Overview

A TEC thermoelectric cooler, commonly referred to as a Peltier cooler, represents a sophisticated solid-state device that leverages the Peltier effect to establish a temperature differential conducive to efficient heat transfer. This capability renders it particularly suitable for applications demanding precise thermal management.

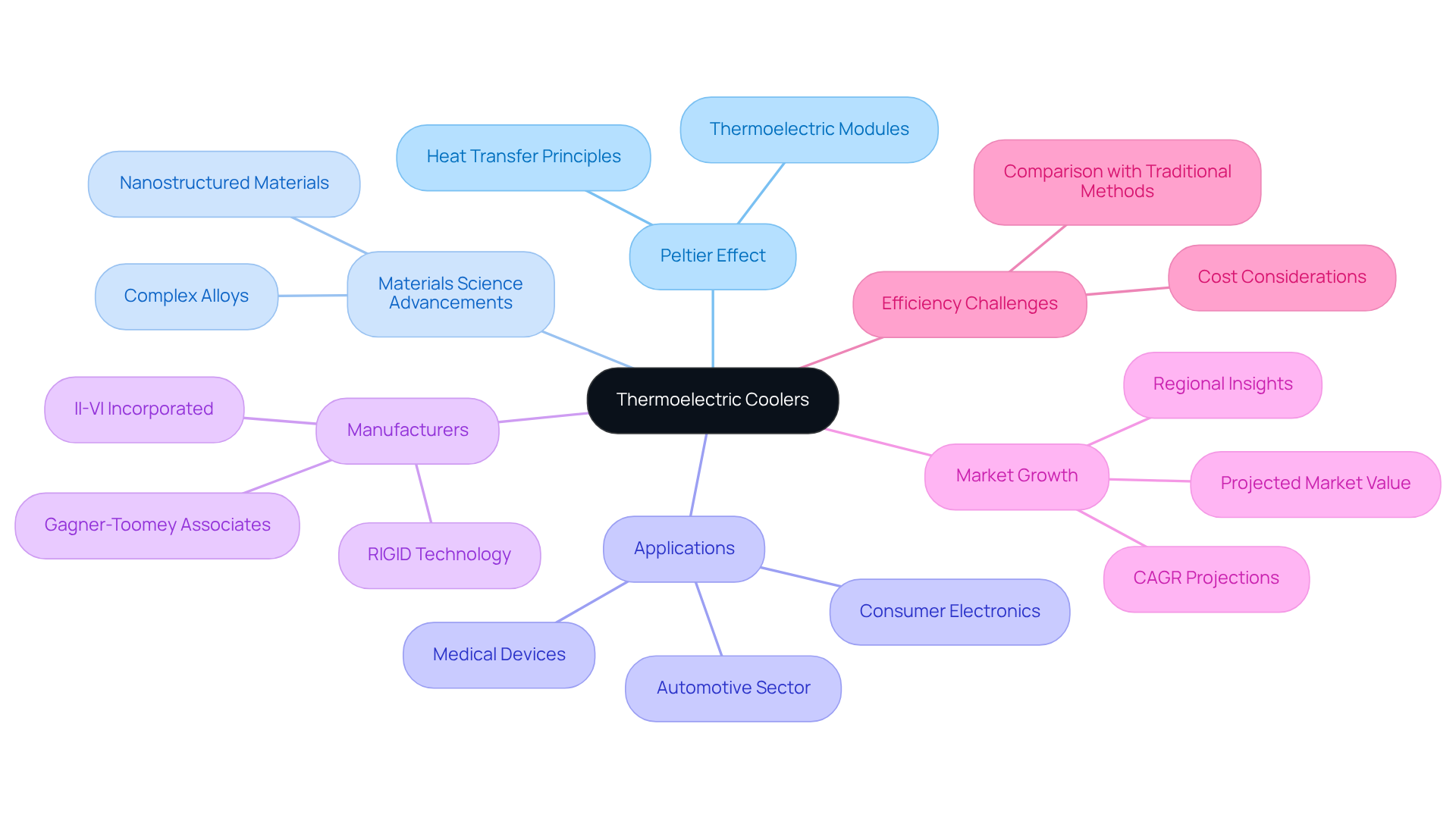

