Overview

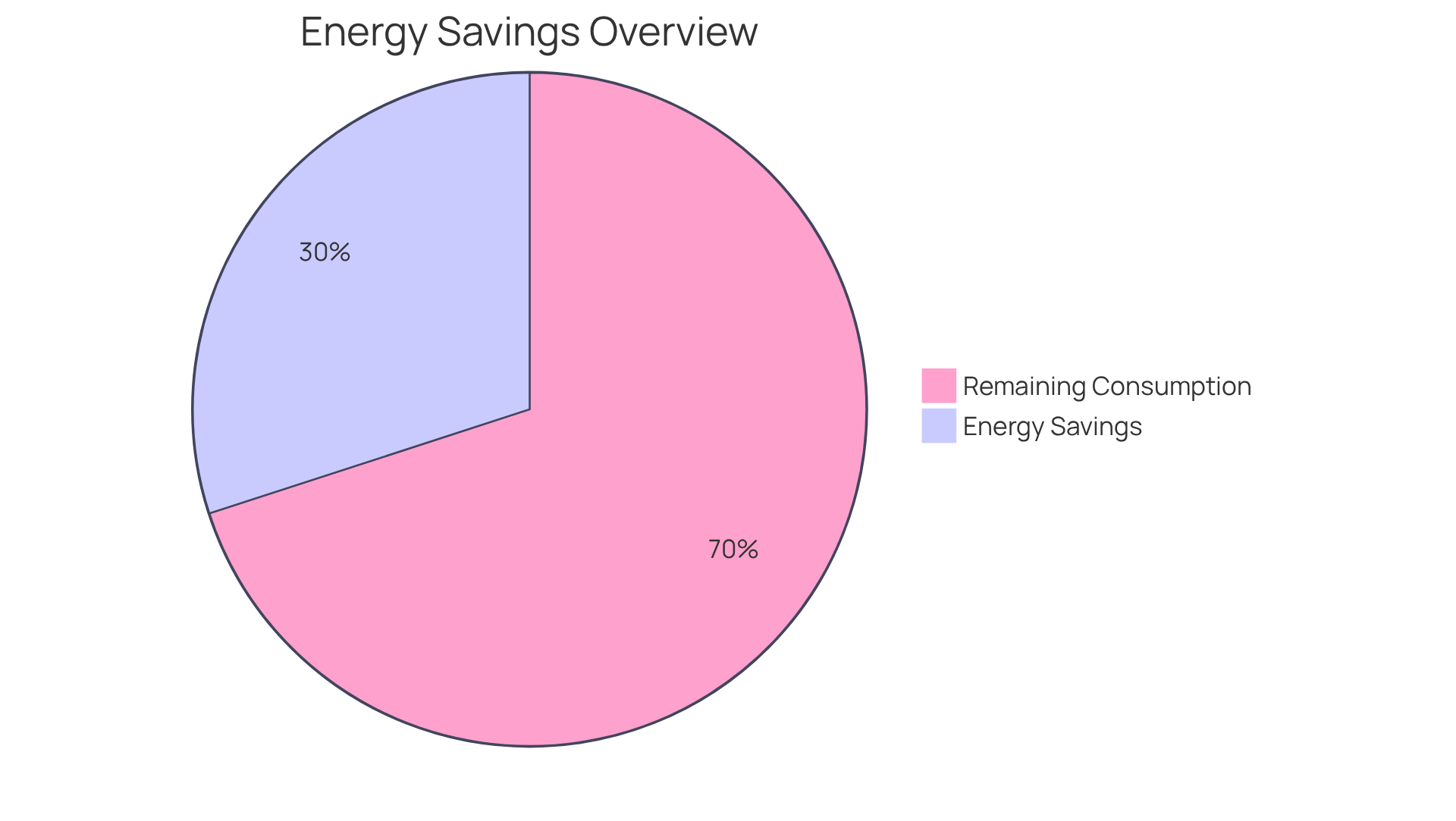

This article delineates ten pivotal advantages of cooling fan PWM technology for engineers, underscoring its significance in enhancing energy efficiency, diminishing noise levels, and bolstering the reliability of electronic systems. The benefits are substantiated by compelling evidence indicating that PWM technology can facilitate energy savings of up to 30%, reduce operational noise by 30%, and prolong the lifespan of electronic components. Such advancements render PWM technology a critical innovation in contemporary thermal management strategies.

Introduction

The evolution of cooling technologies has become paramount in the electronics industry, where efficiency and performance are non-negotiable. Among these advancements, Pulse Width Modulation (PWM) technology stands out as a transformative approach to managing thermal conditions, offering engineers a powerful tool to enhance system performance. This article delves into the myriad benefits of PWM technology in cooling fans, exploring how it not only enhances energy efficiency but also reduces noise and extends the lifespan of electronic components. However, as technological change accelerates, engineers must consider how to effectively harness PWM to meet the escalating demands of modern electronic systems.

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Efficiency

Gagner-Toomey Associates stands at the forefront of providing state-of-the-art tailored for the electronics industry. By employing cutting-edge methods, the company significantly boosts the efficiency of electronic components, ensuring . Notably, recent advancements in temperature regulation techniques, particularly involving , have demonstrated of up to 30%. This innovative approach not only elevates but also meets the rising demand for .

The effective application of cooling fan PWM innovations in temperature regulation systems has been pivotal in addressing , solidifying Gagner-Toomey as a leader in the sector. Industry leaders recognize the critical importance of in ensuring the reliability of electronic systems, further underscoring the company’s unwavering commitment to excellence in solutions.

