Overview

This article delves into the mechanics, applications, and selection criteria for high airflow fans, underscoring their critical role in effective cooling solutions across diverse industries. High airflow fans are not just components; they are essential tools that influence performance through airflow dynamics, static pressure, and innovative fan design.

In sectors such as HVAC, automotive, and electronics, the specific cooling needs are paramount. Understanding how these factors interplay is crucial for achieving optimal temperature regulation and energy efficiency. Selecting the right fan is not merely a choice; it is a decisive factor that can enhance operational effectiveness and reduce energy costs.

By examining case studies and technical data, this article provides insights into how the right fan selection can lead to significant improvements in system performance. The importance of these fans cannot be overstated, as they serve as the backbone of cooling systems that support critical operations.

In conclusion, the selection of high airflow fans should be approached with careful consideration of their design and application. This ensures that industries can maintain efficiency and reliability in their cooling solutions.

Introduction

High airflow fans are not merely components; they play a crucial role in the intricate process of temperature regulation across various industries. With technological advancements and an increasing demand for efficient cooling solutions, it’s essential for engineers and decision-makers to grasp the mechanics and applications of these fans.

What challenges do you face when selecting the right fan for your specific needs? How can you navigate the complexities of airflow dynamics to ensure optimal performance?

This article explores the mechanics, applications, and selection criteria for high airflow fans, equipping you with the knowledge necessary to make informed choices in your cooling strategies.