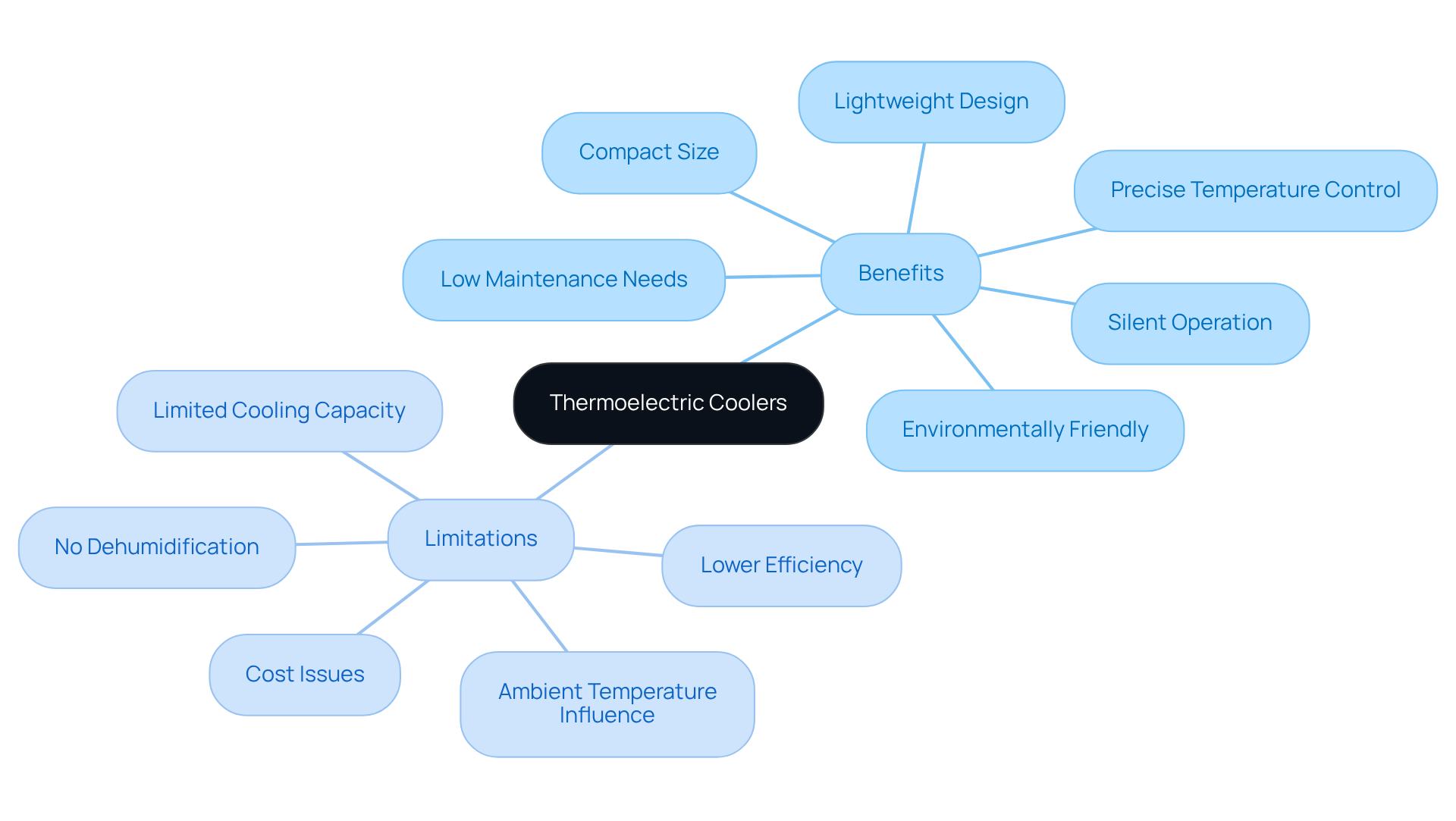

The article elaborates on its diverse applications across various industries, including electronics and medical devices, thereby underscoring its relevance. Furthermore, it highlights advantages such as a compact design and eco-friendliness, while also addressing inherent limitations in efficiency when juxtaposed with traditional cooling methods.

