Overview

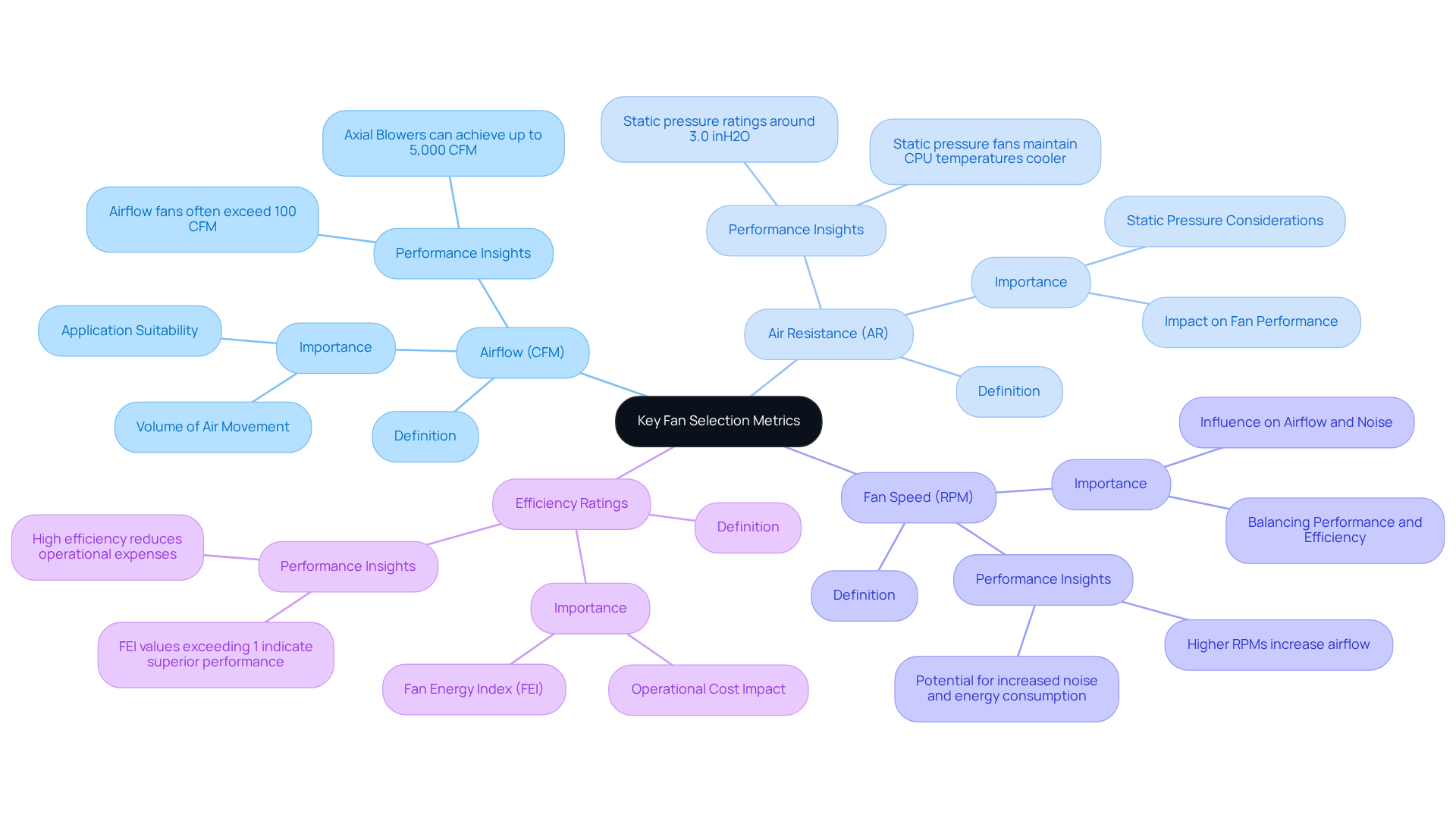

This article highlights the critical metrics engineers must grasp for effective fan selection: airflow (CFM), air resistance (AR), fan speed (RPM), and efficiency ratings. Understanding these metrics is not just beneficial; it’s essential. By mastering them and considering environmental factors such as temperature and altitude, engineers can make informed decisions that significantly enhance cooling performance and reliability across various applications.

