimation Checklist and fan curves, engineers can make informed decisions that meet the demands of contemporary cooling solutions and contribute to sustainable practices in energy consumption. The significance of CFM extends beyond mere measurement; it is a foundational element that can drive innovation and efficiency in the ever-evolving field of electronics engineering.

Frequently Asked Questions

What does CFM stand for in relation to fans?

CFM stands for Cubic Feet per Minute, which quantifies the volume of air a fan can move in one minute.

Why is CFM important in fan design and selection?

CFM is essential for determining the appropriate fan size and type needed to achieve desired airflow rates, ensuring optimal performance and efficiency in applications like electronics cooling and HVAC systems.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a range of DC input Tube Axial units and Centrifugal Blowers optimized for performance, efficiency, and low noise.

How is CFM calculated?

CFM can be calculated using the formula: CFM = Area (sq ft) × Velocity (FPM).

Can you provide an example of CFM calculation?

Yes, for a duct size of 12 inches with a velocity of 600 FPM, the CFM would be 474, demonstrating how precise calculations are important for effective HVAC system design.

Why is accurate measurement of CFM important in laboratory settings?

Accurate measurements of CFM in laboratories can lead to significant operational cost reductions and improved indoor air quality, as laboratories are among the most energy-intensive building types.

What challenges do engineers face when measuring CFM?

Engineers must be cautious of common pitfalls, such as neglecting to account for temperature variations that can affect air density.

How can resources like the HVAC Estimation Checklist assist engineers?

Resources like the HVAC Estimation Checklist can aid in making precise calculations of CFM on fans, helping to avoid common measurement errors.

What is the future demand for CFM knowledge in engineering?

As the demand for efficient cooling solutions continues to grow, mastering CFM will be vital for engineers to optimize HVAC system performance across diverse environments.