Overview

This article delves into the principles, structure, and benefits of DC brushless fan motors, emphasizing their efficiency, durability, and diverse applications. These motors operate without brushes, utilizing electronic commutation to enhance performance. With efficiency rates ranging from 85% to 90%, they are particularly suited for energy-sensitive environments such as HVAC systems and consumer electronics.

Understanding the mechanics behind these motors is crucial. By eliminating brushes, DC brushless motors reduce friction and wear, leading to longer lifespans and lower maintenance costs. This innovative design not only boosts performance but also contributes to energy savings, making them a preferred choice in various industries.

The applications of DC brushless fan motors are extensive. From cooling systems in residential and commercial buildings to powering devices in consumer electronics, their versatility is unmatched. As industries increasingly prioritize energy efficiency, the demand for these motors continues to grow.

In conclusion, DC brushless fan motors represent a significant advancement in motor technology. Their efficiency, durability, and broad range of applications make them an ideal solution for modern energy-sensitive environments. Embracing this technology can lead to substantial benefits in both performance and cost savings.

Introduction

DC brushless fan motors are transforming electric motor technology, delivering unmatched efficiency, durability, and silent operation that traditional motors cannot replicate. As industries shift towards energy-efficient solutions, it’s crucial for engineers and designers to grasp the fundamental principles and structures of these motors.

The advantages of DC brushless technology are becoming increasingly clear, yet they also raise questions regarding their complexity and cost-effectiveness across various applications. What challenges do engineers encounter when implementing this advanced technology? How can they harness its benefits to elevate product performance?

Understanding these dynamics is essential for leveraging the full potential of DC brushless motors.