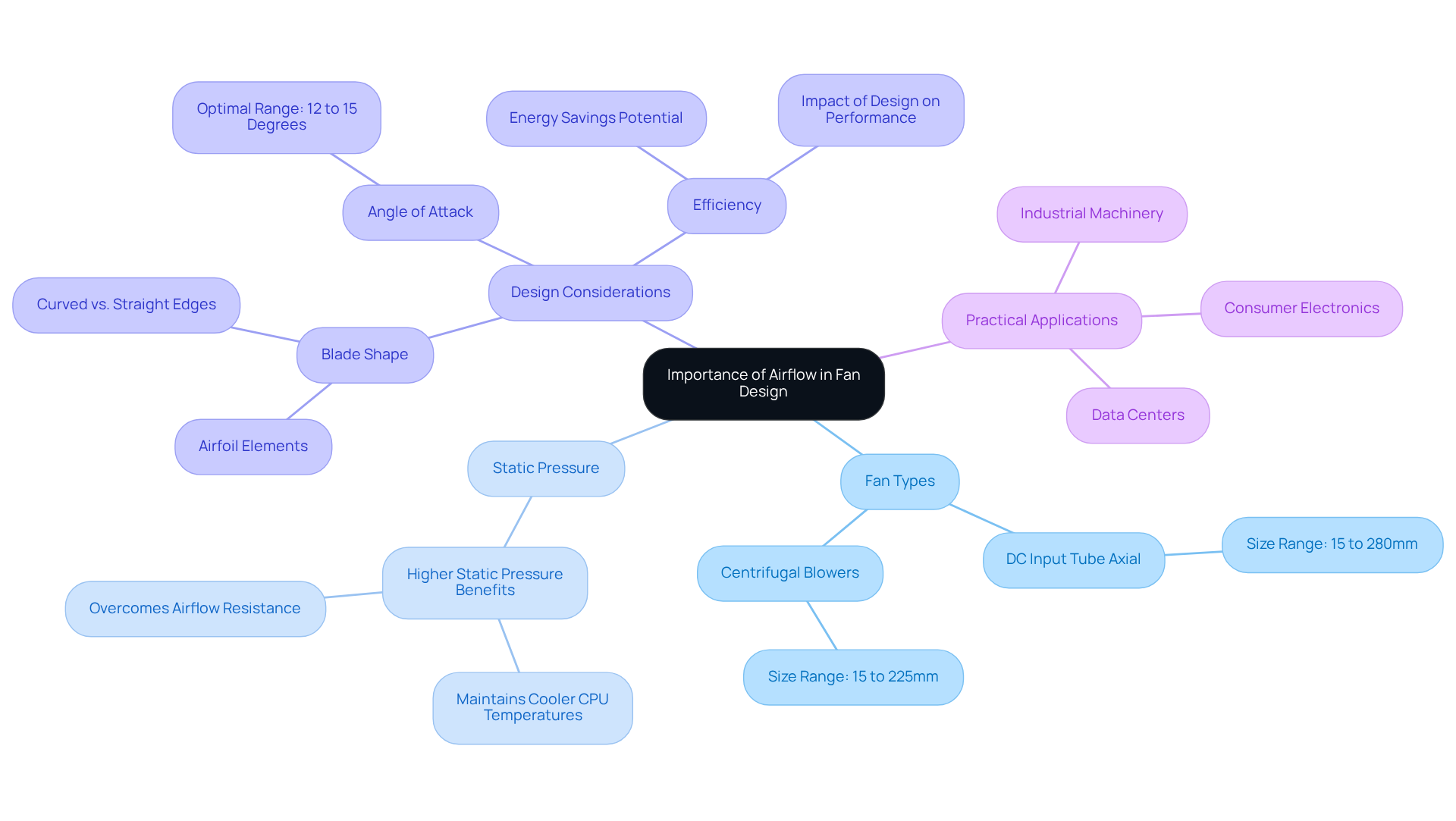

Explore the Importance of Airflow in Fan Design

Airflow is a critical factor in fan design, directly influencing the efficiency of temperature regulation for electronic components and maintaining optimal operating temperatures. High airflow fans, like those provided by Gagner-Toomey Associates, are essential in environments where heat dissipation is crucial, such as data centers, industrial machinery, and consumer electronics. For example, devices with a higher Cubic Feet per Minute (CFM) rating are engineered to move larger volumes of air, which is essential for effective cooling. Gagner-Toomey’s extensive product range includes:

- DC input Tube Axial units ranging from 15 to 280mm

- Centrifugal Blowers from 15 to 225mm

All enhanced for performance and efficiency, making them suitable for a variety of applications. Additionally, most models provide IP protection upon request, further enhancing their adaptability to diverse environments.

Static pressure is another vital consideration; fans that maintain higher static pressure can cool components more effectively by overcoming resistance in the airflow path. Gagner-Toomey’s innovative designs, featuring airfoil elements, significantly enhance efficiency by minimizing drag, establishing them as the gold standard for energy-saving applications.

Understanding ventilation dynamics is crucial for engineers when selecting the appropriate fan for specific applications. The design of the fan blades, including their shape and pitch, directly impacts the efficiency of air movement. For instance, an optimal blade angle of attack between 12 to 15 degrees can improve air movement while reducing energy consumption. Moreover, practical applications demonstrate that optimizing the supply angle of air can lead to more consistent temperature management and energy savings, as evidenced by studies evaluating air distribution in multi-occupancy office spaces.

Ultimately, selecting the right high airflow fans from Gagner-Toomey Associates is essential for achieving effective cooling solutions in electronic systems, ensuring efficient and reliable operation.

