Overview

When engineers select a centrifugal blower fan, several critical steps must be taken into account:

- Assessing airflow requirements

- Evaluating static pressure

- Determining fan category

- Considering speed and power

- Analyzing noise levels

- Ensuring material durability

A thorough evaluation of these criteria is not merely beneficial; it is essential for optimizing performance and cost-effectiveness. This selection process directly influences the efficiency and reliability of air movement systems across various applications, underscoring the necessity for engineers to approach their choices with diligence and expertise.

Introduction

In the realm of industrial applications, centrifugal blower fans are essential for ensuring efficient airflow and maintaining optimal performance. These mechanical devices, driven by the principles of centrifugal force, are engineered to convert rotational energy into powerful air movement.

Selecting the right fan for a specific project, however, can be complex, influenced by various factors such as airflow requirements, static pressure, and noise levels. Engineers must navigate common challenges, from insufficient airflow to excessive noise, to optimize their systems.

This article delves into the essential components of centrifugal blower fans, key selection criteria, and troubleshooting strategies, empowering professionals to make informed decisions for their air delivery needs.

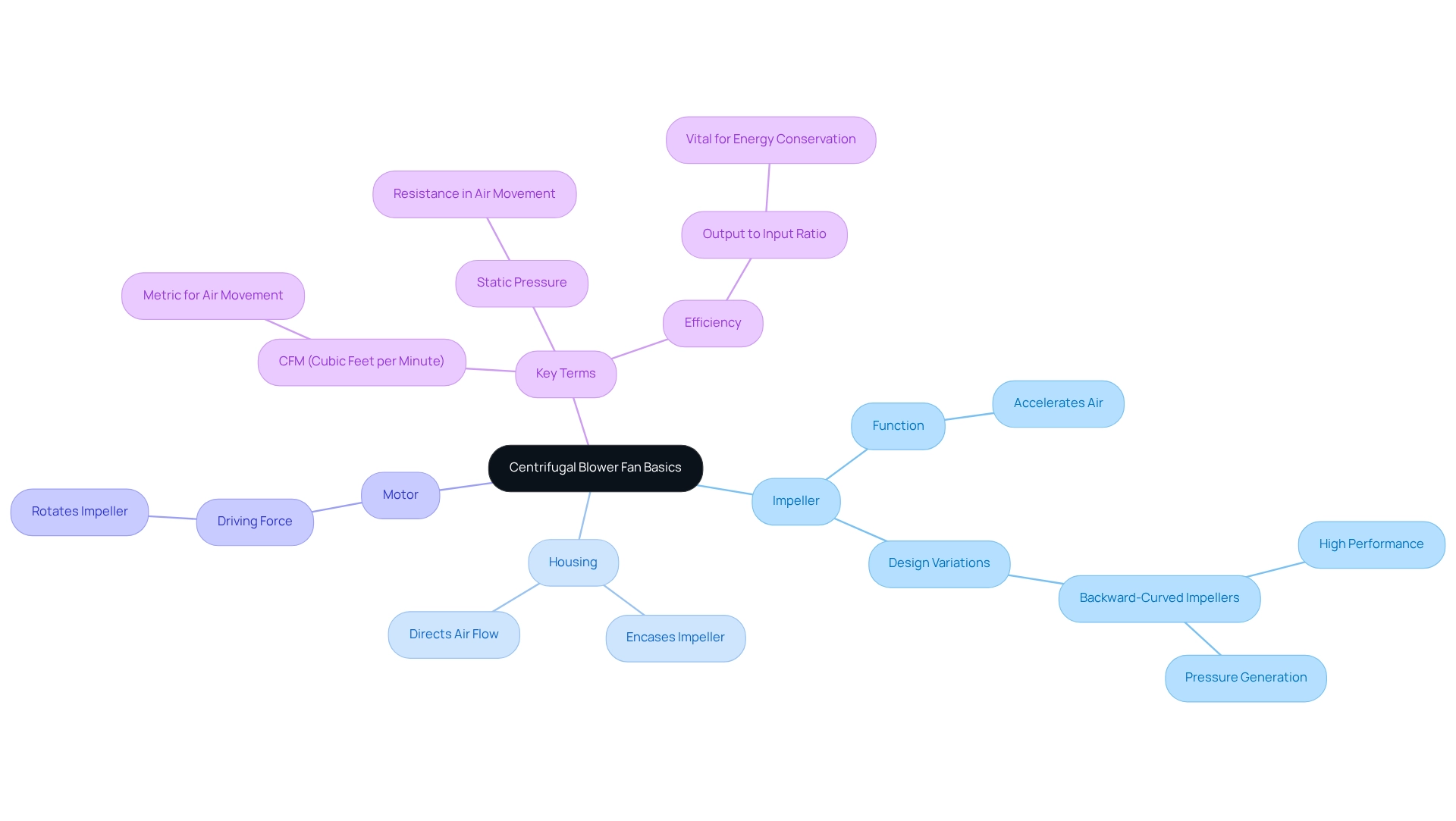

Understand Centrifugal Blower Fan Basics

s are advanced mechanical devices designed to move air or other gases by converting rotational energy into gaseous movement. Operating on the principle of centrifugal force, the centrifugal blower fan draws air into the impeller and expels it at a 90-degree angle from the intake. The essential components include:

- Impeller: The rotating element that accelerates the air.

- Housing: The structure that encases the impeller and directs air flow.

- Motor: The driving force behind the impeller’s rotation.

Understanding the centrifugal blower fan and its components is as it enables them to assess how different designs impact , pressure, and overall performance. For instance, for their exceptional performance and pressure generation, making them particularly suitable for applications that require significant air movement against resistance. as the world’s largest manufacturer of both standard and custom air movers, boasting an extensive product line of ranging from 15 to 225mm in size. Their are meticulously optimized for performance, efficiency, and minimal noise, catering to a diverse array of industrial applications, including the electronics and automotive sectors. Furthermore, most models can be equipped with IP protection upon request, enhancing their adaptability for various environments.

Key Terms:

- CFM (Cubic Feet per Minute): A metric for air movement.

- Static Pressure: The resistance encountered by air movement within a system.

- Efficiency: The ratio of useful output to total input, which is vital for energy conservation.

