Overview

PWM mode for fans represents a sophisticated method that enables precise control of fan speed through the modulation of electrical pulse width. This capability allows for dynamic adjustments based on thermal demands, addressing the critical need for effective temperature management in various applications. Notably, PWM fans exhibit superior energy efficiency and quieter operation compared to traditional DC fans. These advantages make PWM fans particularly well-suited for environments where reduced noise levels are paramount, such as in sensitive settings. Consequently, adopting PWM technology is a strategic choice for those seeking to enhance both performance and comfort.

Introduction

In the realm of modern cooling solutions, PWM (Pulse Width Modulation) fans stand as a transformative force, fundamentally altering how systems manage temperature and airflow. Their capability to dynamically adjust speed according to thermal requirements not only boosts cooling efficiency but also ensures quiet operation, making them particularly suitable for noise-sensitive environments.

As industries strive for innovative strategies to enhance performance and energy efficiency, it becomes imperative to comprehend the advantages of PWM fans in comparison to traditional DC fans. This article explores the operational distinctions, diverse applications, and essential considerations for selecting the optimal PWM fan, underscoring how these advanced cooling solutions are establishing new benchmarks in electronics design and engineering.

Define PWM Fans and Their Functionality

What is PWM mode for fans? It represents a sophisticated method for controlling fan operation by adjusting the width of electrical pulses sent to the motor. Typically equipped with a 4-pin connector, PWM devices employ the fourth pin for the PWM signal, which raises the question of what is PWM mode for fans, facilitating dynamic speed adjustments that align with the system’s thermal demands. This functionality allows PWM devices to operate at lower RPMs without the threat of stalling, which illustrates what is PWM mode for fans, enhancing thermal efficiency and reducing noise levels. Such adaptability is crucial in environments where precise temperature regulation is paramount, including computers and industrial equipment.

Gagner-Toomey Associates stands out as a leading supplier of innovative cooling solutions, offering an extensive range of PWM devices optimized for performance and efficiency. The market for is witnessing substantial growth, fueled by their exceptional performance and efficiency compared to traditional models. These devices not only deliver reliable performance under demanding conditions but also operate quietly at reduced speeds without compromising effectiveness, making them ideal for both personal and professional applications. As the demand for efficient temperature management continues to rise, PWM devices from Gagner-Toomey Associates are becoming increasingly vital to modern electronics design, particularly within the electronics and automotive sectors.

