Overview

This article delineates four essential practices for the effective utilization of temperature-controlled coolers. These practices encompass:

- The selection of the appropriate unit tailored to specific requirements

- The implementation of best usage practices

- The maintenance of optimal performance

- A comprehensive understanding of the distinctions between thermoelectric and compressor coolers

Each of these practices is underpinned by thorough explanations of operational principles, practical maintenance tips, and the critical importance of regular inspections. These measures are vital for ensuring efficiency and preventing spoilage or damage to sensitive items.

Introduction

Temperature-controlled coolers are indispensable across various industries, playing a vital role in preserving food and managing sensitive electronics. Their capacity to maintain precise thermal ranges not only protects valuable items but also significantly boosts operational efficiency. However, the effectiveness of these coolers is contingent upon a thorough understanding of their mechanisms and the implementation of best practices.

What challenges emerge when selecting and maintaining these devices?

Moreover, how can users ensure optimal performance while steering clear of common pitfalls?

Understand Temperature-Controlled Coolers

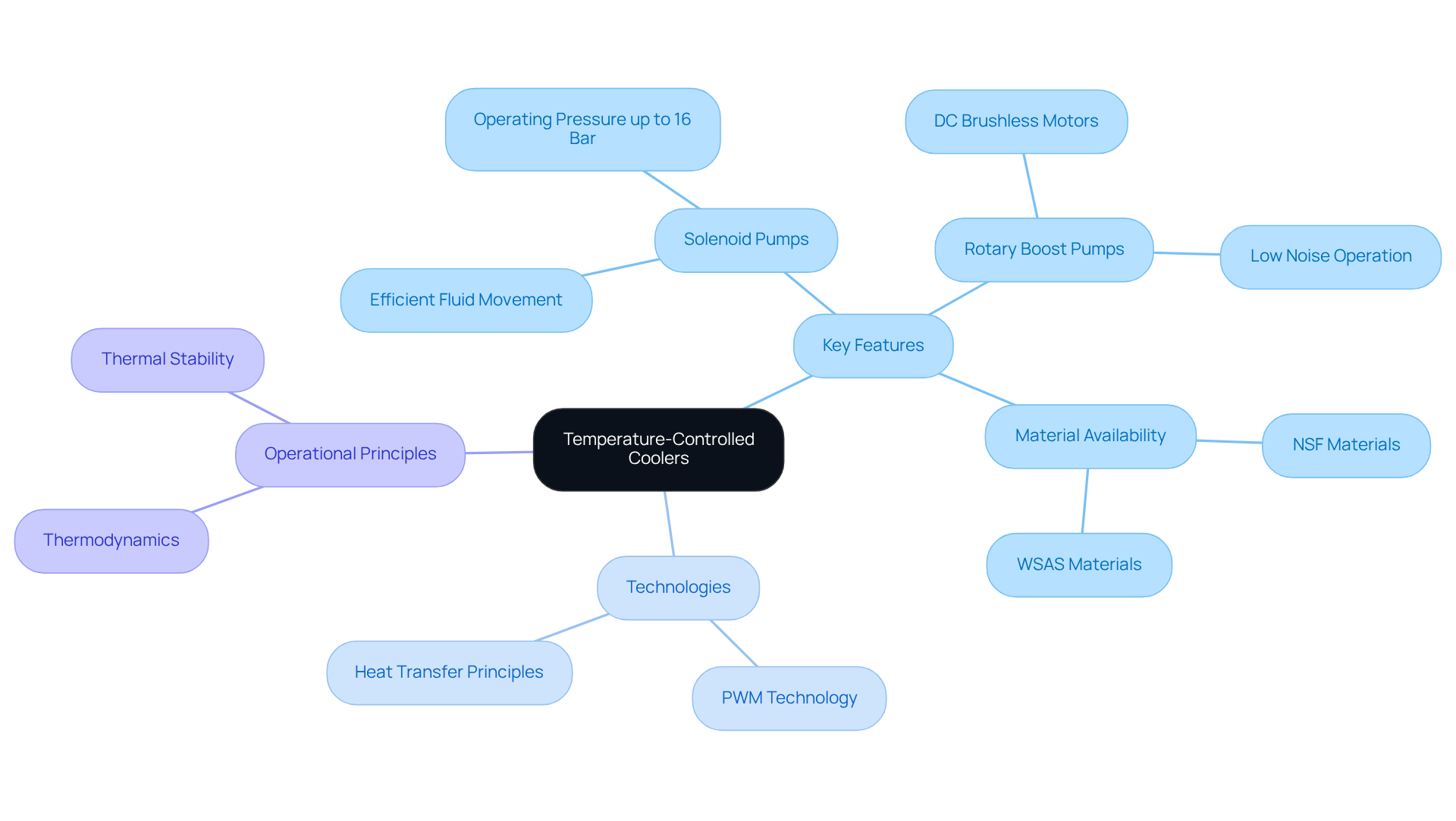

Temperature controlled coolers serve as specialized instruments designed to maintain specific thermal ranges for a variety of applications, including food preservation, electronics management, and laboratory environments. These devices utilize advanced technologies, such as solenoid and rotary boost pumps, to achieve precise temperature control. Key features include:

- Solenoid Pumps: Capable of operating up to 16 Bar, these pumps facilitate efficient fluid movement, which is essential for sustaining optimal conditions in cooling systems.

- Rotary Boost Pumps: Featuring DC brushless motors, these pumps ensure low noise operation and precise control through PWM technology, making them particularly suitable for sensitive electronic components.

- Material Availability: NSF and WSAS materials are accessible for these pumps, ensuring adherence to safety and quality standards.

Understanding the , including thermodynamics and heat transfer, is vital for selecting the appropriate temperature controlled cooler that meets your specific requirements. Recognizing the importance of thermal stability can prevent spoilage or damage to delicate components, making this knowledge indispensable for both engineers and technicians.

Differentiate Between Thermoelectric and Compressor Coolers

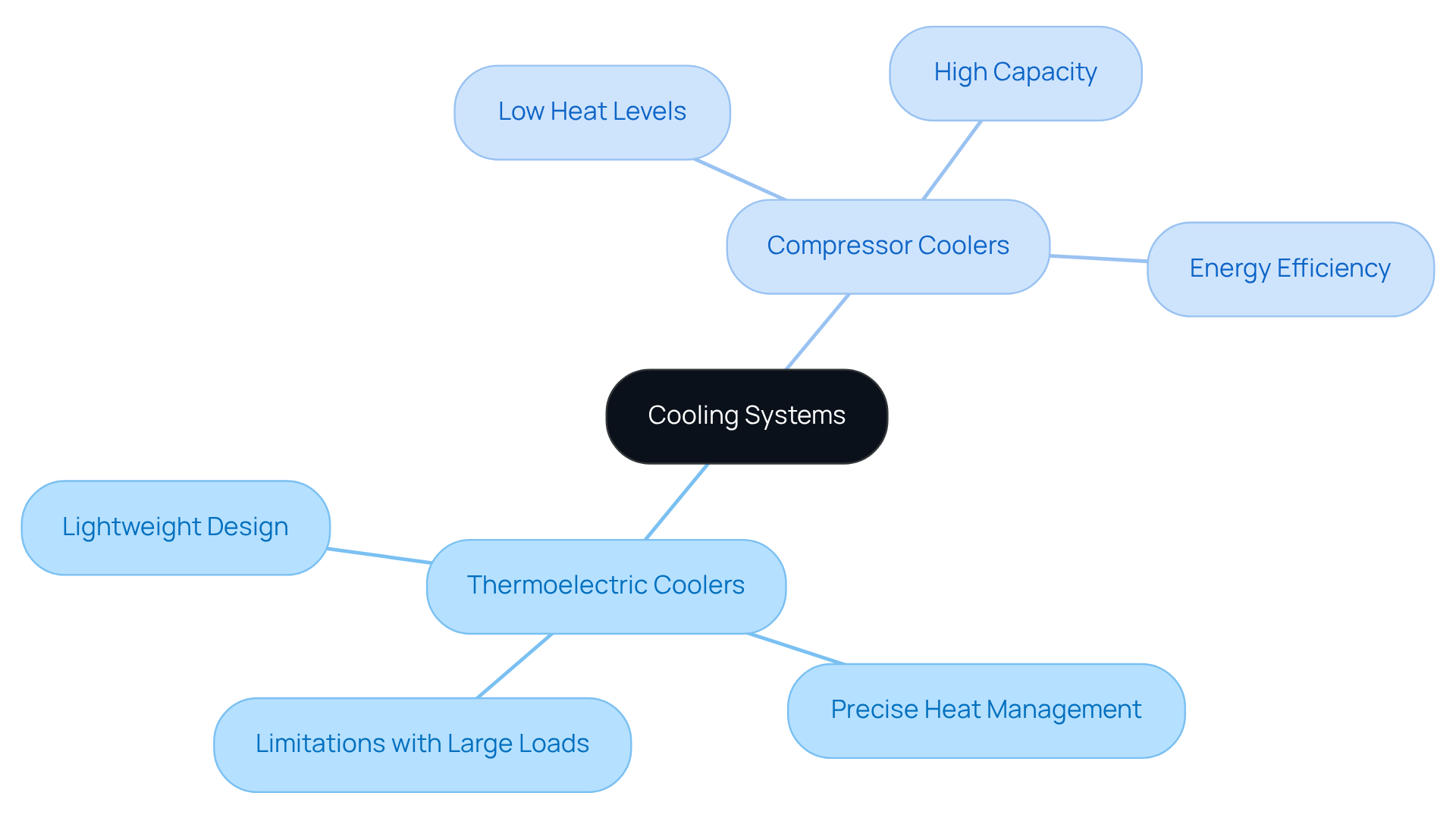

Thermoelectric devices, commonly known as Peltier units, leverage electrical energy to create a thermal differential, facilitating compact and lightweight designs. These units excel in applications requiring ; however, they may struggle with larger thermal loads.

In contrast, compressor units utilize refrigerants and mechanical compression to achieve lower heat levels, making them ideal for high-capacity cooling demands. Recognizing these distinctions is crucial.

For instance, if energy efficiency and space are paramount, thermoelectric units may be the preferable choice. Conversely, for extensive cooling requirements, compressor systems prove to be more effective.

