Overview

The article provides a comprehensive overview of the key features and evolution of advanced motors, emphasizing their exceptional performance, efficiency, and precision across a multitude of applications. It elaborates on significant advancements in technology, such as high-energy magnets and digital control systems, which have markedly enhanced motor efficiency and functionality. These innovations render advanced motors indispensable in contemporary engineering and sustainable technologies.

Introduction

In an era where efficiency and sustainability are critical, advanced motors emerge as pivotal players in technological innovation, reshaping the electric motor systems landscape. These sophisticated devices, crafted with state-of-the-art materials and intelligent control systems, not only enhance performance across diverse applications but also significantly reduce energy consumption. The ramifications of advanced motor technology extend from electric vehicles to industrial machinery, marking a transformative shift in multiple sectors. As industries increasingly adopt these advancements, grasping their key characteristics, historical evolution, and future trends is essential for anyone aiming to navigate the complexities of modern engineering and sustainability initiatives.

Define Advanced Motors: Key Characteristics and Functionality

Advanced motors represent a significant leap forward in electric machinery, meticulously engineered to deliver exceptional performance, efficiency, and precision across diverse applications. These devices harness cutting-edge technologies, including high-energy magnets and sophisticated control systems, along with innovative cooling methods. Notably, the advanced motor’s high torque density facilitates compact designs without compromising power, rendering them ideal for demanding environments such as robotics, aerospace, and automotive sectors.

The functionality of advanced motors extends beyond mere motion; they serve as critical components in systems requiring precise control and rapid responsiveness. For instance, in electric vehicles, the advanced motor mechanisms enable seamless acceleration and deceleration, thereby enhancing the overall driving experience. Recent advancements have further optimized their efficiency, with studies from High Efficiency Electrified Aircraft Thermal Research (HEATheR) revealing that increasing engine efficiency from 96% to 99% can yield a 3% reduction in fuel consumption, underscoring the importance of these technologies in energy conservation efforts.

By 2025, a substantial proportion of sectors is expected to adopt advanced motor systems, highlighting their growing relevance in contemporary engineering. Single-phase induction machines, typically ranging from fractional horsepower to 10 HP, constitute a pivotal segment of this market. Case studies, such as the PrecisionFlow device by Nidec, demonstrate how electronically commutated machines can achieve up to 85% efficiency, surpassing conventional engines by as much as 30%. This efficiency not only minimizes energy waste but also reduces operational costs, making advanced motor technology an attractive option for various applications.

As industries continue to evolve, the integration of artificial intelligence in electric drive development is paving the way for customized eDrive systems that enhance performance while minimizing resource consumption. This trend underscores the vital role of advanced motors in facilitating the transition to more sustainable technologies across multiple sectors. Moreover, the importance of voltage and vibration analysis in identifying harmful current loops and signs of electrical discharge machining in bearings cannot be overlooked, as it plays a crucial role in maintaining performance.

In the realm of maintenance and performance monitoring, Taylor Sheppard, a Field Application Specialist at Fluke Reliability, emphasizes, “Whether on the plant floor, in the field, or in harsh or extreme conditions, VibXpert 3 Balancer’s intuitive interface makes it easy for experts and non-experts to go straight to the root cause of the unbalance and correct it using step-by-step guidance.” This statement highlights the significance of sophisticated monitoring tools in ensuring the reliability of complex system operations.

Furthermore, the recent introduction of the All-In-One DC-UPS by Altech exemplifies the integration of cutting-edge technology in power management solutions, further reinforcing their importance in addressing modern engineering challenges.