Explore the Fundamentals of DC Brushless Motors

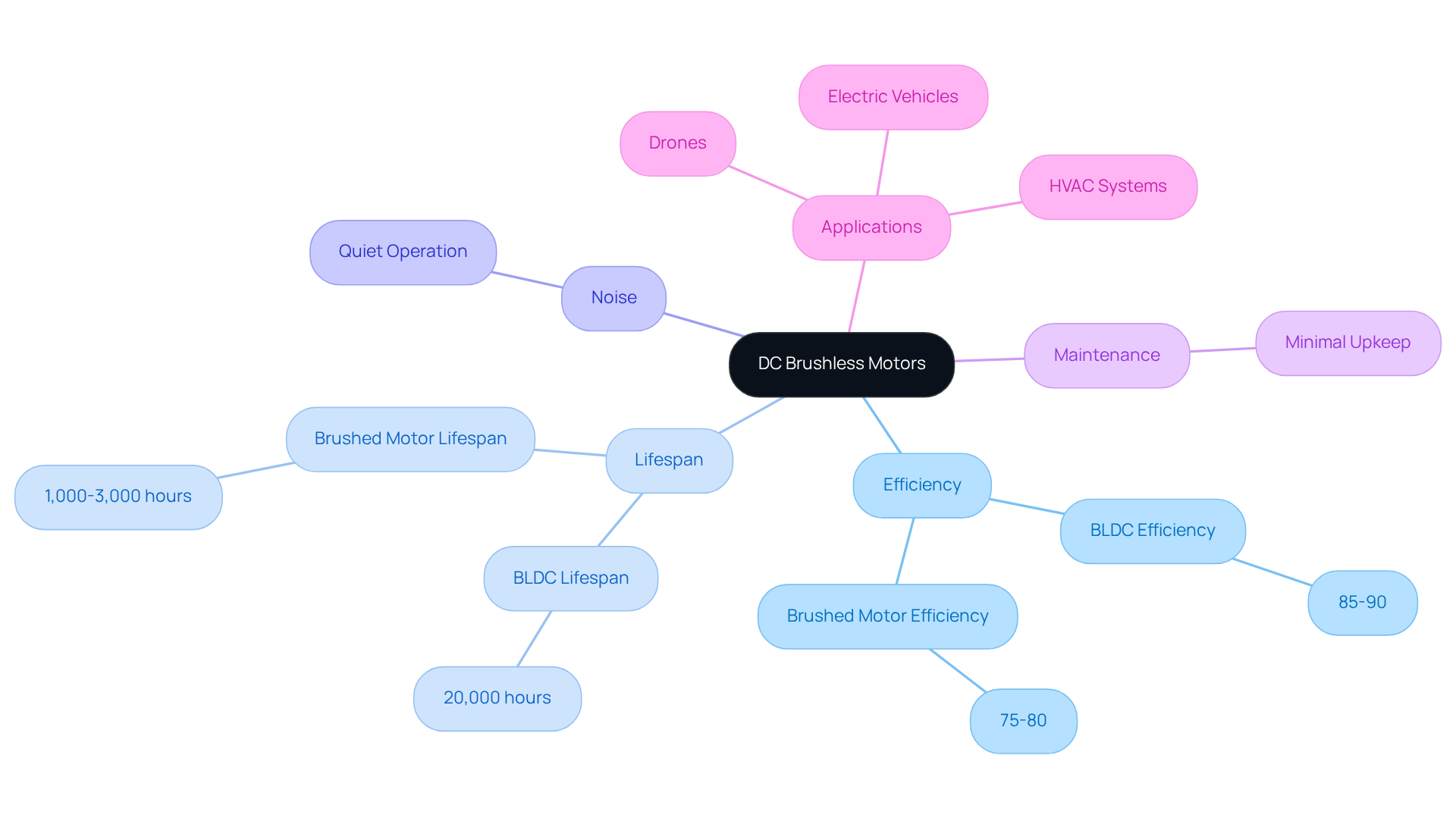

DC brushless fan motors (BLDC) represent a significant advancement in electric motor technology, as they operate without brushes and utilize electronic commutation to enhance performance. This innovative design minimizes friction and wear, resulting in improved efficiency and a longer operational life. Typically, the rotor consists of a permanent magnet, while the stator features windings that create a rotating magnetic field when energized. This configuration not only facilitates smoother operation but also boosts performance across various applications, particularly in cooling systems that utilize a dc brushless fan motor and power management devices.

Engineers have noted that BLDC devices achieve efficiency rates ranging from 85% to 90%, compared to 75% to 80% for their brushed counterparts. Additionally, the average lifespan of a BLDC device can exceed 20,000 service hours, making them a robust choice for demanding applications. In contrast, brushed devices generally last only 1,000 to 3,000 hours due to mechanical wear from brushes.

The benefits of brushless devices extend beyond durability and performance. They operate more quietly, producing less noise, which is crucial in sensitive electronic environments. Furthermore, they generate less heat and require minimal maintenance, making them ideal for a wide range of applications. By 2025, the electronics sector is increasingly relying on dc brushless fan motors for applications such as HVAC systems, where their efficiency can lead to substantial energy savings. Notably, the use of DC in buildings could rise to 74% with the integration of electric vehicle chargers and HVAC systems powered by DC drives, underscoring the growing dependence on DC technology. As the shift from AC to DC-powered devices progresses, understanding the principles and advantages of BLDC technology is essential for engineers seeking to innovate and enhance product performance. However, it is crucial to acknowledge that while BLDC devices offer numerous advantages, their complexity and higher initial costs may pose challenges for certain applications.

