Introduction

Airflow plays a pivotal role in electronics engineering, directly impacting device performance and longevity. By understanding the various types of airflow – from laminar to turbulent – engineers can develop effective thermal management strategies that not only prevent overheating but also enhance system reliability. Yet, with a spectrum of airflow categories available, how can engineers identify the most appropriate type for their specific applications? This article explores the intricacies of airflow, shedding light on its significance and practical applications within the electronics domain.

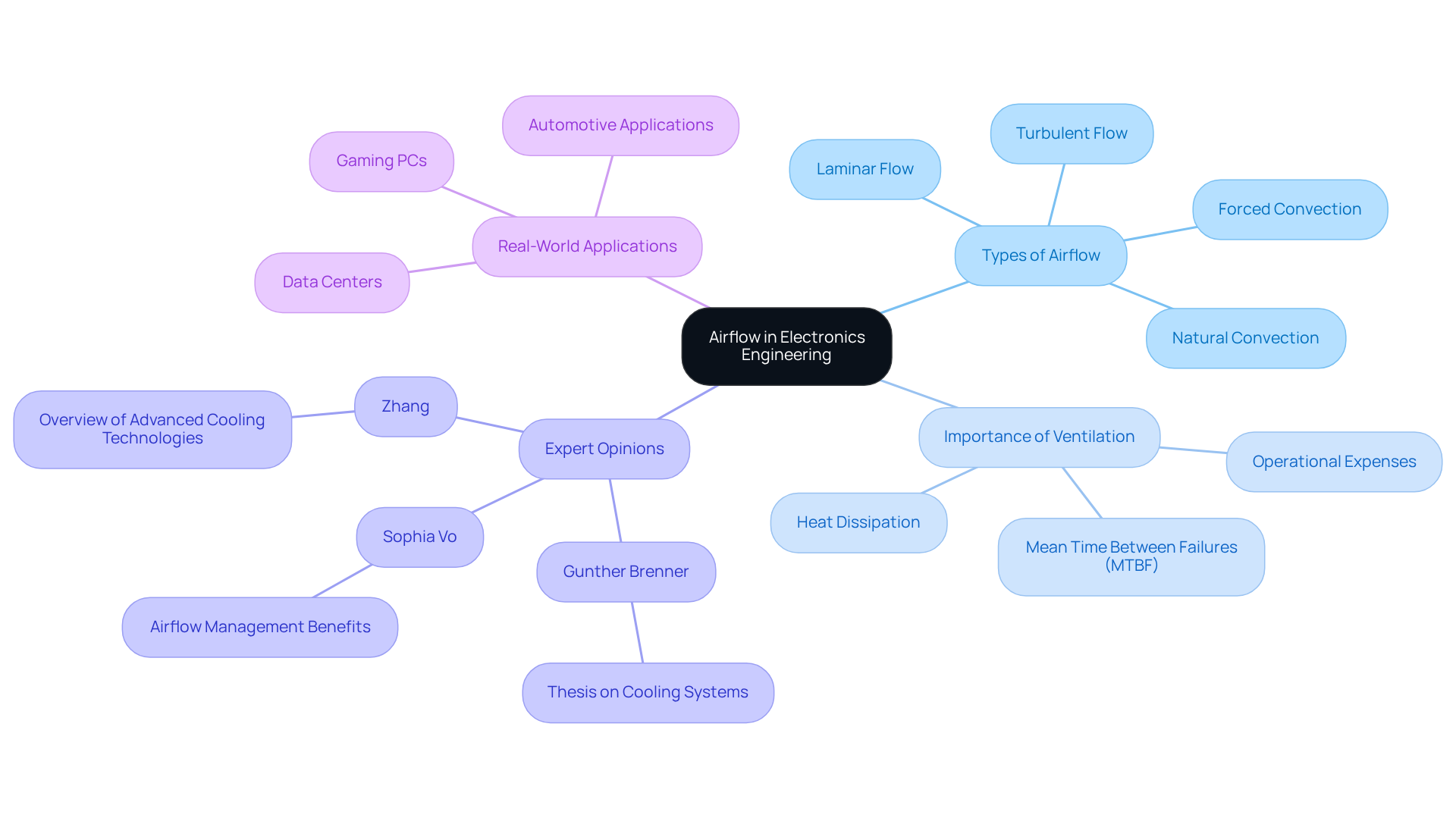

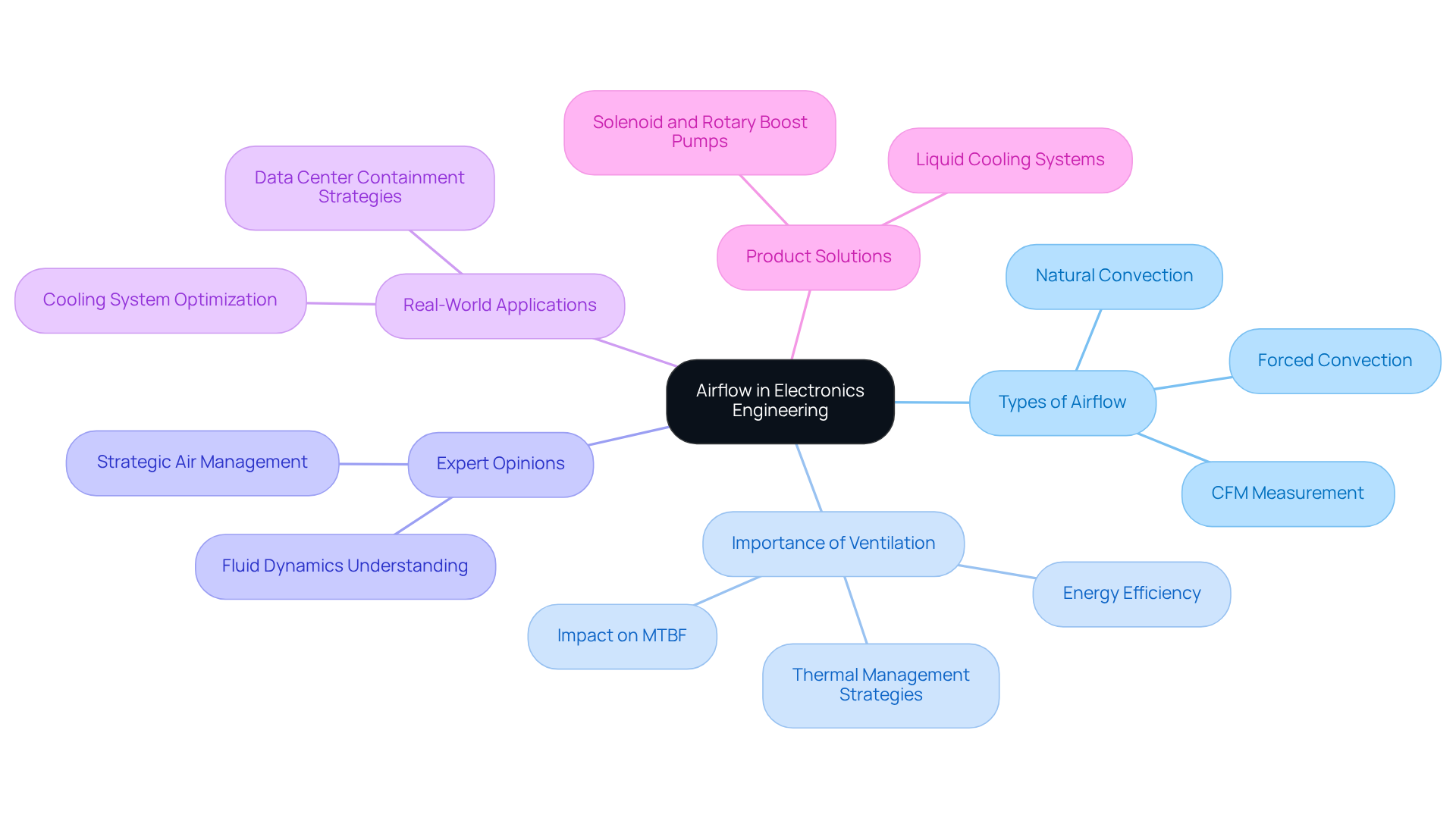

Define Airflow: Importance in Electronics Engineering

Airflow, which refers to the movement of air from one location to another, can be categorized into different types of airflow and is typically quantified in cubic feet per minute (CFM). In the field of electronics