The importance of airflow cannot be overstated. It directly impacts the cooling capacity of a fan, making it a primary consideration in any selection process. Air resistance, on the other hand, affects the efficiency of airflow, which is crucial for optimizing performance. Fan speed (RPM) plays a pivotal role in determining how effectively a fan can operate under different conditions. Lastly, efficiency ratings provide insight into the energy consumption of fans, guiding engineers toward sustainable choices.

Incorporating these metrics into the selection process allows engineers to navigate the complexities of fan performance with confidence. By acknowledging the interplay between these factors and environmental conditions, they can ensure that their choices lead to reliable and efficient cooling solutions.

Introduction

Selecting the right fan for engineering applications is not just a matter of preference; it’s a critical decision that can significantly impact system performance and efficiency. Engineers face a complex landscape of metrics—airflow, air resistance, fan speed, and efficiency ratings—that must be navigated to ensure optimal cooling solutions. With so many variables at play, how can one be certain they are making the best choice?

This article delves into the essential metrics of fan selection, offering insights that empower engineers to make informed decisions tailored to their specific cooling needs. By addressing the challenges posed by varying environmental conditions, we aim to equip you with the knowledge necessary to enhance your engineering projects.

Understanding these metrics is crucial for achieving the desired performance and efficiency in your systems. Let’s explore the key factors that will guide you in selecting the most suitable fan for your applications.

Understand Key Fan Selection Metrics

Before fan selection, it is crucial to understand the key metrics that define its performance, especially when considering the extensive range of cooling solutions offered by Gagner-Toomey Associates. The primary metrics include:

-

Airflow (CFM): This metric quantifies the volume of air a fan can move, typically expressed in cubic feet per minute (CFM). It’s essential for determining whether a fan can meet the cooling requirements of your application. Gagner-Toomey’s supporters, optimized for performance and efficiency, are designed for high air movement, making them suitable for various environments, including electronics and automotive applications. Maintaining air speed above the minimum transport air velocity is crucial to prevent insufficient air movement in dusty environments.

-

Air Resistance (AR): Measured in inches of water gauge (inWG), air resistance indicates the force a fan must overcome to move air through a system. Understanding static pressure (SP) is vital for ensuring that the fan can operate effectively in your specific environment, especially in applications with ducting or filters. Gagner-Toomey’s diverse collection comprises devices that can sustain ideal fixed force, which is crucial for efficient thermal regulation, as insufficient temperature management can diminish equipment lifespan by up to 30%.

-

Fan Speed (RPM): The revolutions per minute (RPM) of the fan motor significantly influence both airflow and static pressure. Higher RPMs generally increase airflow but may also lead to increased noise and energy consumption. Gagner-Toomey’s innovative designs balance these factors, allowing engineers to achieve efficient cooling without compromising system performance.

-

Efficiency Ratings: These ratings assess how effectively a fan converts electrical energy into airflow, impacting operational costs and energy consumption. The Fan Energy Index (FEI) serves as a key efficiency metric, with values exceeding 1 indicating superior performance compared to standard units. Gagner-Toomey’s devices are designed to deliver high efficiency, ensuring that operational expenses are reduced while preserving optimal cooling performance.

By mastering these metrics and recognizing the importance of regular upkeep, including cleaning and inspecting ventilators, engineers can make informed choices regarding fan selection when assessing options. Gagner-Toomey’s extensive array of standard and custom cooling solutions, including DC input Tube Axial units and Centrifugal Blowers, guarantees that they can choose the most appropriate device for their specific cooling requirements, enhancing performance and reliability.

Evaluate Flow Rate (CFM)

