Overview

This article serves as a comprehensive guide for engineers aiming to master air-to-air heat exchangers. These critical devices play a pivotal role in enhancing energy efficiency and improving indoor air quality by effectively transferring thermal energy between exhaust and incoming air. This process is essential for optimizing HVAC systems and achieving substantial energy savings.

Understanding the operation of air-to-air heat exchangers is fundamental. They work by capturing heat from outgoing air and using it to warm incoming air, thereby reducing the energy required for heating and cooling. This not only conserves energy but also contributes to a more comfortable indoor environment.

When selecting an air-to-air heat exchanger, engineers must consider various criteria, including:

- The type of exchanger

- Efficiency ratings

- Compatibility with existing HVAC systems

Different types, such as counterflow and crossflow exchangers, offer unique advantages depending on the specific application. A thorough understanding of these options allows for informed decision-making that aligns with energy efficiency goals.

Maintenance practices are equally crucial. Regular inspections and cleaning ensure optimal performance and longevity of the heat exchangers. Engineers should implement a proactive maintenance schedule to address potential issues before they escalate, thereby safeguarding the efficiency of the HVAC system.

In conclusion, mastering air-to-air heat exchangers is vital for engineers focused on energy efficiency and indoor air quality. By understanding their operation, carefully selecting the appropriate type, and committing to regular maintenance, engineers can significantly enhance HVAC performance and achieve notable energy savings.

Introduction

Understanding the significance of air-to-air heat exchangers is essential for achieving energy efficiency in modern engineering. These innovative devices not only reclaim heat from exhaust air but also improve indoor air quality, making them vital components in HVAC systems. However, with a variety of types and selection criteria to consider, how can engineers ensure they are making the most informed choices for their specific applications?

This guide explores the intricacies of air-to-air heat exchangers, providing insights into their operation, selection, and maintenance. It also addresses the challenges engineers encounter in optimizing these critical systems. By delving into the technical aspects and practical applications, we aim to equip engineers with the knowledge needed to enhance system performance and energy efficiency.