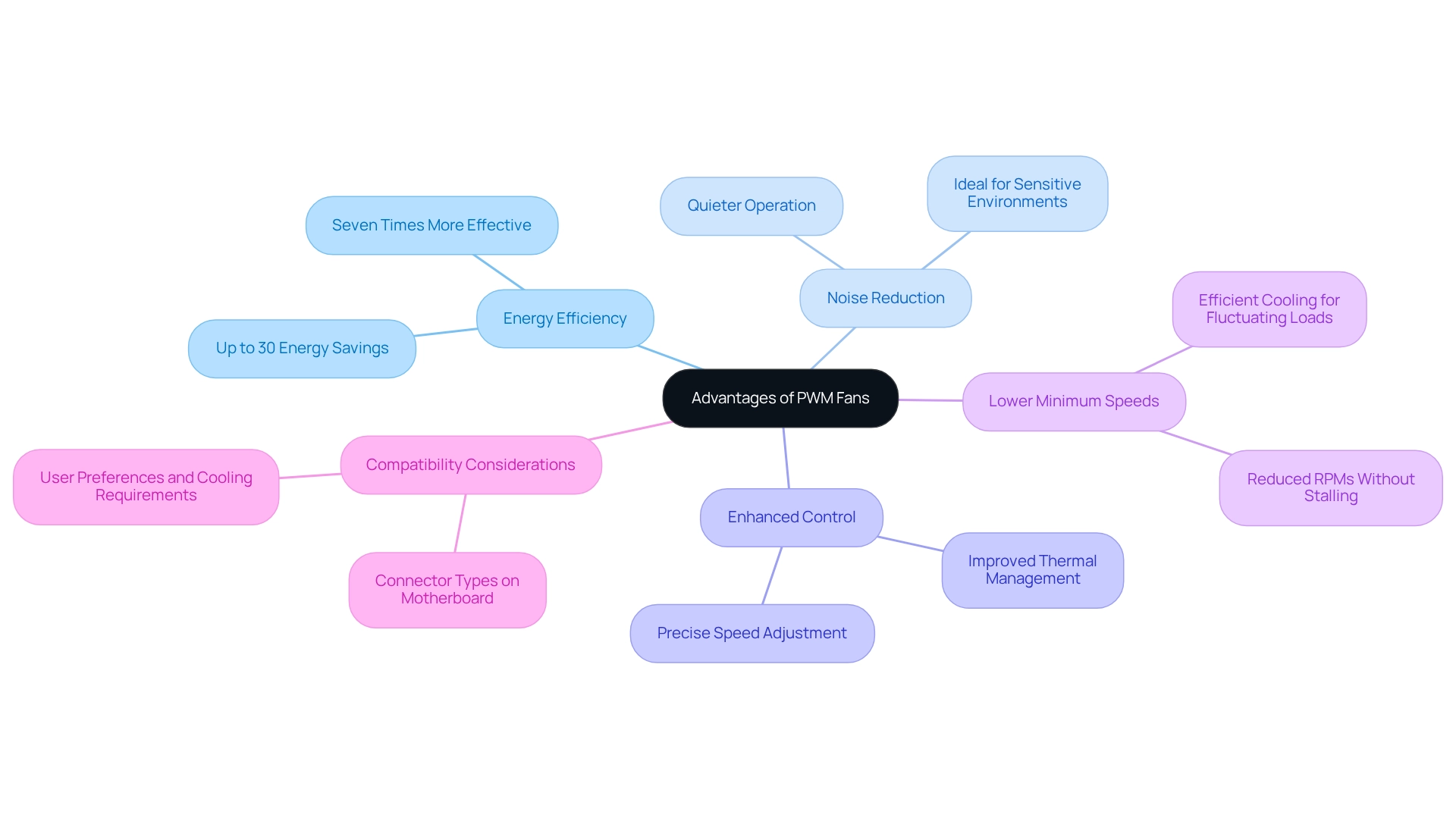

Explore Advantages of PWM Fans Over Traditional Fans

PWM fans offer numerous advantages over , establishing themselves as a superior choice for modern cooling solutions:

- Energy Efficiency: By dynamically adjusting their speed to meet temperature demands, PWM devices can achieve energy savings of up to 30% compared to conventional models. In fact, what is pwm mode for fans technology is reported to be seven times more effective than standard methods. This efficiency is particularly crucial as power regulations become increasingly stringent, highlighting the importance of understanding what is pwm mode for fans in developing more effective temperature management solutions.

- Noise Reduction: PWM devices excel in reducing noise levels. They can operate at lower speeds during periods of low temperature demand, resulting in quieter functionality. This trait is essential in environments where noise control is paramount, such as home theaters or office spaces.

- Enhanced Control: The precise speed adjustment capabilities of PWM devices highlight what is pwm mode for fans, facilitating superior thermal management. This feature not only improves temperature regulation but also helps explain what is pwm mode for fans, contributing to the longevity and reliability of electronic components by ensuring they operate within safe temperature ranges.

- Lower Minimum Speeds: Unlike traditional models, understanding what is pwm mode for fans reveals that PWM devices can function at significantly reduced RPMs without the risk of stalling. This capability is particularly beneficial in systems with fluctuating loads, as it allows for efficient cooling without unnecessary energy consumption.

- Compatibility Considerations: The choice between PWM and DC cooling devices may depend on the types of connectors available on the motherboard. Engineers should take this factor into account when selecting blowers for their designs.

