Introduction

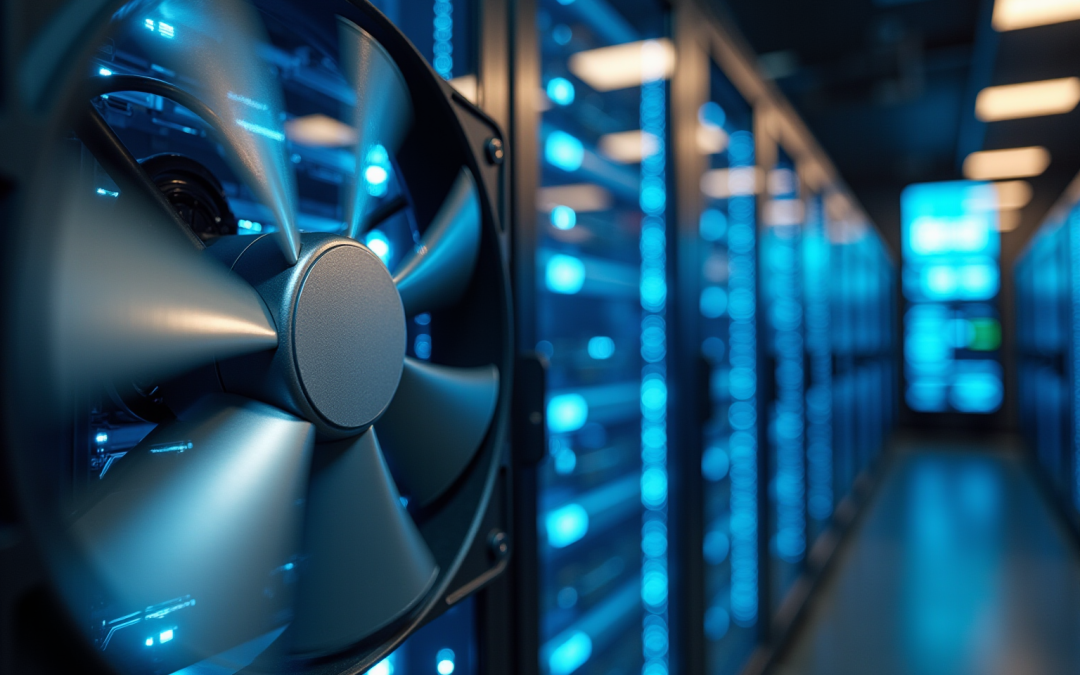

Axial fans play a crucial role in modern electronics, ensuring optimal performance by effectively managing heat across various applications – from personal computers to industrial machinery. Their significance cannot be overstated; understanding the principles behind their operation and the benefits they provide empowers engineers to make informed decisions that enhance thermal management.

However, with a multitude of design options and integration challenges, engineers face a pressing question: how can they maximize the efficiency and effectiveness of these essential components within their systems? By delving into the intricacies of axial fan technology, professionals can unlock the potential for improved performance and reliability in their projects.