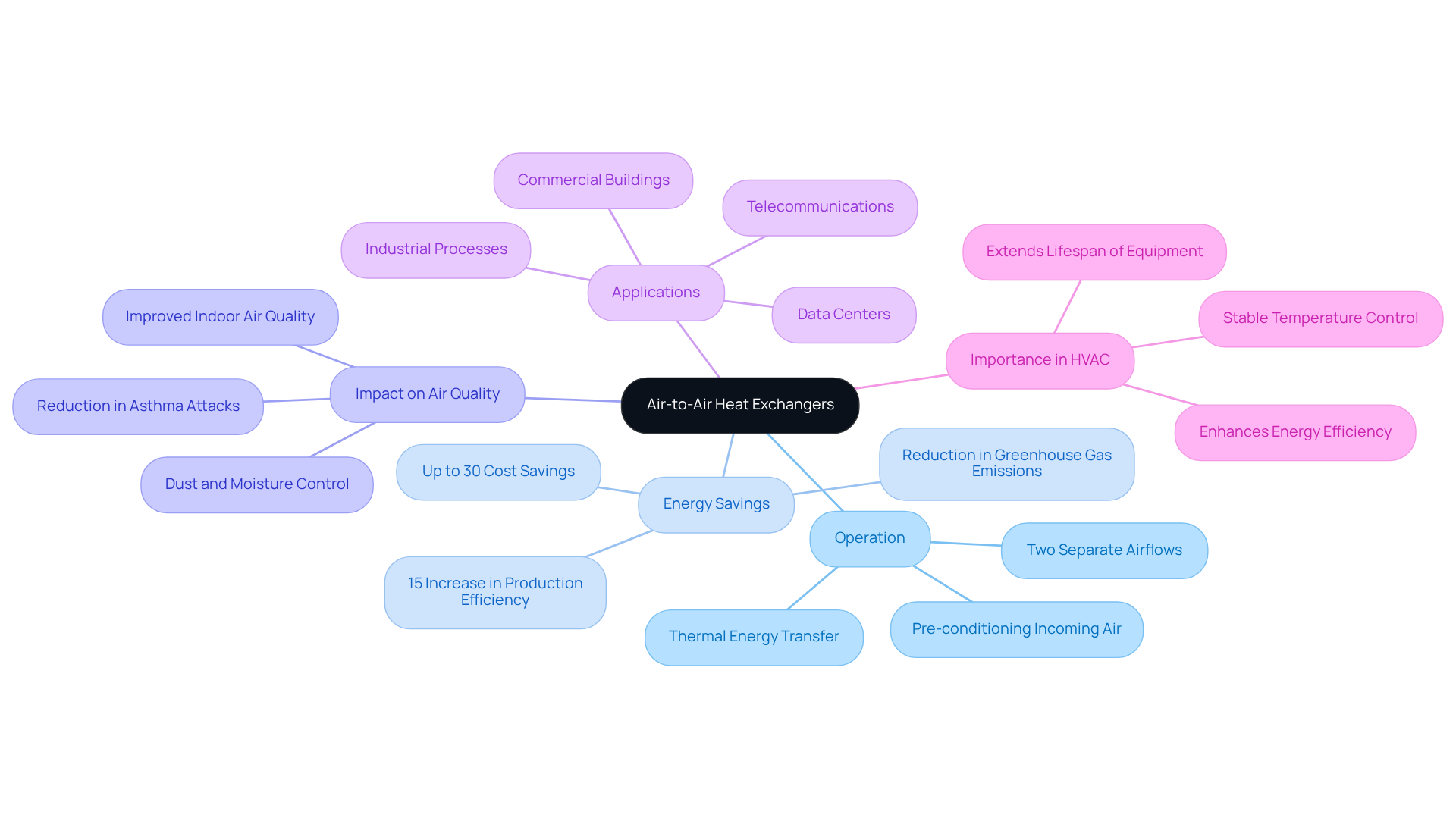

Understand Air-to-Air Heat Exchangers

Heat exchanger air to air devices are specialized instruments designed to facilitate the movement of warmth between two distinct air flows without allowing them to mix. These systems, including the heat exchanger air to air, play a crucial role in HVAC applications by significantly enhancing energy efficiency through reclaiming heat from exhaust air and transferring it to incoming fresh air. This process not only results in substantial energy savings but also improves indoor air quality, making it indispensable for modern engineering designs.

The operation of heat exchanger air to air thermal devices involves two separate airflows: one carrying exhaust air and the other delivering fresh air. As these air flows traverse the heat exchanger air to air, thermal energy is transferred from the warmer exhaust air to the cooler incoming air, effectively pre-conditioning it. This mechanism can yield energy cost savings of up to 30%, alongside a reduction in greenhouse gas emissions by as much as 30%.

In commercial buildings, the implementation of heat exchanger air to air thermal transfer devices has shown a significant improvement in energy performance. Research indicates that integrating these systems can lead to a 15% increase in production efficiency while extending the lifespan of electronic devices by preventing overheating, which can otherwise reduce component durability by up to 50%.

Successful applications of air-to-air thermal devices have been documented across various industries, showcasing their versatility and effectiveness. HVAC specialists emphasize the importance of these systems in achieving energy efficiency goals, with one expert noting that ‘the incorporation of heat exchanger air to air devices into HVAC units enhances reliability by ensuring stable temperature control.’ This underscores the vital role these devices play in optimizing thermal management solutions, particularly in environments where electronic components are sensitive to temperature variations.

In summary, understanding the principles and benefits of air-to-air thermal devices is essential for engineers aiming to implement efficient temperature control strategies in their designs.

