Overview

EC motor fans, or Electronically Commutated fans, represent a pinnacle of technology that employs brushless DC technology to significantly enhance efficiency and performance across various applications, especially within the electronics sector. These advanced devices deliver remarkable benefits, including:

- Exceptional energy savings of up to 70%

- Reduced noise levels

- Compact designs

Such features make them particularly well-suited for environments that demand optimal temperature control and require minimal maintenance. By integrating these fans into your operations, you can achieve a new standard of efficiency and reliability.

Introduction

EC motor fans, or Electronically Commutated fans, signify a remarkable advancement in efficiency and functionality within the electronics industry. By leveraging advanced brushless DC technology, these fans not only optimize energy consumption but also deliver substantial performance enhancements compared to traditional AC models. As engineers explore the evolving landscape of fan technology, a critical question emerges: are the higher initial costs of EC motor fans justified by their long-term benefits in energy savings and operational reliability?

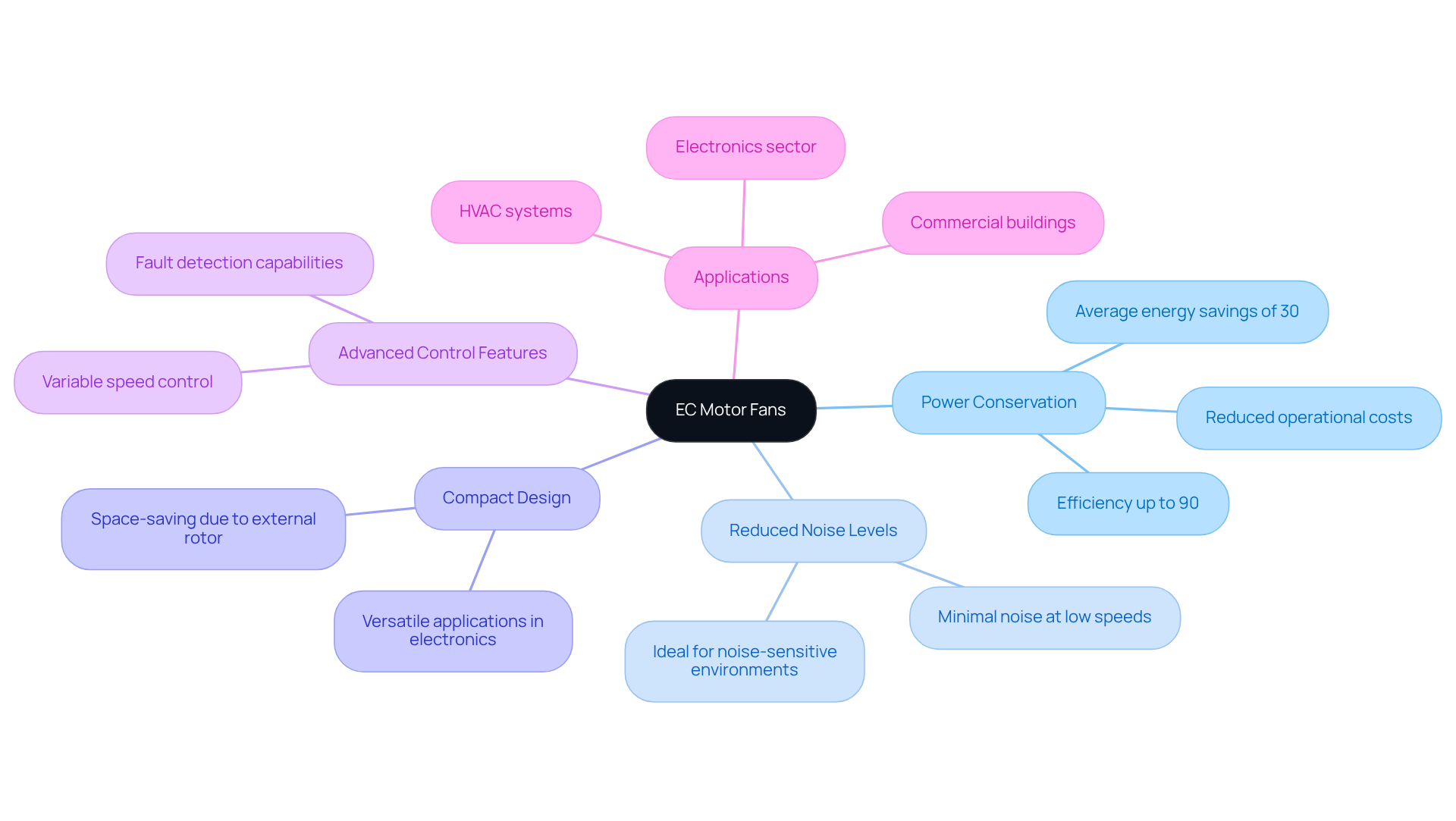

Define EC Motor Fans: Key Characteristics and Mechanisms

EC motor fans, also known as Electronically Commutated fans, leverage brushless DC technology, merging the benefits of both AC and DC systems. The phrase ‘electronically commutated’ highlights the device’s proficiency in converting alternating current (AC) into direct current (DC) through integrated electronics. This cutting-edge design facilitates precise control over fan speed and direction, significantly enhancing effectiveness and performance. Notably, EC devices can achieve performance levels of up to 90%, compared to the 20% to 70% performance range of conventional AC units, resulting in average savings of approximately 30%.

Key characteristics of the EC motor fan blowers include:

- Exceptional power conservation

- Reduced noise levels

- Compact design

These features make them particularly suitable for diverse applications within the electronics sector. The incorporation of advanced electronics not only permits variable speed control but also enables fault detection, optimizing functionality and reliability. For instance, in HVAC systems, EC units can operate at lower speeds while maintaining effectiveness, leading to substantial energy savings and reduced operational costs. Their ability to function quietly at low rotational speeds renders them ideal for noise-sensitive environments, such as libraries and offices, where preserving a tranquil atmosphere is essential.

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers for cooling, offers an extensive range of DC input Tube Axial fans, ranging from 15 to 280mm, and Centrifugal Blowers, from 15 to 225mm, optimized for performance. Furthermore, most models are available with IP protection upon request, enhancing their applicability across various settings. The versatility of EC devices extends to their practical applications, where they can replace various traditional fan types, ensuring high performance even at partial loads. This adaptability, coupled with their compact design, allows for significant space savings in numerous installations. Ultimately, advancements in EC motor fan technology position these units as essential components in the ongoing evolution of within the electronics industry.