Real-world applications underscore the effectiveness of what is PWM mode for fans in technology. For instance, in a recent case study titled “Choosing Between PWM and DC Devices,” users reported a notable reduction in noise levels when switching from DC to PWM units, enhancing the overall user experience in sensitive environments. As David Hanrahan observes, “As power regulations grow stricter, and PCs operate considerably hotter, more advanced temperature-monitoring and fan-speed-regulating methods are being developed to manage the technologies of the future more efficiently.”

In conclusion, the advantages of PWM fans—ranging from energy efficiency to noise reduction—position them as critical components for engineers aiming for optimal temperature management in their designs. Ultimately, the decision between PWM and DC devices should be informed by specific cooling requirements and user preferences.

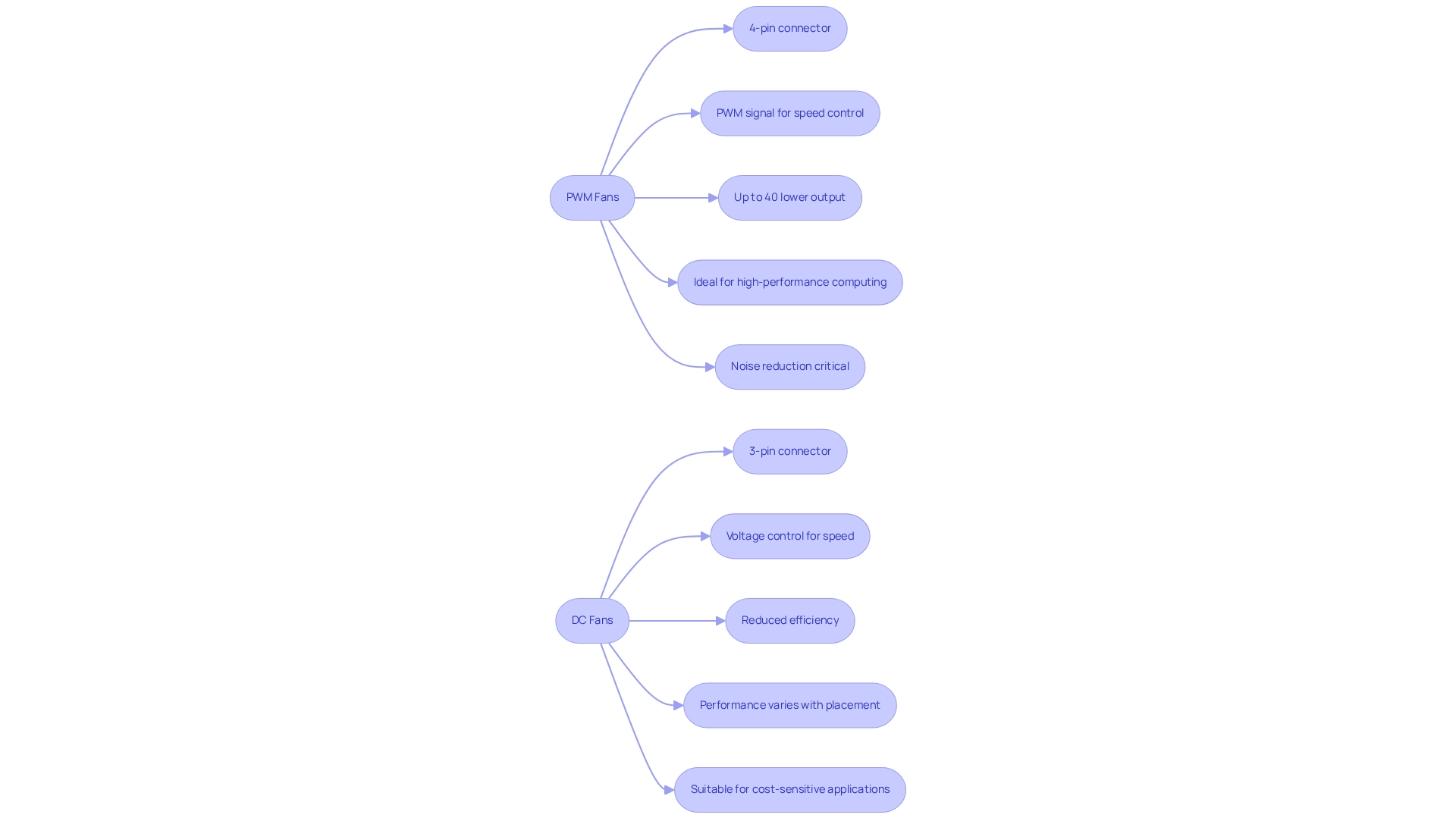

Compare PWM and DC Fans: Operational Differences and Applications

The difference between PWM fans and DC fans primarily lies in what is PWM mode for fans and their control mechanisms.

What is PWM mode for fans? It refers to the use of a 4-pin connector, where the fourth pin sends a PWM signal to control speed. This enables precise pace modifications and effective functioning across a variety of temperatures, illustrating what is PWM mode for fans. It allows them to lower their output by up to 40% of their rated capacity, optimizing airflow while minimizing noise levels, which is crucial in environments such as gaming rigs and data centers. As Friedrich Stiemer notes, “You can only use the respective fan type if your PC’s motherboard offers the appropriate connections.”

DC Fans typically utilize a 3-pin connector, where rotation is regulated by changing the voltage supplied to the fan. This method can lead to reduced efficiency and increased noise levels at slower speeds. Furthermore, DC fans create diminished airflow due to their restricted speed range, and their efficiency can vary significantly based on positioning and setup. A well-placed DC fan can outperform a poorly-placed PWM fan, underscoring the importance of proper installation.

Applications:

- PWM fans are ideal for high-performance computing, gaming rigs, and environments where noise reduction is critical.

