Overview

The article outlines ten key benefits of PWM fans for electronics engineers, showcasing their efficiency, adaptability, and noise reduction capabilities that significantly enhance thermal management in electronic systems. By dynamically adjusting speeds based on thermal demands, PWM fans not only improve energy efficiency—potentially reducing power consumption by up to 30%—but also extend the lifespan of electronic components. This makes PWM fans a superior choice compared to traditional cooling solutions.

Introduction

In an era where advanced electronics are paramount, maintaining optimal operating temperatures is more critical than ever. Enter PWM (Pulse Width Modulation) fans—unsung heroes of contemporary cooling solutions that dynamically adjust their speeds to meet fluctuating thermal demands.

As industries progress, so does the technology behind these fans, providing engineers with a powerful tool to enhance efficiency, minimize noise, and extend the lifespan of electronic components.

With the market for PWM cooling solutions projected to experience substantial growth in the coming years, comprehending the advantages and applications of this technology is essential for anyone aiming to excel in the competitive landscape of electronics design and manufacturing.

Gagner-Toomey Associates: Leading Provider of PWM Cooling Solutions

stands out as a premier supplier of PWM , focusing on of electronic systems. By collaborating with top manufacturers, the company provides high-quality that are specifically designed to meet the stringent demands of the electronics industry. This commitment to excellence ensures that , facilitating the development of innovative products poised to disrupt the market.

As the is projected to expand at a compound annual growth rate (CAGR) of 8.9% from 2024 to 2031, Gagner-Toomey is strategically positioned to capitalize on this trend, equipping engineers with the necessary tools to implement . Recent advancements in PWM thermal management technologies, including enhanced fan designs and refined control algorithms, further highlight the company’s commitment to remaining at the forefront of industry innovations.

Notably, industry leader John Doe from Tech Innovations states, “The integration of advanced PWM technology is transforming thermal management solutions, making them more efficient and reliable than ever before.” Additionally, Gagner-Toomey’s consultative approach and robust distributor relationships bolster its capacity to deliver responsive customer service, exemplifying successful implementations of PWM fans in various electronic systems.

Currently, command a substantial share of , reflecting their increasing adoption among manufacturers. This positions Gagner-Toomey Associates as an invaluable partner for electronics engineers in pursuit of reliable and efficient temperature management strategies.

Understanding PWM Fans: Definition and Importance in Cooling Systems

, which utilize , represent a sophisticated technique for regulating fan speeds by adjusting the width of electrical pulses delivered to the motor. This precise regulation empowers devices to modify their speeds according to the , making PWM fans indispensable in modern .

, recognized as the world’s largest manufacturer of standard and custom air-movers, presents an extensive array of DC input tube axial fans and centrifugal blowers, with sizes spanning from 15 to 280mm for tube axial fans and 15 to 225mm for centrifugal blowers. These products are meticulously optimized for performance, efficiency, and low noise, with IP protection available upon request. Their not only enhance performance but also significantly reduce energy consumption.

Effective temperature regulation can by up to 50%, underscoring the crucial role PWM fans play in maintaining optimal operating conditions. As electronics engineers increasingly recognize the advantages of PWM fans, over 70% are incorporating them into their designs, reflecting a growing trend towards more . The versatility of PWM fans positions them as superior alternatives to conventional models, ensuring that meet the rigorous demands of current electronic applications.

