Overview

This article delineates the essential steps engineers must undertake when working with 24V DC axial fans. It begins by elucidating the operation of these fans, followed by selection criteria, evaluation, and installation processes. A critical emphasis is placed on airflow requirements, energy efficiency, and compatibility—factors that are vital for optimizing fan performance. Furthermore, these elements are crucial for ensuring effective thermal management in electronic systems, thereby underscoring the necessity of a comprehensive understanding of these components.

Introduction

Understanding the mechanics of DC axial fans is paramount for engineers who seek to enhance thermal management in electronic systems. These compact devices not only provide efficient airflow but also play a significant role in energy savings, rendering them indispensable in modern applications.

With a multitude of models and specifications available, engineers face the challenge of selecting and integrating the optimal 24V DC axial fan tailored to their specific needs. This guide explores the essential steps and considerations necessary for mastering the selection, evaluation, and installation of these critical components.

Understand the Basics of DC Axial Fans

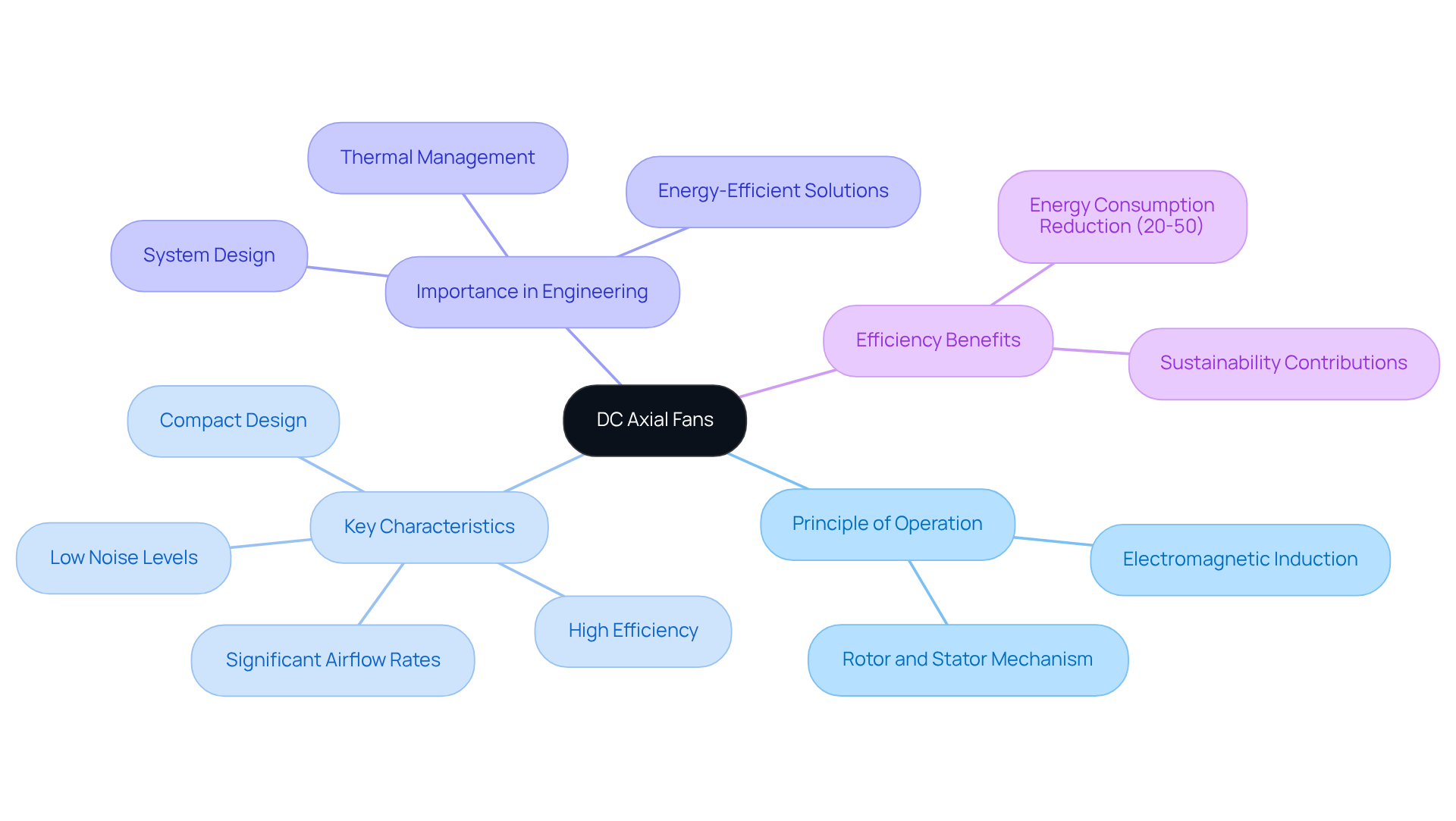

serve as essential instruments that facilitate the movement of air parallel to the unit’s axis, operating on the principle of electromagnetic induction. Utilizing a rotor and stator, these devices generate a current of air that is vital for a variety of applications, particularly in , ventilation, and air movement. Their primary characteristics encompass , , and the capability to deliver while preserving low noise levels.

For engineers, grasping these fundamentals is imperative, as it underscores the critical role of DC radial blowers in effective and system design. Industry leaders emphasize that a thorough understanding of the intricacies of is crucial for enhancing performance in electronic systems, especially in light of the growing demand for .

Real-world examples demonstrate that DC fans can achieve efficiency ratings that surpass those of conventional AC fans, frequently reducing . This enhanced efficiency not only improves thermal management but also contributes to the overall sustainability of electronic systems, establishing them as a preferred choice in contemporary engineering applications.

