Overview

The article delves into the fundamentals and functions of thermoelectric cooler controllers, highlighting their critical role in temperature regulation through various control mechanisms. It elucidates the types of controllers—open-loop and closed-loop—while detailing their essential functions, such as temperature sensing and current regulation. These functions are pivotal for achieving efficient thermal management in applications ranging from medical devices to electronics cooling, underscoring the importance of understanding these systems for optimal performance.

Introduction

Thermoelectric cooling stands at the intriguing intersection of physics and engineering, leveraging the Peltier effect to deliver efficient temperature regulation solutions. As industries increasingly pursue sustainable and precise cooling methods, grasping the fundamentals of thermoelectric cooler controllers becomes imperative. Designers encounter various challenges in selecting the optimal controller to enhance performance. Furthermore, advancements in technology are poised to reshape the future of thermal management, underscoring the necessity for ongoing exploration and understanding in this dynamic field.

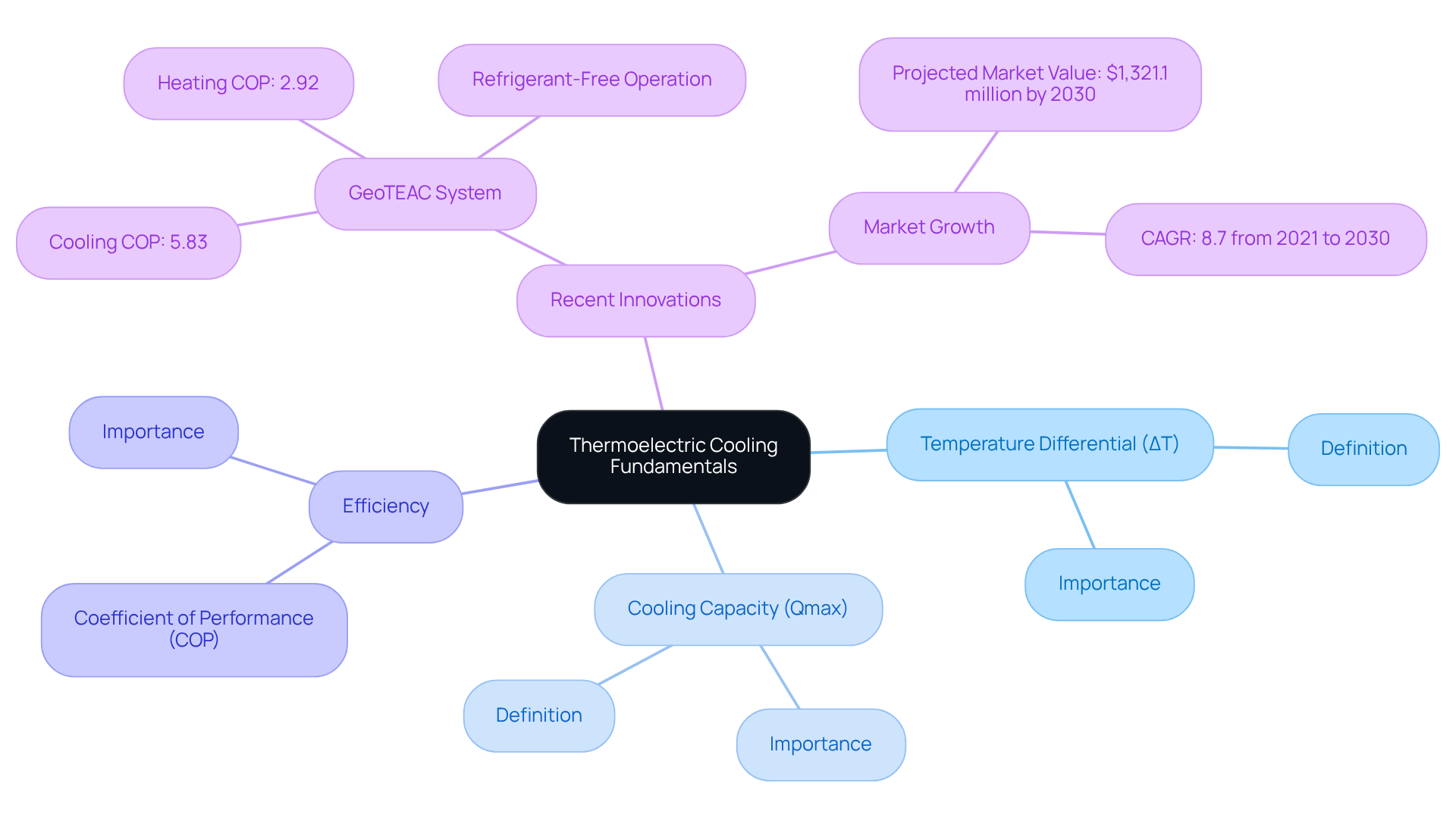

Explore the Fundamentals of Thermoelectric Cooling

Thermoelectric refrigeration leverages the Peltier effect, wherein an electric current traverses two distinct semiconductor materials, generating a thermal differential. This mechanism facilitates heat absorption on one side of the energy conversion module while expelling it on the opposite side, thereby the designated area. Key parameters to consider include:

- Temperature Differential (ΔT): This denotes the maximum temperature difference achievable between the hot and cold sides of the thermoelectric cooler (TEC).

- Cooling Capacity (Qmax): This indicates the maximum heat removal capability of the cooler, which is crucial for evaluating its suitability for specific applications.

- Efficiency: Often assessed by the coefficient of performance (COP), this metric gauges the TEC’s effectiveness in converting electrical energy into refrigeration power.

Recent advancements in thermoelectric temperature regulation technology have concentrated on enhancing efficiency and broadening applications, particularly within the automotive and consumer electronics sectors. For instance, the GeoTEAC system exemplifies cutting-edge innovation, achieving a temperature control COP of 5.83 and a heating COP of 2.92, significantly exceeding that of traditional systems. Furthermore, the GeoTEAC system operates without refrigerants, contributing to reduced CO emissions and bolstering sustainable technology initiatives. Grasping these fundamentals is vital for selecting the appropriate TEC, ensuring optimal performance and efficiency across diverse cooling systems. The market for cooling technologies is projected to reach $1,321.1 million by 2030, underscoring the growing demand for these innovations. Nonetheless, challenges such as higher costs compared to conventional systems remain a consideration for potential users.