engineering, effective ventilation is paramount for maintaining optimal operating temperatures within devices, preventing overheating and subsequent failures. Statistics indicate that insufficient ventilation can lead to a significant reduction in the Mean Time Between Failures (MTBF) of electronic components, underscoring the necessity for robust thermal management strategies.

Effective ventilation management not only enhances the performance of electronic systems but also extends their longevity by facilitating efficient heat dissipation. This is especially crucial in high-density applications, such as servers and power electronics, where heat generation is substantial. Recent research has indicated that enhancing air circulation can decrease temperature regulation needs by as much as four times, resulting in reduced operational expenses and better efficiency in handling IT thermal loads.

Expert opinions emphasize that comprehending fluid dynamics is crucial for engineers to create more efficient cooling systems. For instance, industry leaders emphasize that strategic air management can eliminate hot spots, thereby preventing equipment overheating and potential downtime. Real-world instances, like the execution of containment strategies in data centers, illustrate the effectiveness of ventilation management in achieving consistent IT intake temperatures and notable energy savings. By prioritizing ventilation in electronic design, engineers can significantly enhance system reliability and performance.

Gagner-Toomey Associates provides cutting-edge solenoid and rotary boost pump solutions, including solenoid pumps able to function up to 16 Bar, equipped with a DC Brushless motor and low noise operation, which are intended to facilitate accurate air control in electronic applications. These pumps are compliant with automotive standards and certified with quality management IATF 16969, ensuring reliability and performance.

