Overview

Small blower fans play a crucial role in enhancing electronics cooling solutions by delivering efficient heat dissipation, which is essential for maintaining optimal operating temperatures and preventing component overheating. These fans can significantly reduce temperatures by up to 20°C, a fact that underscores their importance. By strategically managing airflow, they not only prolong the lifespan of electronic components but also improve overall system performance. This combination of benefits makes small blower fans an indispensable asset in the realm of electronics cooling.

Introduction

Small blower fans have emerged as unsung heroes in the realm of electronics cooling, providing essential support in an era where devices are becoming increasingly compact and powerful. These innovative cooling solutions not only enhance performance but also extend the lifespan of sensitive components, making them indispensable in various applications—from data centers to portable electronics. However, as the demand for efficient thermal management intensifies, the question arises: how can engineers effectively integrate these small yet mighty devices to optimize cooling while navigating the complexities of modern electronic design?

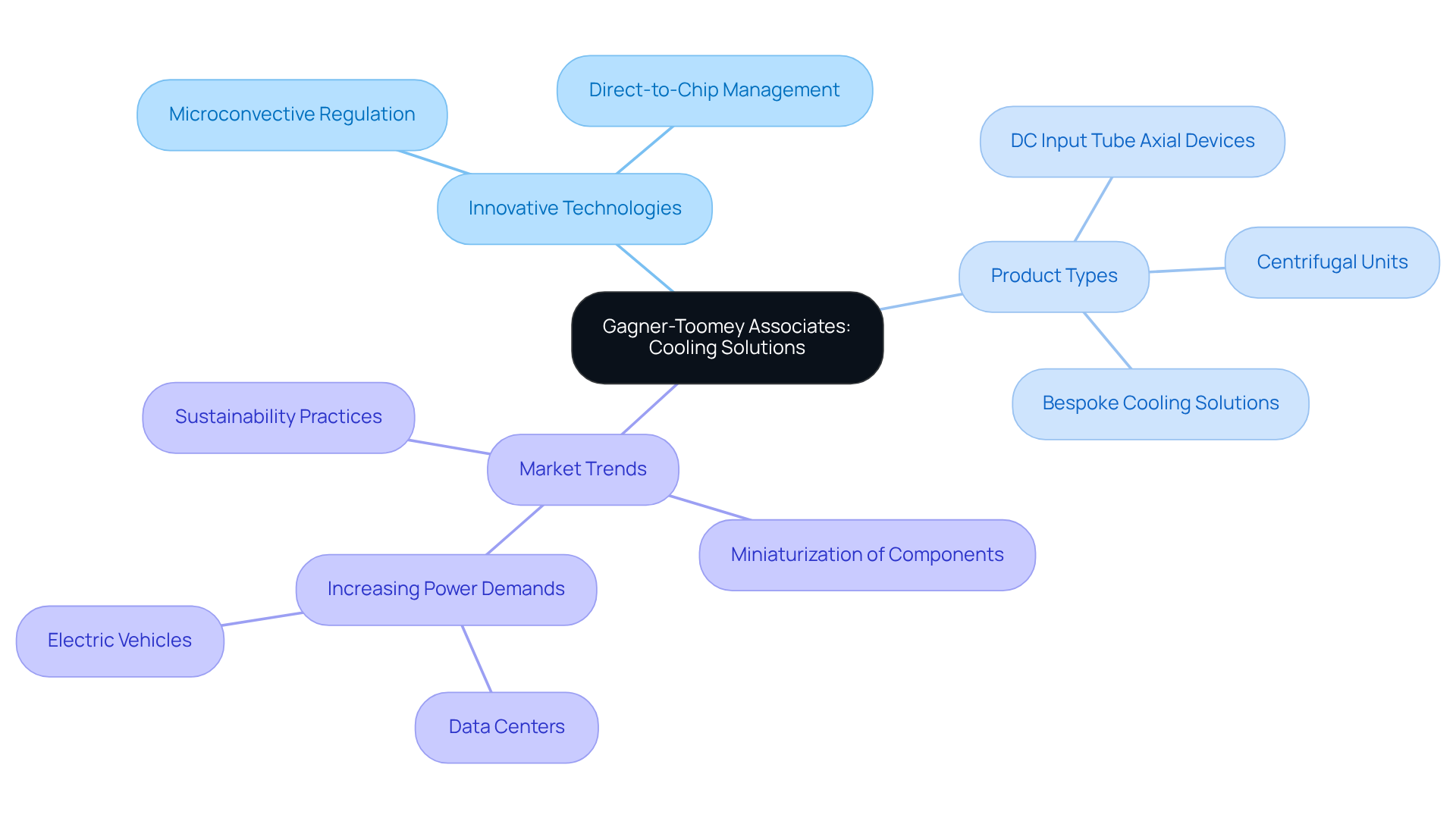

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Design

Gagner-Toomey Associates excels in delivering advanced tailored for the electronics industry. By integrating small ventilation units into their , the company ensures optimal . Recent trends indicate a notable shift in the , propelled by the miniaturization of components and increasing power demands from applications such as data centers and electric vehicles. For instance, studies demonstrate that using can lower component temperatures by as much as 20°C, effectively preventing thermal throttling and prolonging hardware lifespan.

