Overview

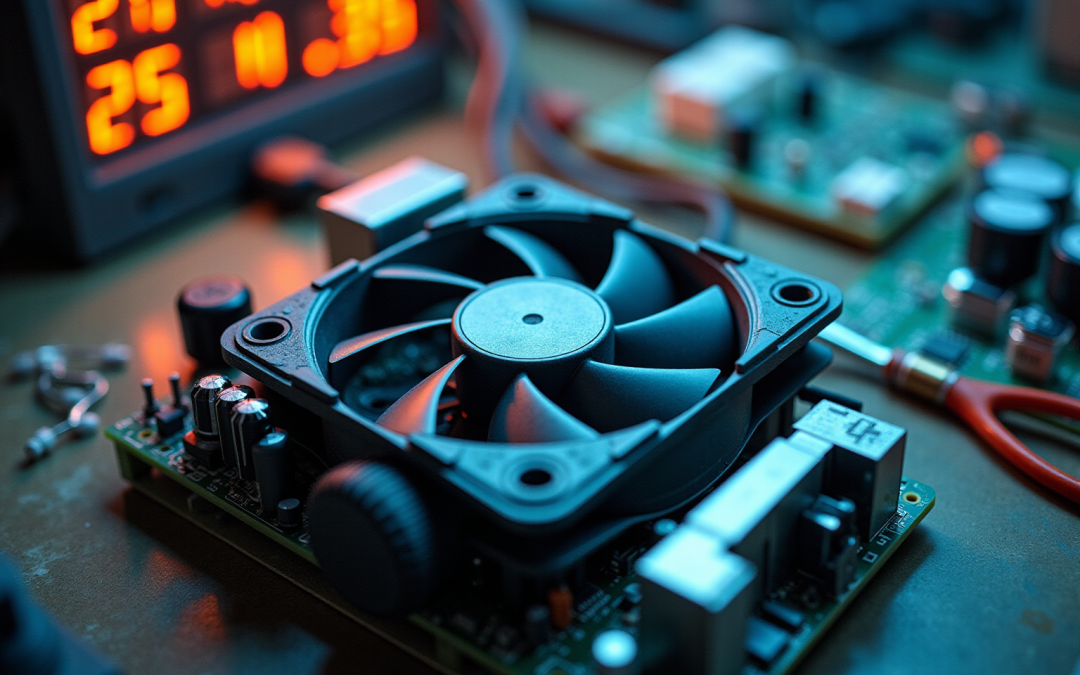

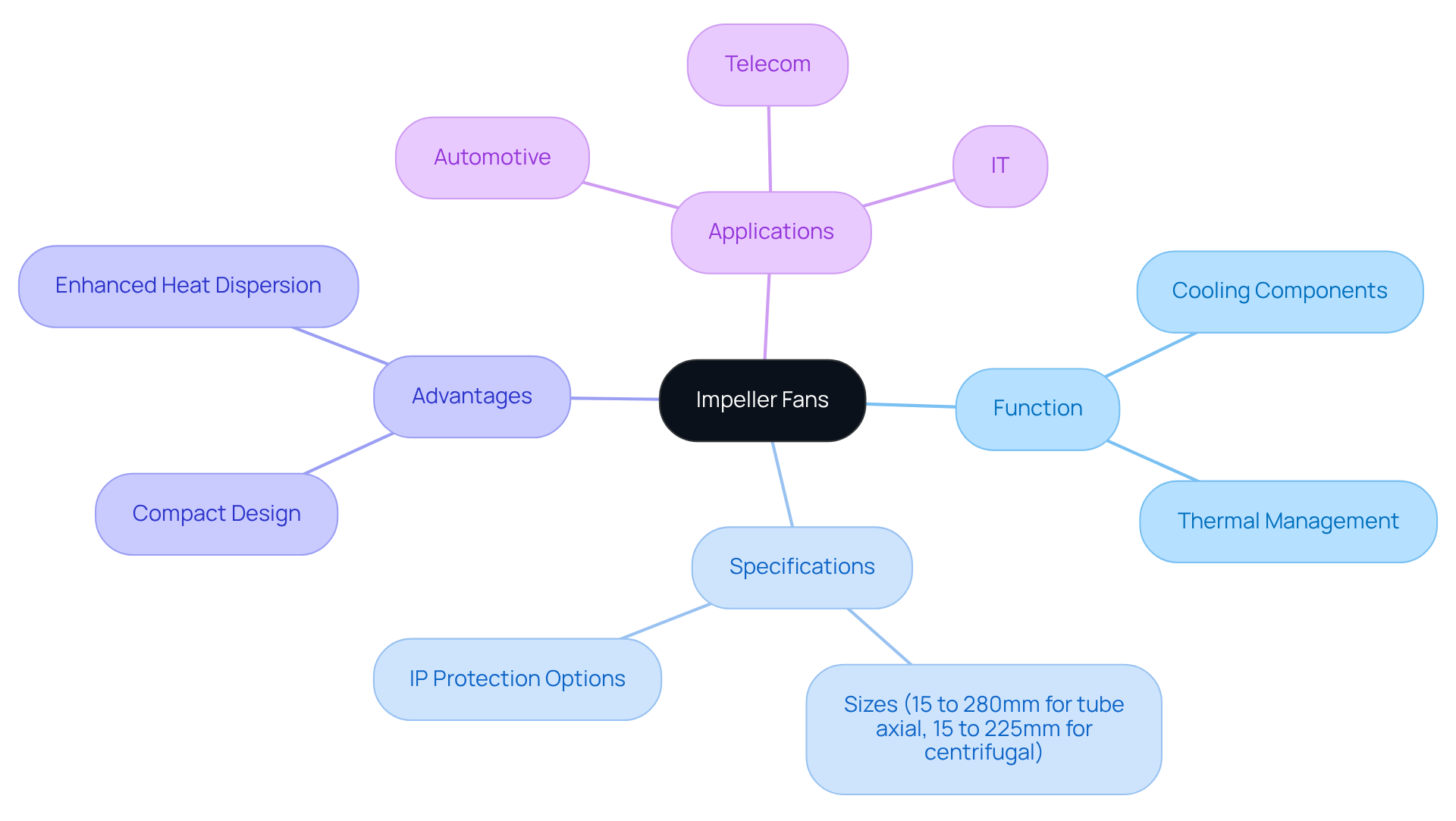

This article provides essential insights for electronics engineers about impeller fans, which play a critical role in cooling and thermal management within electronic systems. Impeller fans offer several advantages, including high efficiency, low noise, and a compact design, making them ideal for various applications. Understanding these benefits is crucial for engineers looking to enhance system performance.

When selecting impeller fans, engineers must consider factors such as airflow requirements, pressure specifications, and noise levels. By carefully evaluating these parameters, they can ensure optimal integration into electronic applications. Furthermore, the article offers guidance on best practices for integrating these fans, which can significantly improve both performance and reliability.

In conclusion, mastering the selection and integration of impeller fans is vital for electronics engineers aiming to optimize their systems. By leveraging the advantages of these fans, engineers can achieve superior cooling solutions that meet the demands of modern electronic applications.

Introduction

Impeller fans play a crucial role in electronics, where effective thermal management is vital for both device performance and longevity. These specialized components not only facilitate airflow but also enhance energy efficiency, making them essential for engineers aiming to optimize cooling systems. Yet, with a variety of types and operational mechanics available, how does one identify the best impeller fan for a specific application?

By delving into the intricacies of impeller fan design and functionality, we can uncover the keys to mastering these indispensable devices in electronic systems. Understanding the unique characteristics and operational principles of different impeller fans will empower engineers to make informed decisions, ensuring optimal performance and reliability in their applications.

Define Impeller Fans and Their Role in Electronics

Impeller fans are specialized devices engineered to move air or fluids through a system, utilizing a rotating impeller to generate airflow. These devices play a crucial role in electronics, essential for cooling components, managing thermal conditions, and ensuring optimal performance. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, provides an extensive range of DC input tube axial devices and centrifugal blowers, all optimized for performance, efficiency, and low noise.