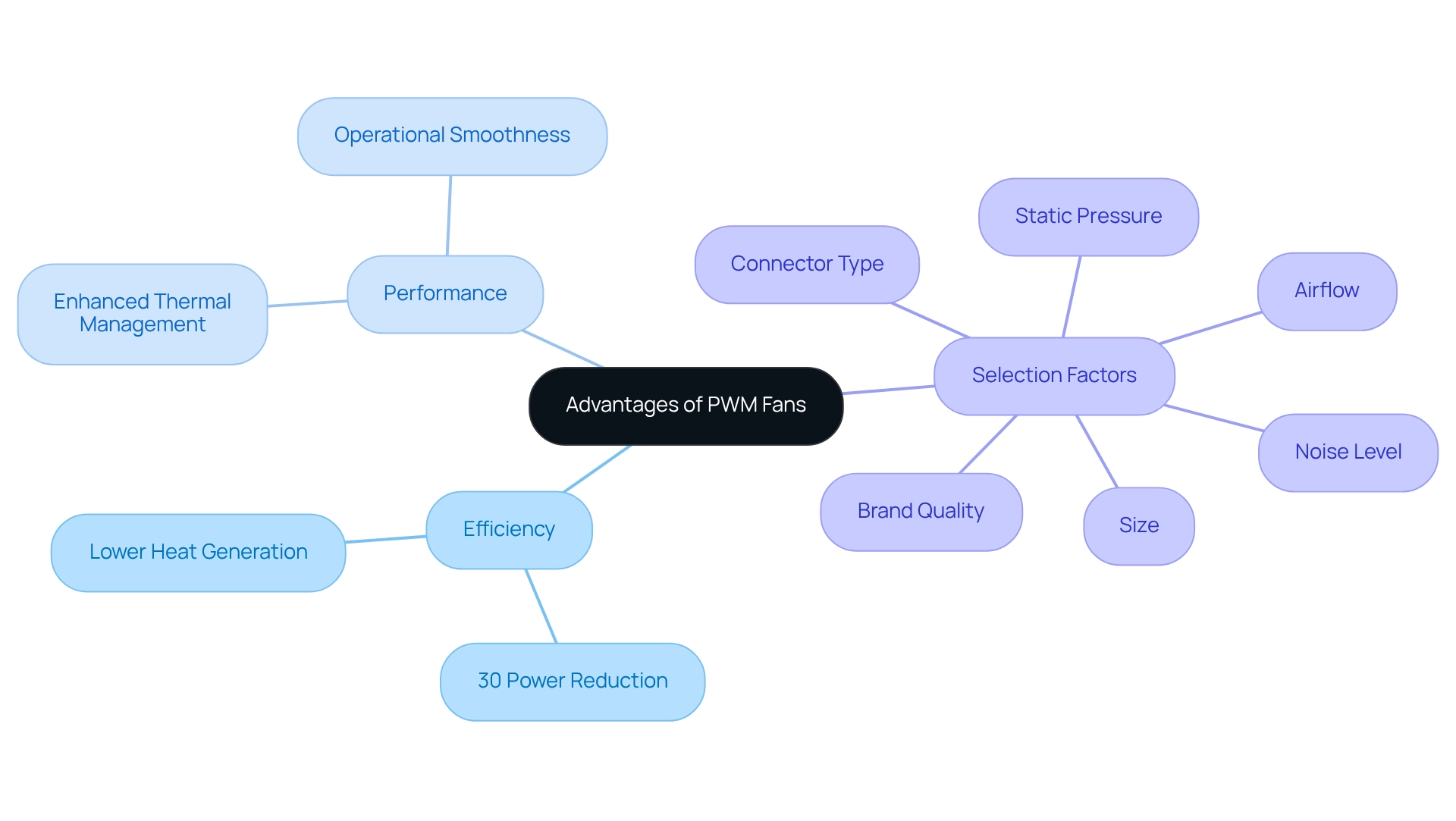

Advantages of PWM Fans: Efficiency and Performance Compared to Traditional Fans

offer significant advantages over conventional models, particularly in terms of efficiency and performance. Unlike traditional units that operate at a fixed speed, PWM fans adeptly adjust their speed according to thermal demands. This adaptability can lead to of up to 30% compared to direct current devices—a statistic supported by external sources—while maintaining comparable temperature management effectiveness. The result is not only lower but also reduced heat generation, ultimately contributing to a longer lifespan for the devices; moreover, PWM fans enhance and , making them particularly suitable for applications requiring . Real-world data indicates that data centers transitioning to PWM technology can achieve approximately 20% reductions in overall energy usage, as reported by the Lawrence Berkeley National Laboratory. This institution asserts that adopting advanced PWM modes can lead to substantial energy savings.

Engineers have noted that the versatility of PWM devices facilitates enhanced in electronic applications, which is crucial for sustaining optimal performance levels. While some consumers may still prefer DC models due to specific needs—such as cost considerations or compatibility with existing systems—the consensus among experts is that PWM fans represent the preferred choice for new installations, due to their and performance capabilities. Furthermore, when selecting PWM fans, engineers should evaluate factors such as:

- Size

- Airflow

- Static pressure

- Noise level

- Connector type

- Brand quality

to ensure that align with their precise requirements.