Innovative technologies, including microconvective temperature regulation and direct-to-chip thermal management, are at the forefront of boosting efficiency. These advancements facilitate of processor hotspots, which is crucial as high-performance computing systems can generate heat outputs exceeding 300 watts per chip. Moreover, the synergy of in is leading to .

As the sector pivots towards more sustainable practices, Gagner-Toomey Associates remains committed to equipping engineers with the tools necessary to address these complex temperature control challenges. Their extensive portfolio features:

- DC input tube axial devices ranging from 15 to 280mm

- Centrifugal units from 15 to 225mm

- Bespoke cooling solutions

This reinforces their position as a trusted partner in electronics design.

Thermal Management: Utilizing Small Blower Fans for Efficient Heat Dissipation

are essential in , playing a crucial role in facilitating efficient in electronic components. These small blower fans enhance airflow, assisting in maintaining and preventing that could lead to component failure. The compact size of small blower fans allows for seamless integration into various designs, making them an ideal choice for contemporary electronics. As the demand for grows, incorporating these devices into your designs can significantly .

and their benefits in electronic designs. The center represents the main topic of thermal management, with branches showing how small blower fans contribute to efficient heat dissipation and their benefits in electronic designs.](https://images.tely.ai/telyai/vfdpozsc-the-center-represents-the-main-topic-of-thermal-management-with-branches-showing-how-small-blower-fans-contribute-to-efficient-heat-dissipation-and-their-benefits-in-electronic-designs.webp)