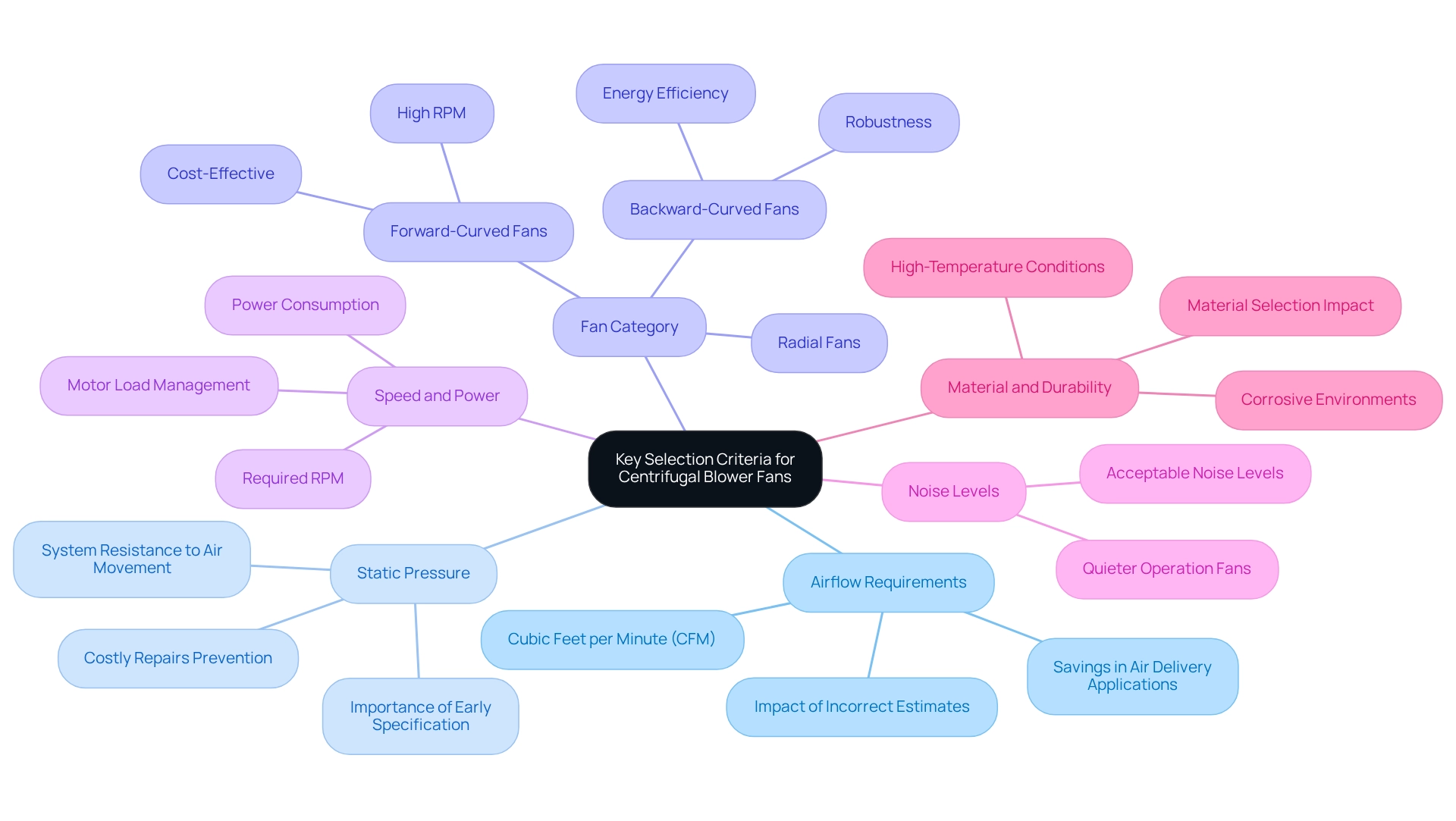

Identify Key Selection Criteria for Your Project

Selecting the right requires a meticulous evaluation of several critical criteria:

- : Begin by determining the essential cubic feet per minute (CFM) necessary for your application, influenced by the size of the space and its intended use. Accurate air movement calculations are vital; incorrect estimates can lead to inefficiencies. Notably, the performance of the centrifugal blower fan can yield substantial savings in air delivery applications, particularly when utilizing compressed air.

- : Evaluate the system’s resistance to air movement. Systems with extended duct runs or filters demand units with elevated to maintain performance and efficiency. and timely identification of airflow issues can avert costly repairs, highlighting the necessity for thorough planning in fan selection.

- : Choose from forward-curved, backward-curved, or radial types based on specific requirements. Understanding the , particularly the centrifugal blower fan, is crucial; for instance, , offering durability and energy efficiency, making them suitable for demanding conditions. A case study titled “Conclusion on Fan Selection” emphasizes this distinction, underscoring the importance of selecting the right fan for particular applications.

- Speed and Power: Analyze the required revolutions per minute (RPM) and power consumption. It is essential to ensure that the motor can handle the load without overheating, as this can significantly affect the fan’s longevity and reliability.

- Noise Levels: Assess the acceptable noise levels for your operational environment. Certain fans are designed for quieter operation, which is critical in noise-sensitive applications.

- Material and Durability: Opt for materials that can withstand the operating conditions, especially in corrosive or high-temperature environments. The appropriate material selection can enhance the fan’s lifespan and performance.

By systematically evaluating these criteria, engineers can ensure that their , ultimately leading to improved performance and reduced operational costs. As Peter Jarvis, Project Manager at Air Control Industries Ltd, remarked, “ACI has been flexible and accommodating to help us accomplish our operating objectives with regard to finding the correct air delivery patterns, volumes and velocities – all with good effect.

