Overview

This article delves into the features, performance, and applications of leading thermoelectric coolers (TECs), elucidating their operational principles and suitability for a variety of uses. It underscores the importance of selecting a thermoelectric cooler that aligns with specific application requirements. Different models, such as the PowerCycling PCX Series and Koolatron P27, present unique advantages in terms of efficiency and portability. These distinctions are further supported by advancements in materials and technology that significantly enhance their performance.

Introduction

Thermoelectric coolers (TECs) are transforming temperature control across various industries due to their distinctive capability to transfer heat without moving parts. As the demand for efficient and reliable cooling solutions escalates, it becomes imperative for both consumers and professionals to understand the features and performance of leading thermoelectric coolers.

However, with a multitude of options available, determining the ideal cooler for specific applications poses a challenge. This article conducts a comparative analysis of top thermoelectric coolers, examining their principles, performance metrics, and the unique advantages they provide for different use cases.

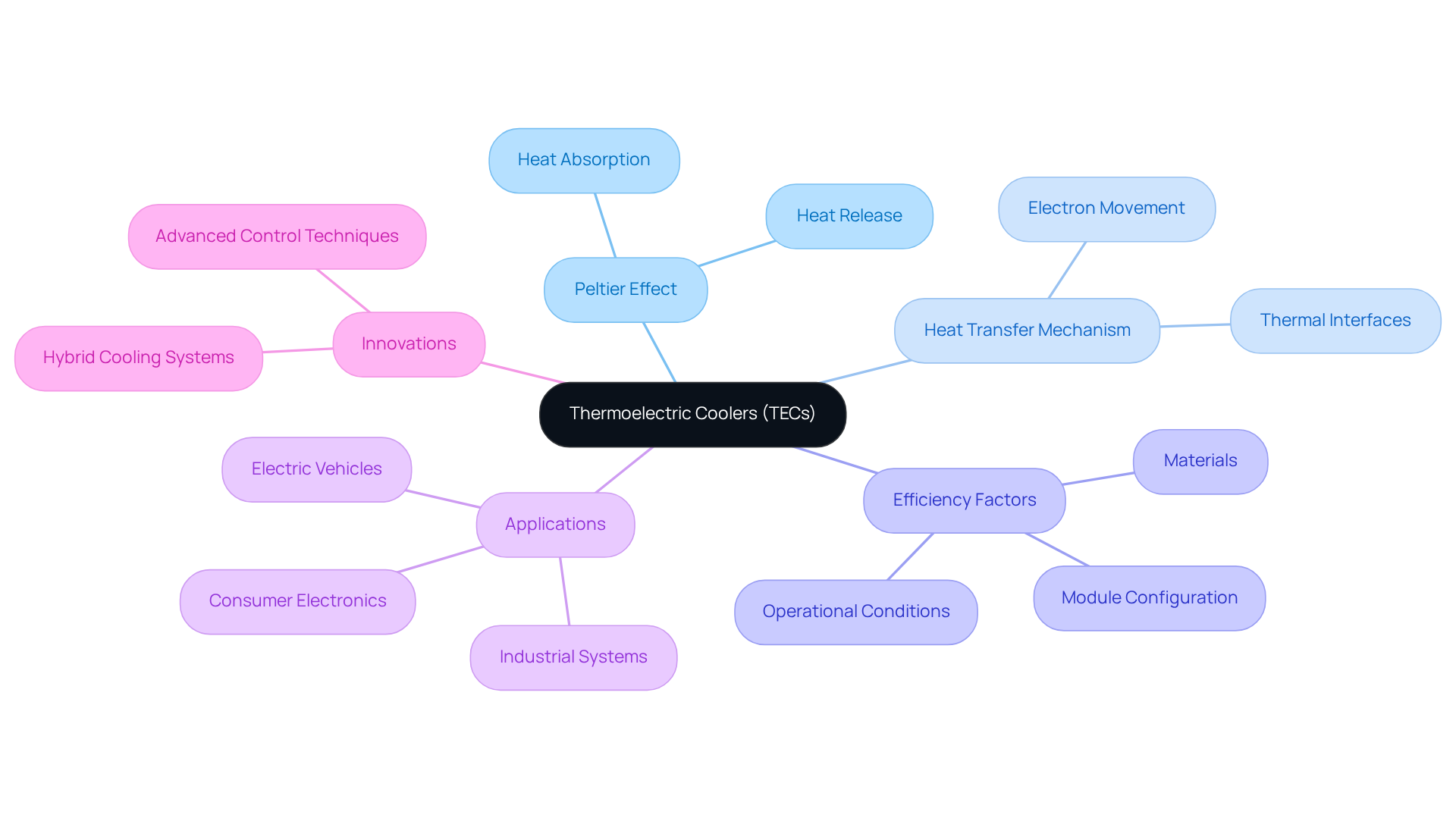

Understanding Thermoelectric Coolers: Principles and Mechanisms

Thermoelectric coolers (TECs), commonly referred to as Peltier coolers, function based on the , which entails the transfer of heat through the movement of electrical current across two distinct conductors. When current flows through the junction of these conductors, one side absorbs heat, resulting in a decrease in temperature, while the opposing side releases heat, leading to an increase in temperature. This is notable for its absence of moving parts, rendering it quieter and more reliable than conventional cooling methods.

The efficiency of a is influenced by factors such as:

- The materials employed

- The configuration of the module

- The operational conditions

Understanding these principles is vital for evaluating the performance and suitability of various applications of across a spectrum, ranging from consumer electronics to industrial systems.

, recognized as the world’s largest producer of standard and custom air-movers, offers a comprehensive array of . Their significantly enhance the performance of . With an extensive selection of DC input fans and blowers, alongside tailored thermal solutions, Gagner-Toomey Associates ensures optimal performance and efficiency for electronics .