Available in sizes from 15 to 280mm for tube axial types and 15 to 225mm for centrifugal blowers, most models also offer IP protection upon request. Unlike conventional devices, turbine systems excel in confined spaces, effectively directing currents where needed—an essential feature for energy regulation and cooling setups. Their compact design allows for seamless installation in modern electronic devices, where space is often at a premium.

Engineers emphasize that turbine devices significantly enhance heat dispersion, improving the reliability and lifespan of electronic components. For instance, Gagner-Toomey’s high-capacity blowers, equipped with advanced fan designs, are recognized for generating substantial airflow while maintaining optimal static pressure—crucial for efficient thermal regulation. This capability not only boosts the efficiency of temperature regulation but also reduces operational costs, solidifying the role of impeller fans in contemporary thermal management strategies.

Applications span various industries, including Automotive, Telecom, and IT, showcasing the versatility of Gagner-Toomey’s cooling solutions. With their proven performance and reliability, these devices are indispensable in the quest for effective thermal management.

Explain the Mechanics of Impeller Fan Operation

Impeller fans are crucial devices that transform rotational energy from a motor into kinetic energy, successfully facilitating the movement of air or fluid. The rotating mechanism, typically composed of blades or vanes, spins at high speeds, creating a pressure differential that draws air into the fan and expels it outward. This operation can be categorized into two primary types: centrifugal and axial.

Centrifugal rotors draw air in at a right angle to their rotation, expelling it outward, making them ideal for high-pressure applications. Conversely, axial fans move air parallel to the axis of rotation, excelling in low-pressure conditions where significant air movement is required. Understanding these mechanics is crucial for selecting the appropriate type of impeller fans for specific applications, as each type possesses distinct airflow characteristics and efficiency levels.

As of 2025, centrifugal blowers achieve an efficiency rating of approximately 60% and have a projected lifespan of 15,000 to 25,000 hours. In contrast, axial units reach around 70% efficiency and last between 20,000 to 30,000 hours. Additionally, centrifugal blowers can generate sound levels as high as 75 dB, while axial units typically operate around 60 dB. This difference is a vital consideration for engineers when evaluating operational environments.

Regular maintenance is essential to enhance the longevity and efficiency of both fan types. Industry experts, including Ryan Smoot, emphasize that the choice between centrifugal and axial devices should be guided by the intended application, available space, and thermal requirements of the system.

Moreover, the market for AC axial ventilators is projected to reach USD 19.18 million in 2024, expanding at a CAGR of 8.7%. This growth underscores the significance of these technologies in the electronics sector.

Highlight Advantages of Impeller Fans in Engineering Applications

Impeller fans offer a multitude of advantages in engineering applications, particularly within the electronics sector. Their compact design optimizes space, making them ideal for integration into small electronic devices. Notably, these units equipped with impeller fans deliver high airflow rates while maintaining low noise levels—an essential feature in sound-sensitive environments. Furthermore, impeller fans can consume up to 70% less power compared to conventional AC units, significantly enhancing energy efficiency in electronics applications.

Dependability and longevity characterize turbine units, which often require less maintenance than other ventilation options. They are engineered to operate effectively in high-temperature settings, boasting an operational lifespan of 8 to 15 years. This durability further solidifies their suitability for power management and cooling tasks. Case studies indicate that utilizing rotor blades can lead to energy savings of up to 70% compared to standard AC units, contributing to a quieter operational environment.

In summary, impeller fans and centrifugal blowers facilitate improved thermal management, extend component lifespan, and enhance overall system efficiency. This makes them an indispensable choice for electronics engineers seeking reliable and efficient solutions.