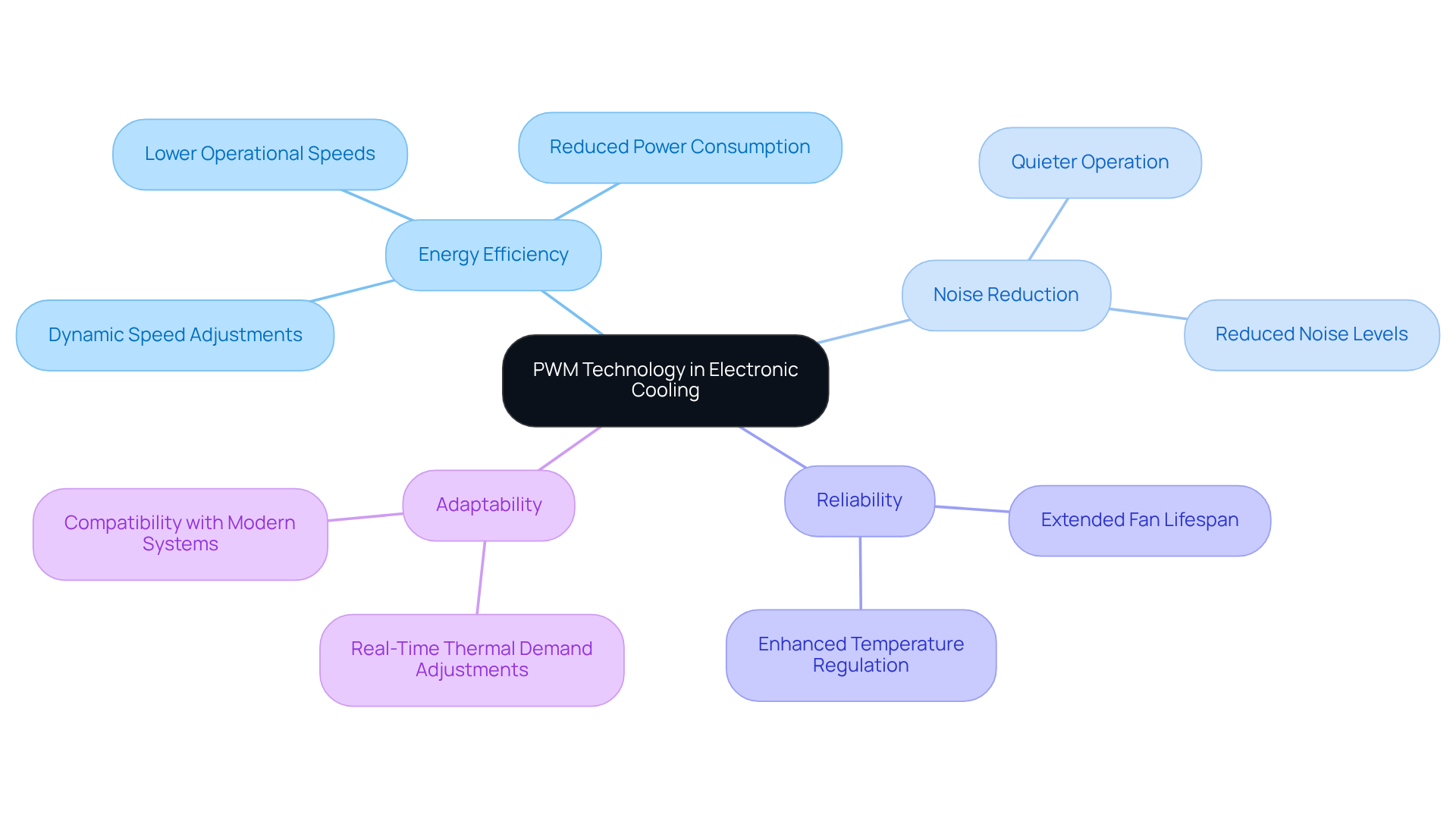

PWM Technology: Understanding the Basics of Efficient Fan Control

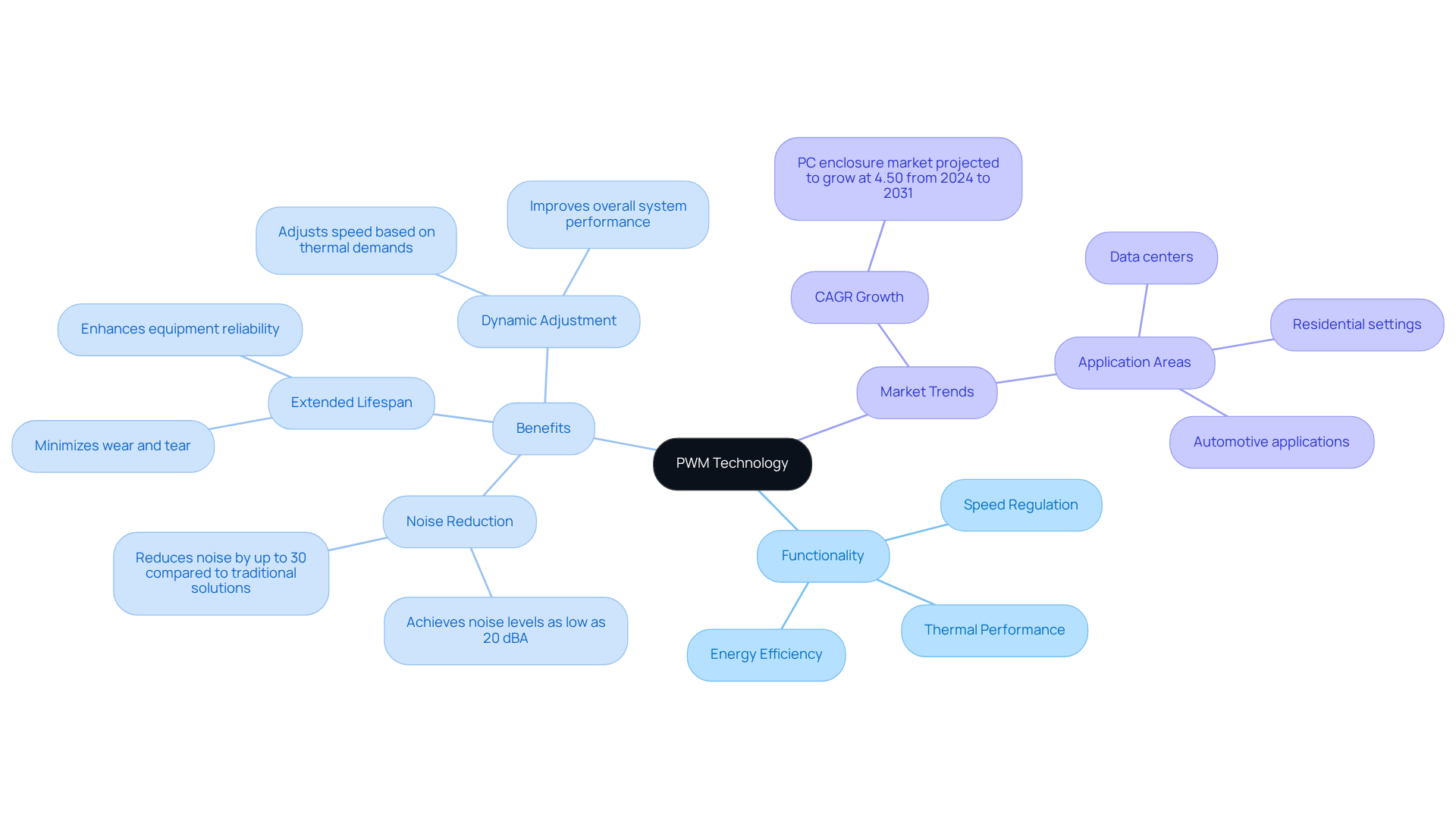

Pulse Width Modulation (PWM) represents a sophisticated approach to , including the , by modifying the width of the electrical pulses directed to the motor. This technique enables , ensuring that devices operate efficiently across a range of load conditions.

By fine-tuning the duty cycle of the PWM signal, engineers can , all while significantly reducing . Notably, systems that utilize PWM can achieve of up to 30% when compared to traditional solutions. PWM units operate as quietly as 20 dBA, whereas conventional units often exceed 30 dBA under similar conditions. This capability is particularly vital in environments where noise control is paramount, such as data centers and residential settings.

Furthermore, the integration of cooling fan PWM technology in electronics cooling is on the rise, with the PC enclosure market projected to grow at a CAGR of 4.50% from 2024 to 2031, underscoring the increasing significance of cooling fan in modern temperature regulation strategies.

Engineers have observed that PWM devices not only bolster energy efficiency but also extend the lifespan of equipment by minimizing wear and tear associated with continuous high-speed operation. The versatility of PWM devices to dynamically adjust their speed in response to thermal demands significantly enhances overall system performance, positioning them as a preferred solution in contemporary electronic applications.

stands out as a leading provider of , prominently featuring devices such as cooling fan PWM that are designed to optimize performance and efficiency in electronic systems.