- DC fans may still be suitable for simpler applications where cost is a primary concern, but they lack the efficiency and control of PWM fans. However, their performance can vary greatly based on placement and configuration, highlighting the significance of installation.

To implement effective fan speed control, designers can utilize PCB Design and Analysis tools such as OrCAD from Cadence, which provide insights into voltage and duty cycle control. These tools facilitate the design process for integrating DC and , enhancing the overall efficiency and performance of cooling solutions in electronic devices.

In summary, while PWM units offer superior control and efficiency, DC models may still find their place in cost-sensitive applications, albeit with limitations in performance and noise management.

Select the Right PWM Fan for Your Engineering Needs

When selecting a PWM fan, several key factors must be considered to ensure optimal performance in engineering applications:

- Size: The fan must fit within the designated space of your application. Common sizes include 120mm and 140mm, widely utilized in various setups. Gagner-Toomey Associates offers a broad range of , varying from 15mm to 280mm, along with a comprehensive selection of DC input Centrifugal Blowers, sizes from 15mm to 225mm. This variety ensures that engineers can locate the appropriate solution for their specific requirements.

- Airflow and Static Pressure: Assess the fan’s airflow, measured in cubic feet per minute (CFM), and static pressure, measured in millimeters of water (mmH2O). These ratings are crucial for meeting specific cooling requirements, especially in environments where efficient thermal management is essential. Gagner-Toomey’s products are optimized for performance and efficiency, making them ideal for demanding applications.

- Noise Level: For applications in noise-sensitive environments, selecting blowers with low dBA ratings is vital. Numerous PWM units, including those from Gagner-Toomey, operate silently at reduced levels without compromising performance, rendering them suitable for both home offices and industrial environments.

- Bearing Type: The choice of bearing type—sleeve, ball, or fluid dynamic—affects both the longevity and noise levels of the fan. Engineers should select the type that aligns with their operational needs and preferences. Gagner-Toomey provides various options to cater to different requirements.