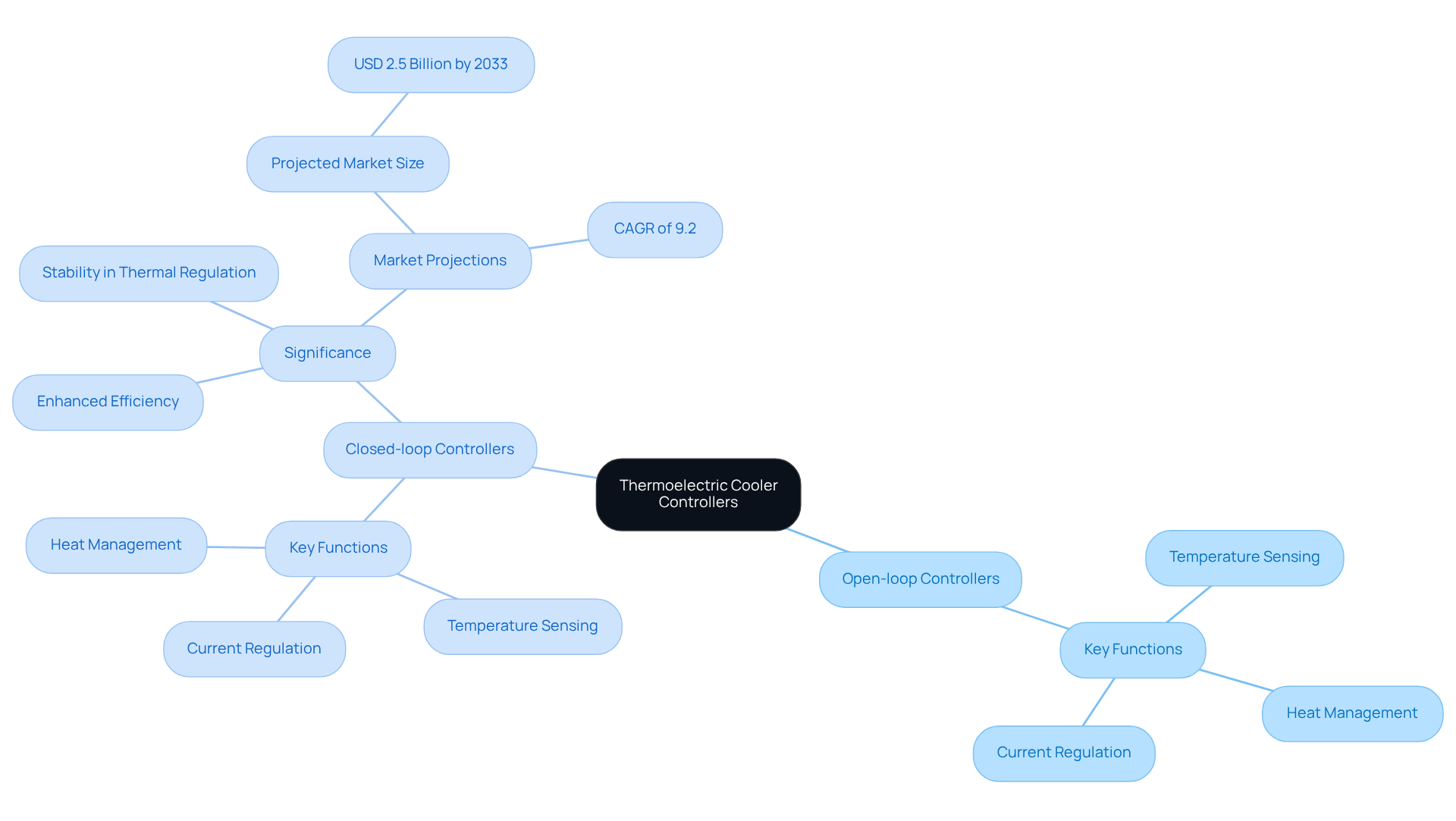

Understand the Role of Thermoelectric Cooler Controllers

An electronic device known as a thermoelectric cooler controller efficiently manages the current and voltage supplied to a thermoelectric cooler (TEC), ensuring precise thermal regulation. These controllers are primarily categorized into two types:

- Open-loop Controllers: These devices provide a constant output without feedback from the system, making them suitable for applications where temperature stability is less critical. They may be employed in environments where heat variations are minimal.

- [Closed-loop Controllers](https://verifiedmarketreports.com/product/thermoelectric-controllers-tec-controllers-market): These utilize feedback systems to adjust the output based on actual thermal conditions, enabling accurate control and adjustments for external influences. This type is essential in applications requiring stringent thermal regulation, such as medical devices or high-performance computing systems.

Key functions of TEC controllers include:

- Temperature Sensing: Monitoring the temperature of the cooled object or environment to maintain it within desired limits.

- Current Regulation: Adjusting the current supplied to the TEC based on temperature readings to effectively sustain the desired temperature.

- Heat Management: Ensuring effective dissipation of heat generated on the hot side of the TEC to prevent overheating, which is critical for maintaining system efficiency and longevity.

The significance of closed-loop controllers in temperature regulation is paramount. They offer enhanced efficiency and stability, making them indispensable in scenarios where accurate thermal management is crucial. Understanding the role of the thermoelectric cooler controller is vital for designing that meet specific thermal management requirements.

The Thermoelectric Controllers (TEC Controllers) market is projected to grow significantly, reaching USD 2.5 billion by 2033. This growth is driven by increasing demand across various industries, including automotive and aerospace. However, the market faces challenges such as high production costs and complex design requirements, underscoring the necessity for advanced closed-loop controllers. Key players in this competitive landscape include Laird, Chroma, and Analog Devices, who are leading innovation in this field.