Enhanced Airflow and Noise Reduction: Advantages of PWM in Cooling Fans

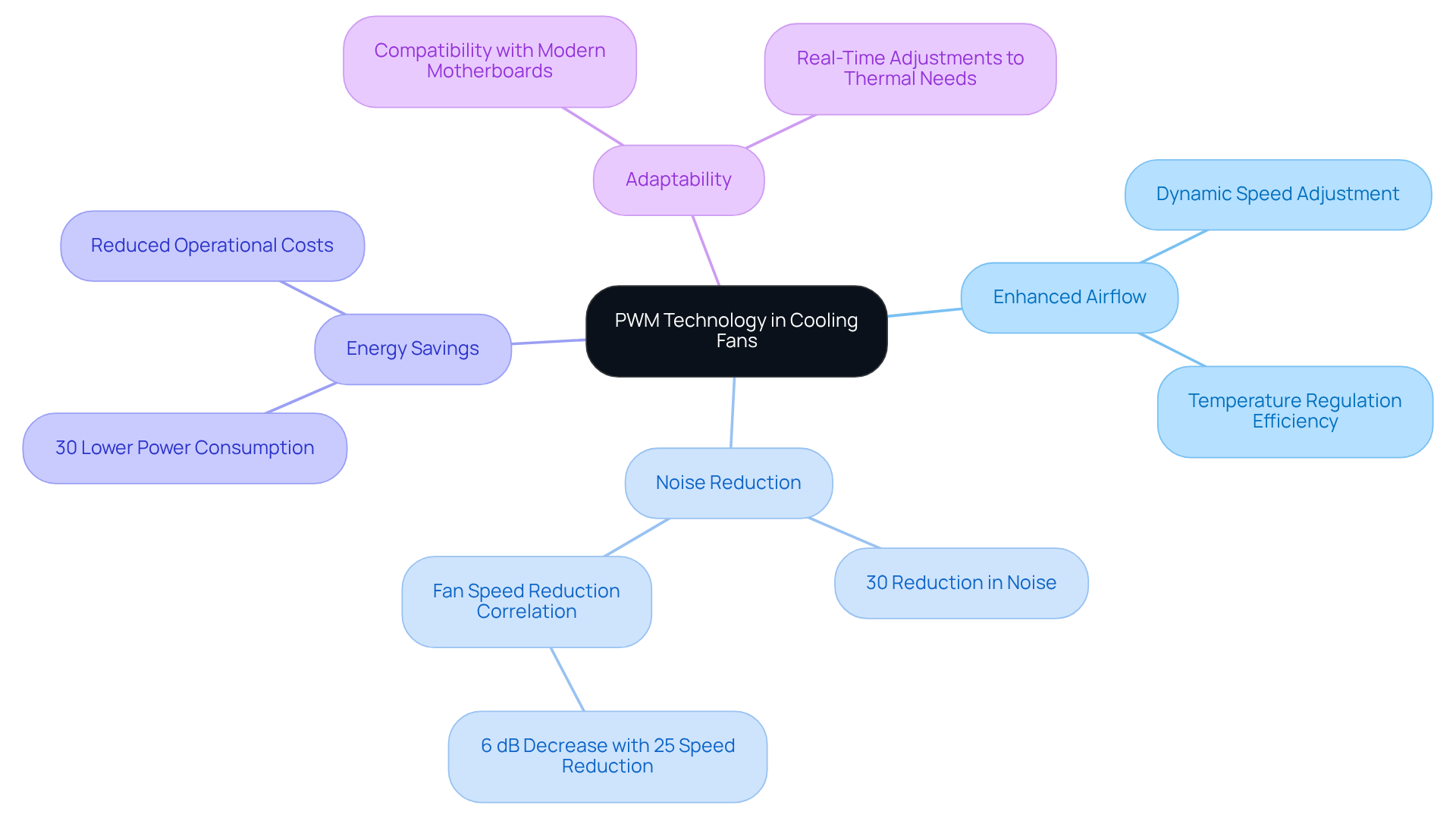

, such as cooling fan PWM, significantly enhances airflow by enabling devices to dynamically adjust their speed according to thermal demands. This adaptability not only boosts temperature regulation efficiency but also minimizes noise levels, rendering especially suitable for environments where is paramount.

Operating at reduced speeds, such as idling at 15% capacity when peak power is unnecessary, allows [PWM devices](https://gagner-toomey.com/?p=9065) to provide while reducing disruptive noise. Research indicates that systems utilizing PWM devices can achieve s of up to 30% compared to traditional temperature regulation systems, thereby enhancing user comfort in sensitive settings.

Engineers have observed that incorporating PWM technology results in smoother speed transitions and heightened responsiveness to temperature variations, further promoting . For example, a 25% decrease in fan speed can lead to a noise reduction of approximately 6 dB, illustrating the efficacy of PWM in .

Moreover, PWM units can lower power consumption by as much as 30% relative to conventional models, positioning them as a viable energy-saving solution for thermal management systems. Additionally, it is crucial for engineers to ensure PWM devices are equipped with a four-pin connector for compatibility with modern motherboards.