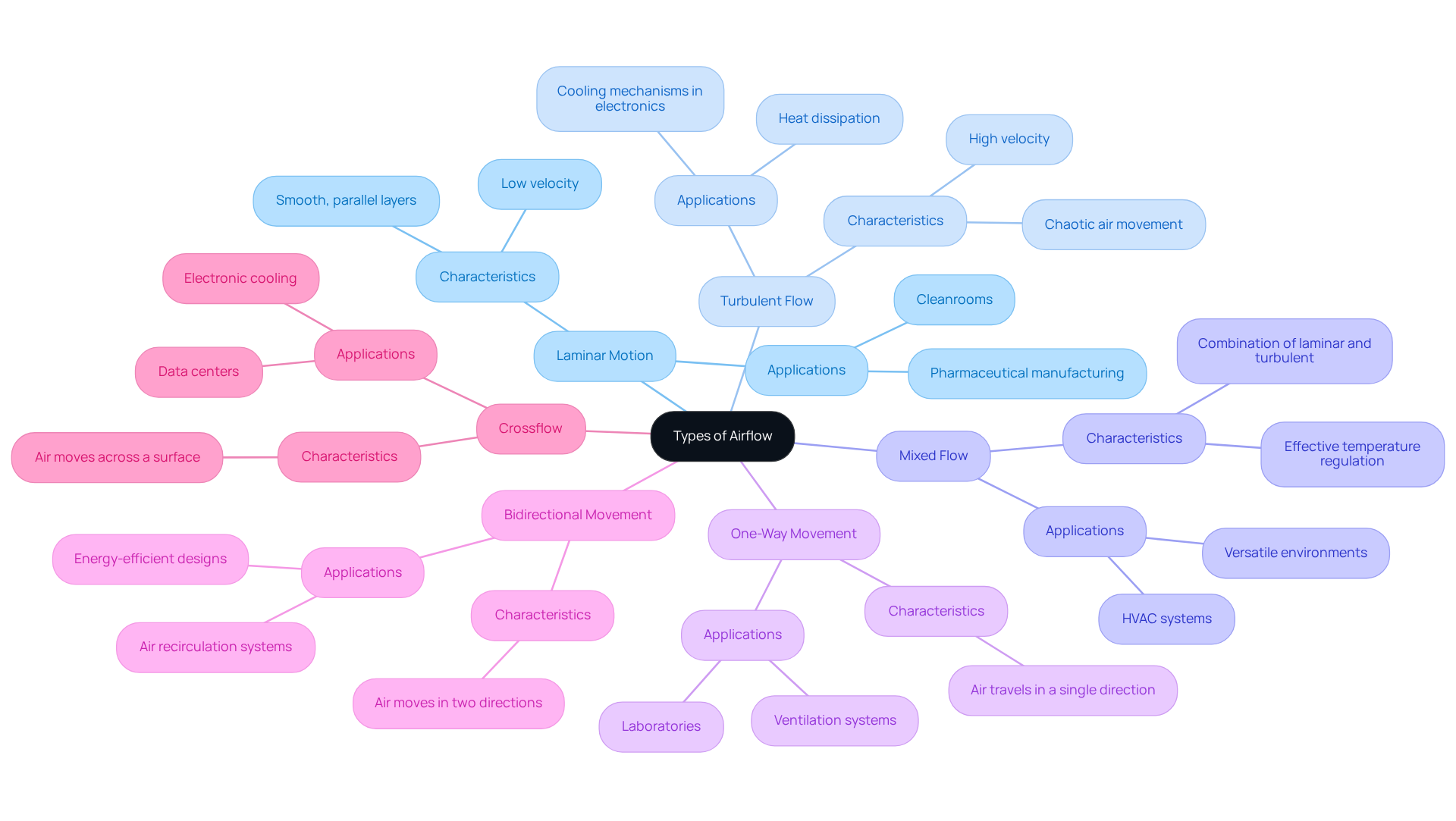

Explore the Six Types of Airflow: Overview and Categories

There are six primary types of airflow: laminar, turbulent, mixed, unidirectional, bidirectional, and crossflow. Understanding these categories is essential for engineers aiming to enhance ventilation systems tailored to specific operational requirements.

-

Laminar Motion: This type is characterized by smooth, parallel layers of air. Laminar motion is ideal for applications that demand precise airflow control, such as cleanrooms. By minimizing contamination, it ensures a sterile environment, which is critical in pharmaceutical and semiconductor manufacturing.

-

Turbulent Flow: In contrast, turbulent flow involves chaotic air movement that enhances mixing. This is particularly beneficial in applications requiring rapid heat dissipation. Turbulent movement is generally noisy and fast, making it vital for cooling mechanisms in electronics, where efficient thermal regulation is crucial for performance and reliability.

-

Mixed Flow: A combination of laminar and turbulent movement, mixed flow is commonly found in HVAC systems where both accuracy and mixing are necessary. This type allows for effective temperature regulation while maintaining air quality, making it a versatile choice for various environments.

-

One-Way Movement: In one-way movement, air travels in a single direction, often utilized in ventilation systems to ensure consistent air quality. This type is particularly important in spaces where contaminants must be controlled, such as laboratories and hospitals.

-

Bidirectional Movement: This type allows air to move in two directions, often employed in systems that require air recirculation. Bidirectional movement enhances energy efficiency by reusing conditioned air, thereby reducing operational costs.

-

Crossflow: In crossflow, air moves across a surface, effectively lowering temperatures of components by dissipating heat from multiple sources simultaneously. This type is especially effective in data centers and electronic cooling applications, where managing heat from densely packed equipment is essential.