Trace the Evolution of Advanced Motors: Historical Context and Development

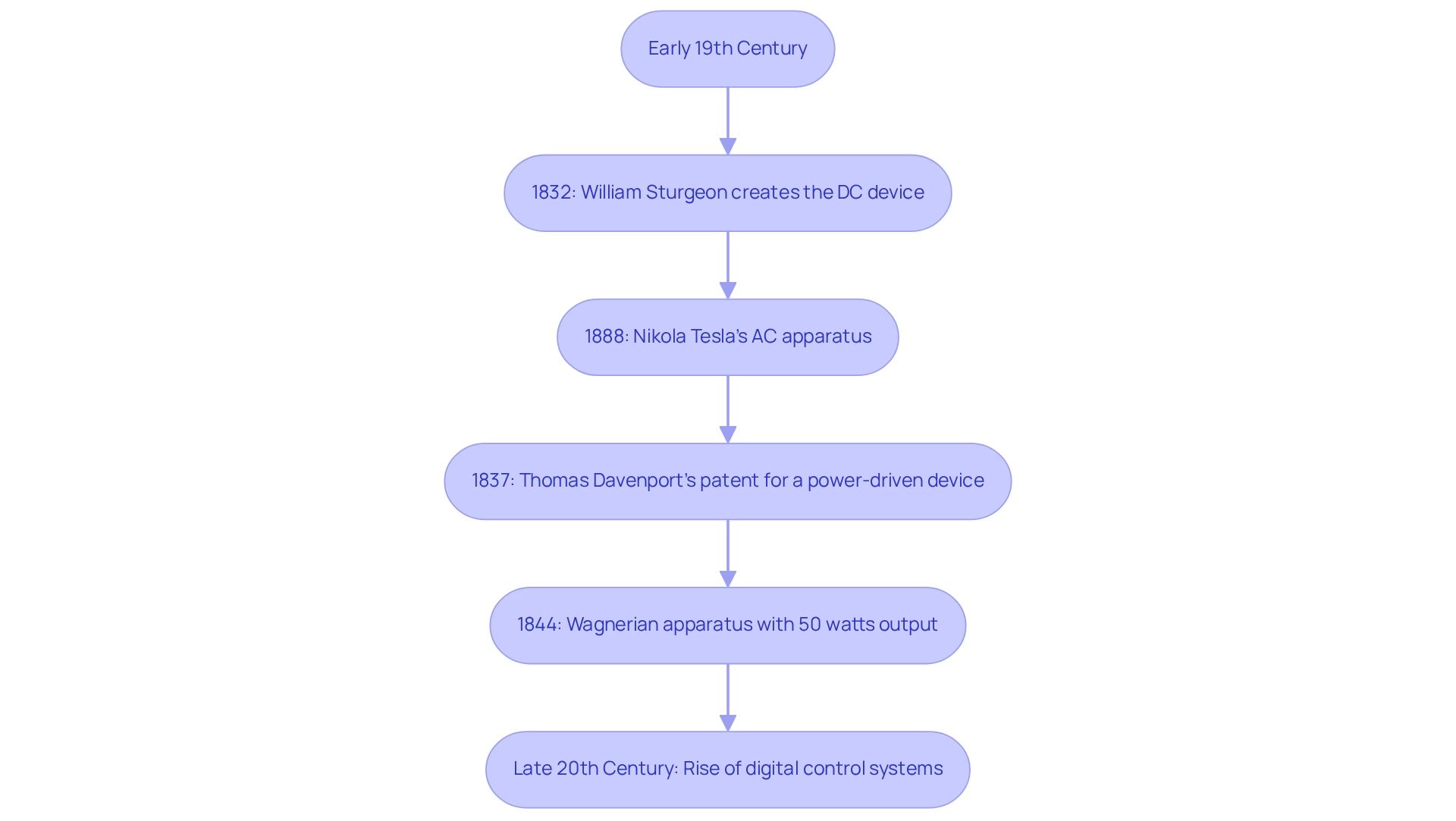

The development of sophisticated engines commenced in the early 19th century with the advent of the first powered machines. A pivotal moment occurred in 1832 when William Sturgeon created the DC device, followed by Nikola Tesla’s groundbreaking work on the AC apparatus in 1888. These innovations laid the groundwork for future advancements. Notably, the first patent for a power-driven device was awarded to Thomas Davenport in February 1837, representing a significant milestone in the history of such machines. Although Davenport’s design was less advanced than earlier European creations, it marked an essential step in the evolution of electric machinery.

Over the decades, advancements in materials, including the introduction of advanced motor technologies such as permanent magnets and high-efficiency windings, have resulted in devices that are not only more powerful but also more compact and energy-efficient. The late 20th century saw the rise of digital control systems, revolutionizing technology by enabling precise regulation and seamless integration into complex systems. This evolution has paved the way for contemporary applications, particularly in battery-powered vehicles and automation, ensuring that advanced motor systems remain the preferred choice for industrial applications for many years to come.