In summary, the implementation of PWM methods in not only optimizes airflow but also markedly enhances acoustic performance.

Energy Efficiency: How PWM Fans Reduce Power Consumption

The from Gagner-Toomey Associates are engineered for superior efficiency compared to traditional fans, dynamically adjusting their speed based on the system’s cooling needs. This adaptability can result in relative to conventional fan systems.

For instance, data centers utilizing PWM methods have achieved a reduction in from 1.55 to 1.42, showcasing the practical impact of this approach. By functioning at reduced speeds during low-load situations—occasionally as low as 10% of peak speed— but also considerably diminish operational expenses.

This approach promotes a more , aligning with the growing emphasis on energy efficiency in modern engineering practices. Moreover, research suggests that applying by as much as 50%.

As , ‘This capability not only allows for quieter operation but also reduces power consumption during low-load conditions,’ making it a crucial consideration for .

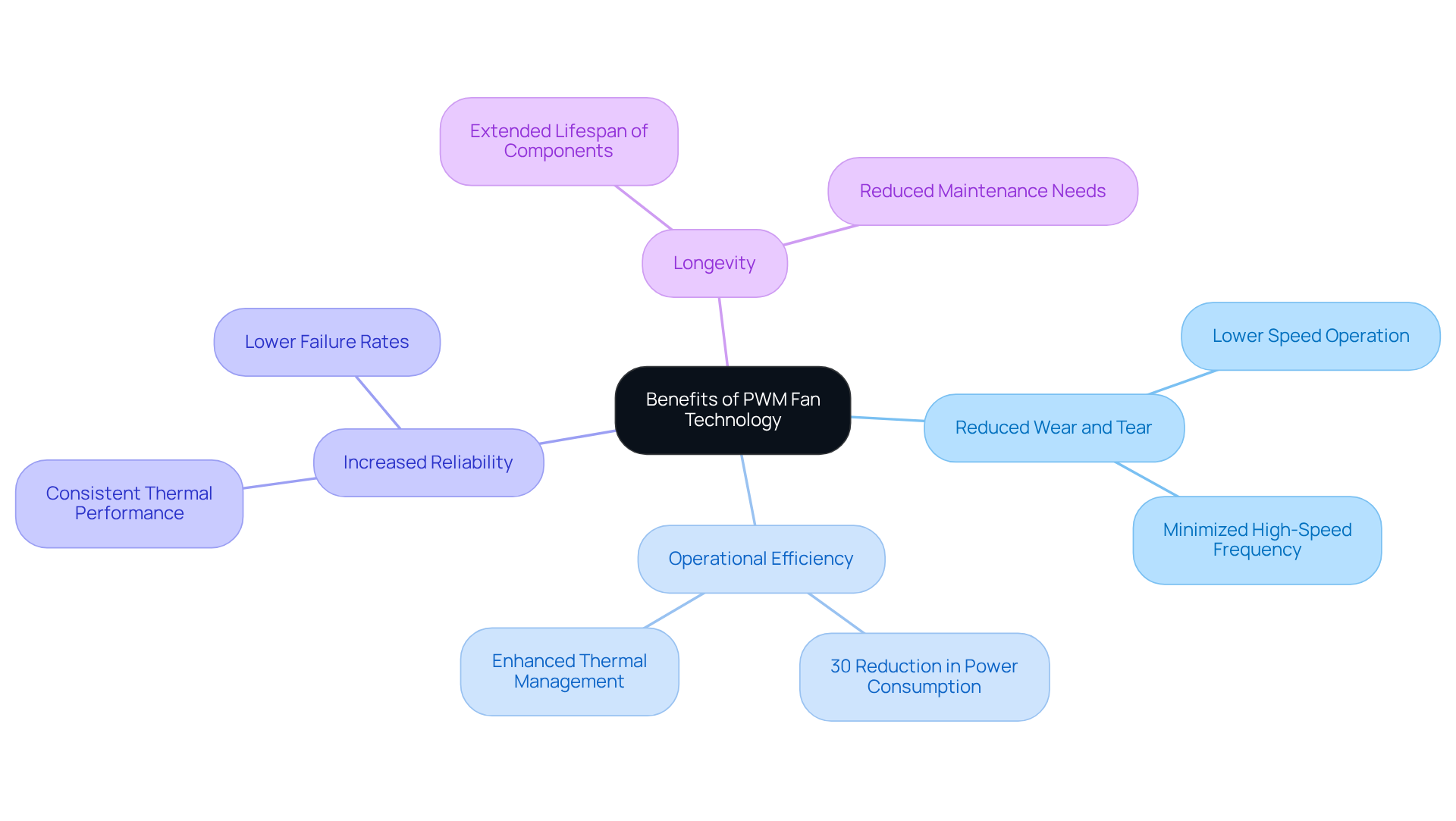

Increased Reliability and Longevity: Benefits of PWM Fan Technology

PWM units operate with significantly compared to conventional models, primarily due to their ability to function at lower speeds when demands are minimal. This not only diminishes strain on the components but also enhances the of . By minimizing the frequency of , effectively extends the lifespan of ventilators, positioning them as a for long-term applications.