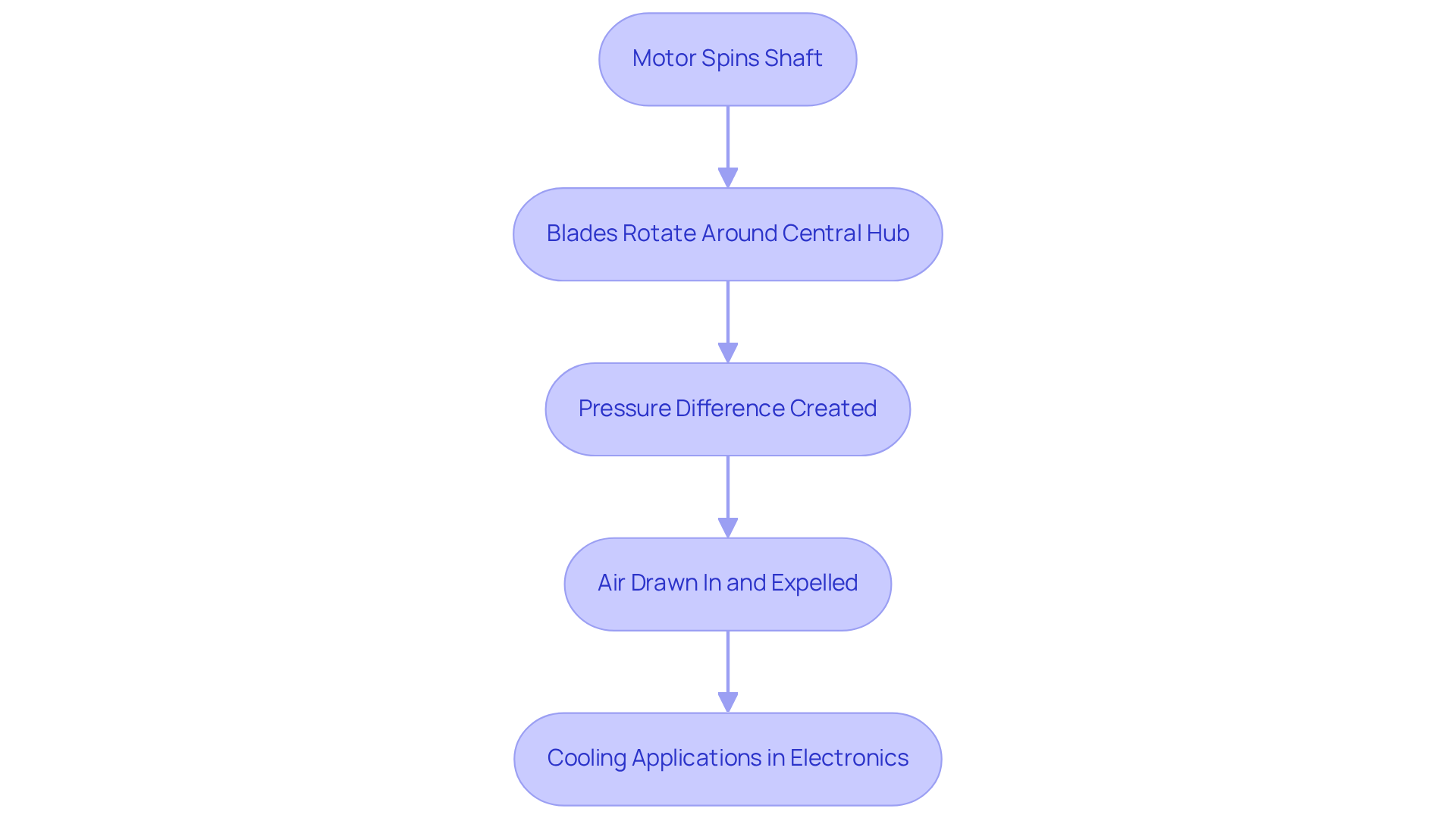

Understand Axial Fan Working Principles

Axial devices play a pivotal role in transforming rotational energy into air movement, utilizing blades that revolve around a central hub. As the motor spins the fan’s shaft, these blades create a pressure difference that draws air in and expels it parallel to the axis of rotation. This mechanism is essential for generating substantial air movement at low pressure, making axial ventilators ideal for cooling applications in electronics.

Gagner-Toomey Associates stands as the world’s largest manufacturer of both standard and custom air-movers, offering an extensive range of DC input tube axial fans. These fans are optimized for performance, efficiency, and low noise, catering to the diverse needs of the industry. Understanding the principles behind these devices enables engineers to appreciate how design choices – such as blade shape and pitch – impact airflow efficiency and noise levels.

For instance, optimizing blade design can lead to significant enhancements in fan performance for specific applications, such as regulating sensitive electronic components. This is further supported by Gagner-Toomey’s innovative thermal management solutions, which provide engineers with the tools necessary to achieve optimal performance in their designs.

