Introduction

Cooling fans serve as the unsung heroes of modern electronics, quietly ensuring optimal performance by managing heat across a multitude of applications. As technology advances, the selection and integration of these fans have become increasingly critical. Engineers must navigate a complex array of options and innovations to achieve efficient thermal management.

What challenges arise when balancing performance, energy efficiency, and noise levels in cooling fan integration? Understanding these challenges is essential for engineers to make informed decisions tailored to their specific applications. By addressing these concerns, we can ensure that the right choices are made, ultimately enhancing the performance and reliability of electronic systems.

Understand Different Types of Cooling Fans and Their Applications

Cooling fans play a crucial role in managing heat within electronic systems, with three primary types each offering unique advantages:

-

Axial Blowers: These devices move air parallel to the shaft, making them ideal for applications that require high airflow with low resistance. Commonly found in cooling enclosures and electronic devices, the axial airflow devices market is projected to lead, with an estimated market size of USD 10,746.0 million in 2025, expected to grow to USD 29,967.0 million by 2035. Gagner-Toomey Associates provides a comprehensive range of RFI/EMI filters that enhance the efficiency of axial devices in sensitive electronic environments.

-

Centrifugal Blowers: These devices draw air into the center and expel it at a right angle, generating high pressure. They are well-suited for applications that need to overcome resistance, such as in ducted networks. The demand for centrifugal blowers remains strong in high-pressure applications, particularly in HVAC systems. Gagner-Toomey Associates’ expertise in power conversion products ensures these devices can be seamlessly integrated into systems that require reliable power supplies.

-

Cross Flow Units: These devices push air across a narrow profile, making them effective for cooling compact spaces, such as in electronic devices where space is at a premium. While they hold a smaller market share, cross flow units are gaining popularity in specialized applications due to their compact design. Gagner-Toomey Associates offers modified and custom power supplies tailored to meet the specific needs of applications utilizing cross flow fans.

Recent advancements in fan technology, including AI integration for smart thermal management solutions and noise-reduction technologies, are becoming increasingly vital in consumer electronics and healthcare equipment. Engineers should consider these innovations when selecting temperature regulation solutions, as they can significantly impact performance and reliability.

Real-world applications of these devices are diverse, ranging from data centers employing axial types for optimal airflow management to automotive systems utilizing an instrument cooling fan and centrifugal models for efficient engine temperature regulation. For example, axial fans are essential in data centers to manage heat generated by high-performance computing, while centrifugal fans are critical in automotive applications to ensure engine reliability. Understanding the specific requirements of each application enables engineers to make informed decisions, ensuring that the selected fan meets both performance and operational needs.