Identify Key Selection Criteria for 24V DC Axial Fans

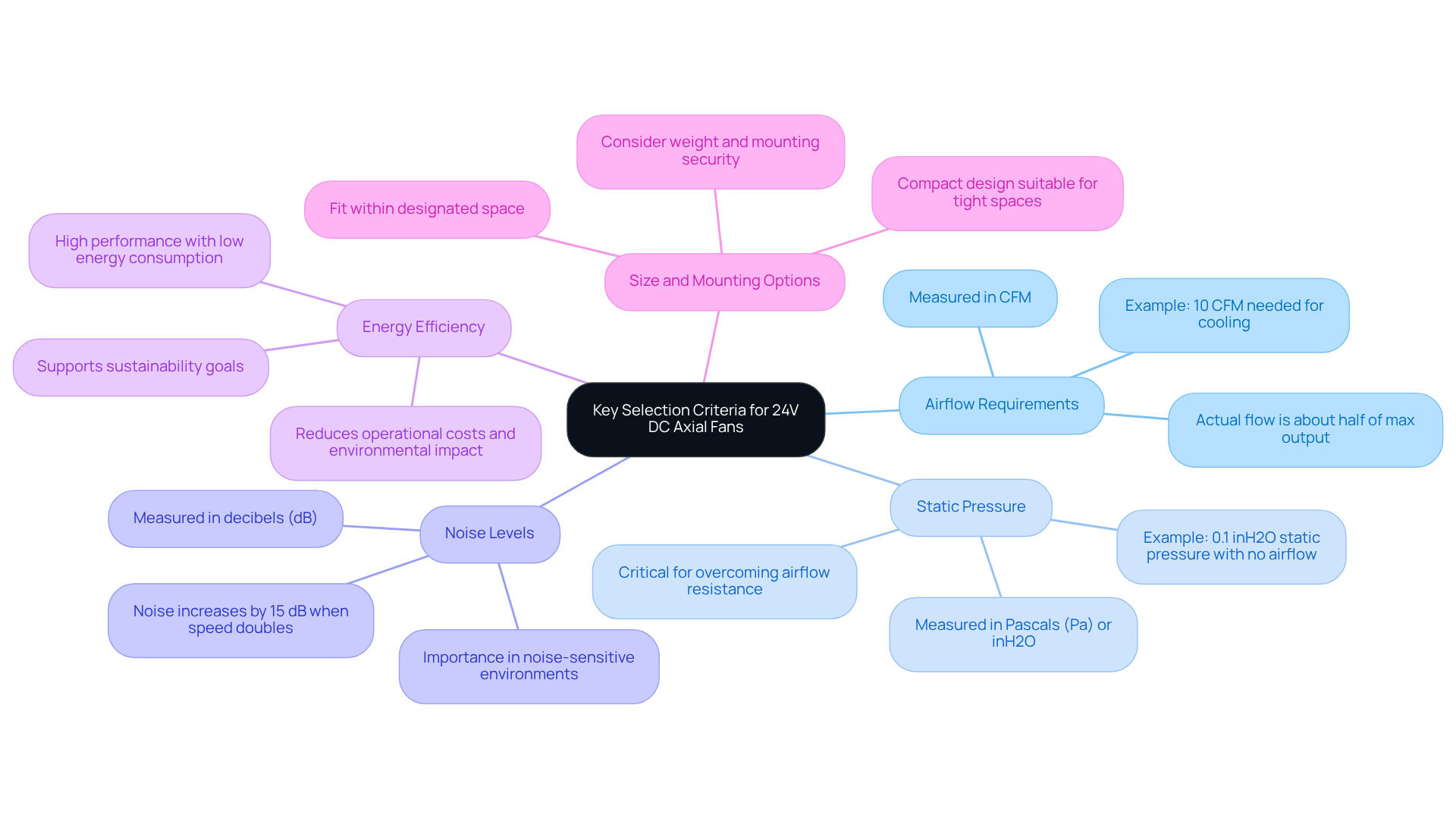

When selecting a , several key criteria must be considered to ensure optimal performance and efficiency.

- : Accurately determining the volume of air needed for is essential, typically measured in cubic feet per minute (CFM). For instance, a product requiring 10 CFM ventilation is crucial for maintaining optimal temperatures in electronic devices. It’s important to note that actual circulation is often assumed to be about half of the fan’s maximum output, which should be factored into the selection process.

- : Assessing the fan’s ability to overcome resistance in the flow path is particularly vital in situations with obstructions. The static pressure rating, measured in Pascals (Pa) or inches of water (inH2O), should align with the specific cooling needs of the system. This consideration is crucial for ensuring in environments where airflow may be restricted.

- : Evaluating the sound output of the fan is important, especially in noise-sensitive environments. Fans with lower decibel ratings are preferable, as noise levels can increase significantly with fan speed—doubling the speed can raise noise by 15 dB. Selecting devices engineered for silent performance can enhance user experience and comfort, particularly in environments where noise reduction is essential.

- : Opting for devices that provide while consuming less energy is critical. This choice is essential for reducing operational expenses and minimizing environmental impact, as energy-efficient ventilation devices can significantly decrease utility costs and reliance on fossil fuels. Furthermore, their efficient operation contributes to reduced greenhouse gas emissions, aligning with sustainability goals.

- Size and Mounting Options: Ensuring the fan fits within the designated space and can be securely mounted is necessary. Consider the , as these types of fans typically occupy less space compared to centrifugal fans, making them suitable for compact applications. This aspect is vital for maintaining design integrity in space-constrained environments.

By thoroughly assessing these criteria, engineers can select the most appropriate for their specific cooling needs, ensuring efficient heat dissipation and improved reliability of electronic systems.