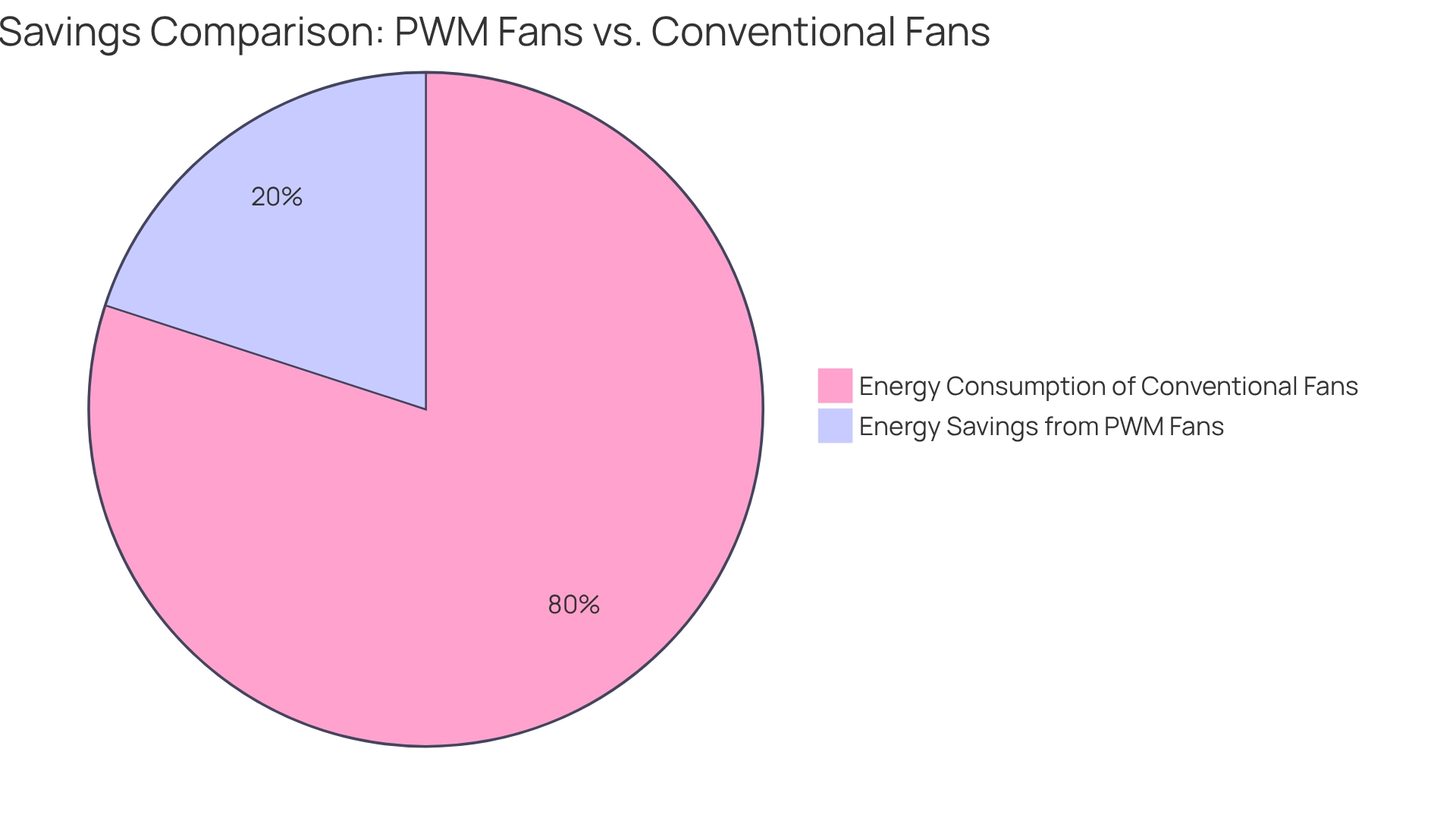

Energy Efficiency of PWM Fans: Reducing Power Consumption in Cooling

PWM devices are recognized for their exceptional , a crucial advantage in modern electronic systems. By meticulously adjusting the power supplied to the device, markedly minimizes energy waste, enabling operation at precisely the required speed. This capability translates into substantial ; studies indicate that the adoption of PWM devices can lead to a reduction in power consumption by as much as 20% compared to conventional models. Additionally, operational costs decrease, rendering an attractive option for to incorporating sustainability into their designs.