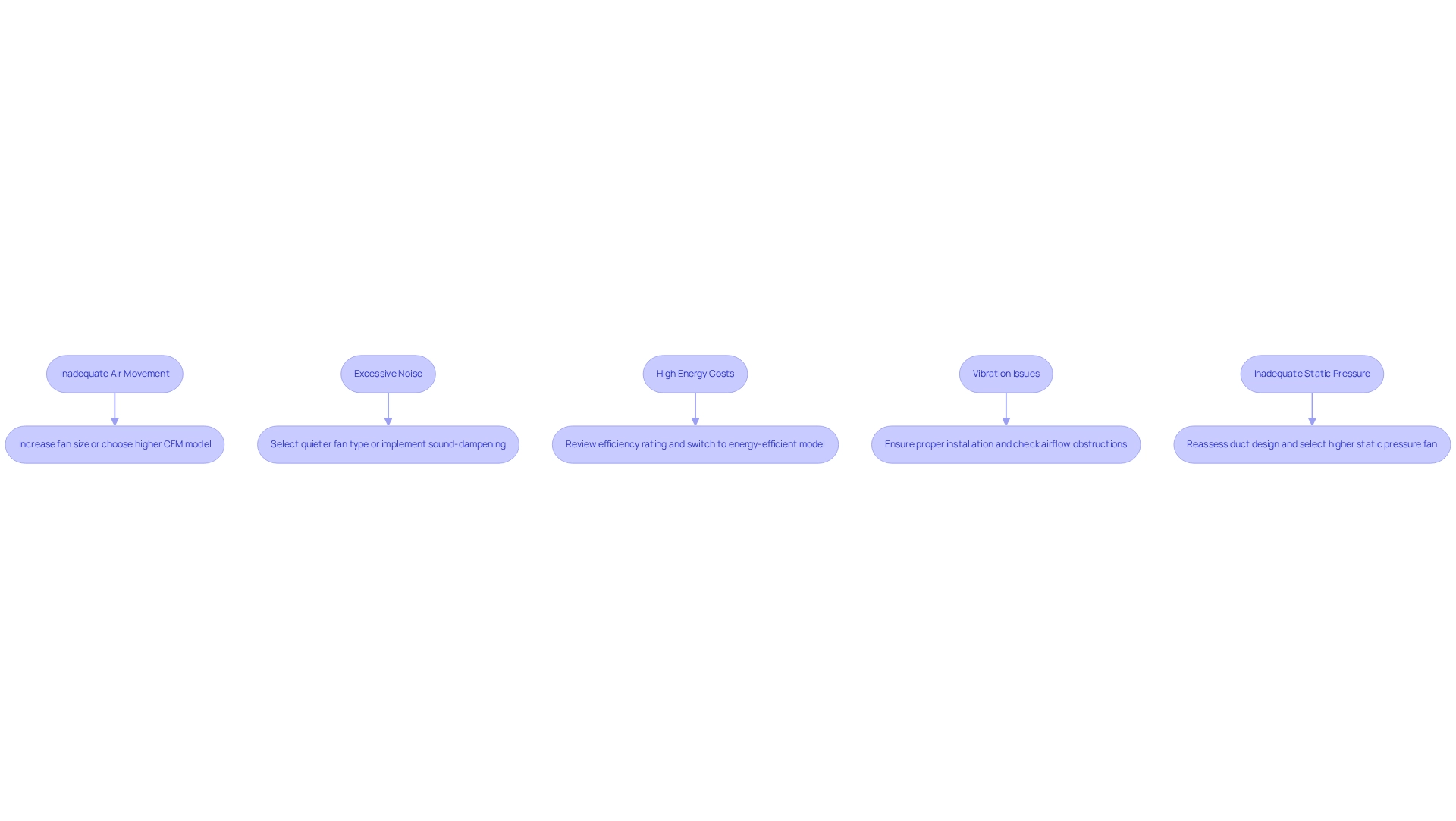

Troubleshoot Common Selection Challenges

Engineers can face several challenges when selecting the right . Common issues arise, but are available:

- : When a fan fails to meet air movement requirements, increasing its size or opting for a model with a higher CFM (Cubic Feet per Minute) rating is advisable. This adjustment can significantly enhance performance.

- : If noise levels are unacceptably high, assess the fan type. Models designed for quieter operation or the implementation of sound-dampening measures can effectively mitigate this issue.