Introduction

Thermoelectric coolers, or TECs, signify a revolutionary advancement in temperature regulation, leveraging the Peltier effect to facilitate efficient heat transfer without the reliance on moving parts or environmentally detrimental refrigerants. As industries increasingly pursue compact and eco-friendly solutions for thermal management, these devices have found applications across a spectrum of fields, from consumer electronics to critical medical equipment.

However, despite their myriad advantages, TECs face notable efficiency challenges when juxtaposed with traditional cooling methods. What does the future hold for thermoelectric cooling technology as it endeavors to surmount these limitations and fulfill the escalating demands of diverse sectors?

Define Thermoelectric Coolers: Principles and Mechanisms

Thermoelectric coolers, commonly known as Peltier coolers, represent a significant advancement in solid-state technology, harnessing the Peltier effect for effective heat transfer. When an electric current flows through two distinct semiconductor materials—typically n-type and p-type—it induces a thermal differential: one side heats up while the other cools down. This principle enables thermal energy converters to achieve precise heat regulation, making them ideal for applications that require reliable thermal management without the complications of moving parts or harmful refrigerants.

Recent strides in materials science and design have further enhanced the efficiency and adaptability of thermoelectric converters, allowing their implementation across a broad spectrum of electronic applications, from temperature regulation in consumer electronics to maintaining optimal conditions in medical devices.

Gagner-Toomey Associates, recognized as the world’s largest manufacturer of standard and custom air-movers for temperature regulation, offers an extensive range of thermal management solutions, including their tec thermoelectric cooler optimized for peak performance and efficiency.

Engineers have increasingly acknowledged the significance of the Peltier effect in these systems, highlighting its contribution to the development of compact, eco-friendly temperature control solutions that meet the demands of contemporary technology. Ongoing research aims to improve the efficiency and cost-effectiveness of thermoelectric devices, which is crucial for their broader acceptance.

Nevertheless, it is essential to note that TECs often face efficiency hurdles when juxtaposed with traditional temperature control methods such as vapor-compression refrigeration. The tec thermoelectric cooler market is projected to grow substantially, reflecting the increasing demand for these innovative across diverse sectors.