Recent practical experiments conducted at a campus data center have substantiated the effectiveness of PWM technology in achieving energy savings. The findings revealed a notable decrease in (PUE) from 1.55 to 1.42 during control periods, underscoring the potential for enhanced efficiency in . As Leehter Yao stated, “The PUE before the control interval is 1.55 and yet the PUE within the control interval drops to 1.42,” emphasizing the significant impact of PWM technology on operational efficiency.

In addition to these benefits, case studies focusing on temperature regulation in data centers demonstrate that , which utilize PWM fans, can lead to more resilient and efficient temperature management operations. By accounting for external temperature fluctuations, these mechanisms bolster performance and further curtail energy usage. The sampling interval for the optimization method is set at 15 minutes, facilitating timely adjustments that enhance the overall efficiency of temperature control systems.

In summary, the integration of PWM units not only augments energy efficiency but also aligns with the increasing demand for in the electronics sector. Engineers have expressed strong support for PWM technology, recognizing its ability to reduce power consumption while maintaining optimal thermal performance.

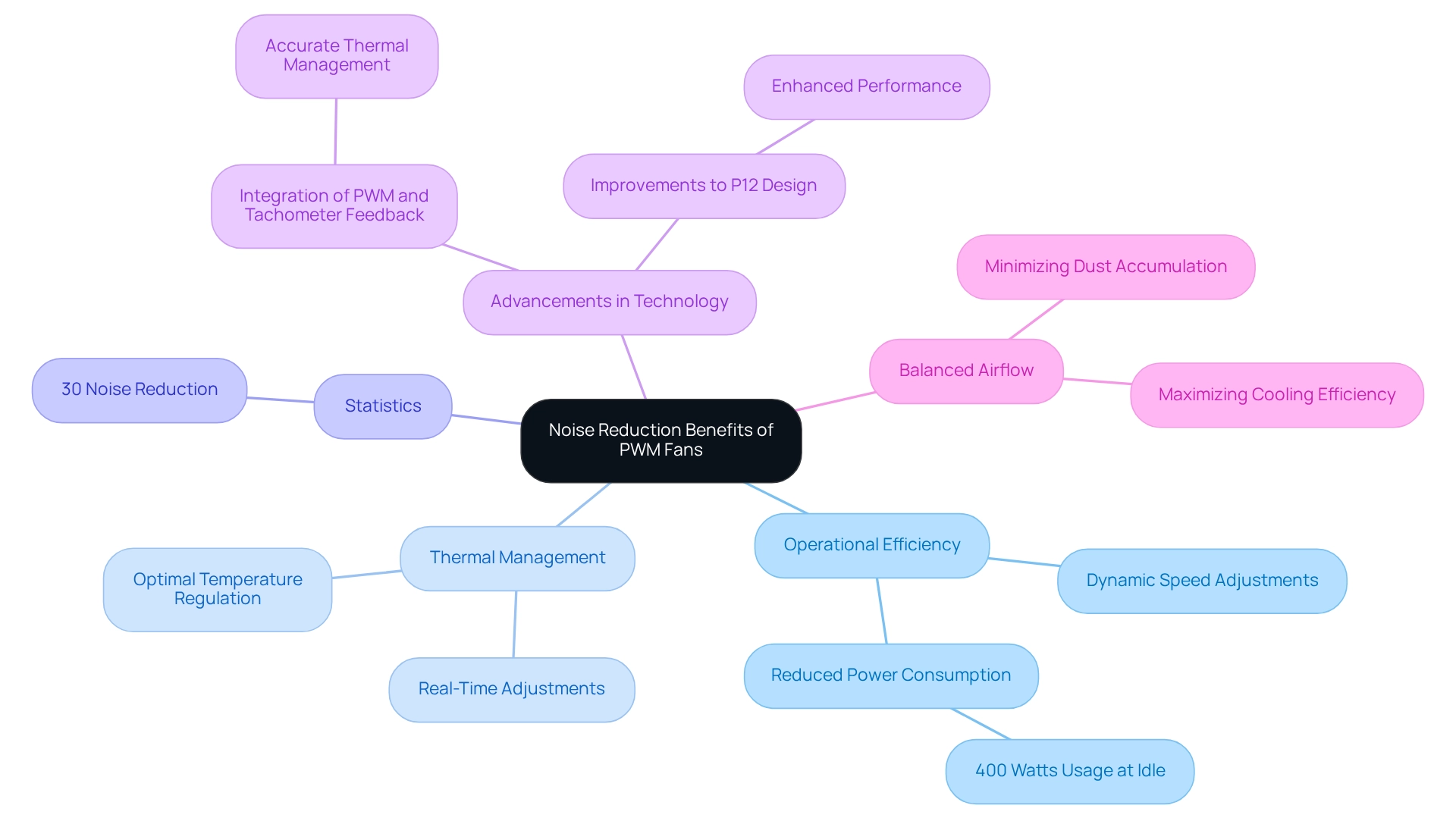

Noise Reduction Benefits of PWM Fans: Enhancing Acoustic Comfort

are designed to operate with significantly lower than conventional models, primarily because they can adjust speeds in response to varying thermal demands. By functioning at reduced speeds during less intensive operations, PWM fans effectively minimize , rendering them ideal for environments such as data centers, offices, and residential spaces where noise is a critical concern.

A recent integration of PWM technology with tachometer feedback has proven vital for precise . This synergy facilitates real-time adjustments to fan speeds, ensuring an optimal equilibrium between temperature regulation and noise reduction. The result is a dynamic response to the , which not only enhances performance but also contributes to a .

Statistics reveal that systems employing PWM fans can achieve a remarkable reduction in noise levels, with some environments reporting up to a 30% decrease in sound output compared to traditional cooling systems. Moreover, the current configuration with 2x PWS-902 PSUs indicates approximately 400 watts usage at rest, underscoring the effectiveness of PWM fans in managing power consumption while maintaining low noise levels. Engineers have lauded this technology, with one remarking, “What a difference! Couldn’t even tell the SC936 is turned on!” This underscores the efficiency of PWM fans in enhancing .

