Overview

This article examines the diverse types of fans and blowers, with a particular emphasis on centrifugal models and their engineering applications. Centrifugal fans and blowers are characterized by their operational principles, efficiency, and their suitability for specific tasks. Their significance is underscored in critical systems such as HVAC, dust collection, and electronic cooling, which are essential for optimizing performance and energy efficiency across various industries.

Introduction

Understanding the intricate world of fans and blowers is essential for engineers navigating the complexities of air movement across various applications. These mechanical devices, designed to move air or gas, operate on distinct principles that cater to specific needs—from the gentle circulation of a fan to the concentrated force of a blower.

As industries increasingly prioritize energy efficiency and performance, the challenge lies in selecting the appropriate type of fan or blower for each unique application.

What factors should engineers consider to ensure optimal airflow and operational efficiency in their designs?

Define Fans and Blowers: Key Concepts for Engineers

Types of fans and blowers serve as mechanical devices designed for the movement of air or gas, yet they function on differing principles and fulfill distinct roles. A fan typically generates low-pressure airflow, making it ideal for circulating air within a space, and operates at noise levels ranging from 25 to 50 dB. In contrast, a ventilator produces higher pressure airflow, which is essential for directing air in a specific direction, generating noise levels between 60 and 85 dB.

According to ASME, air movers operate with a pressure ratio of up to 1.11, while air handlers function within a pressure ratio range of 1.11 to 1.2. This difference is vital in various engineering applications, particularly in HVAC systems, where types of fans and blowers are favored for general airflow due to their energy efficiency, while blowers are employed for tasks requiring concentrated airflow, such as in forced hot air furnaces and hair dryers.

Furthermore, these devices are frequently utilized in cooling electronic components, making their selection crucial for engineers. Understanding these distinctions is essential for engineers to select the according to system requirements and operational efficiency.

As Sam Pelonis observed, “Blowers direct air in a specific direction, while air circulators move air throughout a defined space.