Evaluate and Compare Different 24V DC Axial Fan Models

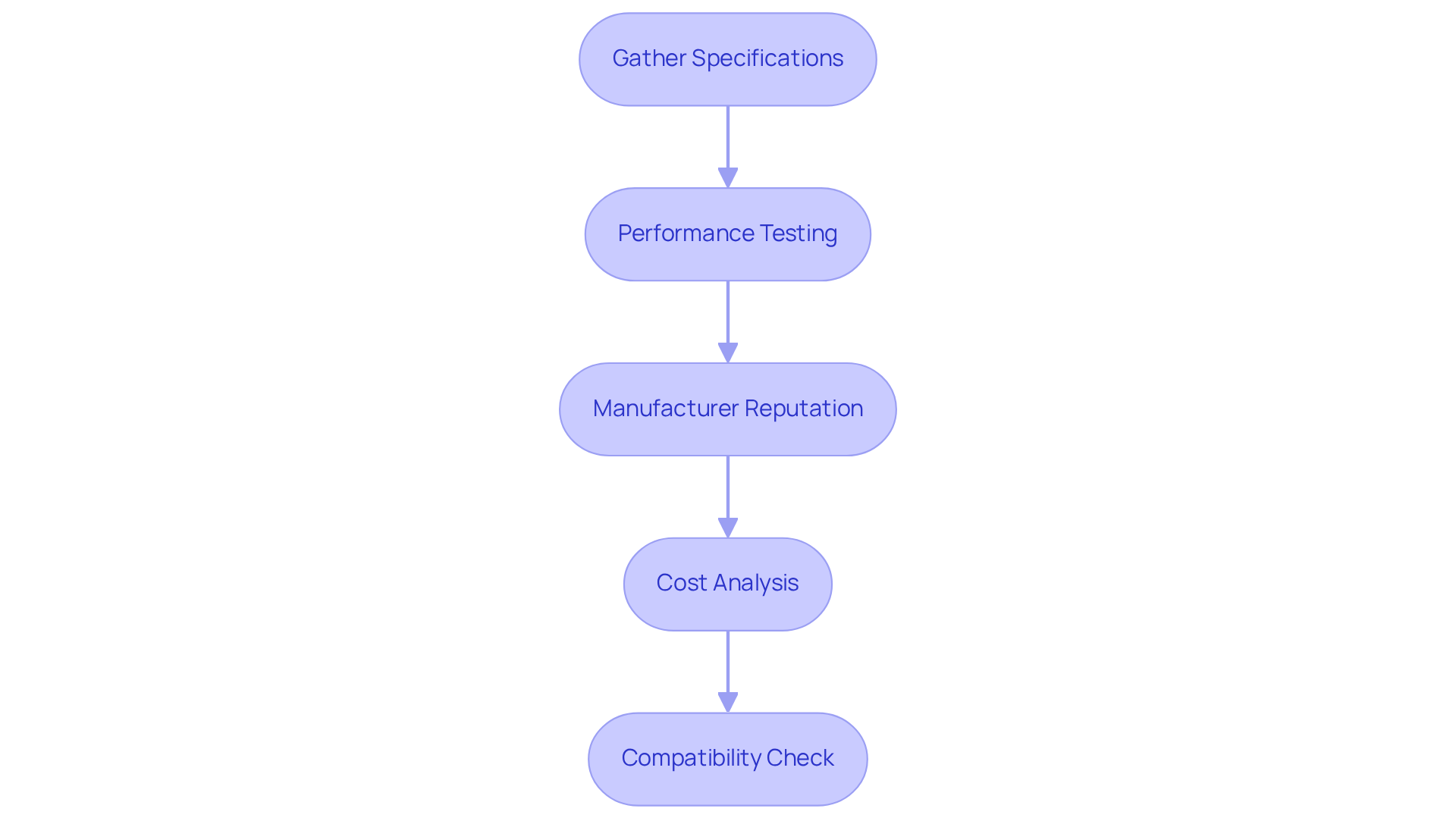

To effectively evaluate and compare various , engineers must adhere to these essential steps:

- Gather Specifications: Begin by collecting data sheets from manufacturers, emphasizing critical metrics such as , static pressure, noise levels (in decibels), and power consumption. For example, understanding that 1 Amp times 12 volts equals 12 Watts aids in assessing power requirements. Comprehending these specifications is vital for selecting a fan that meets the temperature control needs of your application.

- : Whenever feasible, conduct performance assessments to evaluate actual ventilation and noise levels under load conditions. This hands-on evaluation reveals how effectively a fan performs in real-world scenarios, ensuring it meets the necessary without generating excessive noise. Case studies, such as “Determining Required Airflow for Electronics Cooling,” provide valuable insights into .