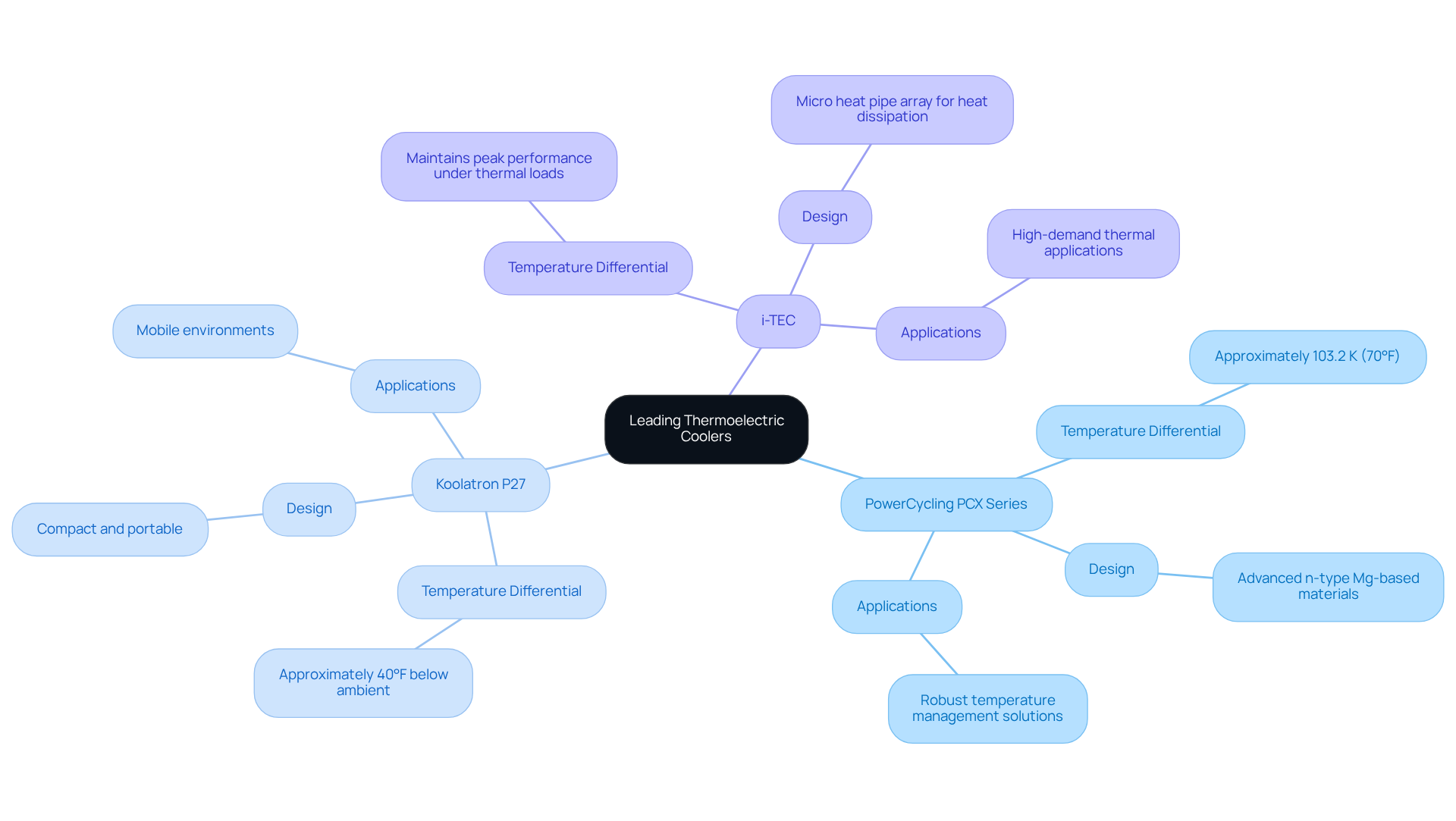

Comparative Analysis of Leading Thermoelectric Coolers: Features and Performance

In today’s competitive market, several of the top stand out due to their innovative designs and exceptional performance. The PowerCycling PCX Series, for instance, utilizes that significantly enhance temperature management efficiency, achieving a remarkable temperature differential of approximately 103.2 K (or about 70°F). This capability makes it particularly suitable for applications that require for robust .

Conversely, the Koolatron P27 prioritizes portability, showcasing a compact design that enables efficient operation in mobile environments, albeit with a somewhat reduced temperature drop of approximately 40°F below ambient conditions.

Another noteworthy contender, the i-TEC, incorporates a . This design allows the i-TEC to even under demanding thermal loads.

Each of these models of top thermoelectric coolers presents unique benefits and drawbacks, highlighting the necessity of aligning specific with the appropriate device.

Furthermore, the of these models can be characterized through various methodologies, including the application of thermally conductive silicone grease to , thereby ensuring optimal thermal management.