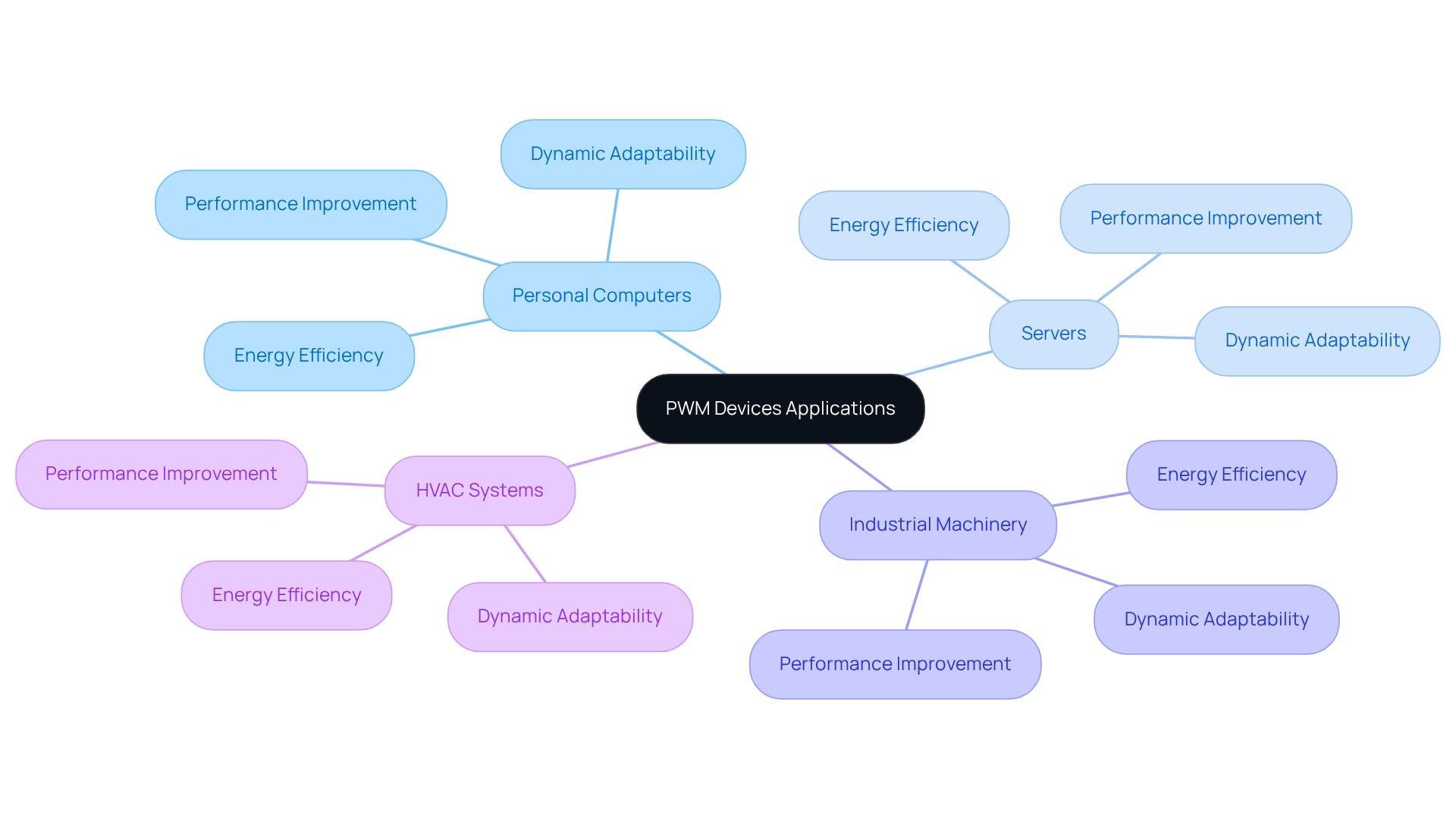

Versatile Applications: Utilizing PWM Fans Across Electronic Systems

are critical to a diverse array of applications, including personal computers, servers, industrial machinery, and HVAC systems. Their ability to dynamically adapt to varying thermal loads renders them particularly effective in environments with fluctuating cooling demands. This adaptability not only boosts performance but also , establishing PWM devices as the preferred choice across various sectors.

For instance, in settings, PWM devices can by up to 30%, while extending the lifespan of electronic components by as much as 50%. Furthermore, the is evident, with 61% of users opting for PWM-capable devices due to their and efficiency.

Industry leaders recognize the transformative potential of PWM solutions, highlighting their role in improving across multiple systems. As the electronics landscape continues to evolve, the versatility of PWM devices positions them as indispensable components in achieving .