Implement Best Practices for Cooler Selection and Usage

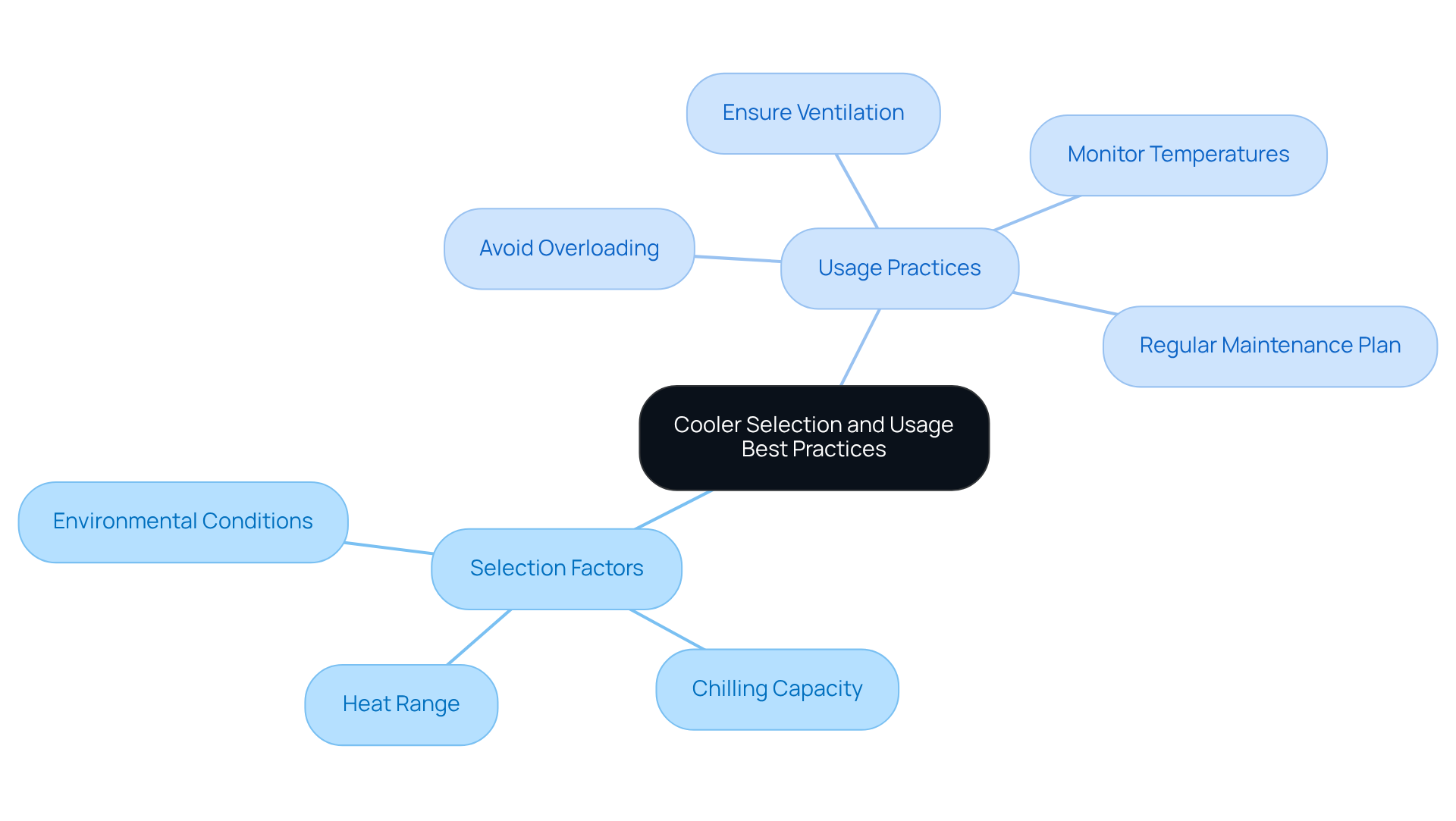

When selecting a temperature controlled cooler, it is crucial to consider several key factors:

- The required heat range

- The capacity for chilling items

- The surrounding environmental conditions

Evaluating the energy efficiency ratings and operational costs of the appliance is essential for informed decision-making. Once the appropriate chiller is selected, implementing effective usage practices is vital. This includes:

- Avoiding overloading the unit

- Ensuring adequate ventilation

- Regularly checking the settings

For instance, utilizing a thermometer to monitor internal temperatures can help maintain optimal conditions and prevent overheating. Additionally, establishing a regular maintenance plan is beneficial, as it can enhance the appliance’s efficiency and prolong its lifespan.