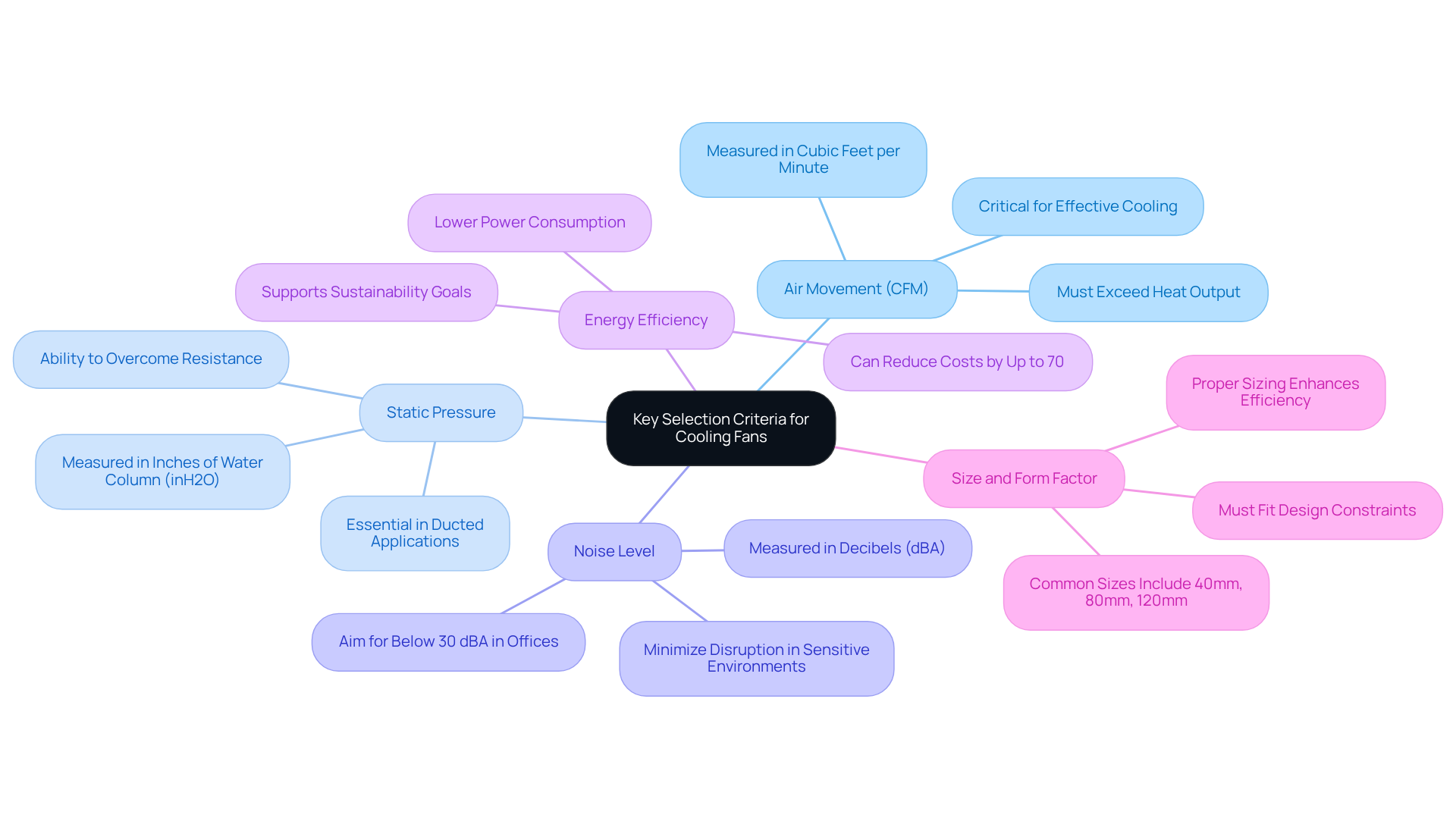

Evaluate Key Selection Criteria for Cooling Fans

When it comes to selecting a cooling fan, several key criteria demand careful evaluation:

-

Air Movement (CFM): The fan’s capacity for air movement, measured in cubic feet per minute (CFM), must align with the cooling requirements of your application. Adequate ventilation is essential for components that generate significant heat, such as the instrument cooling fan, ensuring effective thermal management.

-

Static Pressure: This metric reflects the fan’s ability to overcome resistance within the system. In ducted applications, a fan with higher static pressure is vital for maintaining airflow efficiency, especially in environments equipped with filters or heatsinks.

-

Noise Level: Measured in decibels (dBA), the noise level is a crucial consideration for applications where sound is a concern, such as in office settings. Engineers typically aim for devices that operate below 30 dBA to minimize disruption.

-

Energy Efficiency: Opting for devices that consume less power while delivering adequate ventilation can lead to substantial cost savings over time. Energy-efficient instrument cooling fans can reduce power consumption by up to 70% compared to conventional units, thereby supporting sustainability goals.

-

Size and Form Factor: The physical dimensions of the fan must fit within the design constraints of the setup. Proper sizing can enhance efficiency by up to 30%, improving circulation while reducing noise and vibration in electronic devices.

By meticulously evaluating these criteria, engineers can ensure they select an instrument cooling fan that meets performance requirements and aligns with energy efficiency objectives. This approach ultimately enhances the reliability and lifespan of electronic devices.