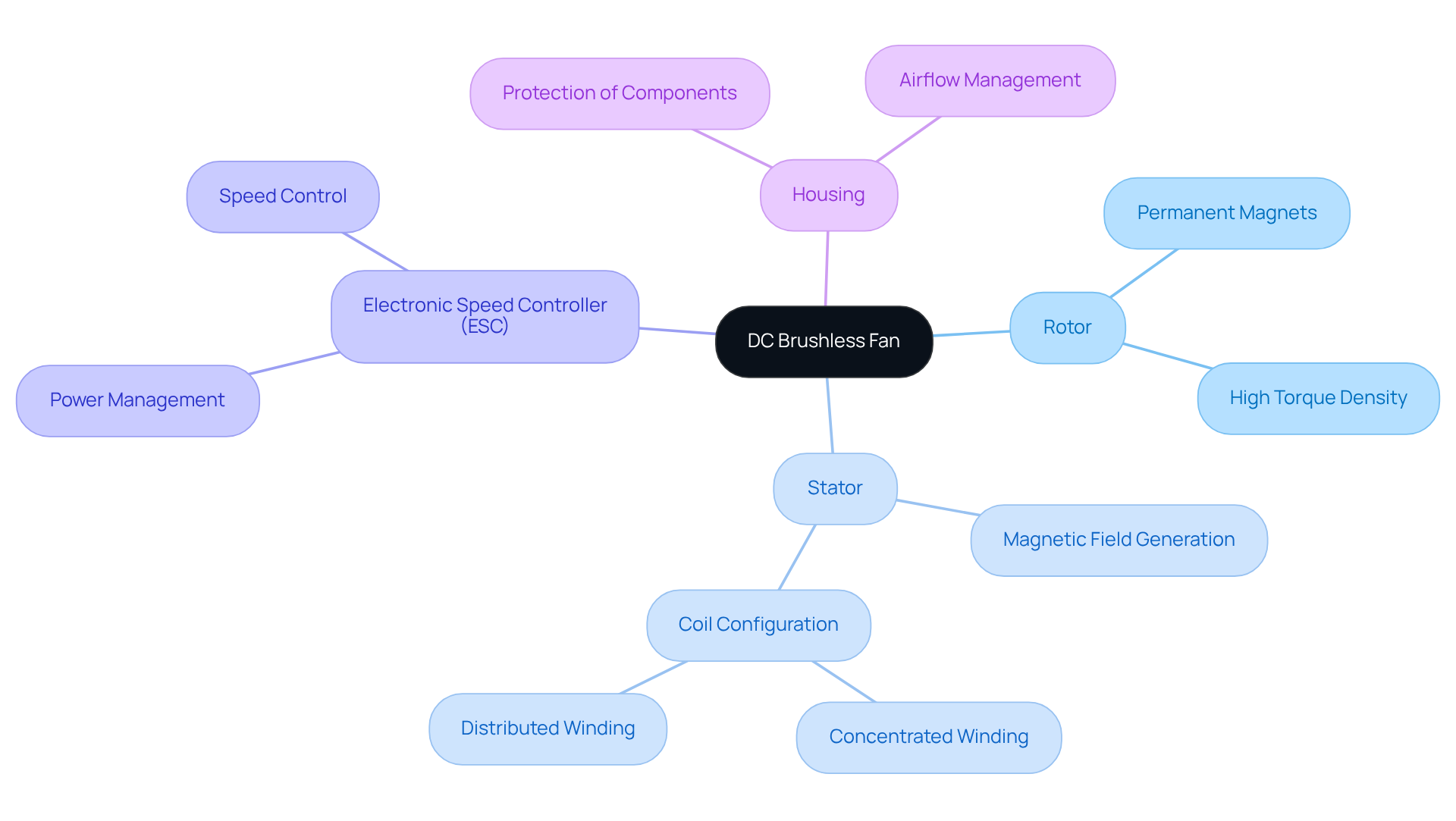

Analyze the Structure and Components of DC Brushless Fans

The components of a DC brushless fan motor include the rotor, stator, electronic speed controller (ESC), and housing. The rotor, which houses permanent magnets, rotates within the stator, consisting of coils that generate a magnetic field. This interaction is vital for efficient fan operation. The ESC plays a crucial role by controlling the power delivered to the motor, allowing for precise speed management and enhancing overall fan efficiency.

Research shows that proper maintenance can prevent up to 80 percent of electric motor failures, highlighting the significance of reliable ESCs in fan design. The housing not only protects these components but also aids in airflow management. Understanding this structure is critical for engineers tasked with designing systems that require effective thermal management, as it directly influences the fan’s performance and reliability.

Gagner-Toomey Associates offers a diverse range of DC input tube axial units, varying from 15 to 280mm, alongside centrifugal blowers from 15 to 225mm, all optimized for performance, effectiveness, and low noise. Practical applications demonstrate that integrating advanced ESCs can lead to substantial improvements in energy performance and noise reduction, making them indispensable in modern fan designs.

Moreover, DC brushless fan motors achieve efficiencies of 80-90%, compared to 60-75% for similar AC induction units, reinforcing the advantages of DC brushless systems. Gagner-Toomey’s innovative cooling solutions, which feature an extensive array of thermal management products, further enhance the capabilities of the dc brushless fan motor across various applications.