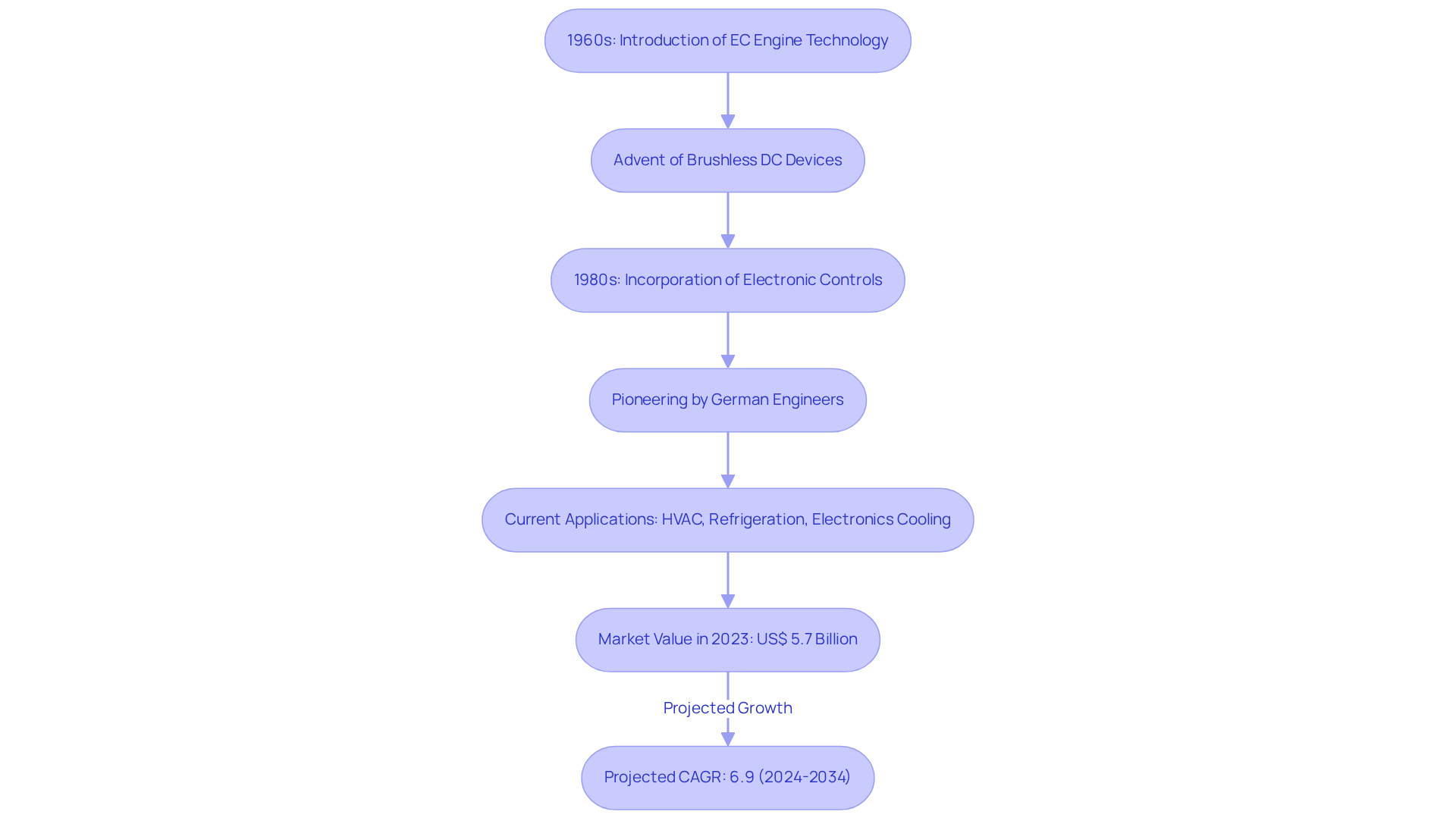

Explore the Evolution of EC Motor Technology in Electronics

The development of EC engine technology commenced in the 1960s, initially focusing on enhancing the performance of conventional AC devices. A pivotal moment occurred with the advent of brushless DC devices, which eliminated mechanical brushes, significantly reducing wear and maintenance needs. By the 1980s, the incorporation of electronic controls and electronic commutation technology further advanced performance and energy efficiency. This adaptation of EC technology for contemporary applications was notably pioneered by German engineers, underscoring innovation within the field.

Today, are widely utilized across various applications, including HVAC systems, refrigeration, and electronics cooling, due to their superior efficiency, durability, and reliability. Notably, the electronically commutated engines market was valued at approximately US$ 5.7 billion in 2023 and is projected to grow at a CAGR of 6.9% from 2024 to 2034, driven by the increasing demand for energy-efficient solutions. The continuous advancements in smart technologies further enhance the capabilities of EC devices, solidifying their status as the preferred choice for engineers in the electronics sector. Their advantages over traditional AC and DC machines, along with their contributions to power savings and reduced maintenance requirements, further underscore their significance in today’s market.