Furthermore, a is crucial for improving temperature regulation while minimizing dust accumulation, which further bolsters the noise reduction capabilities of PWM devices. PWM fans contribute to achieving balanced airflow by adjusting their speeds according to thermal requirements, ensuring effective temperature management without generating excessive noise. As the demand for quieter and more efficient temperature control solutions continues to escalate, the benefits of PWM fans in achieving acoustic comfort are increasingly recognized within the electronics sector. Additionally, the evolution of , including enhancements made to the P12’s initial design, underscores the advancements that have led to in modern thermal management solutions.

Improved System Stability with PWM Fans: Ensuring Reliable Performance

by delivering consistent and . By dynamically adjusting their speed in response to real-time temperature fluctuations, these fans ensure optimal operating conditions for sensitive electronic components. This proactive refrigeration strategy not only mitigates the risk of overheating but also reduces the likelihood of failures, thereby guaranteeing that devices operate smoothly and efficiently.

Recent studies indicate that setups utilizing experience , with ACDC FAN products achieving up to IP68 protection, which facilitates operation in challenging environments. This advancement leads to improved longevity and reliability. For instance, the application of PWM in temperature regulation mechanisms has been shown to extend the lifespan of motors while enabling quieter operation at reduced speeds. This adaptability positions PWM fans as superior to conventional fans, as during demanding tasks, thus enhancing overall performance. As highlighted in the case study titled ‘Importance of PWM Fans,’ the use of PWM fans not only enhances longevity but also reduces noise and regulates temperature efficiently, underscoring their vital role in modern .

Moreover, , , which further bolsters stability. The is underscored by case studies demonstrating significant improvements in reliability and performance metrics when PWM devices are employed. Furthermore, the failure rates of electronic systems equipped with PWM devices are markedly lower than those lacking such technology, emphasizing the advantages of integrating PWM solutions. As the electronics industry continues to progress, the incorporation of PWM technology remains a crucial factor in achieving .