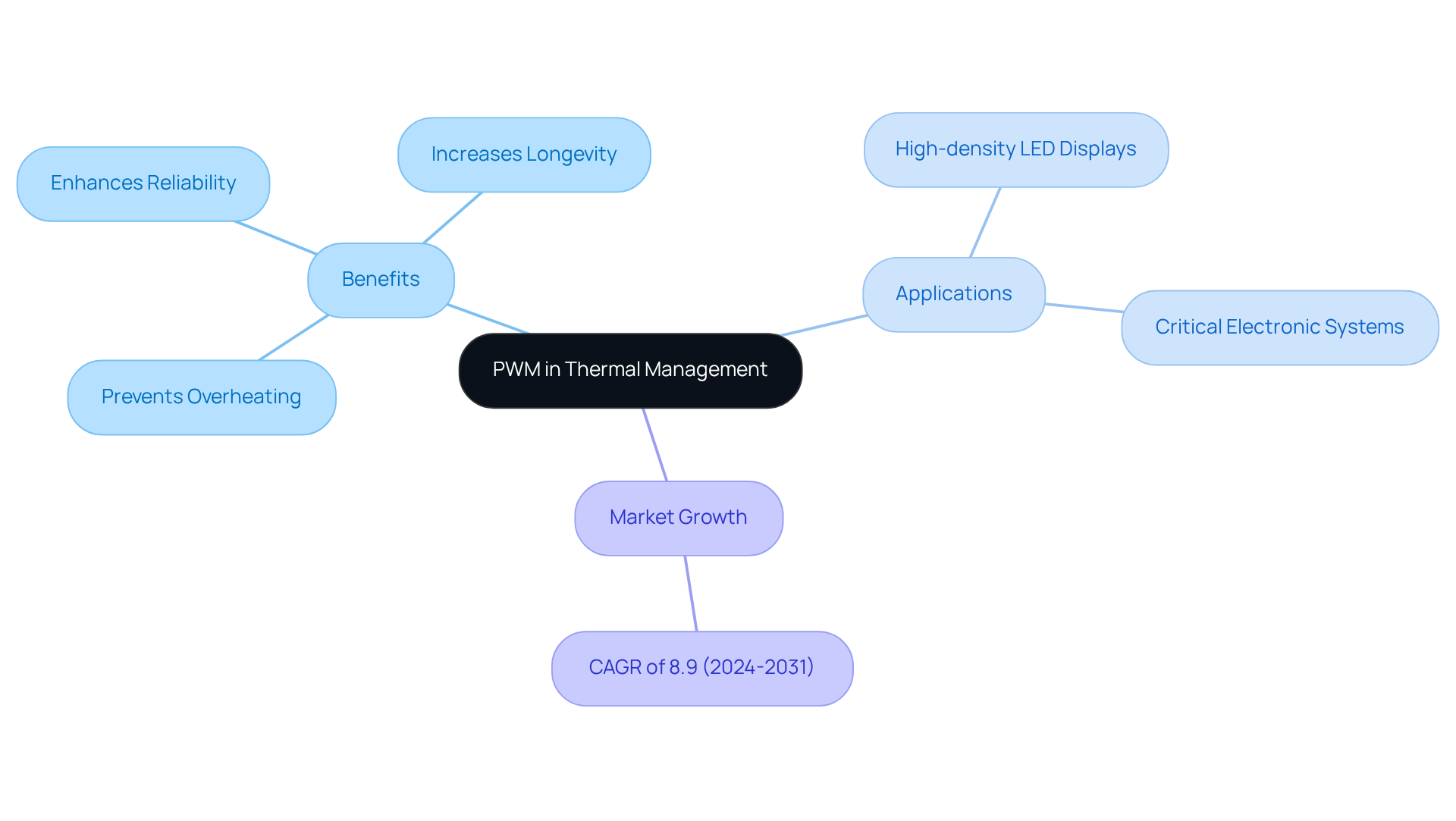

Thermal Management: The Role of PWM in Maintaining Optimal Temperatures

Effective is crucial for ensuring that electronic systems operate under optimal conditions. Pulse Width Modulation (PWM) technology significantly enhances this process by allowing devices to dynamically adjust their speeds in response to real-time temperature fluctuations. This adaptability enables to effectively , keeping electronic components within safe temperature ranges and thus enhancing overall system reliability.

Engineers acknowledge that PWM devices significantly enhance heat management in , highlighting their essential function in . For instance, in high-density LED displays, PWM devices have been shown to maintain temperatures within critical limits, and reducing maintenance costs.

As one unnamed expert noted, ‘This adaptability makes PWM devices superior to traditional models in terms of both performance and efficiency.’ This level of efficiency not only enhances performance but also contributes to the longevity of electronic devices, making PWM fans an in modern thermal management strategies.

Furthermore, the PWM secondary side controllers market is anticipated to grow at a compound annual growth rate (CAGR) of 8.9% from 2024 to 2031, indicating the rising significance and uptake of PWM methods in the industry.