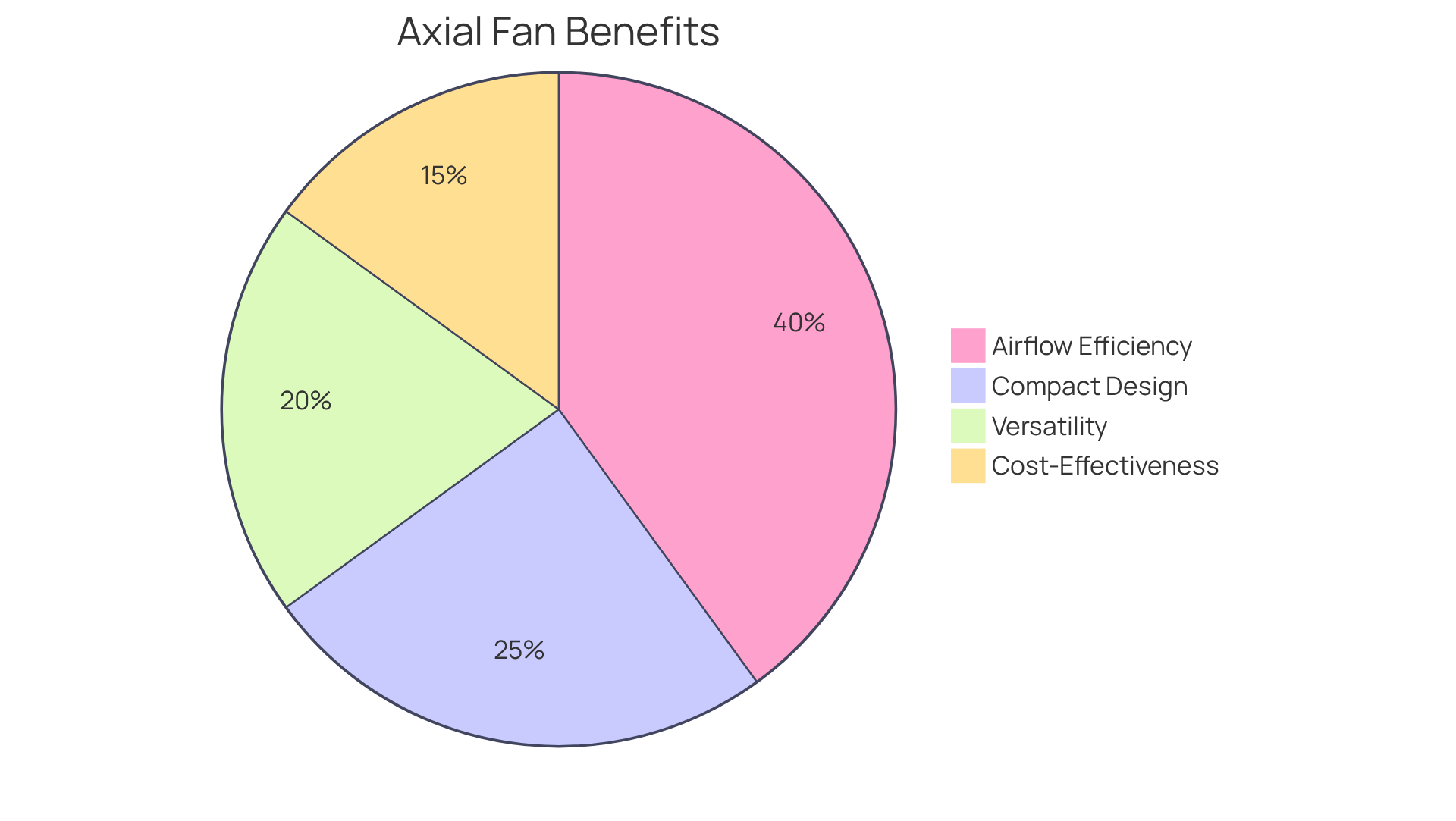

Evaluate Key Characteristics and Benefits of Axial Fans

Axial blowers excel in transporting air along their axis of rotation, making them ideal for various electronic cooling applications. Their advantages are significant:

-

High Airflow Efficiency: Designed to deliver substantial airflow with minimal energy consumption, axial fans are crucial for maintaining optimal operating temperatures in electronic devices. They generate a large volume of airflow at low pressure, which is particularly advantageous in heat-intensive environments where effective thermal management is essential.

-

Compact Design: The small footprint of these ventilators allows for seamless integration into confined spaces, such as server racks and compact electronic enclosures. This compactness provides versatile installation options, ensuring that temperature regulation solutions can be implemented even in space-constrained environments, as evidenced by various case studies.

-

Versatility: Available in a wide range of sizes and configurations, these ventilation devices can be tailored to meet diverse cooling requirements across multiple applications. Their adaptability makes them suitable for everything from personal computers to large industrial systems.

-

Cost-Effectiveness: With lower operational costs stemming from their energy efficiency and reduced maintenance needs, these devices offer a budget-friendly solution for long-term use. Their simpler manufacturing process further enhances affordability, making them a preferred choice across many industries.