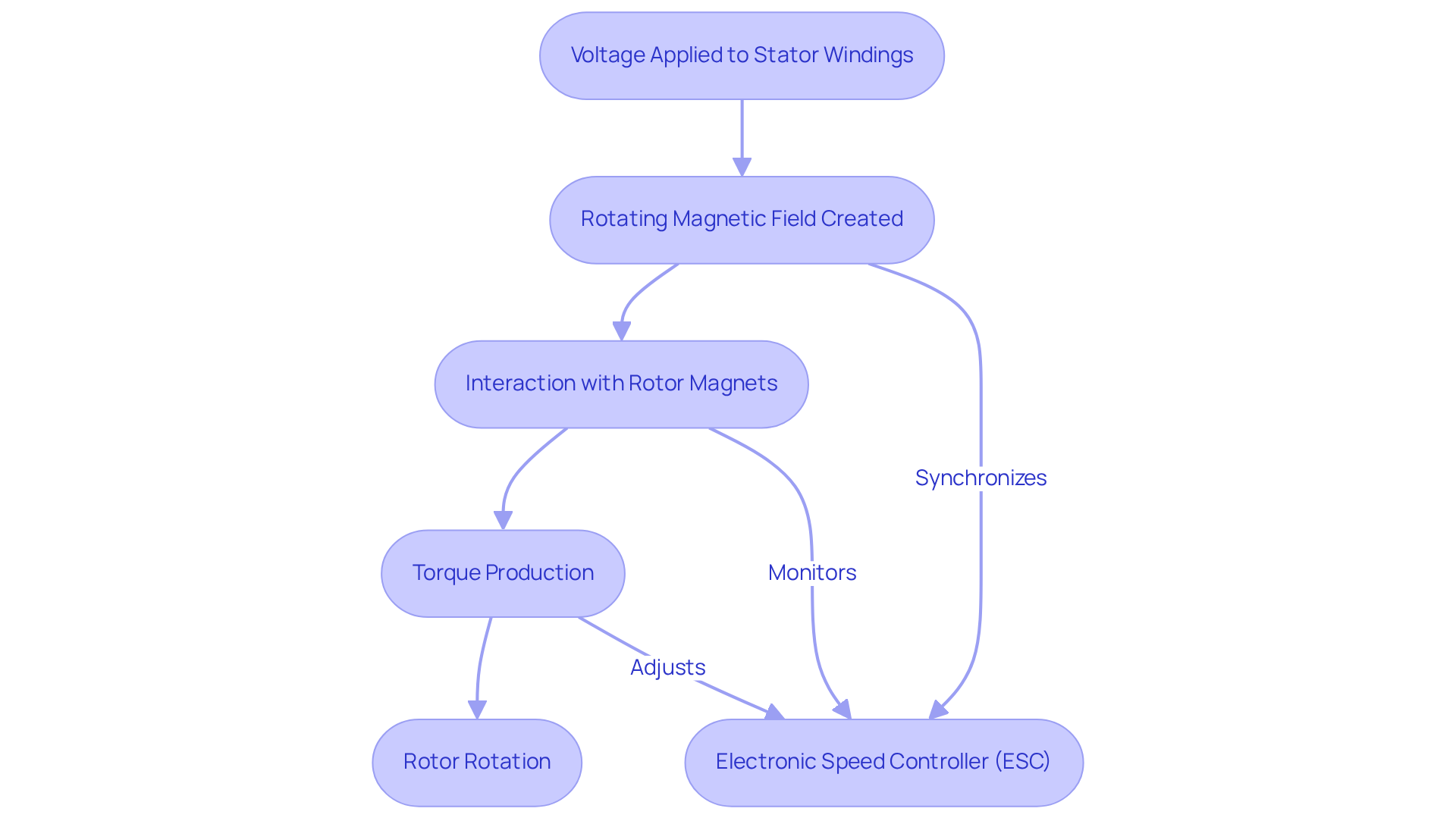

Understand the Operating Principles of DC Brushless Motors

The operation of a dc brushless fan motor hinges on the principles of electromagnetic induction and electronic commutation. When voltage is applied to the stator windings, it generates a rotating magnetic field that interacts with the permanent magnets on the rotor. This interaction produces torque, leading to the rotor’s rotation. The electronic speed controller (ESC) fine-tunes the timing of the voltage applied to the stator, ensuring synchronization between the magnetic fields and the rotor’s position. This precise control results in high efficiency, often exceeding 85% to 92%. Contemporary high-performance engines can achieve efficiencies over 95%, with certain premium models reaching an impressive 96% to 98%.