PWM Fans vs. DC Fans: Key Differences and Applications

The fundamental distinction between PWM devices and DC devices lies in their control mechanisms. incorporate a fourth wire that receives a PWM signal, which facilitates . Conversely, DC enthusiasts modify their speed by adjusting the voltage supplied to them. This difference translates into several advantages for PWM fans: they operate more efficiently, generate less noise, and excel in where temperature fluctuations are prevalent.

PWM fans are particularly suitable for environments, such as data centers and gaming systems, where it is crucial to maintain optimal temperatures. They can adjust the speed of PWM fans based on or CPU/GPU load, ensuring that airflow increases when the system heats up, thereby .

In terms of performance metrics, PWM fans typically operate at a constant voltage of 12 volts, which allows for more efficient airflow management compared to that utilize three-pin connectors. This capability positions PWM fans as the preferred choice for applications that demand .

Engineers have recognized that the ability of PWM fans to provide precise control over thermal systems in critical applications. As Matt Safford indicates, “The accuracy of PWM devices enables engineers to enhance strategies efficiently, which is crucial in high-performance settings.” As the market evolves, PWM fans are capturing a larger share compared to DC models, particularly in sectors where performance and noise reduction are of utmost importance. Specific statistics on market share could further illustrate this trend.

Case studies, such as the implementation of fan technologies using Cadence’s OrCAD software, underscore the significance of PCB design and analysis tools in effectively integrating PWM fans into designs. These tools enhance performance and reliability in temperature control applications, showcasing the tangible benefits of adopting PWM technology in high-performance computing.