Understanding these types of airflow categories aids engineers in designing systems that ensure efficiency and effectiveness across diverse applications. Additionally, the Reynolds number plays a crucial role in predicting types of movement: values below 2,000 indicate laminar movement, while those above 4,000 suggest turbulent movement. Integrating insights from industry experts can further enhance understanding of these fluid movement classifications and their implications in engineering design.

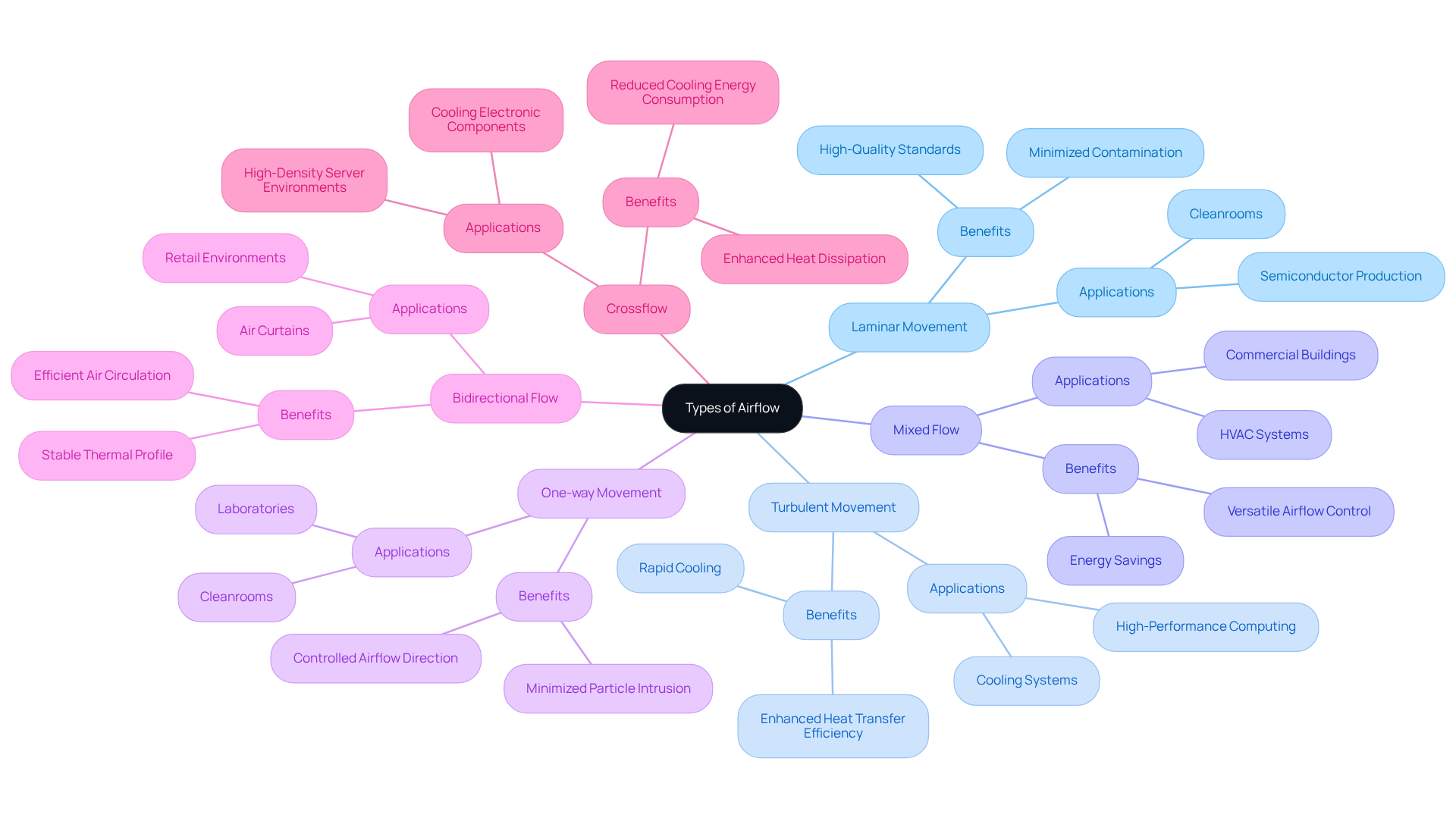

Analyze Each Type of Airflow: Technical Insights and Applications

-

Laminar Movement: In environments where contamination must be minimized, such as semiconductor production, laminar movement setups are indispensable. They maintain steady airflow patterns that significantly reduce particle deposition, ensuring adherence to high-quality manufacturing standards. This precision is vital, as even the slightest contamination can result in major defects in semiconductor devices.

-

Turbulent Movement: Widely used in cooling systems, turbulent movement enhances heat transfer efficiency, making it ideal for high-performance computing environments where rapid cooling is critical. Research shows that various types of airflow, especially turbulent movement, can enhance cooling efficiency by enabling better heat exchange, which is crucial for managing the thermal loads of densely packed electronics. As Sophia Vo states, “Improving efficiency through data center airflow management is crucial for maximizing cooling capacity, reducing energy consumption, and lowering operating costs.”

-