Identify Key Selection Criteria

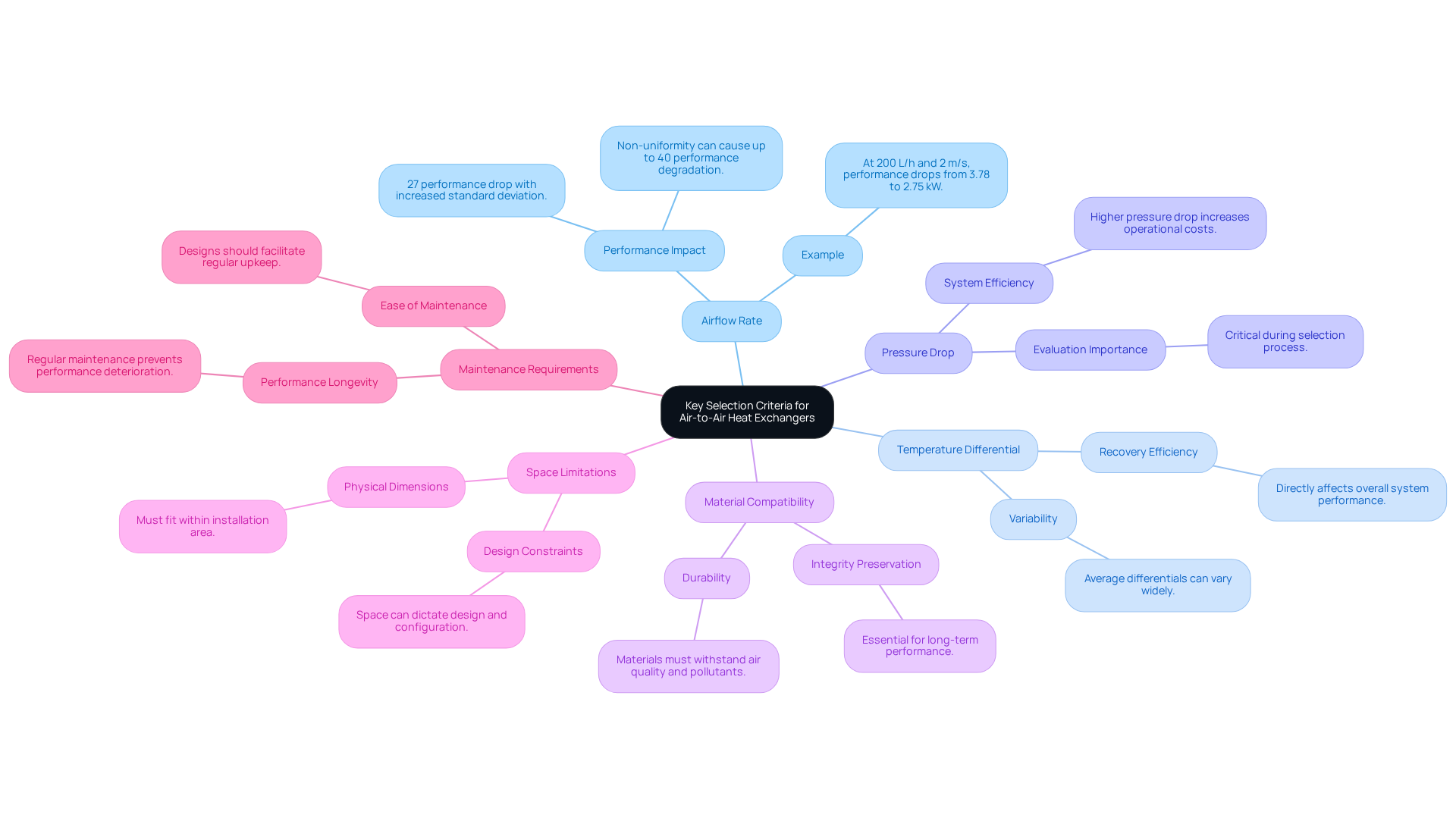

When selecting an air-to-air heat exchanger, engineers must consider several key criteria that can significantly impact performance and efficiency:

-

Airflow Rate: It’s essential to determine the necessary airflow rate for the application, as this greatly influences the dimensions and type of thermal transfer device required. Studies show that airflow non-uniformity can lead to performance degradation of up to 40%, making accurate airflow assessment crucial. For example, at a water flow rate of 200 L/h and a mean airflow velocity of 2 m/s, increasing the standard deviation of airflow velocity distribution from 0 to 2 m/s can result in a total performance deterioration of 27%.