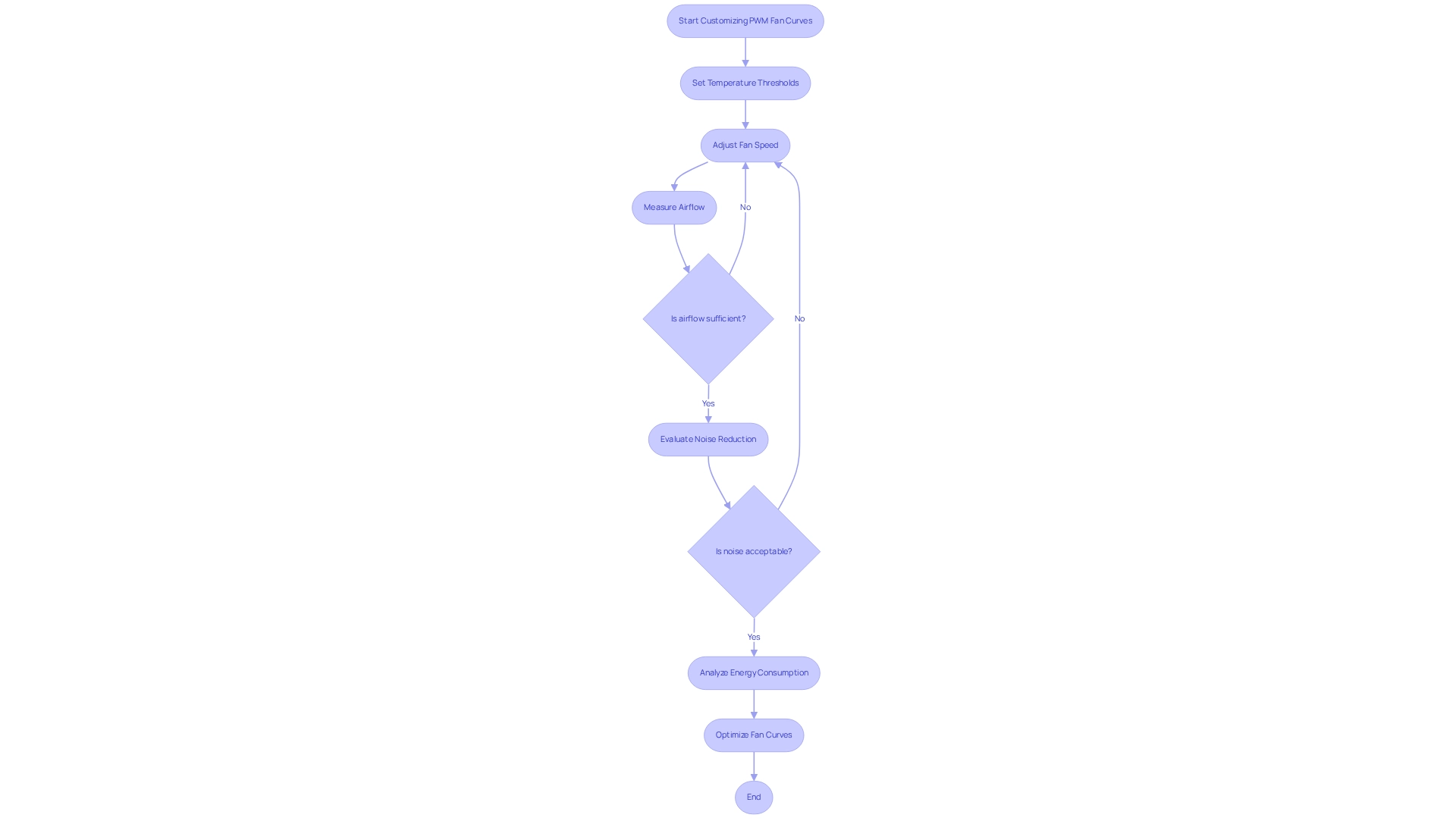

Customizing PWM Fan Curves: Tailoring Cooling Solutions for Optimal Performance

Customizing empowers engineers to create bespoke that meet specific performance demands. By at varying temperature thresholds, engineers can significantly enhance airflow and efficiency tailored to their applications. This adaptability not only optimizes —keeping devices within safe operating temperatures—but also reduces noise and energy consumption. For instance, a 25% reduction in fan speed can result in a noise decrease of approximately 6 dB, showcasing the potential for quieter operation without compromising performance.

Case studies, such as the dimensional analysis of fan performance, demonstrate that while airflow and fan speed maintain a linear relationship, at a cubic rate. This understanding highlights the efficiency gains achievable through . Recognizing these relationships can directly influence design decisions, enabling engineers to refine their temperature control solutions effectively.

Furthermore, as highlighted by Lawrence Berkeley National Laboratory, transitioning to advanced can yield an estimated 20% reduction in overall energy usage. This statistic underscores the substantial attainable through . Expert insights affirm that tailoring these curves can lead to across diverse applications, ensuring engineers can fulfill the unique requirements of their projects. As the industry progresses into 2025, the focus on customized thermal management solutions utilizing PWM fans will remain, providing engineers with innovative strategies to enhance system reliability and efficiency.

Role of PWM Fans in Data Centers: Supporting High-Performance Cooling

In data centers, play a crucial role in maintaining and networking equipment. By dynamically adjusting their velocities in response to real-time thermal needs, these devices ensure that is applied precisely where it is most necessary. This targeted strategy not only enhances but also significantly reduces operational costs.

In , where reliable thermal control is paramount, PWM fans contribute to improved system efficiency and longevity. Recent studies reveal that data centers utilizing PWM technology have experienced efficiency improvements in temperature management of up to 30%, underscoring the importance of these devices in minimizing energy consumption.

As Satya Nadella aptly stated, “—to reenergize, renew, reframe, and rethink their purpose.” This sentiment resonates in the realm of , which are essential for sustaining high-performance operations.

Furthermore, ‘ extensive expertise in providing innovative solutions across various industries, including Telecom, IT/Data Center, and Robotics, enhances customer satisfaction and . Testimonials from clients such as Joseph Dir. of Global Sales & Marketing at Delta Products Corp. emphasize how Gagner-Toomey Associates has been a trusted partner in the North American fan business. Their service offerings, combined with cutting-edge aerodynamic and acoustic training, illustrate how PWM fans are indispensable in optimizing existing setups and pioneering new strategies in modern data center design.

The Essential Role of PWM Fans in Modern Cooling Solutions

to , providing numerous advantages that significantly , performance, and reliability. Their ability to dynamically adjust speeds based on thermal demands renders them ideal for diverse applications, ranging from consumer electronics to industrial systems. This versatility not only improves temperature regulation efficiency but also promotes , positioning as a favored choice within the industry. As one expert noted, “This adaptability makes PWM devices .”