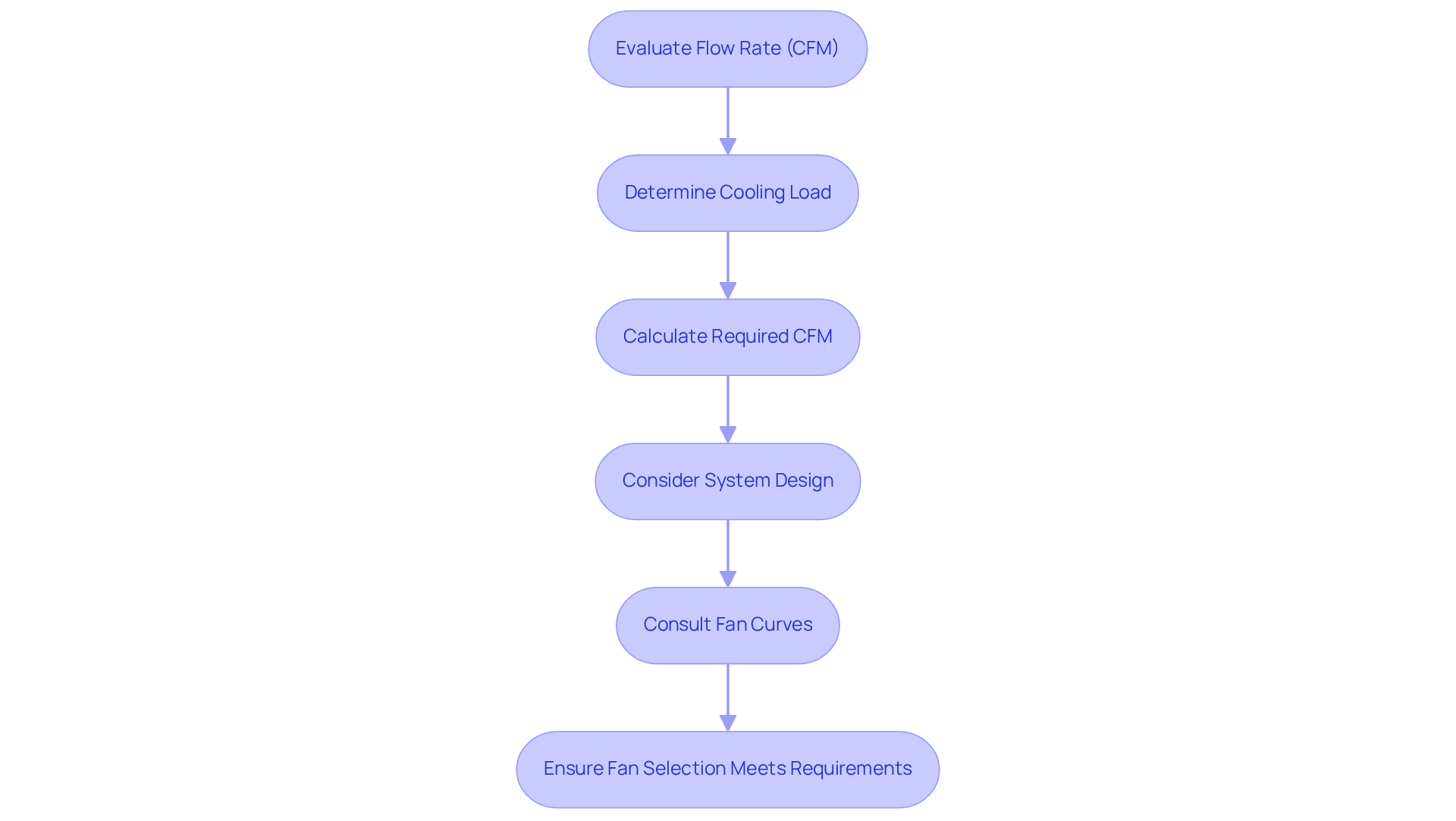

To evaluate the flow rate effectively, follow these steps:

-

Determine the Cooling Load: Start by calculating the total heat load that needs to be dissipated in your application. This can be achieved through thermal analysis or by consulting manufacturer specifications for the components involved.

-

Calculate Required CFM: Use the formula:

CFM = (Cooling Load in BTUs/hour) / (1.08 x Temperature Difference in °F)

This formula helps determine the necessary airflow to maintain the desired temperature. For instance, if your cooling load is 1,200 BTUs/hour and the temperature difference is 20°F, the required CFM would be 60. It’s important to note that residential fans typically require a CFM of 4,000-6,000, while large warehouses may need HVLS fans with a CFM exceeding 80,000, as per industry standards.

-

Consider System Design: Evaluate the layout of your system, including ductwork and any potential obstructions that could impede airflow. Adjust your CFM requirements accordingly to ensure optimal performance.

-

Consult Fan Curves: Refer to the fan curves provided by manufacturers to identify a fan capable of delivering the required CFM at the desired fixed force. This ensures that the fan operates efficiently within your system’s parameters. Remember, AMCA certification is crucial as it guarantees that the CFM measurements reflect the actual capabilities of the fan.

By accurately calculating the required CFM and considering the recommended Air Changes Per Hour (ACH) for your specific environment, you can ensure that your fan selection meets the cooling demands of your application, ultimately enhancing performance and reliability.