- : Elevated energy consumption often indicates inefficiencies. Reviewing the fan’s efficiency rating and potentially switching to a more can lead to substantial cost savings.

- : Excessive vibration typically signals misalignment or imbalance. Ensuring proper installation and checking for obstructions in the airflow path can resolve these concerns and improve operational stability. The case study on rotating looseness in centrifugal fans highlights that wear in roller or flat bearings, poor lubrication, or incorrect assembly can lead to operational inefficiencies. Recommended actions include verifying assembly procedures and auditing lubrication processes to prevent such issues.

- : If the fan struggles to maintain the required static pressure, reassessing the duct design may be necessary. Selecting a fan with a higher static pressure capability can help meet system demands.

According to David Trocel from GTS Confiabilidad C.A., “the driving equipment can be an AC motor, a DC motor or even steam turbines,” emphasizing the importance of selecting the appropriate motor type based on operational characteristics. By proactively addressing these challenges, engineers can significantly enhance the performance and reliability of their systems that utilize centrifugal blower fans. Understanding these common challenges and their solutions is crucial for and ensuring efficient operation.

Conclusion

Centrifugal blower fans are integral to a multitude of industrial applications, driving efficient airflow and optimizing system performance. Engineers must grasp the fundamental components—such as the impeller, housing, and motor—to assess the impact of various designs on airflow, pressure, and overall efficiency. With an array of options, including specialized models from Gagner-Toomey Associates, professionals can select fans that precisely align with operational requirements.

Selecting the appropriate centrifugal blower fan necessitates a comprehensive analysis of critical criteria, including:

- Airflow needs

- Static pressure

- Fan type

- Speed

- Noise levels

- Material durability

By systematically evaluating these factors, engineers can secure optimal fan performance, which translates directly into enhanced efficiency and reduced operational costs. Insights from industry experts underscore the importance of meticulous planning and precise specifications in achieving desired air delivery patterns.

Furthermore, addressing common challenges—such as insufficient airflow, excessive noise, and elevated energy costs—is essential for sustaining the reliability of centrifugal blower fan systems. By proactively identifying and resolving these issues, engineers can bolster performance and prolong the lifespan of their equipment. In conclusion, a thorough understanding of centrifugal blower fans, coupled with astute selection and troubleshooting, empowers professionals to refine air delivery systems, ultimately enhancing efficiency and effectiveness within their industrial applications.

Frequently Asked Questions

What is a centrifugal blower fan?

A centrifugal blower fan is an advanced mechanical device designed to move air or other gases by converting rotational energy into gaseous movement, operating on the principle of centrifugal force.

How does a centrifugal blower fan operate?

It draws air into the impeller and expels it at a 90-degree angle from the intake.

What are the essential components of a centrifugal blower fan?

The essential components include the impeller (the rotating element that accelerates the air), the housing (the structure that encases the impeller and directs airflow), and the motor (the driving force behind the impeller’s rotation).

Why is understanding centrifugal blower fans important for engineers?

Understanding these fans enables engineers to assess how different designs impact air movement, pressure, and overall performance.

What is the significance of backward-curved impellers?

Backward-curved impellers are known for their exceptional performance and pressure generation, making them suitable for applications that require significant air movement against resistance.

Who is Gagner-Toomey Associates?

Gagner-Toomey Associates is the world’s largest manufacturer of both standard and custom air movers, offering an extensive product line of DC input centrifugal blower fans ranging from 15 to 225mm in size.

What industries benefit from Gagner-Toomey’s centrifugal blower fans?

Their advanced cooling solutions cater to a diverse array of industrial applications, including the electronics and automotive sectors.

Can Gagner-Toomey centrifugal blower fans be customized?

Yes, most models can be equipped with IP protection upon request, enhancing their adaptability for various environments.

What does CFM stand for and why is it important?

CFM stands for Cubic Feet per Minute, which is a metric for measuring air movement.

What is static pressure in the context of centrifugal blower fans?

Static pressure refers to the resistance encountered by air movement within a system.

How is efficiency defined for centrifugal blower fans?

Efficiency is the ratio of useful output to total input, which is vital for energy conservation.