Maintain and Optimize Cooler Performance

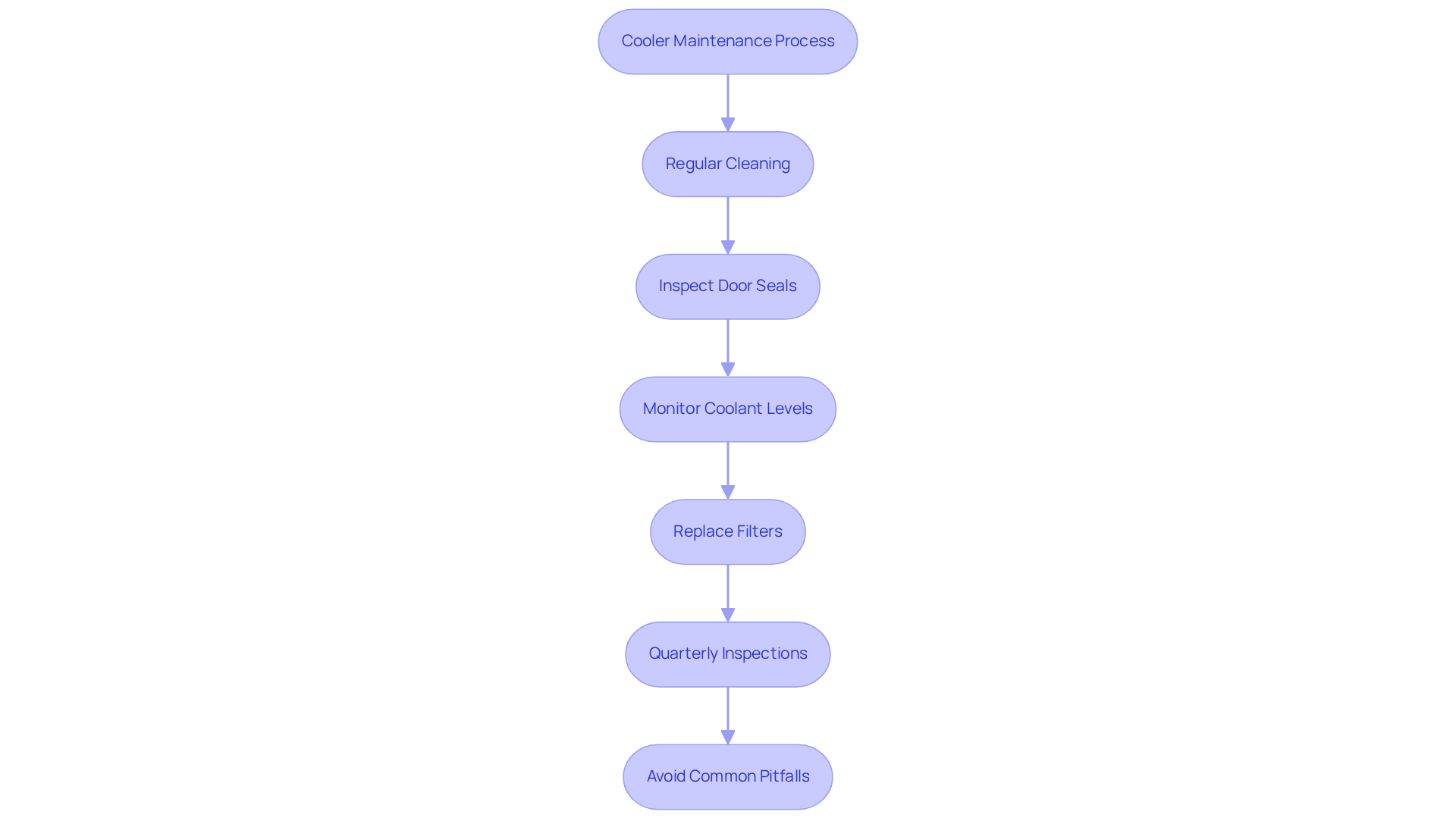

To maintain and optimize the performance of a temperature controlled cooler, regular cleaning of both the interior and exterior surfaces is essential. Dust buildup significantly impedes airflow, leading to inefficiencies. Technicians emphasize the importance of inspecting door seals and hinges, as any leaks can cause temperature fluctuations that compromise the performance of the temperature controlled cooler. Furthermore, monitoring coolant levels and replacing filters as necessary are vital steps in ensuring the optimal functionality of the temperature controlled cooler.

Utilizing a simplifies these tasks, guaranteeing that nothing is overlooked. For instance, a quarterly inspection can reveal potential problems early, enabling prompt interventions that enhance the device’s efficiency and lifespan. Notably, indirect evaporative devices sustain low humidity levels while allowing substantial air changes with minimal energy use, underscoring the significance of routine upkeep for energy efficiency.

Practical applications, such as the implementation of an evaporative temperature controlled cooler at Rapid Labels, demonstrate that regular maintenance not only improves working conditions but also helps reduce humidity levels, benefiting both workers and equipment. As highlighted by Bourke Air, both personnel and machinery experience significant advantages from the installed evaporative cooling systems, emphasizing the positive outcomes of proper cooler maintenance.

Avoiding common pitfalls, such as neglecting to check door seals or coolant levels in a temperature controlled cooler, is crucial for ensuring optimal performance.

Conclusion

Temperature-controlled coolers are indispensable tools that preserve the integrity of sensitive items across diverse industries, from food preservation to electronics and laboratory applications. Mastering their effective use requires a comprehensive understanding of their operational principles, distinguishing between types, and applying best practices for selection and maintenance.

Selecting the right cooler based on specific requirements, such as thermal load and energy efficiency, is paramount. Furthermore, recognizing the distinctions between thermoelectric and compressor coolers enables informed decisions that align with operational needs. Adhering to best practices for usage, including regular maintenance and monitoring, is crucial for optimizing performance and extending the lifespan of these devices.