Furthermore, the Wagnerian apparatus evaluated in May and June of 1844 demonstrated early electric engine capabilities with a power output of only 50 watts. As André-Marie Ampère famously noted, “the invention of the cylindric coil (solenoid)” was a significant advancement that contributed to the progression of engine technology. Gagner-Toomey advocates for engaging reliable partners for movement solutions, effectively linking this rich historical context to current practices within the industry.

Examine Components of Advanced Motors: Structure and Mechanisms

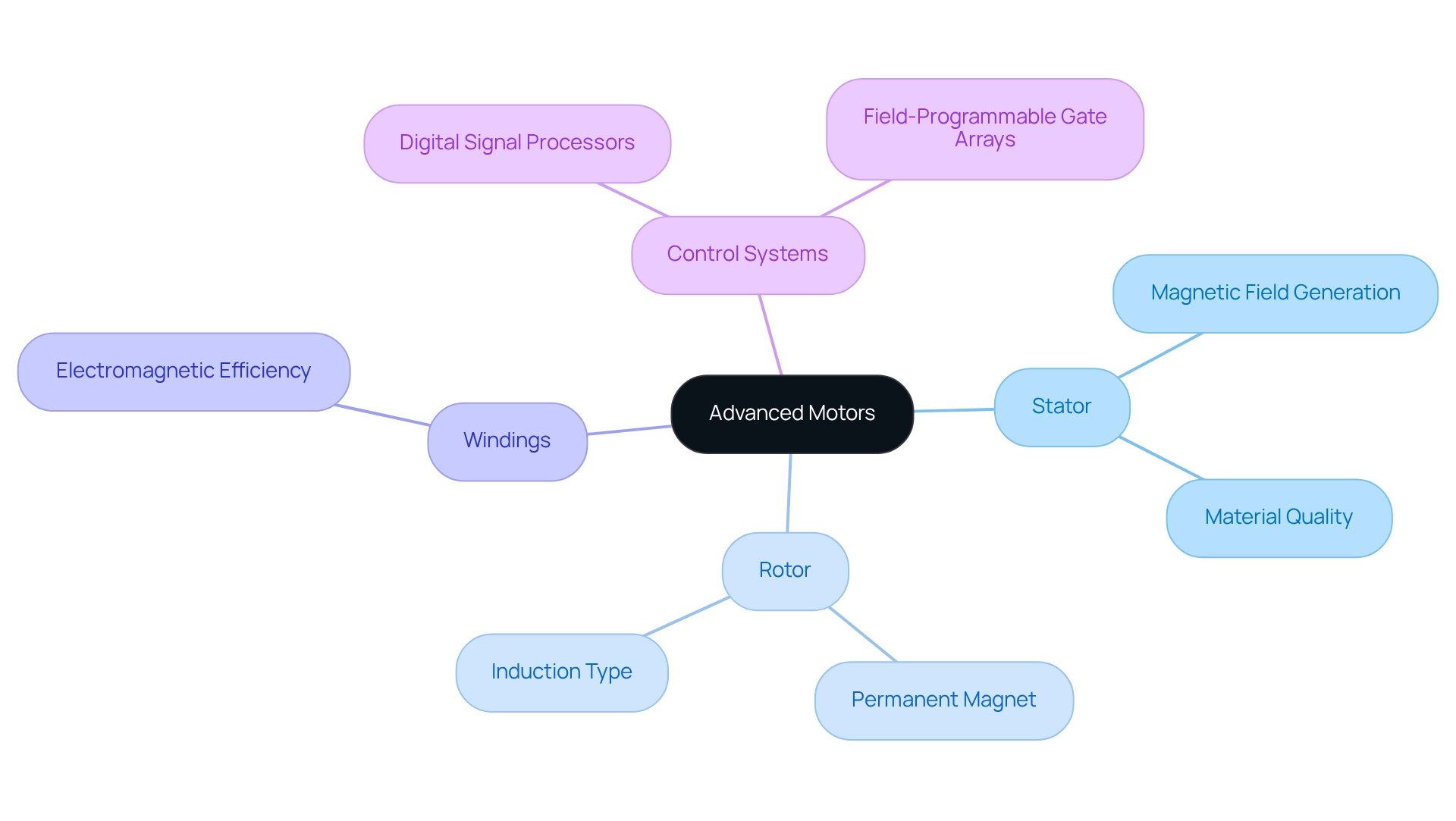

Advanced motors comprise several critical components: the stator, rotor, windings, and control systems. The stator, typically constructed from high-grade magnetic materials, generates a magnetic field that interacts dynamically with the rotor. Depending on the design, the rotor may be a permanent magnet or an induction type, effectively converting electrical energy into mechanical energy. The windings are meticulously designed to enhance electromagnetic efficiency, playing a crucial role in the device’s performance.

Moreover, advanced motor control systems, which utilize sophisticated digital signal processors (DSPs) and field-programmable gate arrays (FPGAs), enable accurate regulation of critical functions such as speed, torque, and position. This synergy among components significantly improves the overall efficiency and responsiveness of the system, making them particularly suitable for applications that require advanced motor performance.

According to industry data, advanced motor parts can attain efficiency ratings surpassing 95%, which is essential for applications demanding high reliability and performance. The typical lifespan of these sophisticated engine parts varies among applications; however, their sturdy design frequently results in prolonged operational durations, aiding in lower maintenance expenses and enhanced reliability in challenging settings.

As highlighted by prominent engineers in the field, ‘The incorporation of advanced motor control systems is crucial in maximizing efficiency and performance, enabling real-time adjustments that improve operational capabilities.’

Furthermore, a recent case study on the competitive environment in the vehicle parts market emphasizes how companies like Robert Bosch LLC are utilizing advanced motor technologies to sustain market leadership, demonstrating the practical implications of these components in real-world applications.