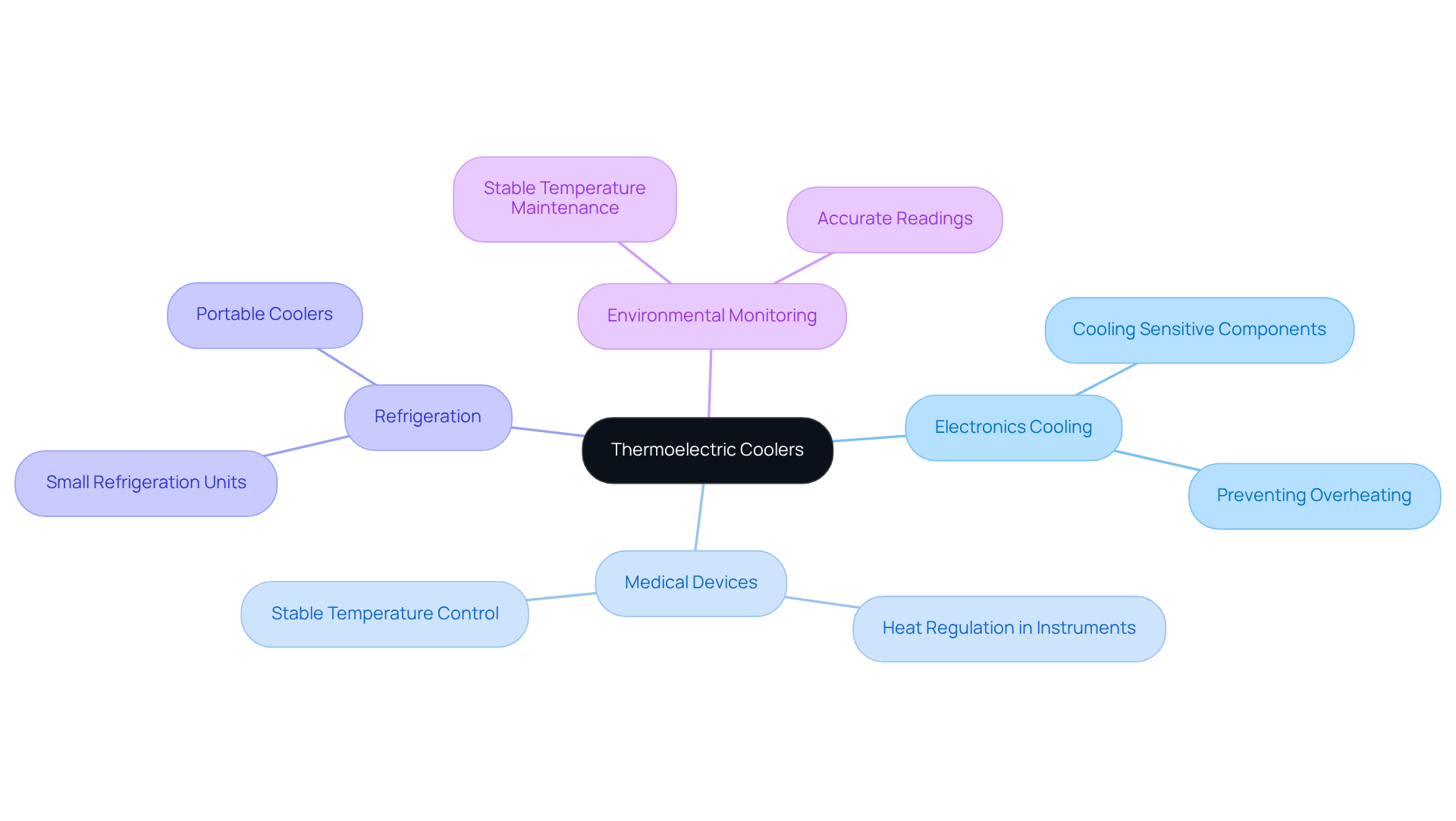

Identify Key Applications of Thermoelectric Coolers

Thermoelectric coolers (TECs) play a pivotal role across various fields due to their compact dimensions, reliability, and ability to provide precise heat regulation. Their significance is underscored by several key applications:

- Electronics Cooling: TECs are widely utilized to cool sensitive electronic components, such as CPUs and lasers. This application is critical for preventing overheating and ensuring optimal performance.