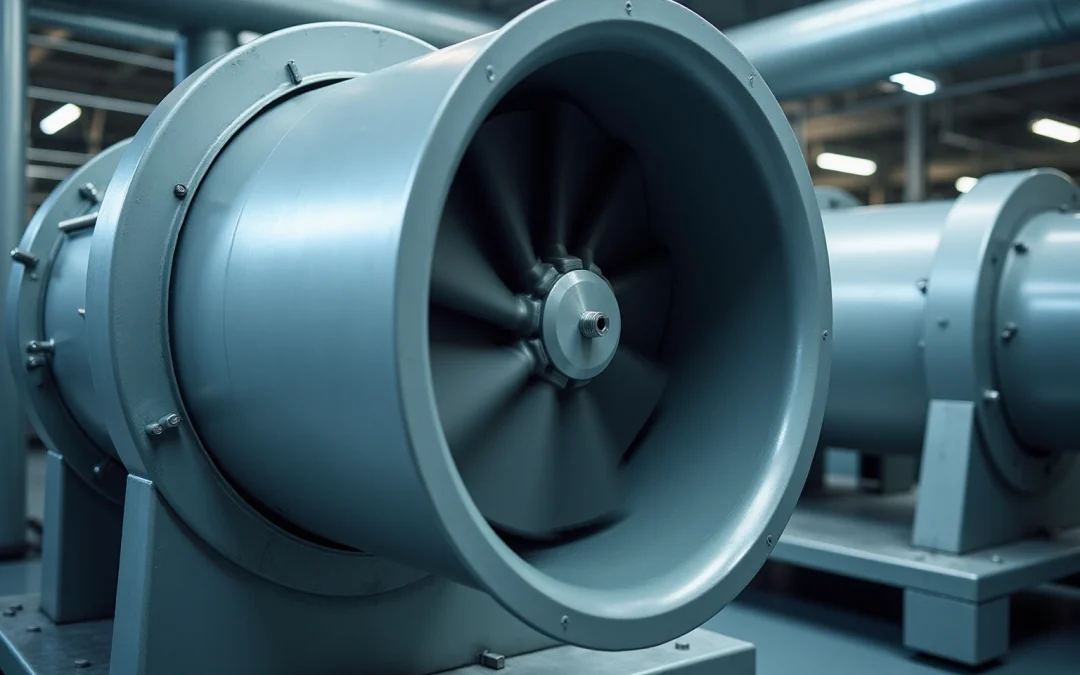

Explore Types of Fans and Blowers: Focus on Centrifugal Models

Centrifugal blowers and devices play a pivotal role in air movement, employing an impeller to elevate air pressure and facilitate radial airflow. These devices are primarily categorized into three distinct types, each exhibiting unique performance attributes:

- Forward-Curved Fans: Designed for high airflow at low pressure, these fans are particularly effective in applications necessitating substantial air volumes, such as HVAC systems and industrial ventilation. Their configuration allows for efficient operation in space-constrained environments.

- Backward-Curved Blowers: Noted for their remarkable efficiency at high pressures, backward-curved blowers are ideal for applications requiring compact designs without sacrificing performance. They are increasingly preferred in scenarios where noise reduction and energy efficiency are paramount, making them suitable for both commercial and industrial settings. The demand for backward-curved blades is anticipated to grow at the highest rate due to their efficiency and noise-reducing capabilities.

- Radial Blowers: Celebrated for their durability, radial blowers excel in high-pressure situations and can adapt to varying airflow conditions. Their robust design positions them as a reliable choice for demanding applications, including pneumatic conveying and dust collection.

Market dynamics reveal that forward-curved fans currently hold a significant market share, accounting for nearly 42.5% of the centrifugal fan market revenue in 2023. Furthermore, the Single-Stage Centrifugal Blowers segment is projected to achieve a valuation of approximately 2.4 USD Billion by 2024. The Centrifugal Blower Market is expected to expand from 4.26 USD Billion in 2025 to 5.91 USD Billion by 2034, reflecting a CAGR of 3.71%. Understanding these distinctions is essential for engineers aiming to select the most appropriate types of fans and blowers for their specific applications, thereby ensuring optimal performance and energy efficiency.

Understand How Centrifugal Blowers Work: Mechanics and Performance

Centrifugal fans are one of the types of fans and blowers that operate by converting rotational kinetic energy into air pressure. As the impeller rotates, it draws air into the center and expels it at a right angle through the outlet. This design allows centrifugal fans to generate higher pressures compared to axial fans. Key performance metrics encompass airflow rate (measured in CFM), static pressure, and efficiency. Engineers must consider these factors when selecting types of fans and blowers for applications such as dust collection, fume extraction, or cooling systems. Moreover, understanding the impact of design elements, such as blade shape and motor speed, can significantly enhance the performance of these devices.

Centrifugal fans are one of the essential types of fans and blowers that play a vital role in air handling units, dust collection systems, and pneumatic conveying, showcasing their versatility across various applications. Backward inclined blades are noted for their efficiency and reduced noise levels, making them suitable for medium to high static pressure applications. In contrast, forward curved blades deliver increased airflow but may sacrifice efficiency.

Centrifugal fans can achieve static efficiencies of up to 84%, particularly in high-pressure environments such as forced draft systems for incinerators. Engineers must critically assess airflow rate and static pressure, as a higher airflow rate can improve system performance, while sufficient static pressure is essential for effective air movement throughout the system.

Real-world applications illustrate these principles. In industrial settings, centrifugal fans are commonly employed in dust collection systems, where maintaining a specific airflow rate is crucial for operational safety. Furthermore, the design of the impeller has a significant impact on performance; variations in blade geometry can result in distinct airflow characteristics and efficiency levels. Understanding these design factors empowers engineers to for their specific applications, ensuring reliable and effective operation.