As the electronics sector increasingly prioritizes , the relevance of PWM devices is projected to rise. A prime example is the Fractal Design Aspect 12 Fan, which operates at a maximum speed of 2000 RPM, achieving an airflow of up to 56 CFM while maintaining an impressively low noise level of 18.3 dBA. It has garnered positive reviews for its silent operation and effective airflow, solidifying its position as a preferred choice for users aiming to enhance their PC ventilation solutions. Such innovations underscore the fusion of performance and design that PWM devices offer, reinforcing their critical role in efficient thermal management.

Looking ahead, the adoption of PWM technology is set to expand, driven by the ongoing demand for innovative temperature control solutions. Engineers recognize the essential function of PWM devices in , with many expressing optimism for future advancements in this technology. As the industry progresses, PWM fans will undoubtedly remain at the forefront of cooling innovations, shaping the future landscape of thermal management in electronics.

Conclusion

The integration of PWM fans into modern cooling solutions represents a transformative advancement within the electronics industry. These fans dynamically adjust their speeds in response to real-time thermal demands, significantly enhancing cooling efficiency while simultaneously reducing power consumption and noise levels. The capacity of PWM technology to prolong the lifespan of electronic components highlights its critical role in sustaining optimal operating conditions, thereby ensuring reliability and performance across diverse applications.

As industries increasingly prioritize energy efficiency and sustainability, the adoption of PWM fans is poised for substantial growth. Their superior performance metrics, particularly when compared to traditional DC fans, make PWM fans the preferred choice for engineers tasked with designing high-performance systems, especially in data centers and other critical environments. The positive impact of PWM technology on operational costs and system stability further solidifies its essential role in contemporary cooling strategies.

Looking ahead, the potential for innovative cooling solutions expands as advancements in PWM technology continue to emerge. The growing recognition of PWM fans as vital instruments for achieving energy efficiency and effective thermal management positions them as key players in the evolving landscape of electronics design and manufacturing. Embracing this technology will not only enhance system performance but also contribute to a more sustainable future, rendering PWM fans indispensable in the pursuit of optimal cooling solutions.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a premier supplier of PWM thermal management solutions, focusing on advanced technologies that enhance the efficiency and performance of electronic systems.

How does Gagner-Toomey ensure high-quality products for the electronics industry?

The company collaborates with top manufacturers to provide high-quality PWM fans specifically designed to meet the stringent demands of the electronics industry.

What is the projected growth rate for the PWM secondary side controllers market?

The PWM secondary side controllers market is projected to expand at a compound annual growth rate (CAGR) of 8.9% from 2024 to 2031.

What advancements have been made in PWM thermal management technologies?

Recent advancements include enhanced fan designs and refined control algorithms, which highlight Gagner-Toomey’s commitment to industry innovations.

What role do PWM fans play in temperature management solutions?

PWM fans utilize Pulse Width Modulation to regulate fan speeds precisely, allowing devices to modify their speeds according to temperature requirements, making them essential for modern temperature management solutions.

What types of fans does Gagner-Toomey manufacture?

Gagner-Toomey manufactures a wide array of DC input tube axial fans and centrifugal blowers, with sizes ranging from 15 to 280mm for tube axial fans and 15 to 225mm for centrifugal blowers.

How do PWM fans contribute to energy efficiency?

PWM fans can reduce power consumption by up to 30% compared to direct current devices while maintaining effective temperature management, leading to lower energy consumption and reduced heat generation.

What percentage of engineers are incorporating PWM fans into their designs?

Over 70% of electronics engineers are incorporating PWM fans into their designs, reflecting a growing trend towards more efficient temperature regulation.

What factors should engineers consider when selecting PWM fans?

Engineers should evaluate size, airflow, static pressure, noise level, connector type, and brand quality to ensure the PWM fans meet their specific requirements.

What benefits do PWM fans offer compared to conventional models?

PWM fans provide significant advantages in efficiency and performance, including adaptability to thermal demands, reduced energy consumption, longer device lifespan, and enhanced operational smoothness.