- Medical Devices: In the healthcare sector, TECs are essential for heat regulation in instruments like portable blood analyzers and thermal imaging cameras, which require stable temperature control for accurate results.

- Refrigeration: TECs are incorporated into small refrigeration units, including wine coolers and portable coolers, where traditional refrigeration methods may not be feasible.

- Environmental Monitoring: TECs are employed in environmental sensors to maintain stable temperatures, thereby ensuring accurate readings.

Understanding these applications is vital for engineers and designers when selecting and implementing in their projects, as it allows for informed decision-making and enhances the effectiveness of their designs.

Conclusion

Thermoelectric coolers (TECs) and their controllers signify a pivotal advancement in temperature regulation technology, harnessing the Peltier effect to deliver efficient cooling solutions across a multitude of applications. A comprehensive understanding of the foundational principles of thermoelectric cooling—encompassing temperature differential, cooling capacity, and efficiency—is essential for selecting the appropriate system tailored to specific needs. The function of thermoelectric cooler controllers, particularly the distinction between open-loop and closed-loop systems, underscores the critical nature of precise thermal management in achieving optimal performance.

Key insights throughout this article have illuminated the innovative strides in TEC technology, exemplified by systems like GeoTEAC, which significantly enhance efficiency and sustainability. The wide-ranging applications of TECs—from electronics cooling to medical devices—underscore their versatility and reliability. Moreover, the anticipated growth of the thermoelectric controllers market highlights the surging demand for these technologies in sectors such as automotive and aerospace, notwithstanding challenges like production costs.

As the reliance on thermoelectric cooling continues to escalate, acknowledging the importance of efficient controller systems becomes paramount. Engineers and designers are urged to meticulously consider the specific requirements of their projects when selecting thermoelectric cooler controllers, as this decision can profoundly impact the effectiveness and sustainability of their cooling solutions. Embracing these advancements not only amplifies technological capabilities but also contributes to a more sustainable future in thermal management.

Frequently Asked Questions

What is thermoelectric refrigeration?

Thermoelectric refrigeration utilizes the Peltier effect, where an electric current passes through two different semiconductor materials, creating a thermal differential that absorbs heat on one side and expels it on the other, effectively cooling the designated area.

What does Temperature Differential (ΔT) refer to in thermoelectric cooling?

Temperature Differential (ΔT) indicates the maximum temperature difference that can be achieved between the hot and cold sides of the thermoelectric cooler (TEC).

What is Cooling Capacity (Qmax) in the context of thermoelectric coolers?

Cooling Capacity (Qmax) represents the maximum heat removal capability of the cooler, which is essential for determining its suitability for specific applications.

How is the efficiency of a thermoelectric cooler measured?

The efficiency of a thermoelectric cooler is often assessed by the coefficient of performance (COP), which measures the TEC’s effectiveness in converting electrical energy into refrigeration power.

What recent advancements have been made in thermoelectric temperature regulation technology?

Recent advancements have focused on improving efficiency and expanding applications, particularly in the automotive and consumer electronics sectors, with systems like GeoTEAC achieving high temperature control COP and operating without refrigerants.

What is the significance of the GeoTEAC system in thermoelectric cooling?

The GeoTEAC system exemplifies innovation in thermoelectric cooling, achieving a temperature control COP of 5.83 and a heating COP of 2.92, which surpasses traditional systems and operates without refrigerants, thus reducing CO emissions.

What is the projected market size for cooling technologies by 2030?

The market for cooling technologies is projected to reach $1,321.1 million by 2030, indicating a growing demand for these innovations.

What challenges do thermoelectric coolers face compared to conventional systems?

One of the main challenges for thermoelectric coolers is their higher costs compared to conventional cooling systems, which potential users need to consider.