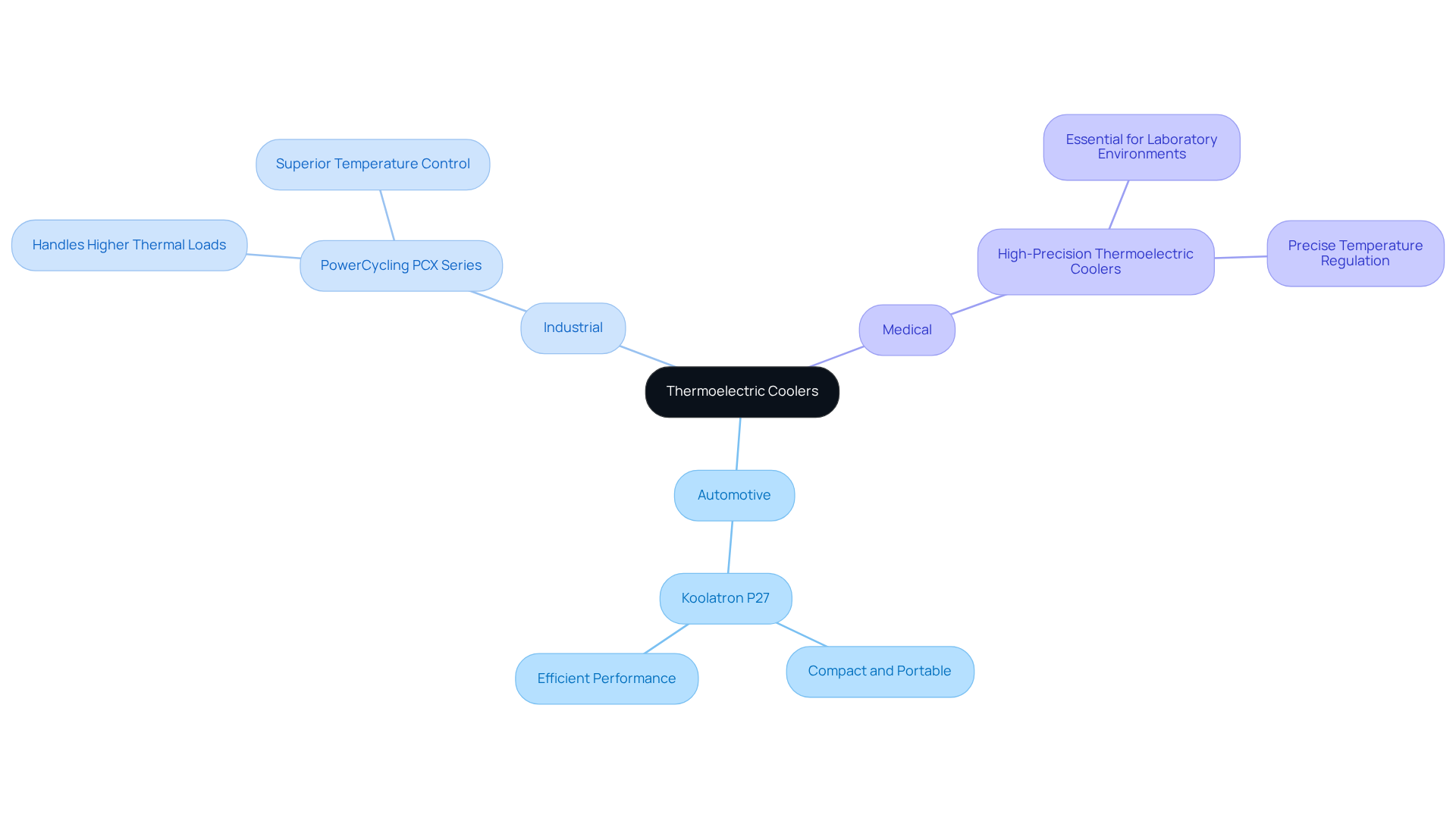

Selecting the Right Thermoelectric Cooler: Applications and Suitability

When selecting a , it is crucial to consider the intended application. In automotive systems, where space constraints are a significant factor, such as the Koolatron P27 emerge as the preferred choice due to their portability and efficiency. Conversely, industrial applications often necessitate more robust solutions, exemplified by the PowerCycling PCX Series, which is designed to handle higher thermal loads while providing superior . Additionally, in medical settings, is paramount, making high-precision s essential for laboratory environments. By aligning the specifications of the cooling unit with the specific requirements of each application, users can achieve in their temperature control systems.