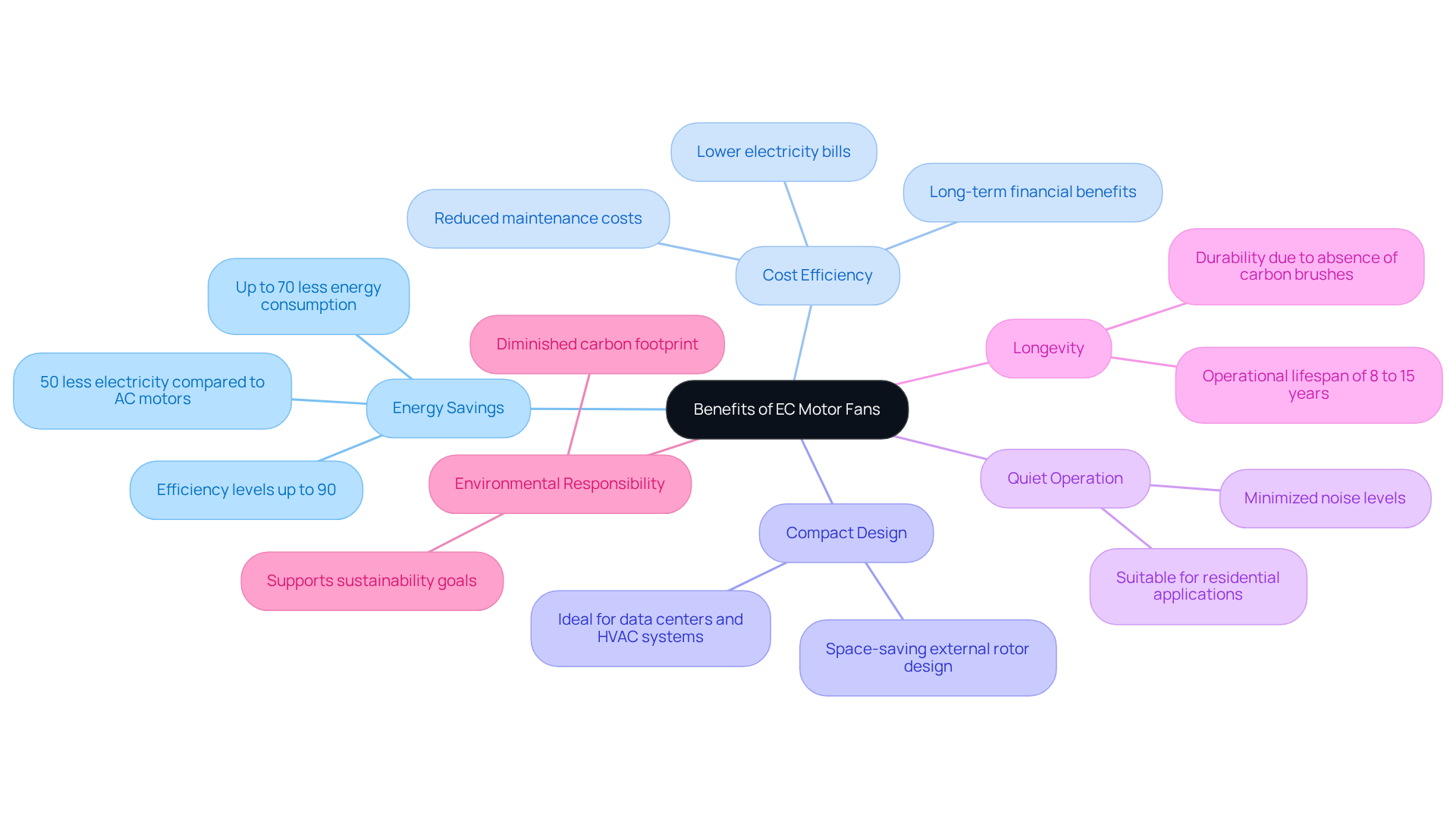

Identify the Benefits of EC Motor Fans for Engineering Applications

EC propulsion devices present substantial advantages for engineering applications, particularly in terms of power conservation and cost efficiency. With performance ratings exceeding 90%, these fans can than traditional AC fans, and they can achieve energy savings of up to 50% compared to their AC counterparts. This results in significantly lower electricity bills and a diminished carbon footprint, positioning them as an environmentally responsible choice for engineers.

Their compact design and quiet operation make them particularly suitable for space-sensitive environments, such as data centers and residential HVAC systems, where noise reduction is a critical factor. Furthermore, the longevity and reliability of EC fans—often lasting between 8 to 15 years—translate into reduced maintenance costs, thereby enhancing their overall attractiveness.

The absence of carbon brushes in EC devices minimizes wear and tear, bolstering their durability and operational efficiency, which in turn promotes a longer lifespan and reliable performance. As John Palomba from ebm-papst Inc. articulates, “In an era where every watt counts, the EC fan advantages provide a clear path forward—one that supports both operational excellence and environmental responsibility.”