Assess Static Pressure (SP)

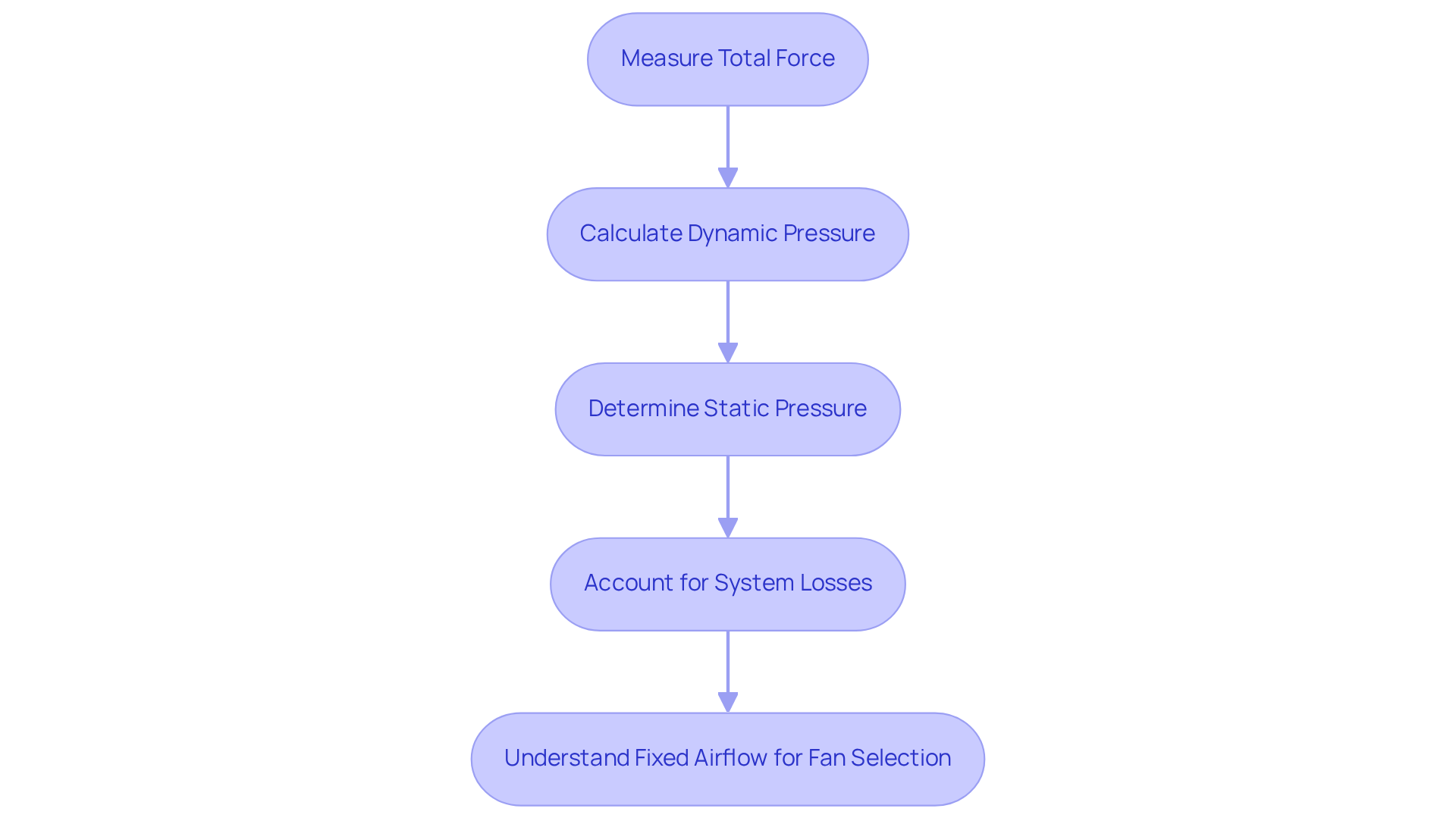

To accurately assess static pressure, follow these essential steps:

-

Measure Total Force: Utilize a manometer to gauge the total force at the fan inlet, which encompasses both stationary and dynamic forces.

-

Calculate Dynamic Pressure: Dynamic pressure can be determined using the formula:

Dynamic Pressure = (Velocity Pressure) = (Air Velocity in FPM)² / (2 x 0.004)

Here, 0.004 is a constant representing air density.

-

Determine Static Pressure: To find the static pressure, subtract the dynamic pressure from the total pressure:

Static Pressure = Total Pressure – Dynamic Pressure

-

Account for System Losses: Factor in any additional losses caused by ductwork, filters, or other components within the system. This consideration will produce a more accurate depiction of the fixed force the fan must overcome.