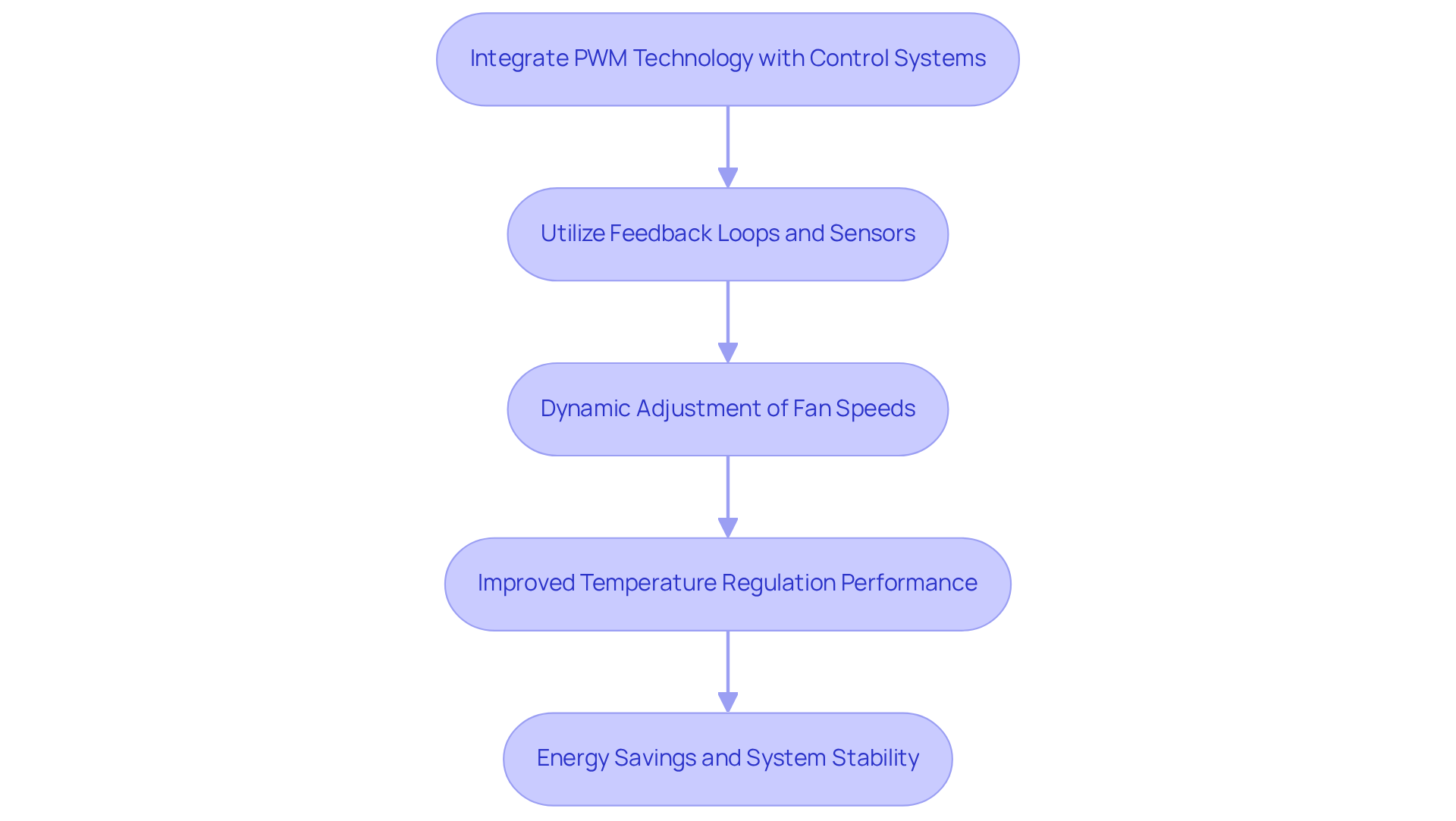

Integration with Control Systems: Enhancing Performance with PWM Technology

PWM technology seamlessly integrates with various control systems, significantly enhancing the performance and efficiency of in applications. This integration addresses the critical challenge of .

By utilizing , engineers can develop that dynamically adjust fan speeds based on real-time data. This adaptive approach not only improves temperature regulation performance but also leads to substantial and .

For instance, precise sensing and the application of to conserve 29% in site energy in U.S. commercial buildings, showcasing the practical efficacy of this innovation.

As Dean Kamen aptly stated, ‘ to the world’s problems using math, science, and innovation,’ highlighting the transformative potential of PWM in electronic temperature regulation systems.

Moreover, the implementation of feedback loops facilitates precise control over the cooling fan PWM, ensuring that systems respond effectively to varying thermal loads. This capability is essential in applications where maintaining optimal temperatures is critical for reliability and longevity.