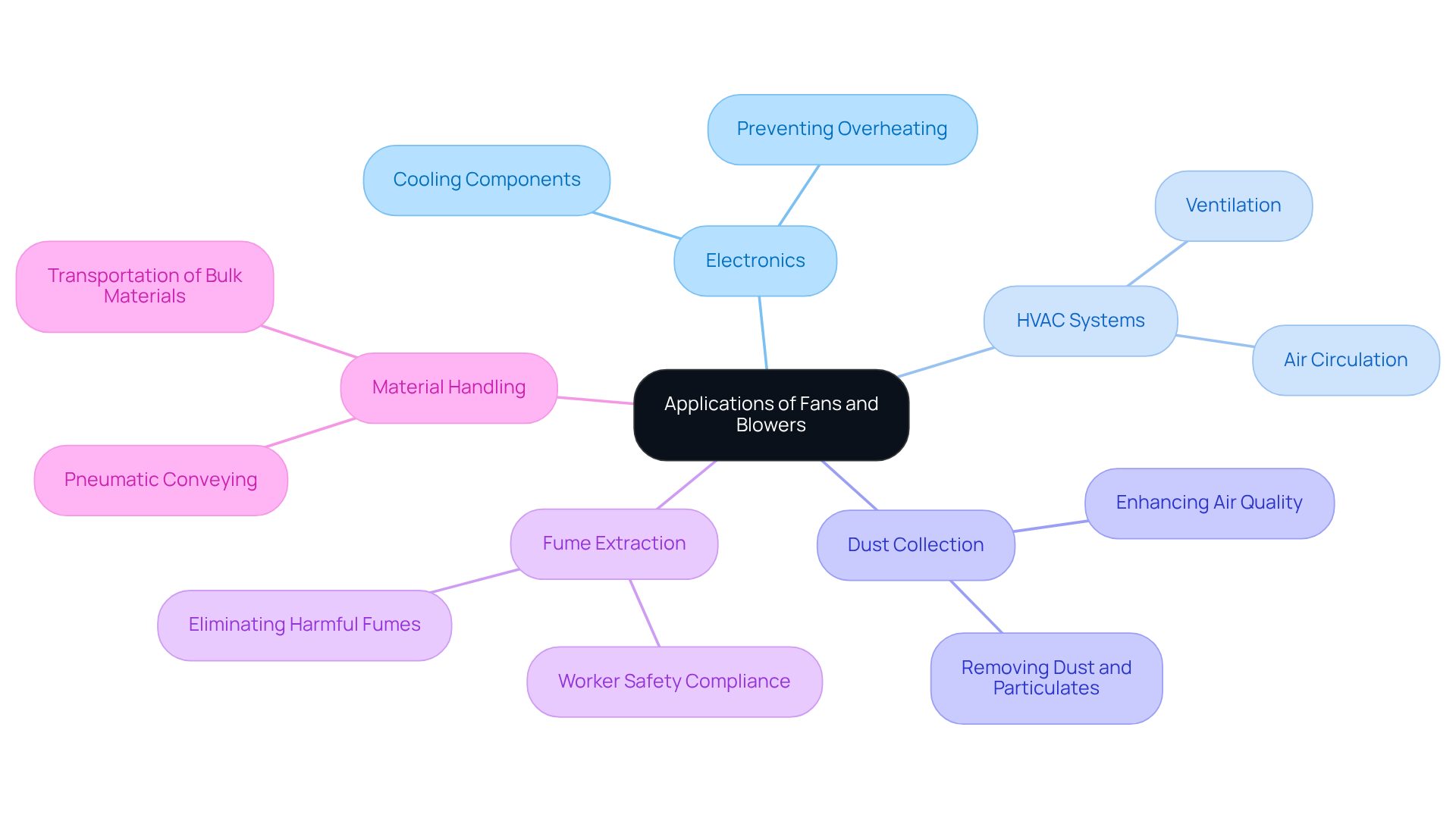

Identify Applications of Fans and Blowers: Engineering Contexts and Uses

The types of fans and blowers play a pivotal role across diverse industries and applications. In the electronics sector, centrifugal fans are indispensable for cooling components in devices such as computers and servers, effectively preventing overheating and ensuring optimal performance. Within , fans facilitate ventilation and air circulation, while exhaust devices are employed to efficiently move air through ductwork. Other notable applications include:

- Dust Collection: Centrifugal blowers excel in removing dust and particulates from industrial environments, significantly enhancing air quality and safety.