Understanding fixed airflow is crucial for fan selection that operates effectively within your system’s limitations. For instance, in HVAC systems, a typical goal for total external resistance is approximately 0.5 inches w.g., balancing effective airflow with quiet operation. Contemporary high-efficiency systems can manage fixed forces up to 0.7 to 0.8 inches w.g. without major performance issues. Furthermore, elevated atmospheric force can lead to increased energy usage, illustrated by a 55 percent rise in power consumption when atmospheric force doubles from 0.5 to 1 inch w.g. This can also result in frequent filter changes and earlier motor replacements, common outcomes of high resistance in HVAC systems. By carefully evaluating constant force, engineers can ensure optimal fan efficiency and system reliability.

Consider Air Temperature and Altitude Adjustments

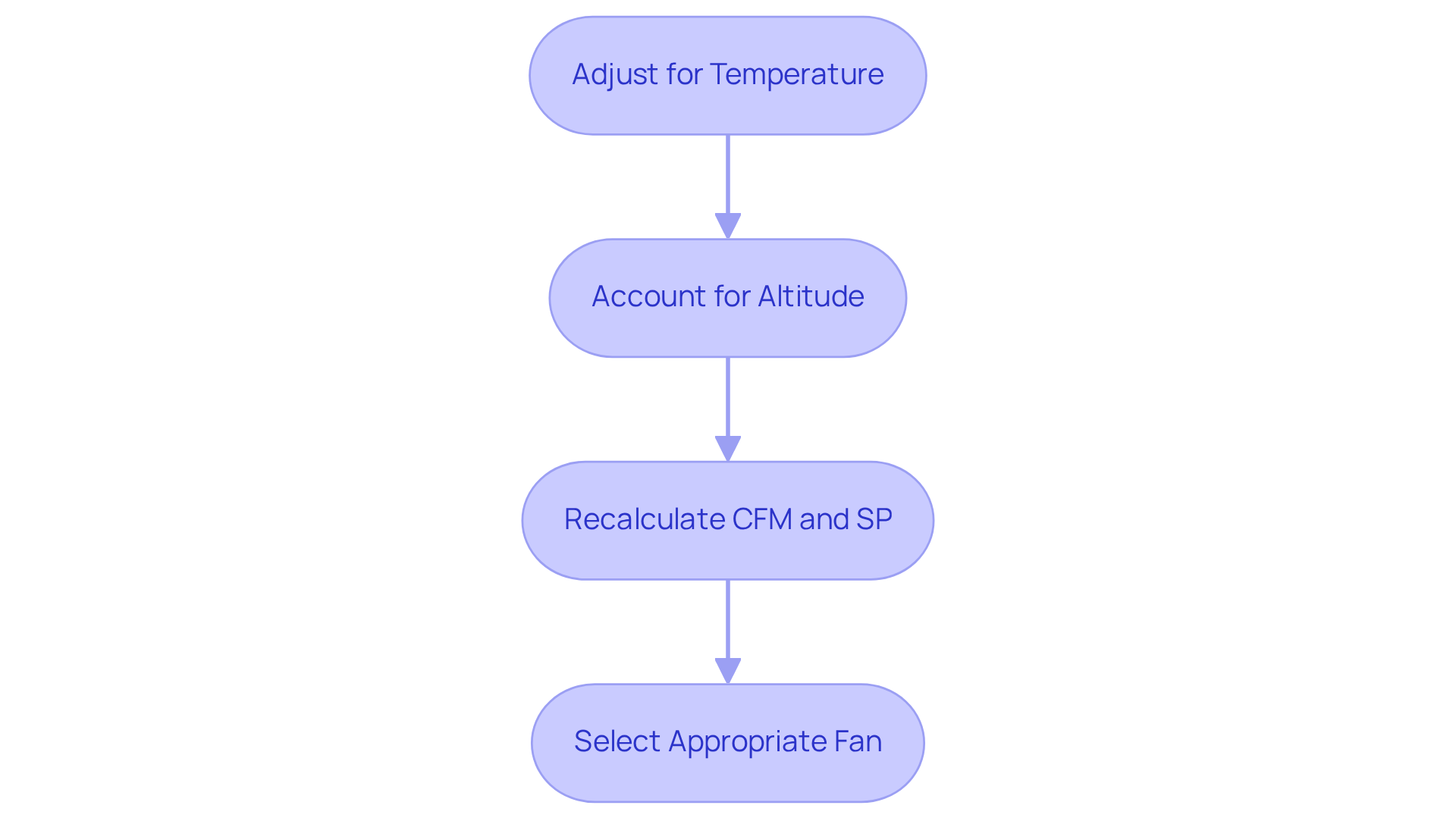

When evaluating air temperature and altitude for fan selection, it’s crucial to follow these guidelines:

-

Adjust for Temperature: Higher temperatures lead to reduced air density, which can adversely impact airflow and fixed force. To refine your calculations based on the operating temperature, utilize correction factors provided by fan manufacturers.