These attributes position axial blowers as a top choice for engineers aiming to enhance the thermal management of electronic systems, ensuring reliability and durability in performance.

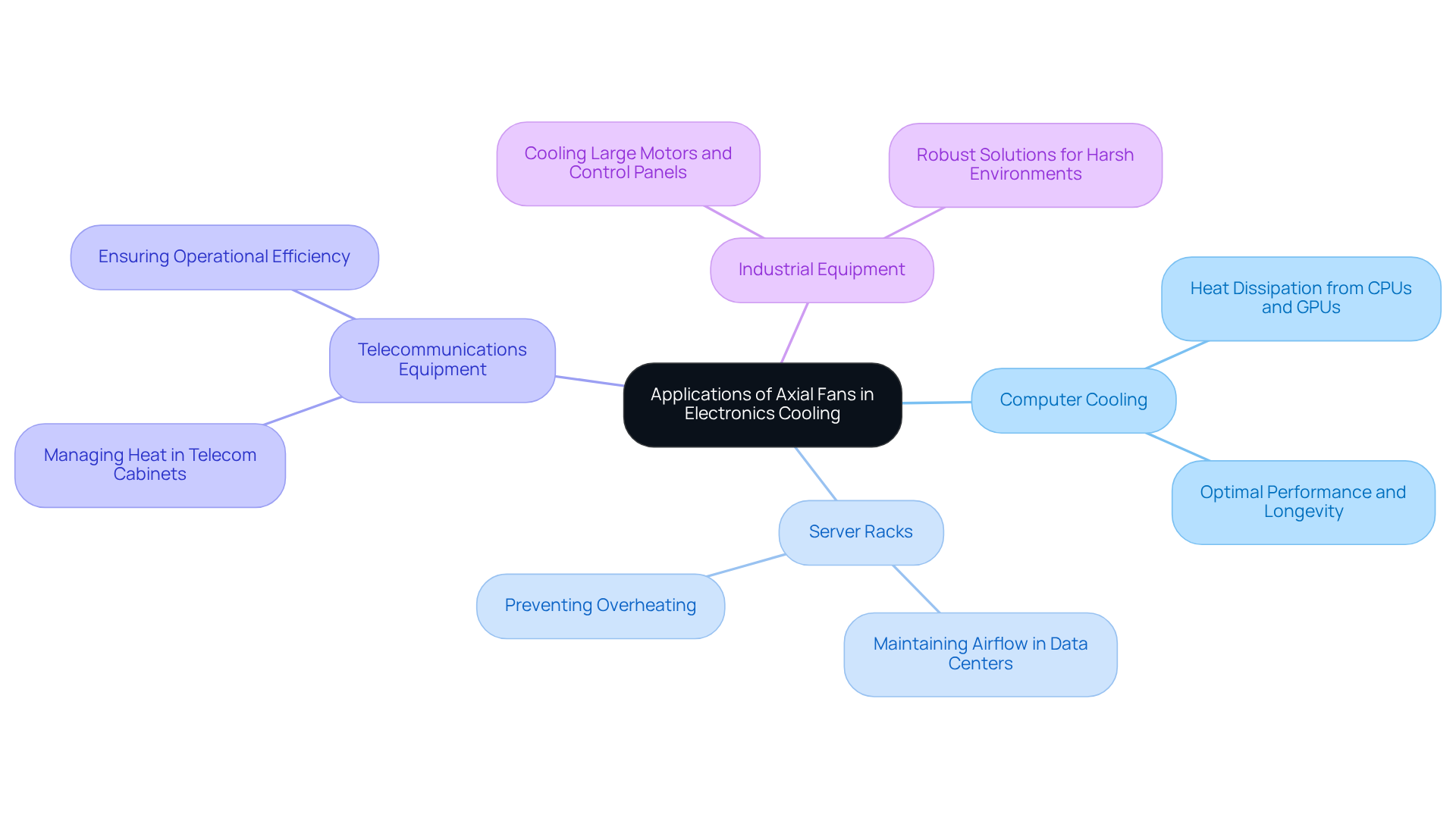

Explore Applications of Axial Fans in Electronics Cooling

Custom axial fans play a crucial role in various electronics cooling applications, addressing the pressing need for effective heat management. Here are some key areas where they are indispensable:

- Computer Cooling: Essential for dissipating heat from CPUs and GPUs, axial fans ensure optimal performance and extend the longevity of computer systems.