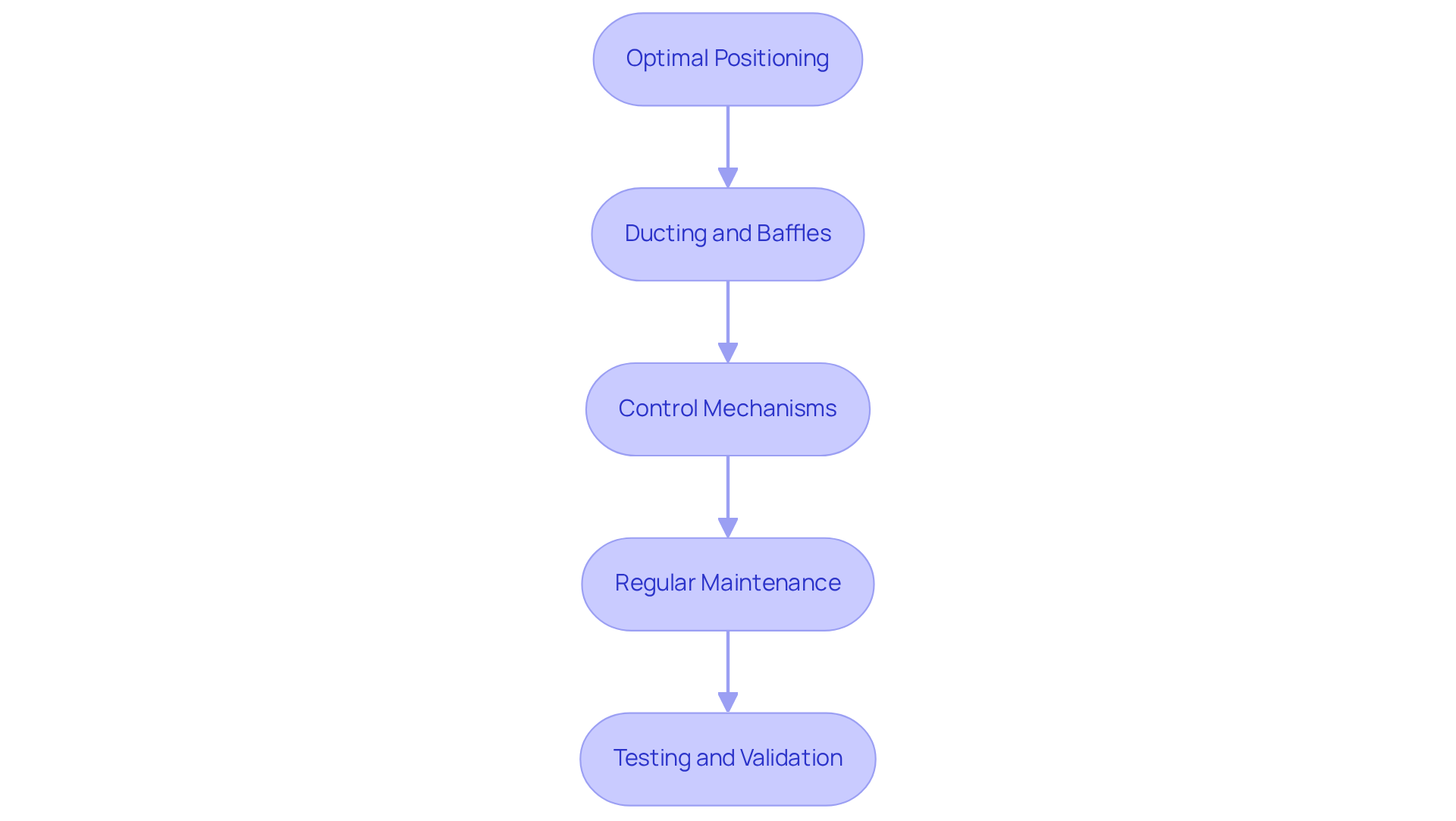

Implement Effective Strategies for Cooling Fan Integration

To effectively integrate cooling fans into electronic systems, consider the following strategies:

-

Optimal Positioning: Position blowers strategically to enhance circulation over heat-producing elements. For example, placing intake fans at the front and exhaust fans at the back creates a natural ventilation route, significantly improving cooling efficiency.

-

Ducting and Baffles: Employ ducting to direct air movement precisely where it’s needed, and install baffles to reduce turbulence and enhance overall efficiency. This method can lead to airflow improvements of up to 46% compared to unoptimized setups.

-

Control Mechanisms: Implement fan speed control mechanisms, such as Pulse Width Modulation (PWM), to dynamically adjust fan speeds based on real-time temperature readings. This approach not only optimizes energy consumption but also minimizes operational noise from the instrument cooling fan, making it particularly suitable for noise-sensitive environments.

-

Regular Maintenance: Schedule routine maintenance to clean fans and check for obstructions. Regular upkeep can reduce failure rates by nearly 80%, ensuring consistent performance over time and extending the lifespan of refrigeration units.

-

Testing and Validation: Conduct thorough thermal testing to verify that the temperature regulation mechanism meets design specifications. Adjust fan settings as necessary to ensure optimal airflow and static pressure, which are crucial for effective temperature regulation in densely packed environments.