- PWM Control Compatibility: Ensure that your motherboard or fan controller supports PWM control. This compatibility allows for precise speed adjustments, enhancing the fan’s efficiency and responsiveness to thermal demands. Gagner-Toomey’s products are designed with this compatibility in mind, ensuring seamless integration into modern systems.

- Protection Ratings: Consider devices from Gagner-Toomey, which can achieve high IP protection ratings, allowing operation under harsh conditions. This is particularly important for applications exposed to dust and moisture, ensuring reliability and longevity.

By thoroughly assessing these elements, engineers can select PWM devices that meet their thermal needs while also understanding what is PWM mode for fans to enhance the overall functionality and energy efficiency of their systems. Gagner-Toomey Associates distinguishes itself as a prominent supplier of thermal management solutions, providing a comprehensive portfolio of standard and custom thermal solutions, including efficient airflow and low noise levels. Additionally, practical uses of PWM devices in personal computers and industrial setups illustrate what is PWM mode for fans and demonstrate their effectiveness in enhancing cooling efficiency and supporting effective thermal control across diverse environments. As noted by Aaron Liu, a verified supplier representative, “Trusted brands like Gagner-Toomey offer higher reliability, consistent quality, and robust customer support,” which can guide engineers in their purchasing decisions. Furthermore, the case study titled “Practical Applications of PWM Fans” illustrates how these fans are utilized in various settings, reinforcing their role in effective thermal management.

Conclusion

The exploration of PWM fans underscores their substantial advantages over traditional DC fans, establishing them as pivotal in modern cooling solutions. By leveraging Pulse Width Modulation technology, these fans significantly enhance energy efficiency and ensure quieter operation, rendering them ideal for noise-sensitive environments. Their capability to dynamically adjust speeds facilitates superior thermal management, which is essential in today’s high-performance applications, ranging from gaming rigs to industrial machinery.

The operational distinctions between PWM and DC fans are evident, with PWM fans providing enhanced control and efficiency. While DC fans may still serve a purpose in simpler, cost-sensitive applications, the advantages of PWM technology—such as reduced noise levels and energy savings—position them as the preferred choice for engineers and designers striving for optimal performance in their cooling systems.

When selecting the appropriate PWM fan, considerations such as size, airflow, noise level, and compatibility with existing systems become paramount. By prioritizing these factors, engineers can ensure that their cooling solutions not only meet performance expectations but also contribute to the overall sustainability of their projects. As the demand for effective thermal management continues to escalate, the integration of PWM fans into electronic designs is increasingly vital, setting new benchmarks for efficiency and reliability within the industry.

Frequently Asked Questions

What is PWM mode for fans?

PWM mode for fans is a method of controlling fan operation by adjusting the width of electrical pulses sent to the motor, allowing for dynamic speed adjustments based on the system’s thermal demands.

How does PWM mode enhance fan performance?

PWM mode enables fans to operate at lower RPMs without the risk of stalling, which improves thermal efficiency and reduces noise levels.

What types of environments benefit from PWM fans?

PWM fans are particularly beneficial in environments that require precise temperature regulation, such as computers and industrial equipment.

What is the significance of the 4-pin connector in PWM fans?

The 4-pin connector in PWM fans includes a fourth pin that carries the PWM signal, which is essential for controlling the fan speed.

Why is the market for PWM cooling devices growing?

The market for PWM cooling devices is growing due to their exceptional performance and efficiency compared to traditional models, as well as their ability to operate quietly at reduced speeds.

Who is a leading supplier of PWM devices?

Gagner-Toomey Associates is recognized as a leading supplier of innovative cooling solutions, offering a wide range of PWM devices optimized for performance and efficiency.

In which sectors are PWM devices becoming increasingly vital?

PWM devices are becoming increasingly important in modern electronics design, particularly within the electronics and automotive sectors.