Guide on Integrating Impeller Fans into Electronic Systems

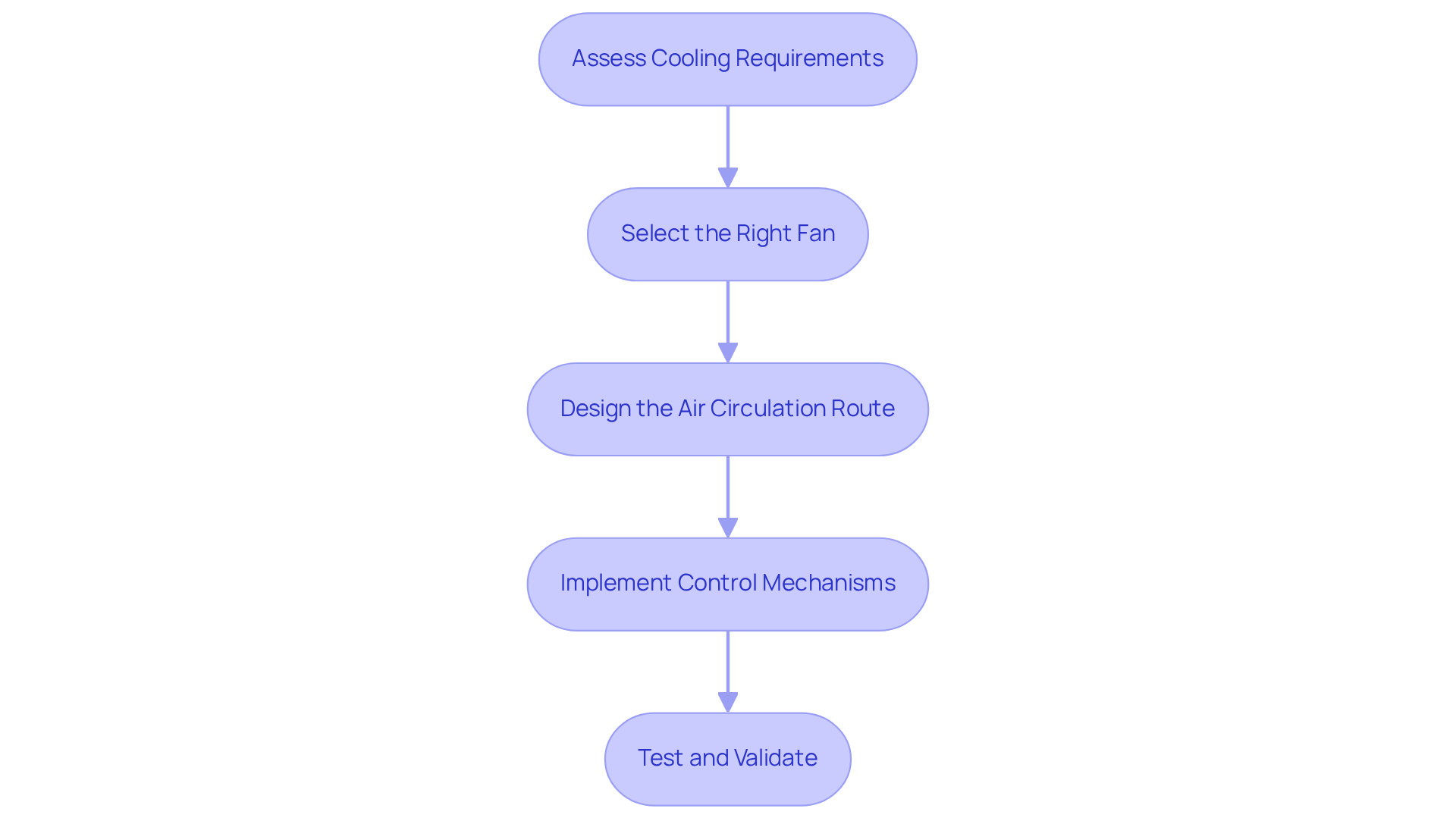

A systematic approach is required to incorporate impeller fans into electronic systems for efficient temperature regulation. Here’s how to do it:

-

Assess Cooling Requirements: Start by determining the thermal load of the components needing cooling. This assessment is vital for selecting the right fan size and type. Understanding the heat output in watts and the maximum allowable temperature increase aids in calculating necessary air movement.