Moreover, dc brushless fan motors offer significant advantages in demanding environments such as electric vehicles and robotics. Their extended lifespan—ranging from 10,000 to 50,000 hours—coupled with reduced maintenance requirements, is essential for these applications. Understanding these principles is vital for enhancing performance across various sectors, from consumer electronics to industrial automation. Additionally, it is important to consider the different types of losses that can impact motor performance, including:

- Copper loss

- Eddy current loss

- Inverter loss

All of which can affect overall functionality.

Identify the Benefits and Applications of DC Brushless Fans

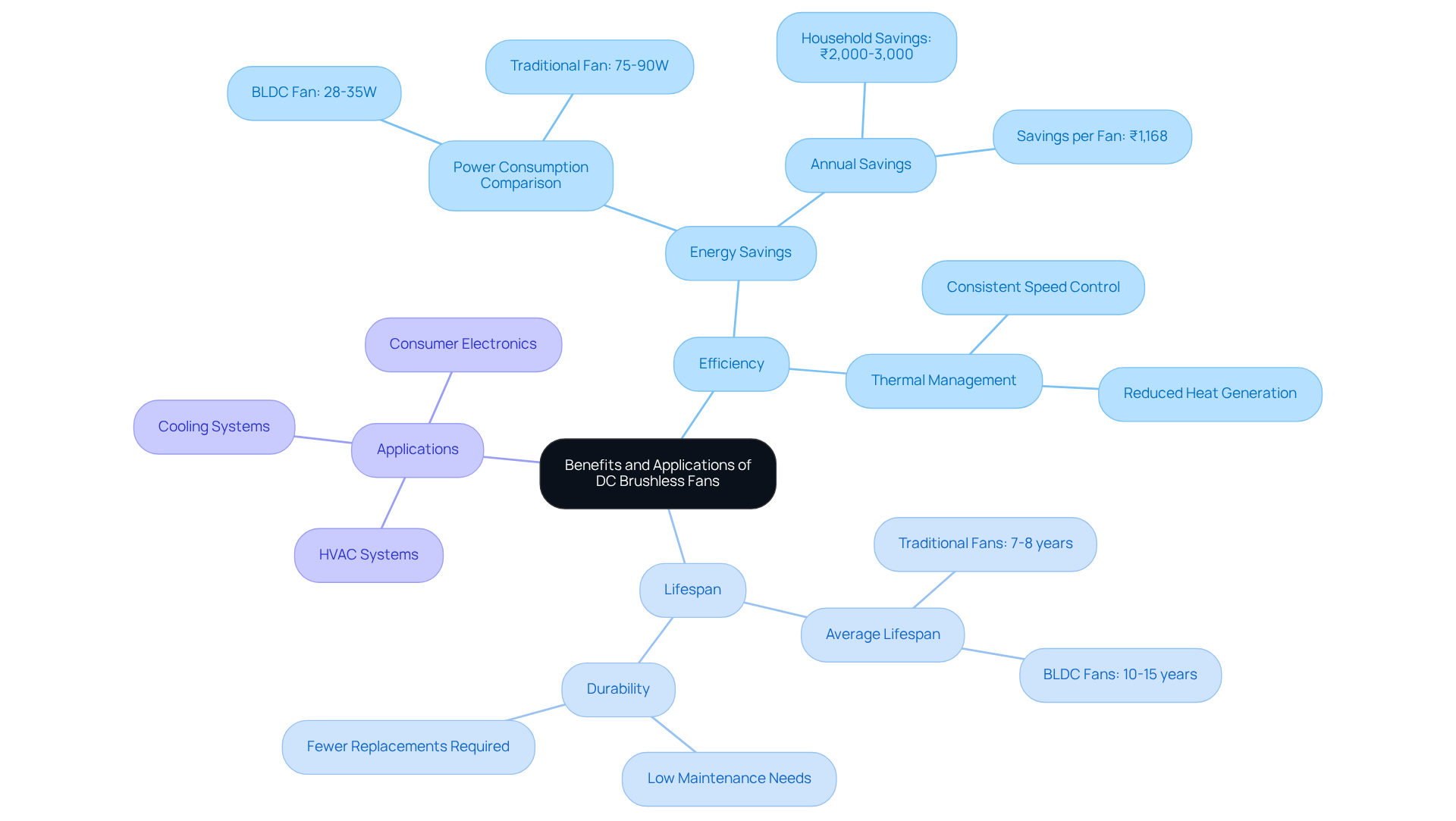

DC brushless devices offer significant advantages over conventional models, including enhanced efficiency, longer lifespan, and quieter operation. Typically consuming between 28 to 35 watts, these fans can reduce energy consumption by up to 65% compared to traditional fans that use around 75 to 90 watts. This remarkable efficiency makes them ideal for energy-sensitive applications.