Ultimately, the proficient use of temperature-controlled coolers not only safeguards valuable contents but also enhances operational efficiency. By implementing the insights and practices discussed, individuals and organizations can ensure that their cooling solutions operate at peak performance, leading to improved outcomes in their respective fields. Embracing these practices is essential for all users, as prioritizing proper selection and maintenance of temperature-controlled coolers will yield significant benefits.

Frequently Asked Questions

What are temperature-controlled coolers used for?

Temperature-controlled coolers are specialized instruments designed to maintain specific thermal ranges for applications such as food preservation, electronics management, and laboratory environments.

What technologies do temperature-controlled coolers use for temperature control?

They utilize advanced technologies, including solenoid and rotary boost pumps, to achieve precise temperature control.

What is the function of solenoid pumps in temperature-controlled coolers?

Solenoid pumps can operate up to 16 Bar and facilitate efficient fluid movement, which is essential for maintaining optimal conditions in cooling systems.

How do rotary boost pumps differ from solenoid pumps?

Rotary boost pumps feature DC brushless motors for low noise operation and use PWM technology for precise control, making them particularly suitable for sensitive electronic components.

What materials are available for the pumps used in temperature-controlled coolers?

NSF and WSAS materials are available for these pumps, ensuring compliance with safety and quality standards.

Why is it important to understand thermodynamics and heat transfer when selecting a temperature-controlled cooler?

Understanding these principles is vital for selecting the appropriate cooler that meets specific requirements and helps prevent spoilage or damage to delicate components.

Who can benefit from knowledge about temperature-controlled coolers?

This knowledge is indispensable for both engineers and technicians involved in applications requiring thermal stability.