Consequently, engineers can anticipate not only immediate energy savings but also enduring financial benefits stemming from decreased maintenance and replacement costs.

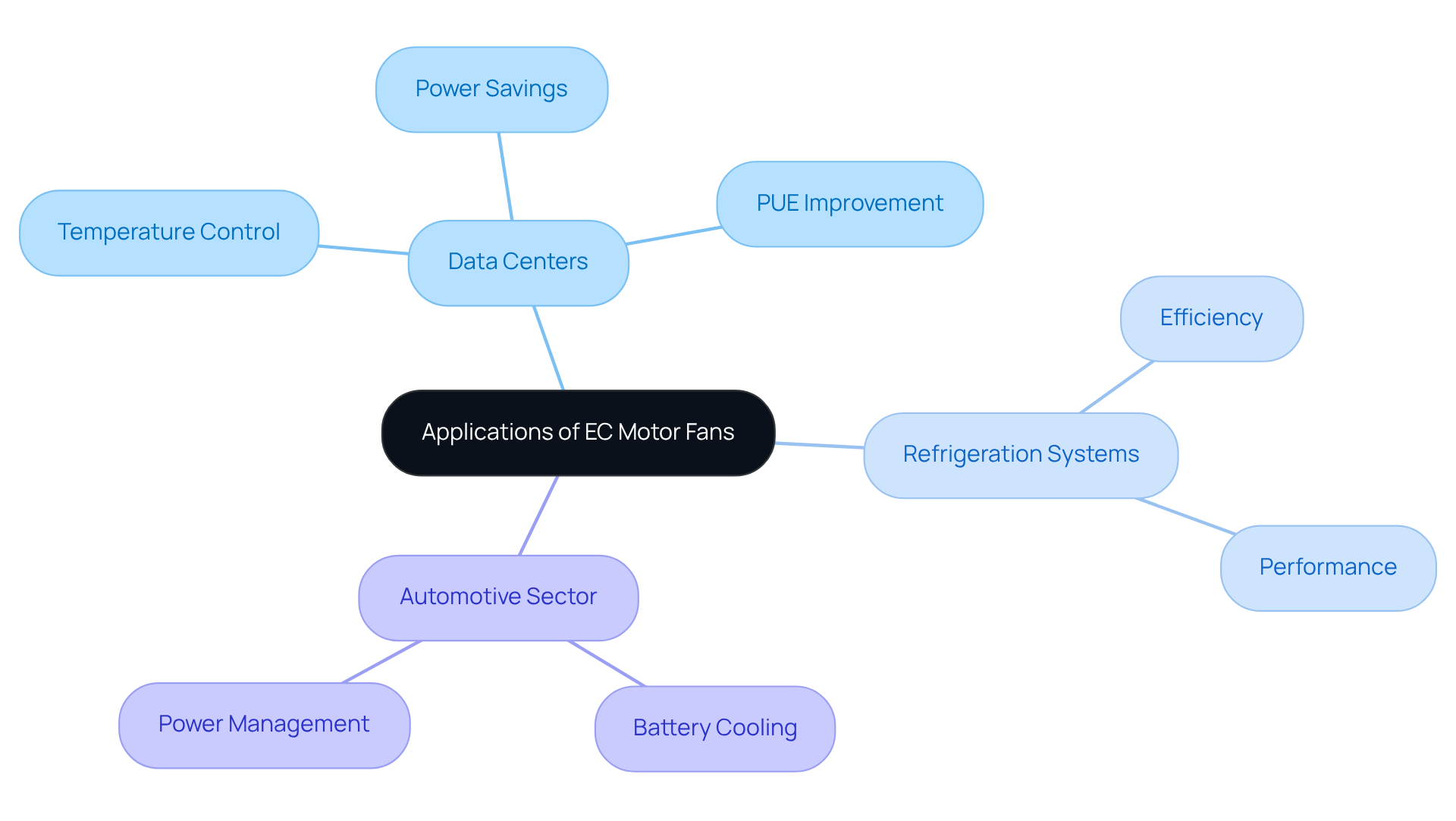

Applications of EC Motor Fans in the Electronics Industry

EC motor fans are indispensable in various applications within the electronics industry, particularly in data centers where they are crucial for maintaining optimal temperature control. By effectively regulating airflow, an EC motor fan significantly mitigates the risk of overheating and equipment failure, which is vital for the reliability of sensitive electronic systems. Their versatility is transformative, leading to reduced operational costs and supporting . For instance, EC units can lower cooling power consumption by up to 40%, contributing to improved Power Usage Effectiveness (PUE) ratings while enhancing overall performance. Data centers that have upgraded their cooling systems with EC devices report substantial power savings, underscoring the importance of these technologies in modern infrastructure.

In addition to data centers, EC cooling devices are critical in refrigeration systems, enhancing both efficiency and operational performance. The automotive sector benefits from these devices as well, especially in electric and hybrid vehicles, where they improve battery cooling and overall power management. As technology evolves, the applications for EC engine units are expected to broaden, highlighting their importance in contemporary engineering solutions. Notably, experts assert that integrating EC devices with intelligent building technologies can further enhance energy efficiency and system performance, making them a key component in the pursuit of more sustainable operations. However, it is essential to acknowledge that the initial investment in EC motor fans may be higher than that of traditional AC motors, which could potentially deter price-sensitive customers. Nevertheless, the long service life and minimal maintenance needs of an EC motor fan offer significant benefits that enhance its overall value.

Conclusion

EC motor fans signify a considerable leap forward in fan technology, merging the efficiency of brushless DC systems with the adaptability of AC systems. Their innovative design facilitates precise speed control, exceptional energy savings, and quieter operation, rendering them an optimal choice for diverse applications within the electronics industry. As the demand for energy-efficient solutions escalates, EC motor fans are increasingly vital for engineers aiming to enhance performance while minimizing operational costs.

Throughout this article, the key advantages of EC motor fans have been underscored, including:

- Impressive energy efficiency

- Durability