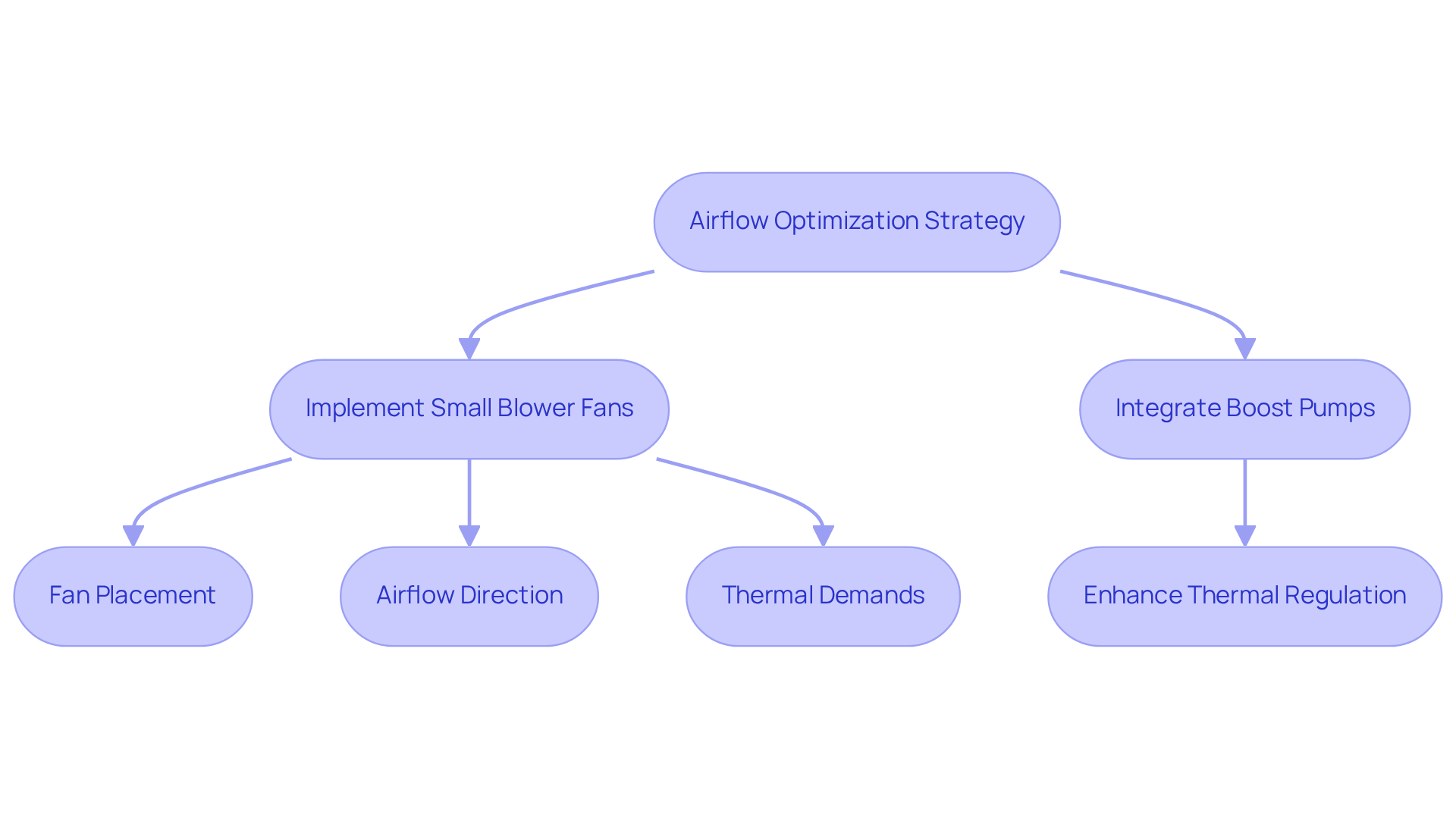

Airflow Optimization: Enhancing Performance with Small Blower Fans in Enclosures

is crucial for ensuring both functionality and reliability. Compact air circulation devices are engineered to generate directed airflow, effectively dissipating heat from critical components. By strategically positioning these devices, , which directly correlates with .

For instance, the implementation of can yield , thereby . Additionally, the use of these devices promotes superior , particularly in high-density scenarios where heat accumulation poses a risk to functionality.

To fully leverage these advantages, engineers must consider factors such as:

- Fan placement

- The specific thermal demands of the system

Furthermore, integrating solenoid and rotary boost pumps can amplify by providing precise control over fluid dynamics and enhancing overall thermal regulation. By employing these strategies, the adoption of small blower fans not only optimizes cooling but also enhances the overall functionality of electronic systems.