Trace the Evolution of Thermoelectric Cooling Technology

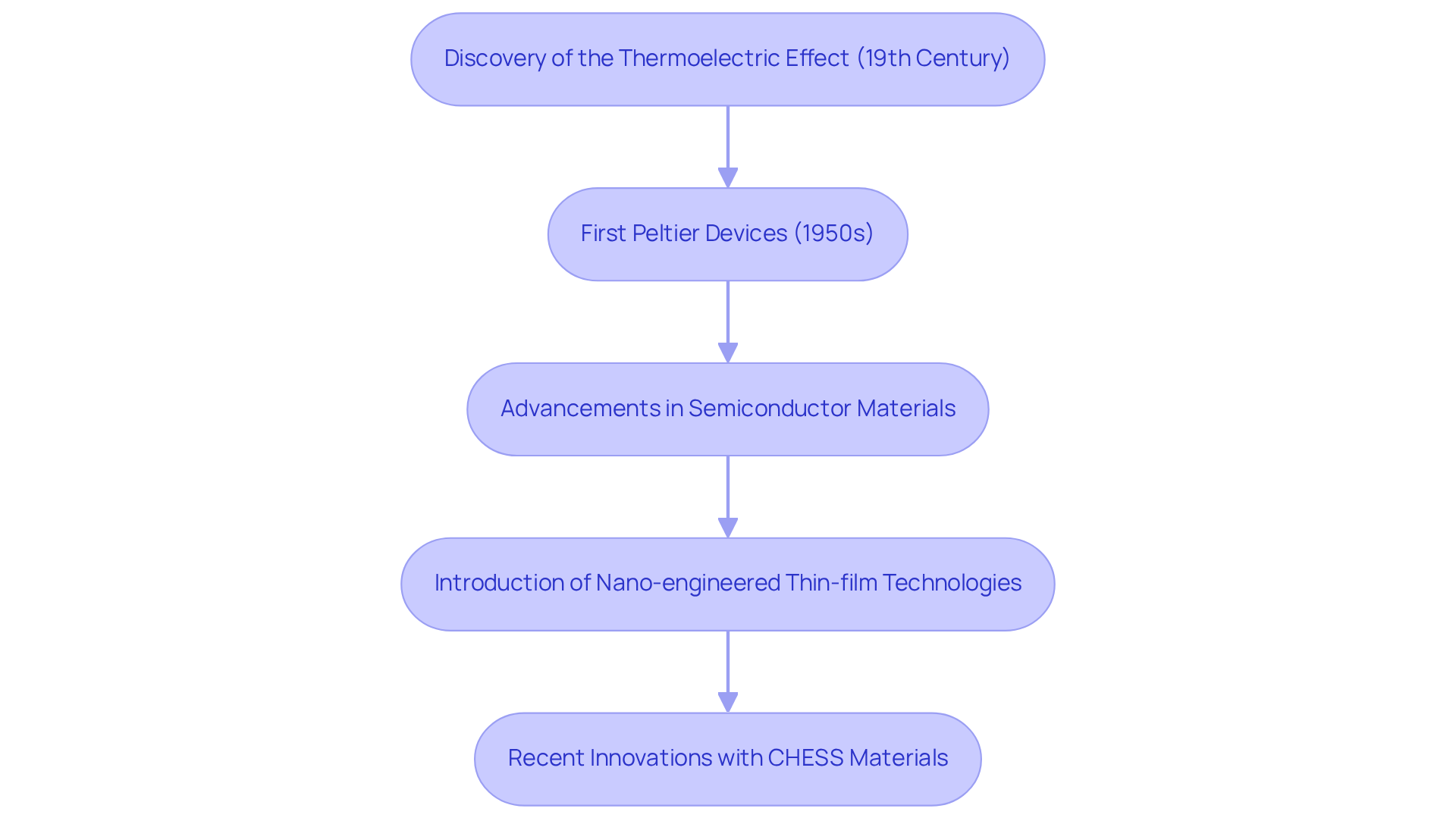

The development of thermoelectric temperature control technology traces back to the early 19th century, marked by Thomas Johann Seebeck’s discovery of the thermoelectric effect. However, it wasn’t until the mid-20th century that practical applications began to take shape, particularly with the advent of Peltier modules. These modules utilize the Peltier effect, where an electric current creates a temperature differential across semiconductor materials, enabling efficient cooling without moving parts.

Key milestones in this journey include:

- The development of the first Peltier devices in the 1950s, notably demonstrated by RCA Laboratories, which laid the groundwork for contemporary thermoelectric cooling systems.

- Significant advancements in semiconductor materials, particularly the introduction of nano-engineered thin-film technologies, which have dramatically enhanced the efficiency and reliability of thermoelectric devices.

- Recent innovations employing CHESS materials that have attained almost 100% enhancement in efficiency compared to conventional thermoelectric materials at ambient conditions and are twice as effective as presently utilized bulk devices in refrigeration, highlighting the potential for compact and scalable cooling solutions.

Today, the tec is integral to various applications, including consumer electronics, automotive systems, and medical devices. Their versatility is further underscored by their ability to maintain precise temperature control, with feedback circuitry enabling stability within ±0.01 °C. As the demand for energy-efficient and eco-friendly refrigeration solutions escalates, the thermoelectric device market is anticipated to grow considerably, particularly in regions such as Asia-Pacific, which is predicted to secure a significant portion due to increasing consumer demands and technological progress.

Furthermore, the ecological benefits of thermoelectric devices are noteworthy, as they operate without refrigerants, circumventing the environmental issues associated with conventional refrigeration techniques. In summary, the journey of thermoelectric cooling technology reflects a continuous pursuit of efficiency and innovation, with recent developments paving the way for next-generation applications that promise to revolutionize the industry.