- Lower maintenance requirements

With performance ratings frequently surpassing 90%, these fans not only reduce electricity expenses but also contribute to a diminished carbon footprint. Their applications encompass crucial sectors such as:

- Data centers

- HVAC systems

- Refrigeration

Where they are instrumental in boosting efficiency and reliability. The evolution of EC motor technology has paved the way for a future where sustainable engineering practices are not merely desirable but imperative.

In conclusion, adopting EC motor fans represents a progressive decision for engineers committed to enhancing performance and sustainability in their projects. As technology evolves and the demand for energy-efficient solutions intensifies, the integration of EC motor fans will be crucial in fostering innovation and operational excellence across various sectors. The long-term advantages—both financial and environmental—present a compelling case for their adoption, urging engineers to incorporate these advanced solutions into their designs and systems.

Frequently Asked Questions

What are EC motor fans?

EC motor fans, or Electronically Commutated fans, utilize brushless DC technology to combine the advantages of AC and DC systems, allowing for efficient conversion of alternating current (AC) into direct current (DC) through integrated electronics.

What are the key characteristics of EC motor fans?

Key characteristics include exceptional power conservation, reduced noise levels, and a compact design, making them suitable for various applications in the electronics sector.

How do EC motor fans improve energy efficiency?

EC motor fans can achieve performance levels of up to 90%, compared to the 20% to 70% range of conventional AC units, resulting in average energy savings of approximately 30%.

In what applications are EC motor fans particularly useful?

They are particularly useful in HVAC systems and noise-sensitive environments, such as libraries and offices, where they can operate quietly at lower speeds while maintaining effectiveness.

What advantages do EC motor fans offer in terms of functionality?

The advanced electronics in EC motor fans allow for variable speed control and fault detection, optimizing functionality and reliability.

What types of fans does Gagner-Toomey Associates manufacture?

Gagner-Toomey Associates manufactures a wide range of DC input Tube Axial fans (15 to 280mm) and Centrifugal Blowers (15 to 225mm), optimized for performance and available with IP protection upon request.

How do EC motor fans contribute to space savings in installations?

Their compact design and versatility allow EC motor fans to replace various traditional fan types, ensuring high performance even at partial loads and enabling significant space savings in numerous installations.