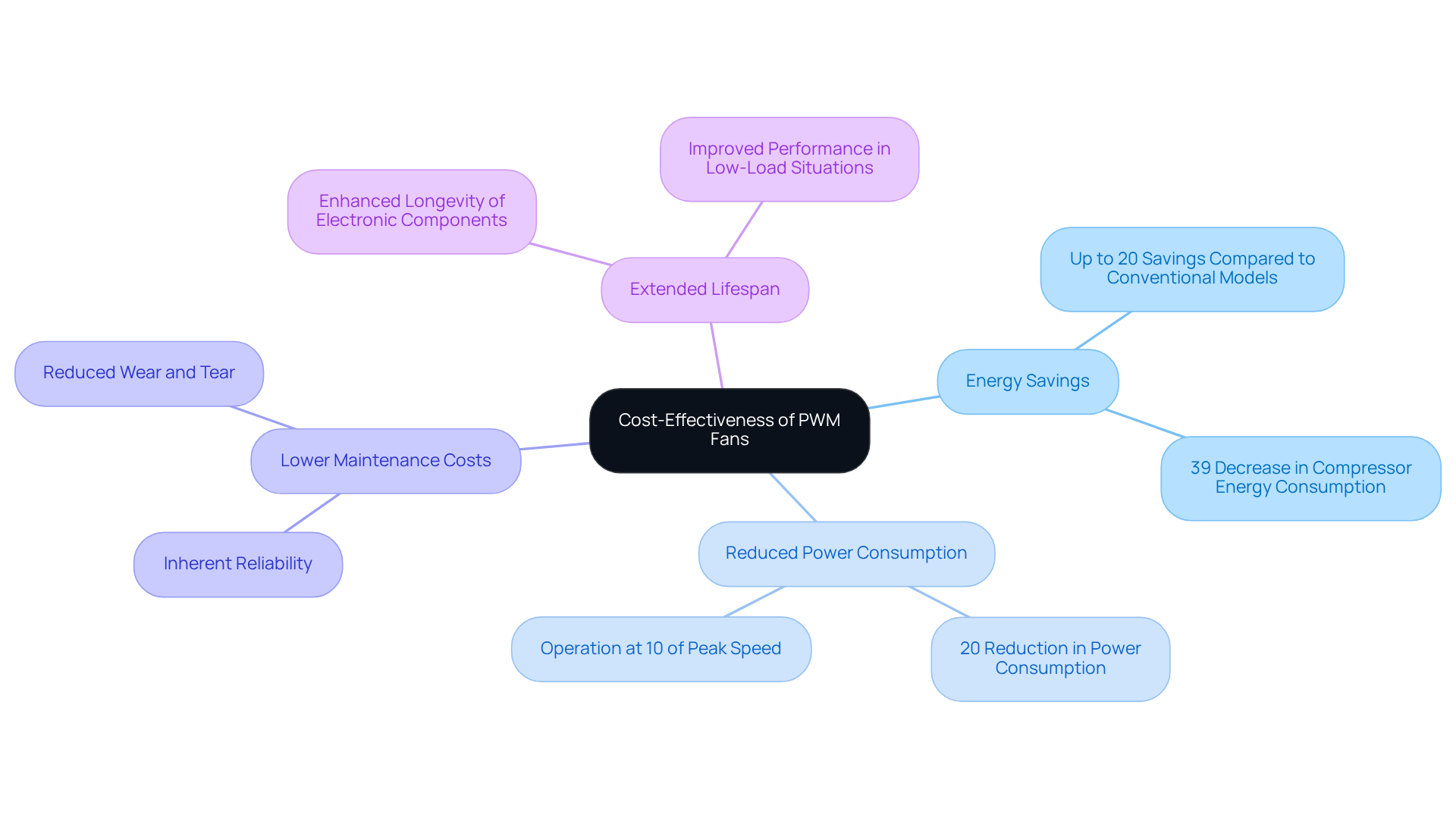

Cost-Effectiveness: The Economic Benefits of PWM Fan Implementation

Implementing offers , primarily because of its . By dynamically adjusting speeds based on thermal demands, significantly reduce electricity costs, with studies indicating potential energy savings of up to 20% compared to traditional models. Moreover, the adoption of cooling fan PWM devices can result in a by as much as 20% compared to conventional models, highlighting their efficiency advantages. Their inherent reliability results in lower maintenance and replacement expenses, as these devices are engineered to operate efficiently even at reduced speeds during low-load situations. This adaptability not only enhances their cost-effectiveness but also extends the lifespan of electronic components, ensuring a prudent investment for both immediate and long-term projects.

For instance, a recent pilot initiative demonstrated that incorporating PWM devices led to an impressive 39% decrease in compressor energy consumption during the temperature regulation period, as highlighted in a case study focused on retrofit applications in affordable housing. Overall, the of cooling fan PWM devices position them as a critical factor for engineers striving to .

As Gagner-Toomey Associates notes, of cooling fan PWM controllers against budget constraints and specific application requirements when deciding between cooling fan PWM and DC models.

Overall Impact: The Significance of PWM Technology in Electronic Cooling

The incorporation of cooling fan in signifies a significant advancement in electronic cooling solutions. By utilizing a cooling fan PWM through Pulse Width Modulation to regulate speeds according to temperature requirements, PWM fans enhance , minimize noise levels, and bolster reliability. This innovation is revolutionizing for engineers.

As sectors increasingly emphasize high-performance and energy-efficient solutions, the role of PWM systems is set to expand, driving advancements in refrigeration systems. Notably, dynamic speed adjustments made by cooling fan PWM based on real-time thermal demands exemplify how these fans are , ensuring optimal performance while reducing energy consumption.

Furthermore, the adaptability of PWM devices facilitates and a reduced carbon footprint, reinforcing their importance in contemporary electronic designs. As one industry leader noted, ‘The is essential for meeting the rigorous demands of modern electronic cooling solutions.

Conclusion

The integration of cooling fan PWM technology signifies a transformative shift in electronic cooling solutions. By leveraging Pulse Width Modulation to regulate fan speeds based on real-time temperature demands, this innovative approach not only enhances energy efficiency but also significantly reduces noise levels and improves the overall reliability of electronic systems. As the electronics industry evolves, the importance of PWM technology becomes increasingly evident, establishing it as a cornerstone of modern thermal management strategies.

Key benefits of PWM technology include:

- Its ability to dynamically adjust airflow

- Lower power consumption

- Extended lifespan of electronic components

The versatility of PWM devices across various applications, from personal computers to industrial machinery, showcases their adaptability to fluctuating cooling needs. Furthermore, the substantial cost savings associated with implementing PWM systems underscore their economic viability for engineers focused on performance and sustainability.

In light of these advancements, it is crucial for engineers and industry stakeholders to embrace PWM technology as an essential component in their cooling solutions. The ongoing demand for high-performance and energy-efficient systems illustrates the growing significance of PWM in achieving optimal thermal management. By prioritizing the adoption of PWM methods, the electronics sector can enhance operational efficiency while contributing to a more sustainable future.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for providing innovative temperature control solutions specifically tailored for the electronics industry, enhancing the efficiency and reliability of electronic components.

How does Gagner-Toomey Associates improve energy efficiency?

The company employs advanced temperature regulation techniques, particularly cooling fan Pulse Width Modulation (PWM), which can improve energy usage efficiency by up to 30%.

What is Pulse Width Modulation (PWM)?

PWM is a method used to regulate the speed of ventilation devices, such as cooling fans, by adjusting the width of the electrical pulses sent to the motor, allowing for precise control over air circulation speed.

What are the benefits of using PWM technology in cooling fans?

PWM technology enhances airflow and thermal performance while reducing energy consumption and noise levels by up to 30% compared to traditional solutions, making it ideal for environments requiring noise control.

How does PWM technology affect noise levels in cooling systems?

PWM devices can operate as quietly as 20 dBA, significantly reducing noise levels compared to conventional units that often exceed 30 dBA, particularly important in sensitive environments like data centers and residential areas.

What impact does PWM have on the lifespan of equipment?

PWM devices help extend the lifespan of equipment by minimizing wear and tear associated with continuous high-speed operation through their ability to adjust speed based on thermal demands.

What is the projected market growth for cooling fan PWM technology?

The PC enclosure market, which includes cooling fan PWM technology, is projected to grow at a compound annual growth rate (CAGR) of 4.50% from 2024 to 2031.

What are the key advantages of using PWM in temperature regulation systems?

The key advantages include enhanced airflow, improved energy efficiency, reduced noise levels, and extended equipment lifespan, making PWM a preferred solution in modern electronic applications.