-

Select the Right Fan: Choose an impeller fan that fulfills the air movement and pressure requirements of your application. Considerations include noise levels—such as a fan generating 58 dBA at 3000 RPM—dimensions, and power consumption (22 Watts at 3000 RPM) to ensure compatibility with your system. As noted by NMB, “Life expectancy of a fan is a critical element in thermal design,” underscoring the importance of selecting a fan that meets these criteria.

-

Design the Air Circulation Route: Strategically plan the layout of your electronic system to optimize air movement. Position the fan to effectively draw in air and direct it over the components requiring temperature regulation, minimizing barriers in the airflow path. This is crucial, as static pressure and airflow calculations significantly influence the choice of fan for specific applications.

-

Implement Control Mechanisms: Integrate temperature sensors and control systems to dynamically adjust fan speed based on real-time thermal conditions. This not only enhances energy efficiency but also ensures that temperature regulation responds effectively to varying loads.

-

Test and Validate: After installation, conduct comprehensive thermal testing to confirm that the impeller fan manages heat effectively. Use performance data to make necessary design adjustments, ensuring optimal temperature management. Case studies, such as the role of high-efficiency ventilation devices in server rooms, highlight the importance of effective integration in maintaining appropriate temperatures and preventing critical failures.

By following these guidelines, engineers can successfully achieve reliable cooling and improved performance by integrating impeller fans into their electronic systems.

Conclusion

Impeller fans are essential components in the electronics industry, playing a crucial role in managing airflow to maintain optimal thermal conditions. Their unique design and operational mechanics facilitate efficient air movement, making them indispensable for cooling electronic components and enhancing overall system performance. By grasping the significance of impeller fans, engineers can harness their capabilities to boost reliability and efficiency across various applications.

This article has shared key insights into the mechanics of impeller fans, their operational efficiencies, and the advantages they bring to engineering applications. We highlighted the distinctions between centrifugal and axial fans, emphasizing their respective strengths in high-pressure and low-pressure environments. Furthermore, we underscored the importance of selecting the right fan type based on specific cooling requirements, along with best practices for integrating these fans into electronic systems.

The insights presented reinforce the critical role that impeller fans play in modern electronics. As technology continues to evolve, the demand for efficient thermal management solutions will only increase. Engineers are urged to prioritize the integration of impeller fans into their designs—not just to enhance the performance and longevity of electronic components, but also to contribute to energy efficiency in their systems. Embracing these advancements will pave the way for more reliable and sustainable electronic solutions in the future.

Frequently Asked Questions

What are impeller fans?

Impeller fans are specialized devices designed to move air or fluids through a system using a rotating impeller to generate airflow.

What is the primary role of impeller fans in electronics?

Impeller fans play a crucial role in cooling components, managing thermal conditions, and ensuring optimal performance in electronic devices.

Who is Gagner-Toomey Associates?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a wide range of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise.

What sizes do impeller fans come in?

Impeller fans are available in sizes ranging from 15 to 280mm for tube axial types and 15 to 225mm for centrifugal blowers.

What is the advantage of turbine systems in confined spaces?

Turbine systems excel in confined spaces by effectively directing air currents where needed, which is essential for energy regulation and cooling setups.

How do impeller fans enhance heat dispersion?

Impeller fans significantly improve heat dispersion, which enhances the reliability and lifespan of electronic components.

What are some features of Gagner-Toomey’s high-capacity blowers?

Gagner-Toomey’s high-capacity blowers are equipped with advanced fan designs that generate substantial airflow while maintaining optimal static pressure, crucial for efficient thermal regulation.

What industries utilize impeller fans?

Impeller fans are used across various industries, including Automotive, Telecom, and IT, showcasing their versatility in cooling solutions.

Why are impeller fans considered indispensable in thermal management?

Impeller fans are essential in thermal management due to their proven performance and reliability, which help in effective temperature regulation and reducing operational costs.