- : Investigate the reliability and customer feedback associated with each manufacturer. Brands with a proven track record typically offer superior support and higher quality products, significantly impacting the longevity and performance of the fans. As highlighted, ‘ is crucial.’

- : Compare the costs of different models, considering not only the initial purchase price but also long-term energy savings and maintenance expenses. A thorough cost analysis leads to more informed decisions that benefit both performance and budget.

- : Ensure that the selected fan aligns with your system’s voltage and control requirements, such as PWM (Pulse Width Modulation) or analog control. Compatibility is essential for optimal operation and integration into existing systems. Moreover, assessing noise level criteria alongside thermal performance is crucial to achieve both temperature control and noise reduction objectives.

By following these steps, engineers can make informed choices that enhance the .

Install and Integrate Your Chosen DC Axial Fan

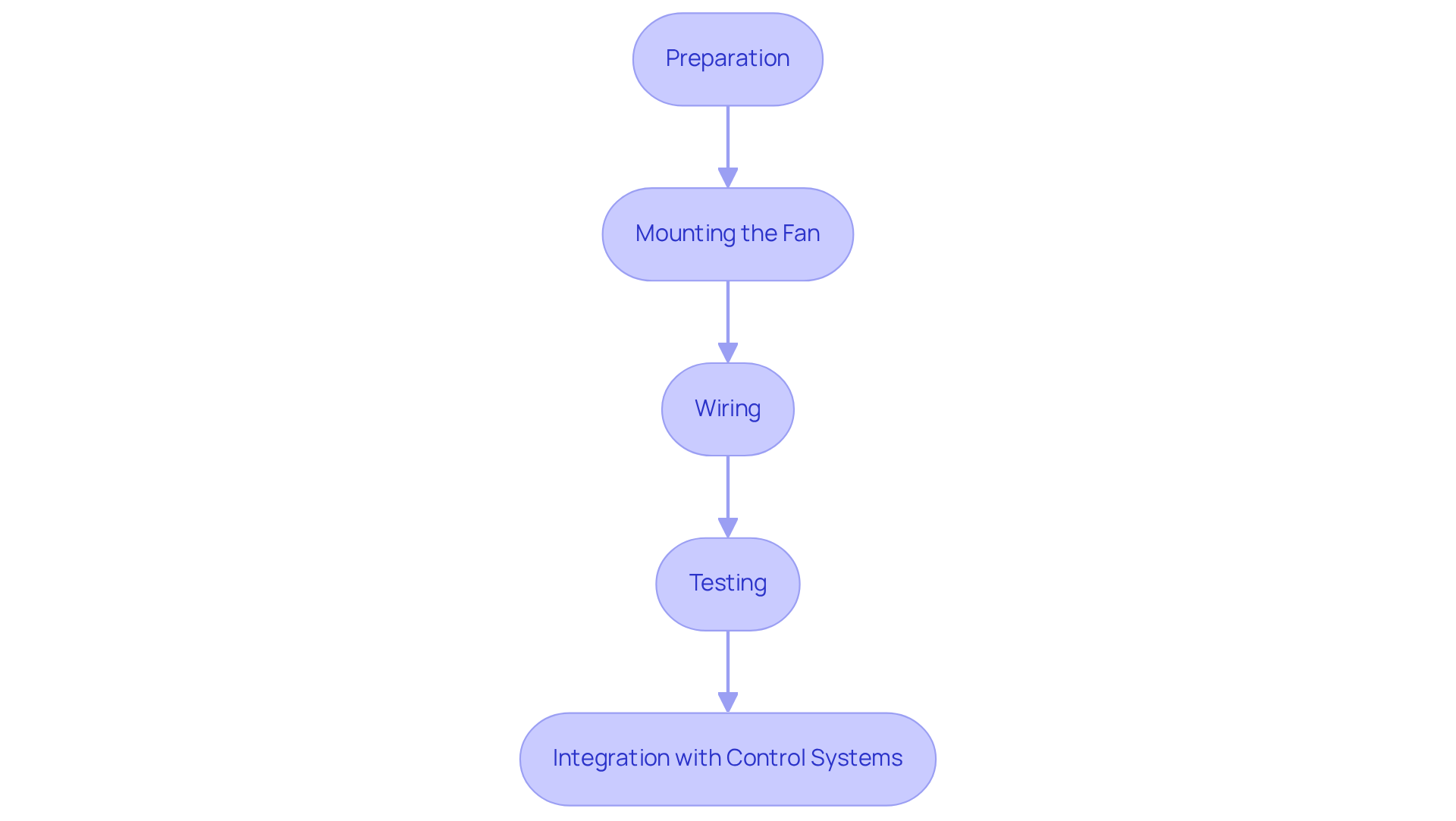

To successfully install and integrate your 24V , follow these :

- Preparation: Begin by gathering the necessary tools, including screwdrivers, mounting brackets, duct sealant, and electrical connectors. Having all essential items ready will prevent delays during the installation process.

- Mounting the Fan: Securely attach the fan to the designated location, ensuring it is oriented correctly to . Utilize the provided mounting hardware, ensuring the fan is mounted straight to avoid any misalignment that could hinder performance.

- Wiring: Connect the fan to the , paying close attention to polarity (positive to positive, negative to negative). Employ appropriate connectors to prevent loose connections, a common installation issue that can lead to fan malfunction.

- Testing: Power on the system and . Check for proper airflow and listen for any unusual noises that may indicate installation issues, such as misalignment or loose wiring.

- Integration with Control Systems: If applicable, with your system’s control mechanisms, such as . This integration allows for dynamic speed adjustments based on real-time conditions, enhancing both energy efficiency and overall performance.

By meticulously following these steps, you can ensure a and integration of your DC axial fan 24V, thereby optimizing its performance for a variety of applications.

Conclusion

Understanding and mastering the use of 24V DC axial fans is crucial for engineers aiming to optimize thermal management in electronic systems. These fans not only enhance airflow efficiency but also significantly reduce energy consumption and noise levels, rendering them an ideal choice for modern applications. By grasping the fundamentals and applications of these devices, engineers can ensure their designs meet the increasing demands for performance and sustainability.