-

Temperature Differential: Assessing the temperature variation between incoming and outgoing air streams is vital, as it directly affects recovery efficiency. Average temperature differentials can vary widely, impacting overall system performance.

-

Pressure Drop: Evaluating the pressure loss across the thermal device is critical, as it can significantly affect system efficiency and energy usage. Engineers often find that a higher pressure drop leads to increased operational costs, necessitating careful evaluation during selection.

-

Material Compatibility: Ensuring that the materials used in the thermal device are suitable for the air quality and any pollutants present is essential for preserving the integrity and durability of the device.

-

Space Limitations: It’s important to consider the physical dimensions of the thermal device to ensure it fits within the available installation area. Space constraints can dictate the choice of design and configuration.

-

Maintenance Requirements: Opt for designs that facilitate easy maintenance to ensure long-term performance and reliability. Regular upkeep is crucial, as it can prevent performance deterioration and extend the lifespan of the unit.

By thoroughly assessing these criteria, engineers can select the most appropriate heat exchanger air to air thermal device for their specific applications, ensuring optimal performance and energy conservation. The importance of energy conservation is underscored by the experimental energy recovering air-conditioner (EAC), which achieved an Energy Efficiency Ratio (EER) increase from 17.4% to 37.3% compared to standard window-type air-conditioners. This highlights the necessity for effective thermal transfer devices in contemporary applications. As noted by Yanming Kang, energy consumption is a pressing issue in China, making these considerations even more critical.

Evaluate Different Types of Air-to-Air Heat Exchangers

Heat exchanger air to air are essential components in HVAC systems, designed to optimize energy efficiency across various applications. Understanding the different types available can significantly impact performance and operational costs. Here’s a closer look at the main types:

-

Plate Thermal Devices: These units consist of several thin plates that facilitate effective thermal transfer between air streams. Their compact design makes them ideal for installations with limited space. With thermal efficiencies ranging from 60% to 90%, plate thermal devices present an economical solution for reducing heating and cooling demands in HVAC systems.

-

Rotary Thermal Devices: Utilizing a rotating wheel, these devices transfer warmth and moisture between air streams, achieving energy recovery rates of up to 80%. They are particularly advantageous in humid environments where moisture recovery is critical. Although they come with higher initial costs and maintenance needs, rotary heat recovery devices provide substantial long-term energy savings.

-

Tube Heat Receptors: Featuring a series of tubes for air flow, these robust devices can handle higher pressures and temperatures. They are well-suited for industrial applications, especially in environments with high particle concentrations, such as dryers and ovens.

-

Crossflow Heat Exchangers: This design allows two air streams to intersect at right angles, making them suitable for applications where space is constrained. Typically, they achieve thermal performance levels between 50% and 70% and are often more affordable than rotary wheel devices, offering a budget-friendly option for diverse industrial needs.

-

Counterflow Heat Exchangers: In this configuration, air streams move in opposite directions, optimizing thermal transfer performance. Counterflow systems are frequently preferred for applications requiring high thermal efficiency, as they can achieve superior energy recovery compared to other designs.

By evaluating these varieties, engineers can make informed decisions to select the most appropriate thermal device for their specific applications, balancing performance, spatial constraints, and operational costs.