-

Account for Altitude: As altitude increases, air density decreases, resulting in diminished airflow. To ensure precise performance predictions, consult manufacturer specifications for altitude correction factors. At sea level, the density of air is approximately 0.075 lbs/ft³ (1.19 kg/m³), while at 25,000 feet, it drops to about 0.034 lbs/ft³ (0.549 kg/m³).

-

Recalculate CFM and SP: After applying adjustments for temperature and altitude, recalculate the required Cubic Feet per Minute (CFM) and static pressure (SP) to confirm that the fan will meet performance requirements in the specific environment. For example, at sea level, approximately 40 CFM is necessary to remove 340W of heat, while at 25,000 feet, this requirement escalates to about 86 CFM due to reduced air density.

-

Select Appropriate Fan: Choose a fan that can accommodate the recalibrated CFM and SP requirements, ensuring it is rated for the specific temperature and altitude conditions of your application. Regular maintenance of bearings, lubrication, and alignment checks is critical to avoid premature failures, especially in varying environmental conditions.

By considering these environmental influences, you can optimize fan selection to achieve enhanced performance and efficiency in practical applications. As AMETEK Rotron states, “With over 75 years of experience, you can trust AMETEK Rotron for a solution that will meet your application’s needs at any temperature or altitude.

Conclusion

Understanding the intricacies of fan selection is crucial for engineers who aim to optimize cooling solutions across various applications. By concentrating on key metrics such as airflow, air resistance, fan speed, and efficiency ratings, professionals can ensure they select the right fan that meets specific performance requirements. Insights from Gagner-Toomey Associates underscore the importance of these metrics in achieving reliable and efficient cooling, ultimately enhancing system longevity and performance.

The article explores critical aspects like evaluating flow rate and static pressure, which are essential for determining a fan’s suitability in a given environment. By accurately calculating cooling loads, adjusting for temperature and altitude, and consulting manufacturer specifications, engineers can make informed choices that align with their operational needs. Regular maintenance and an understanding of environmental influences further contribute to optimal fan performance, reinforcing the necessity for thorough evaluation during the selection process.

In conclusion, the importance of mastering fan selection metrics cannot be overstated. Engineers must apply these principles to enhance performance and efficiency in their cooling systems. By prioritizing informed decision-making and considering the outlined metrics, professionals can ensure their applications operate effectively under varying conditions, leading to improved reliability and reduced operational costs. Embracing these practices will pave the way for innovative solutions in engineering, highlighting the crucial role of effective fan selection.

Frequently Asked Questions

What are the key metrics to consider when selecting a fan?

The key metrics to consider include Airflow (CFM), Air Resistance (AR), Fan Speed (RPM), and Efficiency Ratings.

What does Airflow (CFM) measure?

Airflow (CFM) measures the volume of air a fan can move, expressed in cubic feet per minute. It is essential for determining if a fan can meet the cooling requirements of an application.

Why is Air Resistance (AR) important in fan selection?

Air Resistance (AR) indicates the force a fan must overcome to move air through a system, measured in inches of water gauge (inWG). It is crucial for ensuring effective fan operation in environments with ducting or filters.

How does Fan Speed (RPM) affect fan performance?

Fan Speed (RPM) influences both airflow and static pressure. Higher RPMs generally increase airflow but may also result in increased noise and energy consumption.

What are Efficiency Ratings, and why do they matter?

Efficiency Ratings assess how effectively a fan converts electrical energy into airflow, impacting operational costs and energy consumption. The Fan Energy Index (FEI) is a key metric, with values over 1 indicating superior performance.

How can regular upkeep affect fan performance?

Regular upkeep, including cleaning and inspecting ventilators, is important for maintaining fan performance and ensuring efficient cooling.

What types of cooling solutions does Gagner-Toomey offer?

Gagner-Toomey offers a wide array of standard and custom cooling solutions, including DC input Tube Axial units and Centrifugal Blowers, to meet specific cooling requirements.