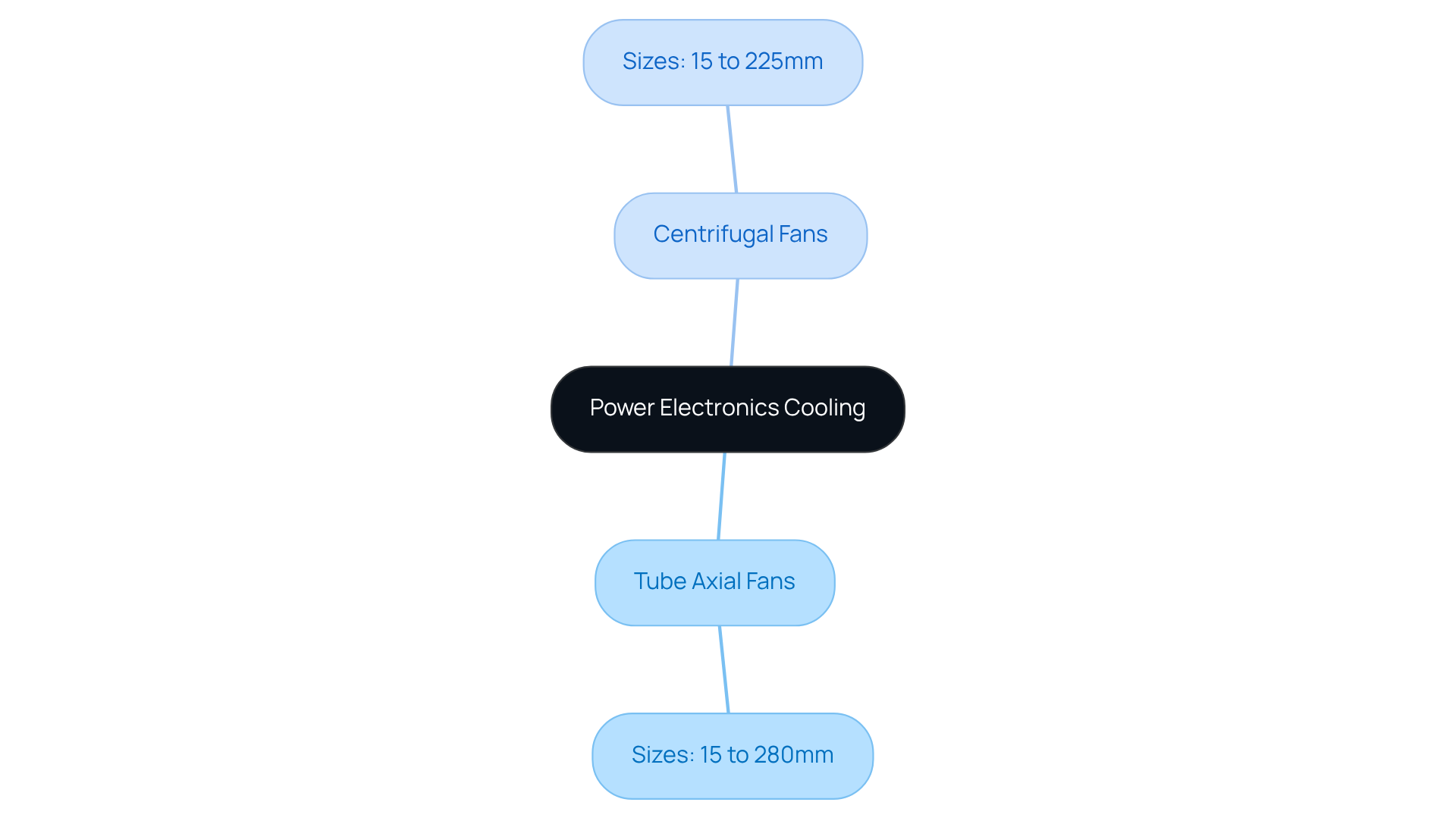

Power Electronics Cooling: Leveraging Small Blower Fans for Thermal Control

In , managing heat is critical to ensuring system reliability and efficiency. , the globe’s largest producer of standard and custom air-movers, offers an extensive selection of designed for and minimal noise.

These devices, known as small blower fans, are available in sizes ranging from:

- 15 to 280mm for tube axial types

- 15 to 225mm for centrifugal models

They effectively dissipate heat generated by high-power components and maintain lower temperatures that enhance the performance of power electronics. Furthermore, many models come with IP protection upon request, making their essential components in modern designs. This positions them as focused on .