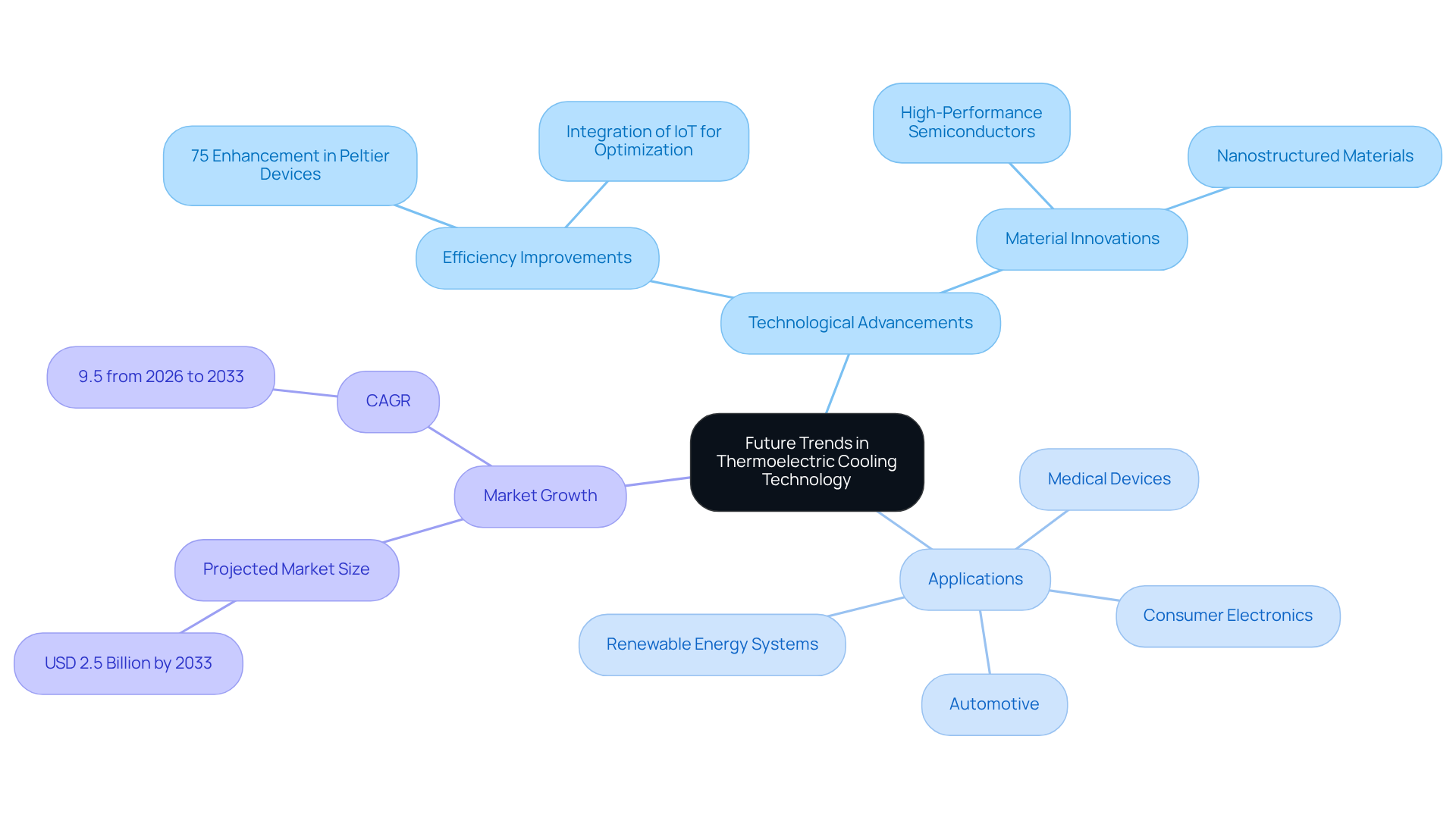

Future Trends in Thermoelectric Cooling Technology

The future of is exceptionally promising, driven by ongoing research aimed at enhancing the efficiency and performance of (TECs). Recent advancements in materials, particularly high-performance semiconductors and nanostructured substances, are set to significantly improve the and .

For instance, have demonstrated an impressive 75% enhancement in efficiency, paving the way for their application across various sectors, including consumer electronics and medical devices. Furthermore, the integration of intelligent technologies, such as IoT connectivity, facilitates of , thereby boosting operational efficiency.

As industries increasingly prioritize , the use of top thermoelectric coolers for temperature regulation is poised to play a crucial role in diverse applications, ranging from automotive to renewable energy systems.

The is projected to expand from USD 1.2 billion in 2024 to USD 2.5 billion by 2033, reflecting a compound annual growth rate (CAGR) of 9.5% from 2026 to 2033. This underscores the growing demand for compact and .

Conclusion

Thermoelectric coolers (TECs) signify a major leap forward in temperature management technology, leveraging the Peltier effect to deliver efficient cooling without moving parts. This article has examined the principles and mechanisms that underpin TECs, highlighting their reliability and quiet operation in contrast to traditional cooling methods. Grasping these foundational concepts is crucial for selecting the appropriate thermoelectric cooler for specific applications, whether in consumer electronics, industrial systems, or medical environments.

A comparative analysis of leading thermoelectric coolers unveils a wide range of options tailored to diverse needs. The PowerCycling PCX Series distinguishes itself with its high efficiency and robust thermal management capabilities, while the Koolatron P27 offers portability for mobile applications. Furthermore, the i-TEC showcases innovative heat dissipation techniques, underscoring the importance of aligning cooler specifications with user requirements. As advancements in materials and technology continue to progress, the performance and efficiency of these systems are poised for enhancement, rendering them increasingly relevant across various sectors.