Explore Benefits of Advanced Motors: Efficiency and Performance Enhancements

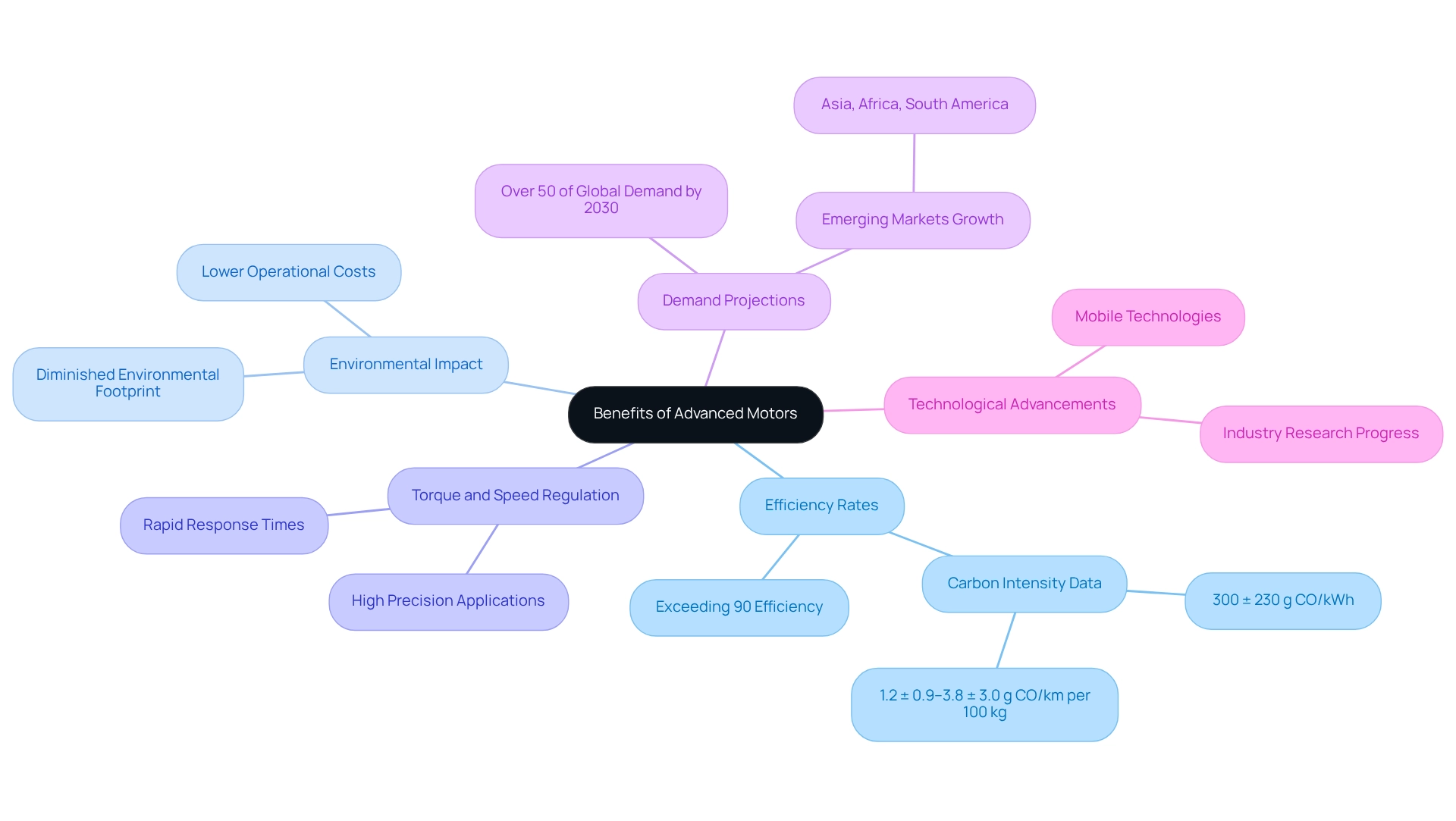

Advanced engines offer a multitude of advantages, primarily centered on their remarkable efficiency and performance. These engines often achieve energy efficiency rates exceeding 90%, a critical factor concerning indirect emissions from electricity with a carbon intensity of 300 ± 230 g CO/kWh, which translates to approximately 1.2 ± 0.9–3.8 ± 3.0 g CO/km for every 100 kg increase in vehicle mass. Consequently, this leads to significantly lower operational costs and a diminished environmental footprint. Their compact design facilitates seamless integration into diverse systems, ranging from battery-powered vehicles to industrial machinery.

Additionally, advanced motors deliver exceptional torque and speed regulation, which are essential for applications that demand rapid response times and high precision. For example, in battery-powered vehicles, these engines enhance driving range and acceleration, positioning them as vital components in the transition to sustainable transportation.

As developing economies continue to industrialize, the demand for such high-efficiency electric devices is projected to rise, with these regions expected to account for over 50% of global demand by 2030. This shift underscores the pivotal role of sophisticated engines in fostering both economic and ecological advancement.

As noted by Tajammul Pangarkar, CMO at Prudour Pvt Ltd, advancements in mobile technologies and industry research signal ongoing progress in engine efficiency, further emphasizing the importance of these innovations within the electronics sector.

Future Trends in Advanced Motor Technology