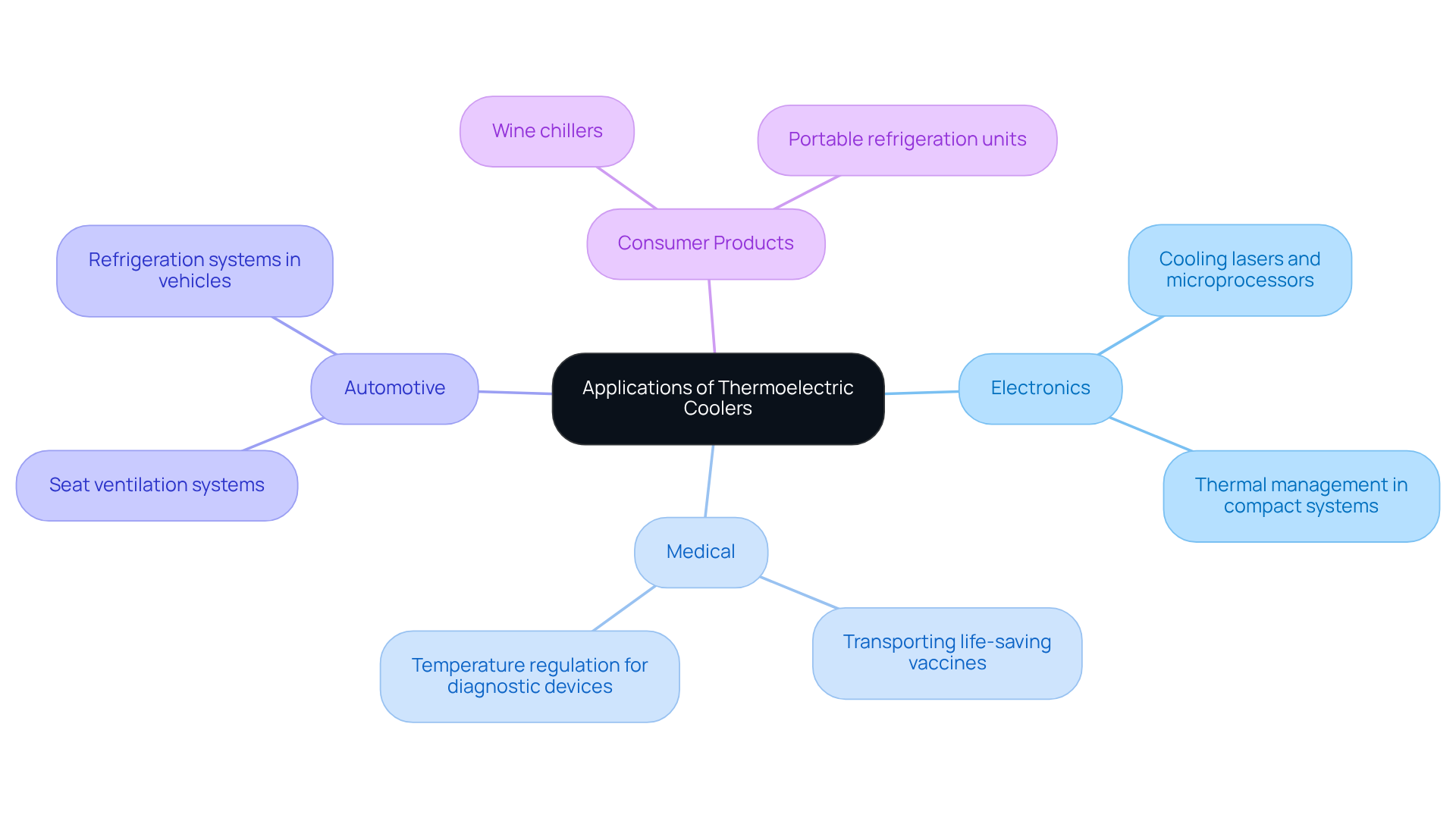

Explore Applications of Thermoelectric Coolers in Industry

Tec thermoelectric coolers play a crucial role in a myriad of applications across diverse sectors. In the electronics industry, they effectively cool components such as lasers and microprocessors, thereby ensuring optimal performance and prolonging their lifespan. The medical field relies on thermal energy converters for portable diagnostic devices and temperature-sensitive equipment, where precise is imperative. For example, these devices are utilized in the transportation of life-saving vaccines, maintaining the necessary conditions throughout transit. The automotive sector also benefits from thermal energy collectors, using them for seat ventilation and refrigeration systems. Furthermore, consumer products like wine chillers and portable refrigeration units leverage the compact size and efficiency of thermoelectric devices, making them ideal for scenarios where traditional cooling methods are impractical. The market for medical devices utilizing tec thermoelectric cooler refrigeration units is projected to experience significant growth, driven by technological innovations and the increasing demand for reliable temperature control. As the healthcare sector evolves, the importance of technology-enhanced care in diagnostics and medical applications is expected to rise, underscoring the critical role of tec thermoelectric cooler in modern medical technology.