Ensure Optimal Maintenance and Efficiency

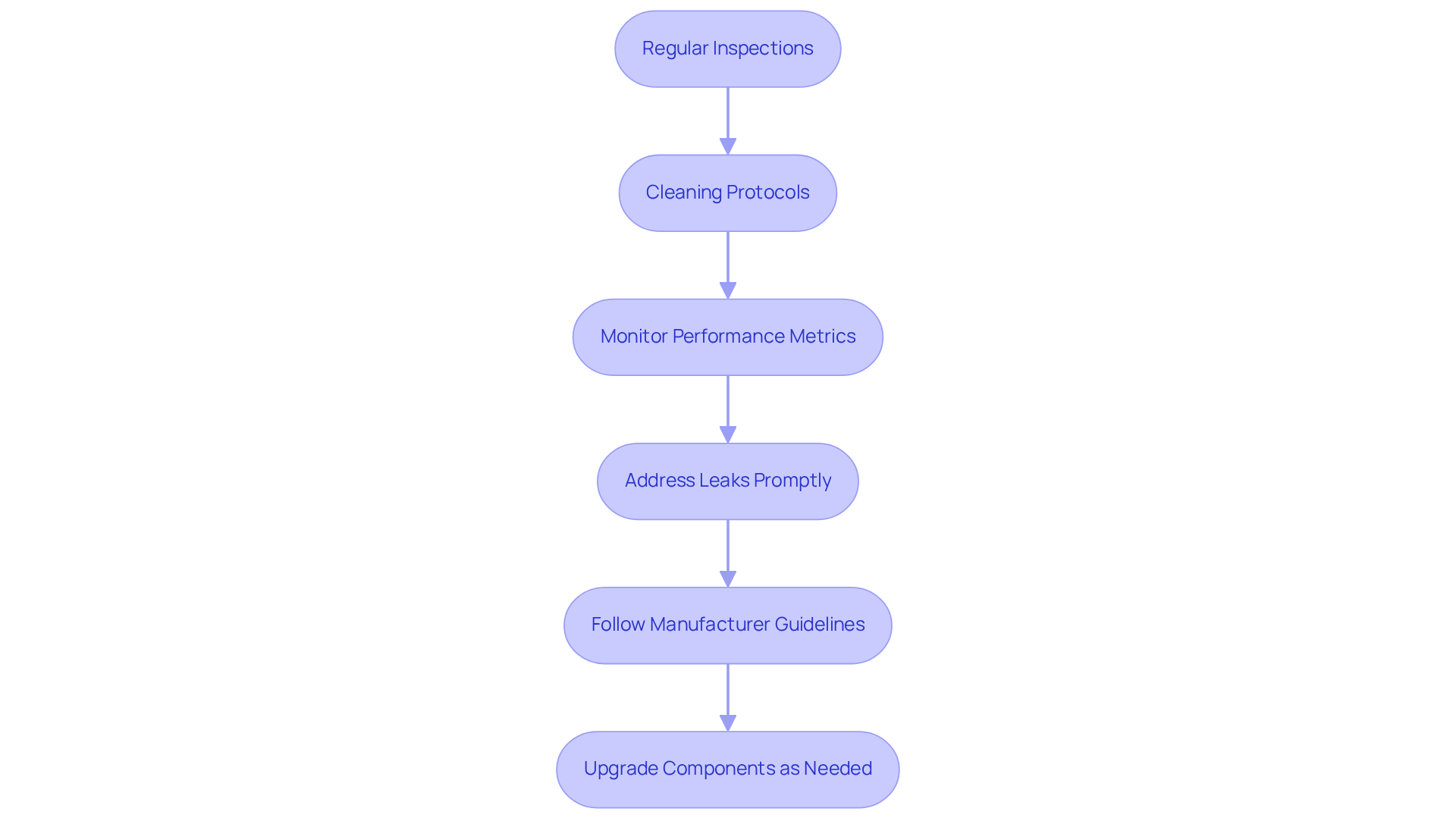

To maintain optimal performance of air-to-air heat exchangers, engineers must adhere to essential maintenance practices:

-

Regular Inspections: Conduct routine inspections at recommended frequencies—monthly for basic checks, quarterly for detailed inspections, and annually for comprehensive evaluations. This approach helps identify signs of wear, corrosion, or fouling that could hinder performance. Routine inspections can uncover problems such as leaks or blockages, which are crucial for preserving efficiency.