The future of advanced vehicle technology is on the cusp of transformative changes, primarily driven by the escalating demand for efficiency and sustainability. A significant trend is the integration of artificial intelligence (AI) within predictive maintenance and control systems, enhancing performance through real-time monitoring and optimization. This integration is expected to expand significantly, with data indicating a dramatic increase in AI implementation in control systems in the coming years. Moreover, advancements in materials science are enabling the development of lightweight composites and high-temperature superconductors, anticipated to yield engines that are not only more efficient but also more powerful. These innovations are crucial as industries transition towards battery-powered vehicles and renewable energy sources, striving to minimize their carbon footprints and enhance energy efficiency. Notably, the Asia Pacific region held the largest market share of the electric vehicle sector in 2023, underscoring the regional factors influencing advanced engine developments.

The global electric engine market is projected to exhibit a compound annual growth rate (CAGR) of 3.32% from 2025 to 2033, reflecting the increasing reliance on innovative engine solutions. This growth is significantly propelled by breakthroughs from South Korean vehicle manufacturers, renowned for their quality and innovation, thereby solidifying their position in the global market. Industry experts anticipate that the next decade will witness a surge in the adoption of these technologies, spurred by the necessity for sustainable solutions across various sectors. Case studies highlight market leaders such as Siemens AG, ABB Ltd., and Nidec Corporation, who are pioneering energy-efficient technologies, leveraging their expertise to meet the evolving demands of the industry. ABB Ltd. has introduced the OmniCoreTM platform, a faster, more precise, and sustainable intelligent automation solution, illustrating the pivotal role of AI in enhancing performance. As these trends unfold, the role of AI in optimizing advanced motor performance will become increasingly critical, shaping the future landscape of technology.