- Server Racks: In data centers, straight-blade ventilators maintain airflow among closely arranged servers, preventing overheating and ensuring reliability.

- Telecommunications Equipment: These fans are vital in telecom cabinets, managing heat generated by electronic components to maintain operational efficiency.

- Industrial Equipment: Many industrial devices rely on radial blowers for cooling, ensuring components operate within safe temperature ranges.

These applications highlight the versatility and effectiveness of custom axial fans in managing heat within electronic systems, making them essential in modern engineering.

Implement Best Practices for Integrating Custom Axial Fans

To effectively integrate custom axial fans into electronic systems, engineers must adhere to several best practices that ensure optimal performance and reliability:

- Correct Sizing: Begin by accurately sizing the fan according to the specific airflow requirements and static pressure conditions of the application. For instance, Gagner-Toomey Associates offers devices ranging from 15mm to 280mm for tube axial units, which guarantees both performance and energy efficiency.

- Optimal Placement: Next, strategically position air circulators to maximize airflow across critical components. This avoids dead zones where heat can accumulate, a crucial factor in maintaining system reliability.

- Minimize Noise: It’s also essential to minimize operational noise. Employ vibration dampening methods and select blowers with low noise ratings, particularly in environments sensitive to sound. Recent advancements indicate that HVAC systems designed with these considerations can help companies save up to 30% on electricity expenses, promoting energy conservation and reducing operational costs.

- Regular Maintenance: Implement a regular maintenance schedule for periodic checks. Cleaning fan blades and verifying proper operation is vital, as dust buildup can significantly hinder performance and lead to overheating. Preventive maintenance can reduce HVAC system failures by up to 95%.

- Utilize Inlet Cones: Finally, integrating inlet cones can enhance ventilation efficiency and reduce turbulence at the fan intake, improving overall temperature regulation.

By following these best practices, engineers can significantly enhance the performance and reliability of axial fans in their electronic cooling applications. As emphasized by Gagner-Toomey Associates, understanding key parameters such as airflow rate and static pressure is essential for optimizing fan performance.

Conclusion

Understanding the principles and applications of custom axial fans is essential for electronics engineers who seek to enhance thermal management in their designs. These fans are not merely components; they are critical to ensuring the reliability and efficiency of electronic systems. By mastering the mechanics of axial fans and implementing effective practices, engineers can significantly boost cooling performance and extend the lifespan of sensitive components.

Key characteristics of axial fans include their high airflow efficiency, compact design, versatility, and cost-effectiveness. These attributes render them ideal for a variety of applications, from computer cooling to industrial equipment, highlighting their vital role in managing heat within electronic systems. To maximize their effectiveness, engineers should adhere to best practices for integrating these fans, such as:

- Proper sizing

- Optimal placement

- Regular maintenance

Ensuring they operate at peak performance.

Ultimately, the effective use of custom axial fans is crucial for achieving optimal thermal management in electronics. Engineers are encouraged to delve deeper into the mechanics and benefits of these devices, exploring innovative solutions that can lead to enhanced system performance. By prioritizing the integration of axial fans in design processes, the industry can continue to advance in reliability and efficiency, paving the way for future technological developments.

Frequently Asked Questions

What is the basic working principle of an axial fan?

An axial fan transforms rotational energy into air movement using blades that revolve around a central hub, creating a pressure difference that draws air in and expels it parallel to the axis of rotation.

What applications are axial fans particularly suited for?

Axial fans are ideal for cooling applications in electronics due to their ability to generate substantial air movement at low pressure.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of both standard and custom air-movers, providing an extensive range of DC input tube axial fans optimized for performance, efficiency, and low noise.

How do design choices affect the performance of axial fans?

Design choices such as blade shape and pitch significantly impact airflow efficiency and noise levels, allowing for optimization tailored to specific applications.

What is the significance of optimizing blade design in axial fans?

Optimizing blade design can lead to significant enhancements in fan performance, particularly for applications that require precise regulation of sensitive electronic components.

What additional solutions does Gagner-Toomey provide to engineers?

Gagner-Toomey offers innovative thermal management solutions that equip engineers with the tools necessary to achieve optimal performance in their designs.