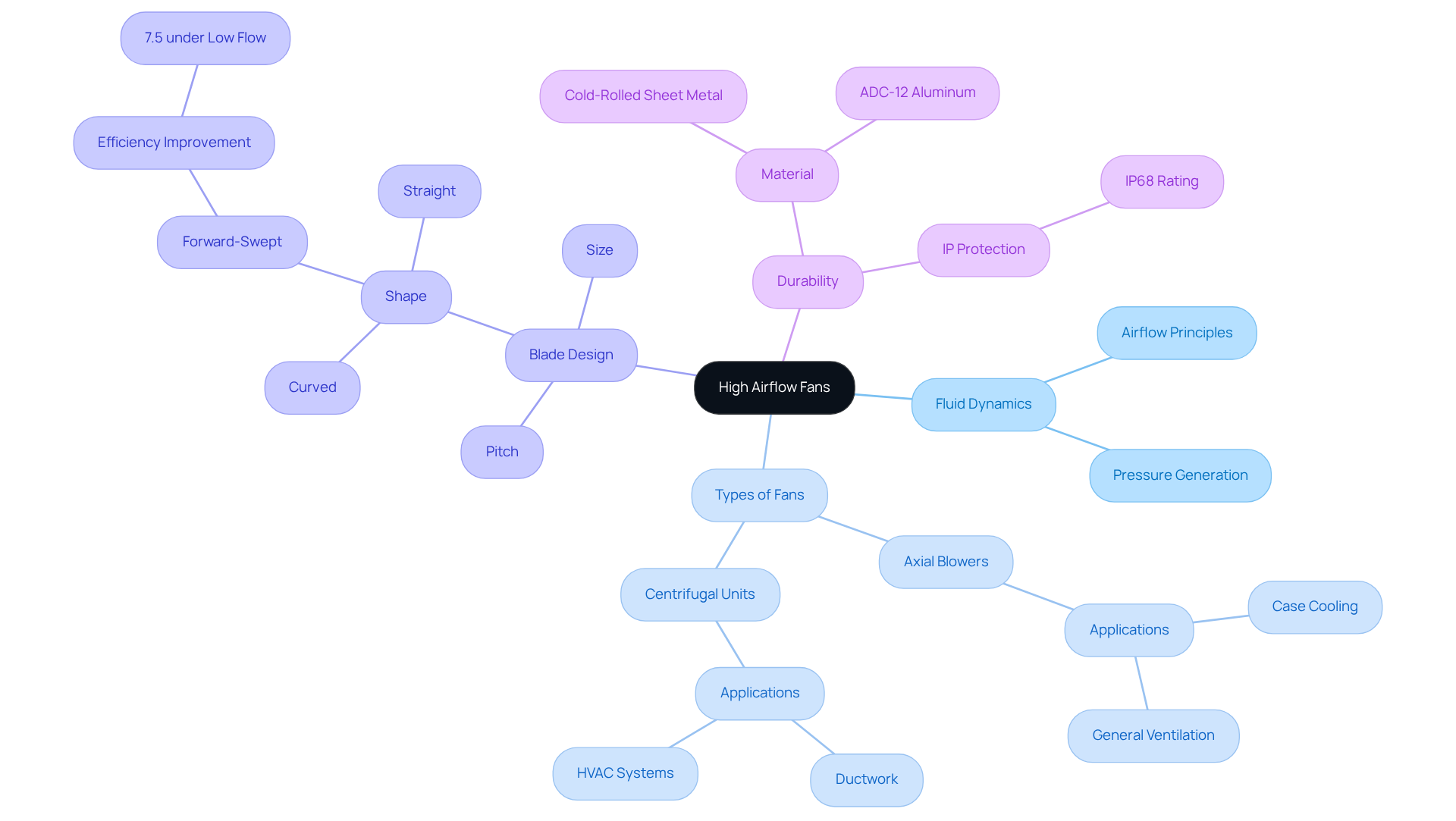

Understand the Mechanics of High Airflow Fans

High airflow fans play a crucial role in enhancing air circulation and minimizing resistance through the application of fluid dynamics principles. Gagner-Toomey Associates stands as the world’s largest producer of both standard and custom air-movers, offering an extensive range of DC input tube axial devices and centrifugal blowers. These products vary in size from 15 to 910mm and are meticulously optimized for performance, efficiency, and low noise levels.

The design of the blades—encompassing their shape, pitch, and size—significantly influences the fan’s air movement capacity. For example, axial blowers facilitate air movement parallel to the unit’s axis, making them ideal for high-volume applications. In contrast, centrifugal units generate pressure to propel air through ducts, excelling in systems that demand greater static pressure. Research shows that forward-swept blades can enhance fan efficiency by up to 7.5% under low flow conditions, underscoring the critical role of blade design in maximizing performance.

Moreover, the effectiveness of equal-variable circulation design blades is nearly identical to that of blades from equal and variable design methods. However, total pressure can be improved by 4%, further emphasizing the importance of blade optimization in achieving desired flow and pressure outcomes. Gagner-Toomey also provides advanced thermal management solutions, including extruded aluminum heatsinks and integrated temperature regulation systems. This ensures engineers can select high airflow fans tailored to their specific air movement and pressure requirements.

Durability is another key aspect, with blades crafted from cold-rolled sheet metal that maintain their shape over time. The frame or casing contributes structural rigidity and minimizes vibration. Additionally, many models offer IP protection upon request, enhancing their adaptability to various environments. By understanding these principles, engineers are empowered to make informed decisions when selecting devices that meet the diverse needs of electronics thermal management, automotive, telecom, and industrial applications.