Mixed Flow: Commonly found in HVAC systems, mixed flow combines the benefits of both laminar and turbulent movements. This method effectively controls temperature and accommodates various types of airflow while ensuring air quality, making it a versatile option for applications such as commercial buildings and data centers. Implementing mixed circulation setups can lead to energy savings of up to 40% in specific HVAC applications.

-

One-way Movement: Critical in cleanrooms and laboratories, one-way movement setups maintain a specific airflow direction that is essential for managing contamination levels. By directing air to flow in one direction, these systems minimize the risk of particle intrusion, which is crucial for sensitive manufacturing processes that necessitate specific types of airflow. Eric Pittana highlights that “Integrating voltage regulation directly on or near the chip can significantly reduce power loss, improve transient response, and minimize parasitics – especially important for high-bandwidth AI and HPC workloads.”

-

Bidirectional Flow: Employed in applications like air curtains, bidirectional flow structures play a vital role in preserving temperature and air quality by facilitating efficient air circulation. This circulation is crucial in environments where maintaining a stable thermal profile is necessary for operational efficiency, particularly in retail and food service sectors, as it involves various types of airflow.

-

Crossflow: Designed to cool electronic components effectively, crossflow mechanisms direct air across multiple surfaces, enhancing heat dissipation and overall performance. This design is particularly advantageous in applications where maximizing cooling efficiency and different types of airflow are paramount, such as in high-density server environments. Real-world implementations have demonstrated that crossflow systems can reduce cooling energy consumption by up to 30%.