The article outlines essential criteria for selecting the right 24V DC axial fan, including:

- Airflow requirements

- Static pressure

- Noise levels

- Energy efficiency

- Size considerations

It emphasizes the importance of evaluating and comparing different models based on specifications, performance testing, manufacturer reputation, cost analysis, and compatibility with existing systems. Each step is designed to guide engineers in making informed decisions that enhance the reliability and effectiveness of their cooling solutions.

Ultimately, integrating and installing the chosen fan correctly maximizes its performance and contributes to the overall success of engineering projects. As the demand for energy-efficient and effective cooling solutions continues to grow, engineers are encouraged to apply the insights from this guide to elevate their designs and meet the challenges of contemporary electronic systems. Taking these steps not only fosters innovation but also aligns with broader sustainability goals, ensuring a more efficient future for technology and engineering.

Frequently Asked Questions

What are DC axial fans and how do they operate?

DC axial fans are devices that facilitate the movement of air parallel to the unit’s axis, operating on the principle of electromagnetic induction. They utilize a rotor and stator to generate a current of air.

What are the primary applications of DC axial fans?

DC axial fans are primarily used for cooling electronic components, ventilation, and general air movement.

What are the key characteristics of DC axial fans?

Key characteristics include high efficiency, compact design, and the ability to deliver significant airflow rates while maintaining low noise levels.

Why is it important for engineers to understand DC axial fans?

Understanding DC axial fans is crucial for engineers as it highlights their critical role in effective thermal management and system design, particularly in the context of increasing demand for energy-efficient solutions.

How do DC fans compare to conventional AC fans in terms of efficiency?

DC fans can achieve efficiency ratings that often surpass those of conventional AC fans, frequently reducing energy consumption by 20-50%.

What impact do DC axial fans have on thermal management and sustainability?

Enhanced efficiency from DC axial fans improves thermal management and contributes to the overall sustainability of electronic systems, making them a preferred choice in modern engineering applications.