-

Cleaning Protocols: Establish a cleaning schedule that incorporates methods like mechanical cleaning, chemical cleaning, and hydroblasting. These techniques effectively remove dust and debris from the exchanger surfaces. Thorough cleaning is vital, as fouling can significantly reduce thermal transfer performance and lead to increased energy consumption.

-

Monitor Performance Metrics: Track key performance indicators such as temperature differentials, pressure drops, and airflow rates. Monitoring these metrics allows for early detection of deviations from expected performance, enabling timely interventions. As HVAC professionals emphasize, “Regular maintenance can prevent costly breakdowns and extend the lifespan of your equipment.”

-

Address Leaks Promptly: Inspect for and repair any leaks in the system immediately. Leaks can lead to efficiency losses and pose safety risks, including hazardous fluid leaks or overheating. Prompt action is crucial for maintaining operational integrity.

-

Follow Manufacturer Guidelines: Adhere to the manufacturer’s maintenance recommendations. Compliance with these guidelines ensures optimal performance and helps maintain warranty coverage, safeguarding your investment in the equipment.

-

Upgrade Components as Needed: Consider upgrading to more efficient components or technologies as they become available. System upgrades can enhance performance and reliability, ensuring that thermal devices meet evolving operational requirements.

Implementing these maintenance strategies not only ensures that heat exchanger air to air operates efficiently but also helps to extend their lifespan. This ultimately contributes to improved system performance and reduced operational costs.

Conclusion

Understanding and implementing air-to-air heat exchangers is essential for engineers focused on enhancing energy efficiency in HVAC systems. These devices not only enable effective thermal energy transfer between air streams but also significantly contribute to energy savings and improved indoor air quality. By optimizing the use of exhaust heat, air-to-air heat exchangers are indispensable in modern engineering designs.

When selecting the right air-to-air heat exchanger, key considerations include:

- Airflow rate

- Temperature differential

- Pressure drop

- Material compatibility

- Space limitations

- Maintenance requirements

Each of these factors can greatly influence system performance and efficiency. Evaluating different types of heat exchangers—such as plate, rotary, tube, crossflow, and counterflow—equips engineers with a comprehensive understanding of how to best meet specific application needs while balancing operational costs.

The importance of regular maintenance cannot be overstated. By adhering to best practices for inspections, cleaning, and performance monitoring, engineers can ensure their heat exchangers operate at peak efficiency, extending their lifespan and reducing overall energy costs. As the demand for energy-efficient solutions continues to grow, leveraging the benefits of air-to-air heat exchangers will be paramount in driving advancements in HVAC technology and promoting sustainable engineering practices.

Frequently Asked Questions

What are air-to-air heat exchangers?

Air-to-air heat exchangers are specialized devices designed to transfer warmth between two distinct air flows without allowing them to mix, playing a crucial role in enhancing energy efficiency in HVAC applications.

How do air-to-air heat exchangers improve energy efficiency?

They reclaim heat from exhaust air and transfer it to incoming fresh air, which leads to substantial energy savings, potentially reducing energy costs by up to 30% and lowering greenhouse gas emissions by the same percentage.

What is the operational mechanism of air-to-air heat exchangers?

They operate by having one airflow carry exhaust air and another deliver fresh air, allowing thermal energy to transfer from the warmer exhaust air to the cooler incoming air, effectively pre-conditioning it.

What benefits do air-to-air heat exchangers provide in commercial buildings?

Implementing these systems can improve energy performance by 15%, increase production efficiency, and extend the lifespan of electronic devices by preventing overheating, which can reduce component durability by up to 50%.

Why are air-to-air heat exchangers important for HVAC systems?

They enhance reliability by ensuring stable temperature control, which is vital for optimizing thermal management solutions, especially in environments sensitive to temperature variations.

In what industries have air-to-air thermal devices been successfully applied?

They have been documented across various industries, showcasing their versatility and effectiveness in improving energy efficiency and thermal management.