Conclusion

Advanced motors stand at the forefront of modern engineering, showcasing remarkable advancements in efficiency, performance, and sustainability. Their key characteristics—including high torque density, sophisticated control systems, and innovative materials—enable them to excel across a diverse range of applications, from electric vehicles to industrial machinery. The historical evolution of these motors, commencing with early inventions in the 19th century, underscores the continuous innovation that has propelled their development into the powerful and compact systems they are today.

The integration of advanced technologies has not only enhanced the operational capabilities of these motors but has also significantly diminished energy consumption and operational costs. As industries increasingly adopt these advanced systems, the benefits become evident, with energy efficiency rates often exceeding 90%. This positions advanced motors as essential components in the transition toward sustainable practices, particularly in emerging markets where demand is anticipated to surge sharply.

Looking ahead, the future of advanced motor technology is set for transformative changes, driven by advancements in artificial intelligence and materials science. The potential for AI to optimize motor performance through real-time monitoring and predictive maintenance is likely to redefine the operational landscape. As the electric motor market continues to expand, propelled by a global push for sustainability, advanced motors will play a crucial role in shaping a more efficient and environmentally friendly future. Embracing these technologies is not merely a choice; it is a necessity for industries aiming to thrive in an increasingly competitive and eco-conscious world.

Frequently Asked Questions

What are advanced motors and what makes them significant?

Advanced motors are highly engineered electric machinery designed for exceptional performance, efficiency, and precision across various applications. They utilize cutting-edge technologies like high-energy magnets, sophisticated control systems, and innovative cooling methods, making them ideal for demanding environments such as robotics, aerospace, and automotive sectors.

How do advanced motors enhance performance in electric vehicles?

In electric vehicles, advanced motors enable seamless acceleration and deceleration, improving the overall driving experience. Their high torque density allows for compact designs without sacrificing power, which is crucial for performance in these applications.

What efficiency improvements have been observed in advanced motors?

Recent advancements have optimized the efficiency of advanced motors, with studies indicating that increasing engine efficiency from 96% to 99% can lead to a 3% reduction in fuel consumption, highlighting their role in energy conservation.

What is the expected adoption rate of advanced motor systems by 2025?

By 2025, a substantial proportion of various sectors is anticipated to adopt advanced motor systems, reflecting their increasing relevance in contemporary engineering.

What are single-phase induction machines and their significance in the advanced motor market?

Single-phase induction machines, typically ranging from fractional horsepower to 10 HP, are a crucial segment of the advanced motor market. They play a pivotal role in various applications, providing efficient performance.

How do electronically commutated machines compare to conventional engines?

Case studies, such as the PrecisionFlow device by Nidec, show that electronically commutated machines can achieve up to 85% efficiency, outperforming conventional engines by as much as 30%, which reduces energy waste and operational costs.

What is the role of artificial intelligence in the development of electric drive systems?

The integration of artificial intelligence in electric drive development is leading to customized eDrive systems that enhance performance and minimize resource consumption, emphasizing the importance of advanced motors in sustainable technology transitions.

Why is voltage and vibration analysis important in advanced motors?

Voltage and vibration analysis are crucial for identifying harmful current loops and signs of electrical discharge machining in bearings, which helps maintain the performance and reliability of advanced motor systems.

What tools are available for maintenance and performance monitoring of advanced motors?

Tools like the VibXpert 3 Balancer are designed for maintenance and performance monitoring, providing intuitive interfaces that assist both experts and non-experts in diagnosing and correcting imbalances in motor systems.

What recent innovations have been made in power management solutions related to advanced motors?

The introduction of the All-In-One DC-UPS by Altech exemplifies the integration of advanced technology in power management solutions, addressing modern engineering challenges associated with advanced motors.