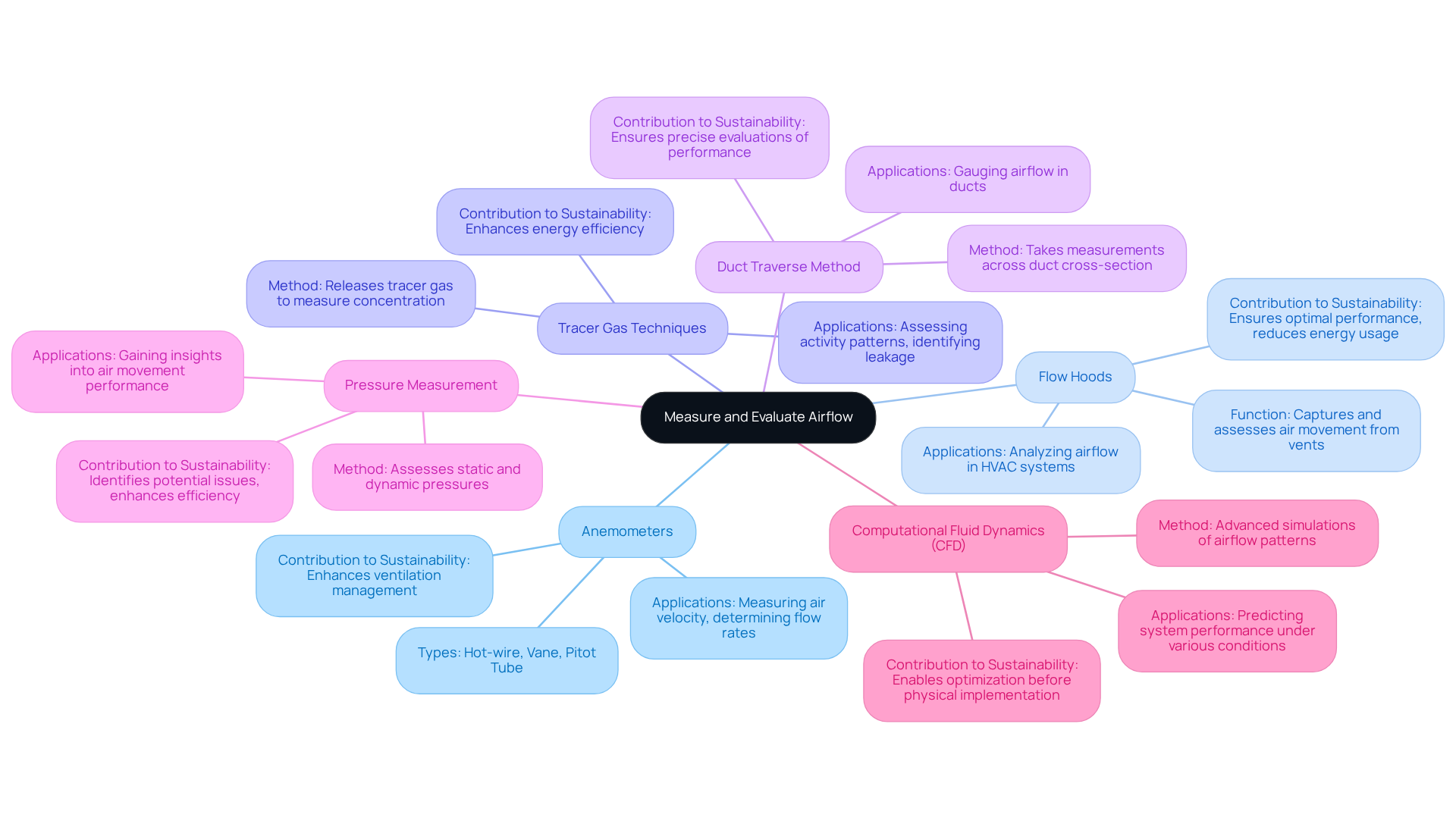

Measure and Evaluate Airflow: Techniques and Tools for Engineers

Engineers can effectively measure and evaluate airflow using a variety of techniques and tools, each contributing to enhanced sustainability in engineering projects:

-

Anemometers: Essential for measuring air velocity and determining flow rates, anemometers come in various types, including hot-wire, vane, and pitot tube models. Each of the types of airflow is designed for specific applications, showcasing advancements in technology that improve accuracy and efficiency. As Mike Quigley noted, effective ventilation management is crucial for public health and environmental sustainability.

-

Flow Hoods: These devices capture and assess the movement of air from vents, providing accurate measurements of air volume. Flow hoods are essential for analyzing types of airflow in HVAC systems and ensuring optimal performance. Inefficient ventilation management can lead to increased energy usage, with cooling unit fans accounting for 5% to 10% of overall data center energy consumption.