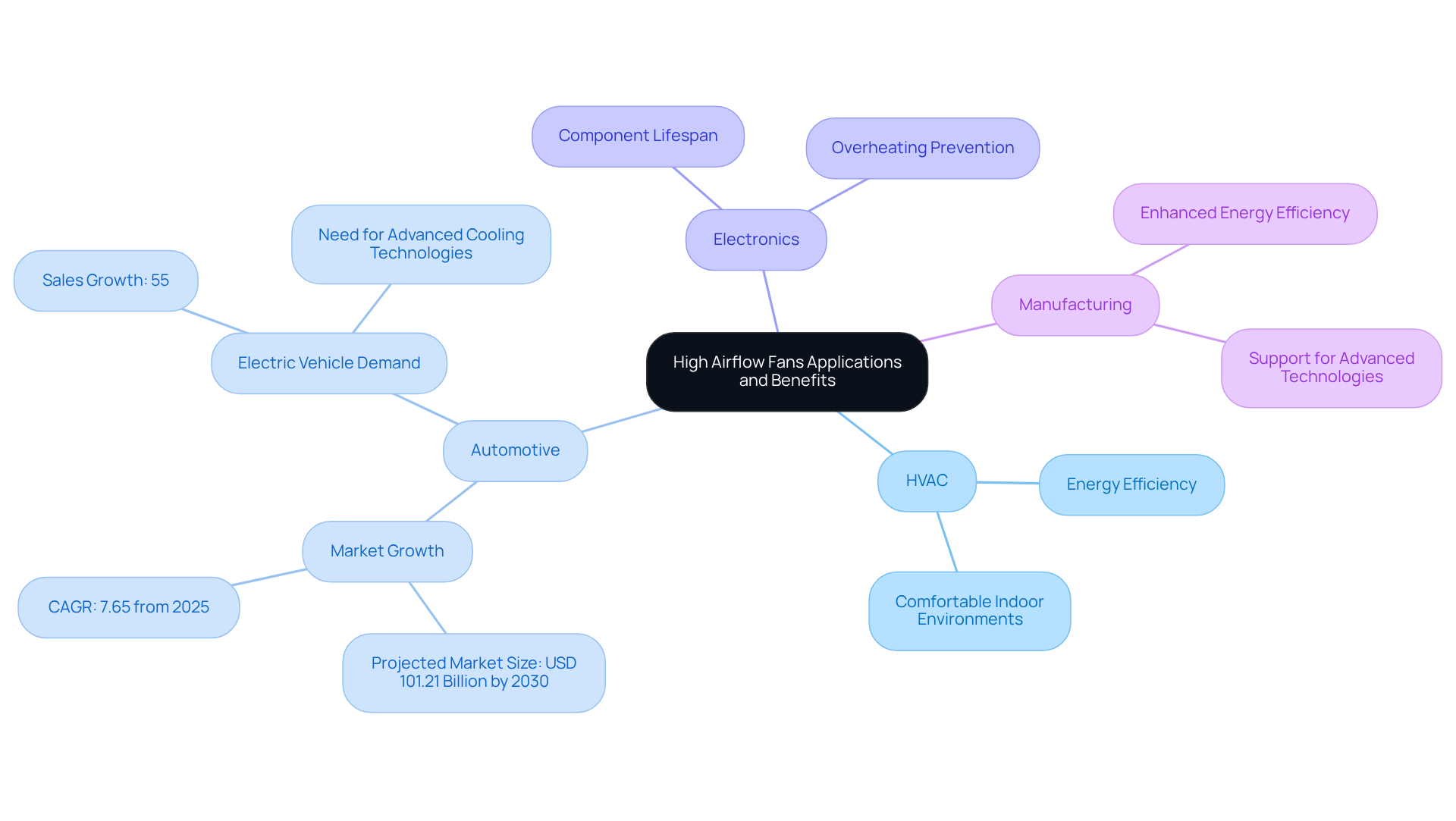

Identify Applications and Benefits of High Airflow Fans in Industry

High-capacity ventilators play a vital role across multiple industries, including HVAC, automotive, electronics, and manufacturing. In HVAC systems, they are crucial for efficiently circulating air, ensuring comfortable indoor environments. The automotive sector, especially with the rise of electric vehicles, depends on high airflow fans to regulate engines and maintain optimal temperatures, effectively addressing the increased heat generated by both engines and battery systems.

Statistics indicate that the automotive fan market is projected to reach USD 101.21 billion by 2030, growing at a compound annual growth rate (CAGR) of 7.65% from 2025. This underscores the pressing need for effective temperature regulation solutions. Furthermore, electric vehicle sales have surged by 55%, further highlighting the demand for advanced cooling technologies in this sector.