Their precise speed control capabilities further enhance thermal management in electronic devices, which is essential for maintaining optimal operating conditions. Common applications include:

- Cooling systems in computers

- HVAC systems

- Various consumer electronics

In HVAC settings, for example, the use of a DC brushless fan motor maintains consistent airflow while consuming less power, leading to substantial energy savings and improved system reliability.

Engineers have noted that the average lifespan of products utilizing a DC brushless fan motor ranges from 10 to 15 years, significantly outlasting conventional models, which typically last only 7 to 8 years. This longevity not only reduces maintenance needs but also lowers replacement costs, making these devices even more appealing.

Statements from engineers highlight the reliability of the DC brushless fan motor units, emphasizing their role in creating efficient and durable systems. One engineer remarked, ‘DC brushless fan motor devices are a game-changer in home cooling,’ underscoring their impact on energy conservation and performance. By integrating these devices into their designs, engineers can effectively meet the increasing demands for energy efficiency and performance in today’s technology-driven landscape.

Moreover, utilizing a DC brushless fan motor can result in annual savings of approximately ₹1,168 per fan, with households potentially saving between ₹2,000 to ₹3,000 when multiple fans are employed. Their intelligent features and low maintenance requirements further reinforce their status as a superior choice for modern applications.

Conclusion

DC brushless fan motors signify a significant advancement in motor technology, delivering unmatched efficiency, longevity, and quiet operation. By eliminating brushes and utilizing electronic commutation, their innovative design not only boosts performance but also greatly minimizes maintenance requirements. As industries increasingly shift towards energy-efficient solutions, grasping the principles and benefits of DC brushless motors becomes essential for engineers and designers alike.

In examining DC brushless fan motors, several key insights arise regarding their structure, operating principles, and numerous advantages. The critical interaction between the rotor, stator, and electronic speed controller (ESC) is essential for achieving high efficiency rates, often surpassing 90%. Moreover, these motors boast impressive lifespans of up to 50,000 hours, making them an excellent choice for applications ranging from HVAC systems to consumer electronics. Their ability to cut energy consumption by as much as 65% further emphasizes their importance in today’s energy-conscious environment.

Given these compelling advantages, integrating DC brushless fan motors into contemporary designs is not merely an option; it is a necessity for those seeking to innovate and enhance performance. As the demand for energy-efficient technologies continues to grow, adopting the principles of DC brushless motors can yield significant operational savings and improved product reliability. Transitioning to these advanced systems represents a step toward a more sustainable and efficient future, urging engineers and industries to reevaluate their design and functionality approaches.

Frequently Asked Questions

What are DC brushless fan motors (BLDC)?

DC brushless fan motors (BLDC) are electric motors that operate without brushes and utilize electronic commutation, which enhances performance by minimizing friction and wear.

What are the main components of a BLDC motor?

A BLDC motor typically consists of a rotor made of a permanent magnet and a stator with windings that create a rotating magnetic field when energized.

How efficient are BLDC motors compared to brushed motors?

BLDC motors achieve efficiency rates ranging from 85% to 90%, while brushed motors typically have efficiency rates of 75% to 80%.

What is the average lifespan of a BLDC motor?

The average lifespan of a BLDC motor can exceed 20,000 service hours, compared to only 1,000 to 3,000 hours for brushed motors due to mechanical wear.

What are the advantages of using BLDC motors?

BLDC motors offer several advantages, including improved durability, quieter operation, reduced heat generation, minimal maintenance requirements, and increased efficiency, particularly in cooling systems and power management devices.

How are BLDC motors expected to impact the electronics sector by 2025?

By 2025, the electronics sector is expected to increasingly rely on BLDC motors for applications such as HVAC systems, leading to substantial energy savings and a potential rise in the use of DC technology in buildings.

What challenges are associated with BLDC motors?

While BLDC motors offer numerous advantages, their complexity and higher initial costs may pose challenges for certain applications.