-

Tracer Gas Techniques: This method involves releasing a tracer gas into the air stream and measuring its concentration at various points. It effectively assesses activity patterns and identifies leakage, contributing to enhanced energy efficiency. Azeezat Afinowi-Subair emphasizes that clean air is a right, underscoring the importance of effective ventilation management in achieving sustainable environments.

-

The Duct Traverse Method: This conventional approach for gauging types of airflow in ducts involves taking several measurements across the duct’s cross-section to achieve an average air rate, ensuring precise evaluations of performance.

-

Pressure Measurement: By assessing static and dynamic pressures within a framework, engineers gain insights into air movement performance and can identify potential issues, thereby enhancing the overall efficiency of cooling setups.

-

Computational Fluid Dynamics (CFD): Advanced simulations using CFD allow engineers to model airflow patterns and predict system performance under various conditions. This capability enables optimization before physical implementation, leading to more sustainable designs.

By employing these techniques, engineers can ensure that their designs not only meet performance specifications but also enhance energy efficiency and sustainability by considering different types of airflow in the electronics industry.

Conclusion

Understanding the various types of airflow is crucial for engineers aiming to optimize electronic systems. This article underscores the significance of airflow in electronics engineering, highlighting its vital role in effective thermal management, performance enhancement, and device longevity. By categorizing airflow into six distinct types – laminar, turbulent, mixed, unidirectional, bidirectional, and crossflow – engineers can tailor their designs to meet specific operational needs and address overheating challenges.

Key insights regarding the applications and benefits of each airflow type have been provided. For instance, the precise control of laminar flow in cleanroom environments contrasts with the efficient heat dissipation achieved through turbulent and crossflow movements. Each category serves a unique purpose in maintaining optimal operating conditions. Furthermore, the importance of measurement techniques, such as anemometers and computational fluid dynamics, has been emphasized, enabling engineers to assess and enhance airflow management effectively.

As the demand for efficient electronic systems continues to rise, understanding and implementing the appropriate types of airflow becomes increasingly critical. Engineers are encouraged to leverage the insights and tools discussed in this article to optimize their designs, ensuring improved energy efficiency and sustainability. By prioritizing effective airflow management, the reliability and performance of electronic devices can be significantly enhanced, paving the way for advancements in technology and engineering solutions.

Frequently Asked Questions

What is airflow in the context of electronics engineering?

Airflow refers to the movement of air from one location to another and is typically quantified in cubic feet per minute (CFM). In electronics engineering, effective airflow is crucial for maintaining optimal operating temperatures within devices.

Why is effective ventilation important in electronics engineering?

Effective ventilation is vital for preventing overheating, which can lead to failures in electronic components. Insufficient ventilation can significantly reduce the Mean Time Between Failures (MTBF) of these components.

How does ventilation management impact the performance and longevity of electronic systems?

Proper ventilation management enhances the performance of electronic systems and extends their longevity by facilitating efficient heat dissipation, especially in high-density applications like servers and power electronics.

What recent findings highlight the benefits of improved air circulation in electronics?

Recent research indicates that enhancing air circulation can reduce temperature regulation needs by up to four times, leading to lower operational expenses and improved efficiency in managing IT thermal loads.

Why is understanding fluid dynamics important for engineers in this field?

Comprehending fluid dynamics is crucial for engineers to design more efficient cooling systems, as it helps in strategic air management to eliminate hot spots and prevent equipment overheating.

Can you provide an example of effective ventilation management in real-world applications?

One example is the implementation of containment strategies in data centers, which demonstrates how effective ventilation management can achieve consistent IT intake temperatures and significant energy savings.

What products does Gagner-Toomey Associates offer related to airflow management?

Gagner-Toomey Associates provides solenoid and rotary boost pump solutions, including solenoid pumps that operate up to 16 Bar, equipped with a DC Brushless motor for low noise operation, designed for accurate air control in electronic applications.

What standards do Gagner-Toomey Associates’ products comply with?

Their products comply with automotive standards and are certified with quality management IATF 16969, ensuring reliability and performance.