In electronics, high-velocity ventilators are essential for preventing component overheating, which ensures reliability and extends the lifespan of devices. The advantages of utilizing high-volume ventilators include enhanced energy efficiency, particularly as the transition from mechanical to electric models reduces parasitic losses and facilitates precise thermal regulation. These benefits position high-performance blowers as a strategic investment for any industry reliant on effective temperature control, especially as technological advancements continue to evolve thermal requirements.

However, it is crucial to acknowledge the challenges faced by the automotive fan market, such as increased power consumption associated with sophisticated temperature regulation systems, which could hinder overall growth. Despite these obstacles, the demand for high-flow fans remains strong, driven by the increasing complexity of temperature management in modern applications.

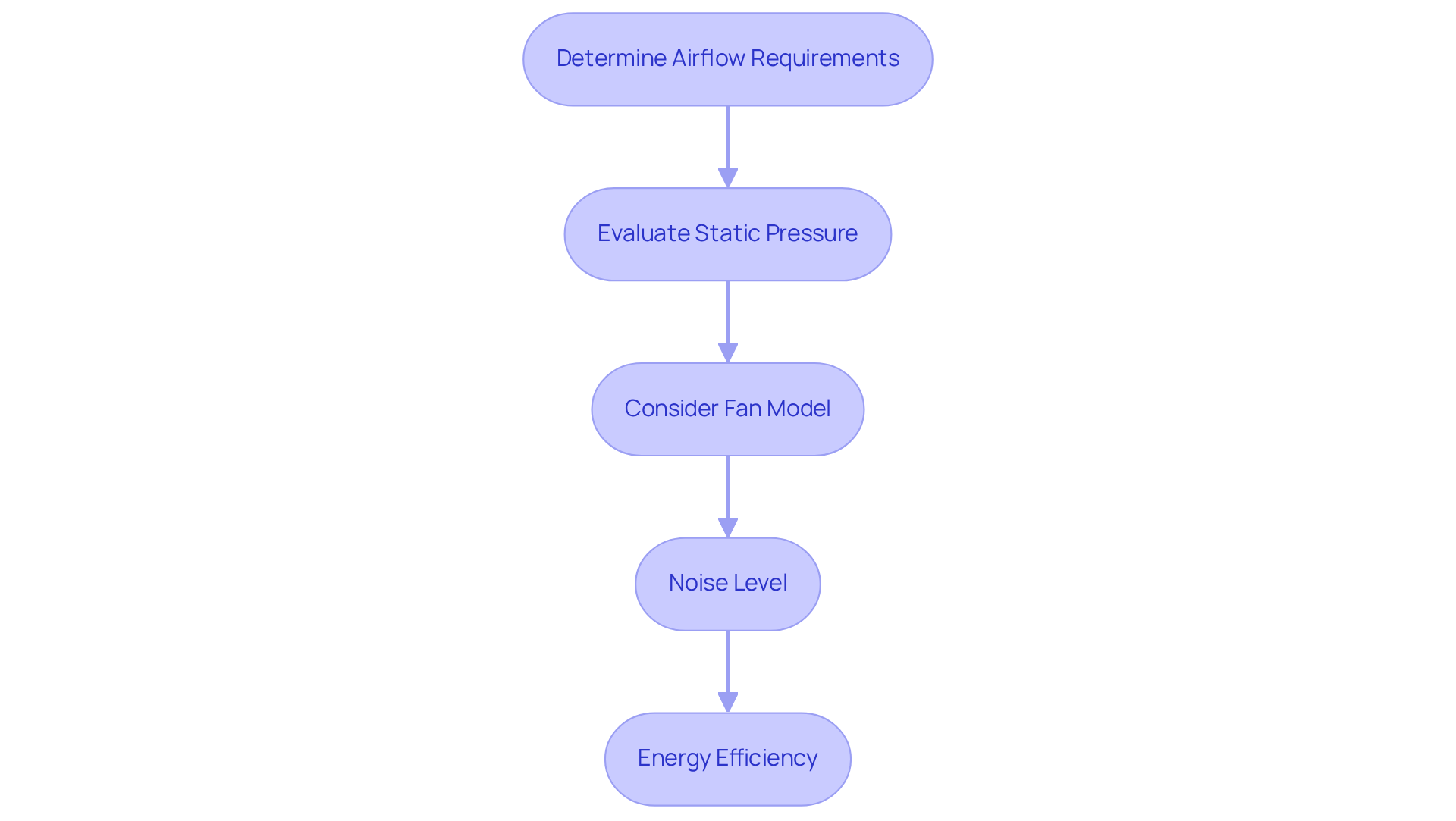

Select the Right High Airflow Fan for Your Needs

Selecting the appropriate high airflow fan requires careful consideration of several key factors:

-

Determine Airflow Requirements: Start by calculating the necessary CFM (Cubic Feet per Minute) for your application. Assess the size of the space and specific cooling needs. For instance, a 2000 ft² residence with a 14 ft ceiling requires approximately 1866.7 CFM to maintain adequate ventilation.

-

Evaluate Static Pressure: Understand the resistance to airflow within your system, as this significantly influences fan selection. Static pressure is impacted by components like filters and coils; notably, a 10% reduction in RPM can lead to a 19% decline in static pressure, which can hinder air movement.

-

Consider Fan Model: Choose between axial and centrifugal models based on your ventilation and pressure requirements. Axial blowers excel in scenarios needing high airflow at low pressure, while centrifugal units are preferred for high-pressure environments, making them ideal for settings such as server rooms.

-

Noise Level: Assess the acceptable noise levels for your application. Some devices are designed for quieter operation, which is crucial in environments like home entertainment centers or offices.

-

Energy Efficiency: Opt for devices that provide energy-efficient performance to minimize long-term operational costs. Fans with a Fan Efficiency Index (FEI) greater than 1 are typically more efficient, ensuring superior performance while consuming less energy. According to AMCA Standard 205, it is advisable to select fans with no more than a 15-percentage-point deviation below the fan’s total peak efficiency.

By thoroughly evaluating these considerations, you can select a high airflow fan that enhances overall system performance while also meeting your operational requirements.

Conclusion

High airflow fans are essential across various industries, delivering crucial cooling solutions that significantly enhance performance and reliability. By grasping the mechanics behind these fans—such as airflow dynamics and blade design—engineers can make informed selections tailored to specific applications. Recognizing the pivotal role of airflow in fan design and understanding the impact of static pressure enables users to optimize their systems for maximum efficiency.

Selecting the right high airflow fan hinges on several factors, including airflow requirements, static pressure, model type, noise levels, and energy efficiency. As temperature management becomes increasingly complex in sectors like HVAC, automotive, and electronics, the demand for high-performance blowers continues to rise. The insights provided here serve as a valuable guide for navigating the intricacies of fan selection and application.

In conclusion, the significance of high airflow fans transcends mere temperature control; they are vital components that drive efficiency and sustainability in modern systems. As industries evolve and technology advances, prioritizing the right fan selection can lead to substantial energy savings and improved operational performance. Embracing these insights facilitates better decision-making, ensuring that systems remain reliable and efficient in the face of changing demands.

Frequently Asked Questions

Why is airflow important in fan design?

Airflow is critical in fan design as it directly influences the efficiency of temperature regulation for electronic components and helps maintain optimal operating temperatures.

In what environments are high airflow fans essential?

High airflow fans are essential in environments where heat dissipation is crucial, such as data centers, industrial machinery, and consumer electronics.

What does a higher Cubic Feet per Minute (CFM) rating indicate?

A higher CFM rating indicates that a fan is engineered to move larger volumes of air, which is essential for effective cooling.

What types of fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers DC input Tube Axial units ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm.

How can static pressure affect fan performance?

Fans that maintain higher static pressure can cool components more effectively by overcoming resistance in the airflow path.

What design features enhance the efficiency of Gagner-Toomey fans?

Gagner-Toomey’s innovative designs include airfoil elements that minimize drag, significantly enhancing efficiency and establishing them as the gold standard for energy-saving applications.

What factors should engineers consider when selecting a fan?

Engineers should consider ventilation dynamics, including the design of the fan blades, their shape, pitch, and the optimal blade angle of attack (between 12 to 15 degrees) to improve air movement and reduce energy consumption.

How can optimizing the supply angle of air benefit cooling solutions?

Optimizing the supply angle of air can lead to more consistent temperature management and energy savings, as demonstrated by studies evaluating air distribution in multi-occupancy office spaces.

Why is it important to select the right high airflow fans?

Selecting the right high airflow fans is essential for achieving effective cooling solutions in electronic systems, ensuring efficient and reliable operation.