By implementing these strategies, engineers can ensure that ventilation devices are seamlessly integrated into electronic systems, significantly enhancing overall performance and reliability.

Monitor and Optimize Cooling Fan Performance

To achieve optimal performance from cooling fans, engineers must adopt effective monitoring and optimization practices:

-

Performance Metrics: Consistently monitor essential performance indicators such as air movement, temperature differentials, and energy consumption to assess fan effectiveness. This foundational step ensures that engineers have a clear understanding of how well the fans are performing.

-

Use of Sensors: Implement temperature and airflow sensors to gather real-time data, enabling dynamic adjustments to fan speed based on immediate cooling requirements. This method allows for precise control, ensuring that devices operate efficiently under varying conditions. As Jackson Murphy highlights, the ongoing evolution of fan technology underscores the critical role fans play in modern technology, driving the continuous pursuit of enhanced performance and energy efficiency.

-

Data Analysis: Regularly analyze performance data to identify trends and potential issues, facilitating proactive maintenance and adjustments before failures occur. This predictive approach can significantly reduce downtime and improve reliability, ultimately leading to more efficient operations.

-

Feedback Loops: Establish feedback mechanisms that allow the temperature regulation process to adapt to varying circumstances, such as increased heat loads during peak operation. This adaptability is crucial for maintaining optimal performance in demanding environments, ensuring that systems can handle fluctuations effectively.

-

Continuous Improvement: Periodically review and refine temperature control strategies based on performance data and technological advancements. Staying informed about the latest innovations guarantees that the refrigeration setup remains efficient and effective. Notably, the adoption of smart fan technology in electronics has surged by over 30% in the past year, highlighting its growing significance in enhancing temperature regulation.

By actively monitoring and optimizing the performance of the instrument cooling fan through these strategies, engineers can significantly enhance the reliability and longevity of electronic systems, effectively addressing the increasing demands for efficient thermal management.

Conclusion

Selecting the right cooling fan is crucial for achieving optimal thermal management in electronic systems. This article has examined the various types of cooling fans – axial, centrifugal, and cross flow – highlighting their unique applications and advantages. By understanding these distinctions, engineers can make informed choices that enhance performance and reliability across diverse environments.

Key selection criteria, including air movement, static pressure, noise level, energy efficiency, and size, are pivotal in the fan selection process. Careful evaluation of these factors ensures that the chosen cooling fan aligns with both operational needs and sustainability goals. Furthermore, effective integration strategies – such as optimal positioning, ducting, and control mechanisms – significantly enhance cooling efficiency and system reliability.

Ultimately, advances in cooling fan technology underscore the necessity of proactive monitoring and optimization practices. By implementing performance metrics, utilizing sensors, and fostering continuous improvement, engineers can greatly enhance the longevity and efficiency of cooling systems. Embracing these best practices not only meets the demands of modern technology but also contributes to the ongoing pursuit of energy-efficient solutions in electronic applications.

Frequently Asked Questions

What are the main types of cooling fans discussed in the article?

The article discusses three main types of cooling fans: Axial Blowers, Centrifugal Blowers, and Cross Flow Units.

What are the characteristics and applications of Axial Blowers?

Axial Blowers move air parallel to the shaft and are ideal for high airflow with low resistance applications. They are commonly used in cooling enclosures and electronic devices, with a projected market size of USD 10,746.0 million in 2025, expected to grow to USD 29,967.0 million by 2035.

How do Centrifugal Blowers operate and where are they typically used?

Centrifugal Blowers draw air into the center and expel it at a right angle, generating high pressure. They are well-suited for applications that need to overcome resistance, such as in HVAC systems.

What advantages do Cross Flow Units offer?

Cross Flow Units push air across a narrow profile, making them effective for cooling compact spaces, such as electronic devices. They are gaining popularity in specialized applications due to their compact design.

What recent advancements in fan technology are mentioned in the article?

Recent advancements include AI integration for smart thermal management solutions and noise-reduction technologies, which are becoming increasingly vital in consumer electronics and healthcare equipment.

What are some real-world applications of these cooling fans?

Axial fans are used in data centers for optimal airflow management, while centrifugal fans are utilized in automotive systems for efficient engine temperature regulation. Each fan type is selected based on the specific requirements of the application.

Why is it important for engineers to understand the specific requirements of each application when selecting cooling fans?

Understanding the specific requirements ensures that the selected fan meets both performance and operational needs, which is crucial for maintaining efficiency and reliability in various systems.