Evaluate the Benefits and Limitations of Thermoelectric Coolers

The tec thermoelectric cooler presents a range of advantages, including its compact size, lightweight design, and lack of moving components, which significantly reduces maintenance needs. Their ability to provide precise temperature regulation using a tec thermoelectric cooler makes them ideal for sensitive applications, such as managing microprocessors and preserving perishable goods.

However, these systems face notable limitations. They generally exhibit lower efficiency compared to traditional refrigeration systems, particularly in larger-scale applications where effective temperature control is critical. For instance, while thermal energy converters function efficiently in confined spaces, their effectiveness diminishes in broader environments due to increased costs associated with additional ceramic plates and higher voltage requirements.

Moreover, the temperature regulation capabilities of thermoelectric devices are heavily influenced by ambient temperature conditions, potentially limiting their efficiency in extreme environments. Engineers have noted that although thermoelectric coolers can serve as heaters in cold settings, they may fall short in delivering adequate cooling in high-temperature scenarios. This dual functionality can be advantageous in specific contexts, yet it underscores the importance of thorough assessment when selecting thermal energy converters for industrial uses.

Real-world examples illustrate these constraints: in the food and beverage industry, temperature control systems are employed to maintain optimal conditions during transit; however, their inability to dehumidify air can pose challenges in environments where humidity management is vital. Additionally, the substantial initial investment required for thermoelectric systems may deter prospective users, particularly in price-sensitive markets. With the anticipated to reach $14 billion by 2026, comprehending these limitations is essential for engineers and designers as they evaluate the appropriateness of TECs for their specific cooling requirements.

Conclusion

Thermoelectric coolers (TECs), also known as Peltier coolers, exemplify a groundbreaking strategy in thermal management, leveraging the Peltier effect for effective heat transfer without the intricacies of conventional refrigeration systems. This technology not only facilitates precise temperature regulation but also meets the escalating demand for eco-friendly and compact cooling solutions across diverse industries.

The evolution of thermoelectric cooling technology has been meticulously traced from its foundational discoveries to its contemporary applications in sectors such as electronics, healthcare, and automotive. Significant advancements have resulted in enhanced efficiency and reliability, while the adaptability of TECs enables their deployment in critical scenarios, including the preservation of medical supplies and the enhancement of consumer products. Nonetheless, it is crucial to recognize the limitations of thermoelectric coolers, particularly their diminished efficiency in larger applications and the influence of ambient conditions on performance.

In conclusion, the relevance of thermoelectric coolers is set to expand as industries increasingly pursue sustainable and efficient temperature control solutions. A comprehensive understanding of both the advantages and limitations of TECs will empower engineers and designers to make informed decisions, ensuring that this technology continues to advance and fulfill the demands of modern applications. By embracing the potential of thermoelectric cooling, we can foster innovative solutions that not only improve performance but also contribute to a more sustainable future.

Frequently Asked Questions

What are thermoelectric coolers?

Thermoelectric coolers, or Peltier coolers, are solid-state devices that utilize the Peltier effect for heat transfer, creating a thermal differential when an electric current flows through two distinct semiconductor materials.

How do thermoelectric coolers work?

They operate by passing an electric current through n-type and p-type semiconductor materials, causing one side to heat up and the other to cool down, allowing for effective temperature regulation.

What are the advantages of thermoelectric coolers?

They offer reliable thermal management without moving parts or harmful refrigerants, making them suitable for various applications, including consumer electronics and medical devices.

Who is Gagner-Toomey Associates?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air-movers for temperature regulation, providing a range of thermal management solutions, including optimized thermoelectric coolers.

What is the significance of the Peltier effect in thermoelectric coolers?

The Peltier effect is crucial for the development of compact and eco-friendly temperature control solutions, which are increasingly recognized by engineers in the field.

What challenges do thermoelectric coolers face?

They often encounter efficiency challenges compared to traditional temperature control methods, such as vapor-compression refrigeration.

What is the future of the thermoelectric cooler market?

The market for thermoelectric coolers is expected to grow significantly due to rising demand for innovative temperature control solutions across various sectors.