Looking ahead, the escalating demand for sustainable and energy-efficient solutions highlights the significance of thermoelectric cooling technology. As industries adopt these innovations, the market for thermoelectric coolers is expected to expand considerably. By prioritizing the selection of the right cooler for specific applications, users can bolster operational efficiency and reliability. Embracing these advancements not only fosters technological progress but also contributes to a more sustainable future in temperature regulation.

Frequently Asked Questions

What are thermoelectric coolers (TECs)?

Thermoelectric coolers, also known as Peltier coolers, are devices that transfer heat through the movement of electrical current across two distinct conductors, resulting in cooling on one side and heating on the other.

How do thermoelectric coolers work?

TECs operate based on the Peltier effect, where the flow of electrical current through the junction of two conductors causes one side to absorb heat (cooling it) and the other side to release heat (heating it).

What are the advantages of thermoelectric coolers compared to conventional cooling methods?

TECs are solid-state devices that have no moving parts, making them quieter and more reliable than traditional cooling systems.

What factors influence the efficiency of thermoelectric coolers?

The efficiency of a thermoelectric cooler is affected by the materials used, the configuration of the module, and the operational conditions.

What are some applications of thermoelectric coolers?

Thermoelectric coolers are used in a variety of applications ranging from consumer electronics to industrial systems, where temperature management is crucial.

Who is Gagner-Toomey Associates?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a wide range of thermal management solutions, including innovative temperature regulation technologies for electrical cooling devices.

What products does Gagner-Toomey Associates provide for temperature management?

They provide an extensive selection of DC input fans and blowers, along with tailored thermal solutions to enhance the performance and efficiency of electronics temperature management applications.