- Fume Extraction: These devices are utilized in laboratories and manufacturing facilities to uphold air quality by eliminating harmful fumes, a critical factor for worker safety and compliance with health regulations.

- Material Handling: Blowers support the transportation of bulk materials in processes like pneumatic conveying, thereby enhancing operations across various industrial uses.

Understanding these tools empowers engineers to effectively integrate types of fans and blowers into their designs, aligning with contemporary trends in energy efficiency and performance enhancement. The global fans and ventilation industry was valued at USD 7.6 billion in 2022 and is projected to expand at a CAGR of 5.7% from 2023 to 2031, potentially reaching USD 12.2 billion by the end of 2031. This growth underscores the escalating demand for advanced ventilation solutions, emphasizing the significance of these technologies in maintaining operational standards across sectors. Leading market players, including ABB Ltd. and Johnson Controls International plc, are spearheading innovations that enhance energy efficiency and performance in various types of fans and blowers applications.

Conclusion

Understanding the diverse types of fans and blowers, particularly centrifugal models, is essential for engineers seeking to optimize air movement across various applications. These mechanical devices serve the common purpose of moving air or gas, yet they operate on distinct principles and are tailored for specific tasks. The differentiation between fans, which generate low-pressure airflow, and blowers, which create higher pressure airflow, underscores the necessity for engineers to select the appropriate device based on their system requirements.

Throughout this article, critical insights regarding the functionality and applications of centrifugal fans and blowers have been shared. The three primary types—forward-curved fans, backward-curved blowers, and radial blowers—each exhibit unique characteristics that render them suitable for distinct environments. Moreover, performance metrics such as airflow rate and static pressure have been emphasized as vital factors influencing the efficiency and effectiveness of these devices in real-world scenarios. The anticipated growth of the centrifugal blower market further highlights the increasing reliance on these technologies across various industries, including HVAC systems, dust collection, and fume extraction.

In light of the information presented, it is clear that a comprehensive understanding of the types of fans and blowers is not merely academic but crucial for practical engineering applications. As industries continue to evolve, the demand for efficient and effective air movement solutions will only escalate. Engineers are encouraged to leverage this knowledge to make informed decisions that enhance operational efficiency and address emerging challenges in air handling and ventilation.

Frequently Asked Questions

What are fans and blowers?

Fans and blowers are mechanical devices designed for the movement of air or gas, but they operate on different principles and serve distinct roles.

How does a fan operate compared to a blower?

A fan typically generates low-pressure airflow, ideal for circulating air within a space, while a blower produces higher pressure airflow, essential for directing air in a specific direction.

What are the noise levels associated with fans and blowers?

Fans operate at noise levels ranging from 25 to 50 dB, whereas blowers generate noise levels between 60 and 85 dB.

What is the pressure ratio for air movers and air handlers?

Air movers operate with a pressure ratio of up to 1.11, while air handlers function within a pressure ratio range of 1.11 to 1.2.

In what applications are fans and blowers commonly used?

Fans and blowers are commonly used in HVAC systems for general airflow, cooling electronic components, and tasks requiring concentrated airflow, such as in forced hot air furnaces and hair dryers.

Why is it important for engineers to understand the distinctions between fans and blowers?

Understanding these distinctions is crucial for engineers to select the appropriate types of fans and blowers according to system requirements and operational efficiency.