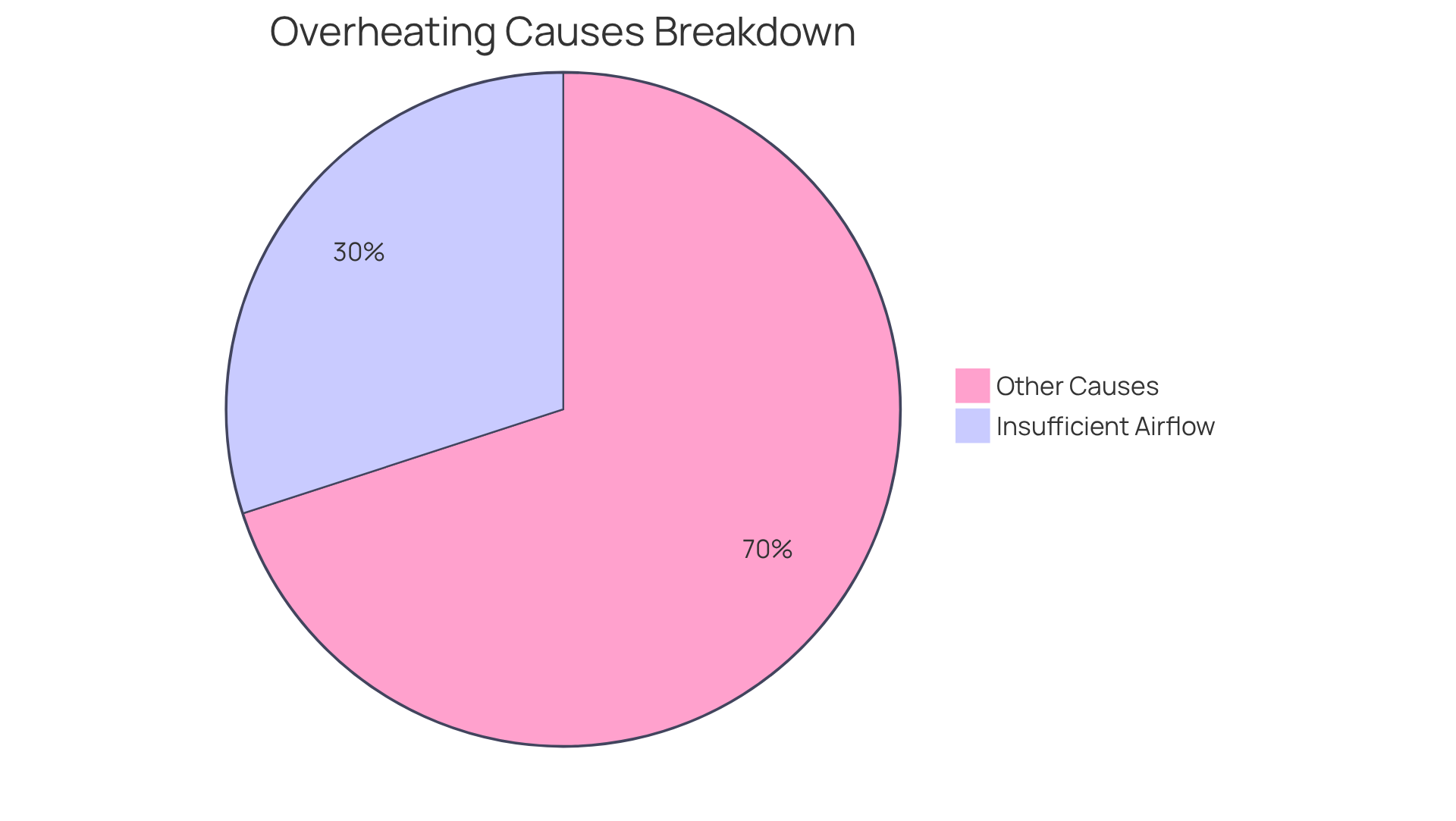

Component Reliability: Preventing Overheating with Small Blower Fans

Overheating represents a , being one of the leading causes of component failure. Statistics indicate that insufficient airflow accounts for approximately 30% of overheating incidents in devices. To mitigate this issue, play a crucial role by providing steady airflow that maintains temperatures within safe limits. By integrating into their designs, the .

Furthermore, systems that utilize filter units not only improve but also reduce maintenance needs by eliminating harmful particles that contribute to overheating. As highlighted by industry experts, “Cooling fans prevent this by ensuring that , dissipating heat and maintaining .”

This proactive approach to airflow management is essential, particularly in high-demand environments where consistent temperatures are vital for optimal performance. Additionally, overheating can pose safety risks, making effective indispensable for the longevity and reliability of electronic systems.

Portable Devices: Integrating Small Blower Fans for Enhanced Cooling Solutions

As portable devices increasingly gain power, efficient become crucial to prevent overheating. , the world’s largest producer of standard and custom air-movers, offers a diverse array of small that can be seamlessly integrated into these mechanisms. Their compact design, coupled with high airflow capabilities, renders them ideal for maintaining optimal temperatures in smartphones, tablets, and other portable electronics. With an extensive selection of and centrifugal units, Gagner-Toomey Associates ensures without significantly increasing volume.

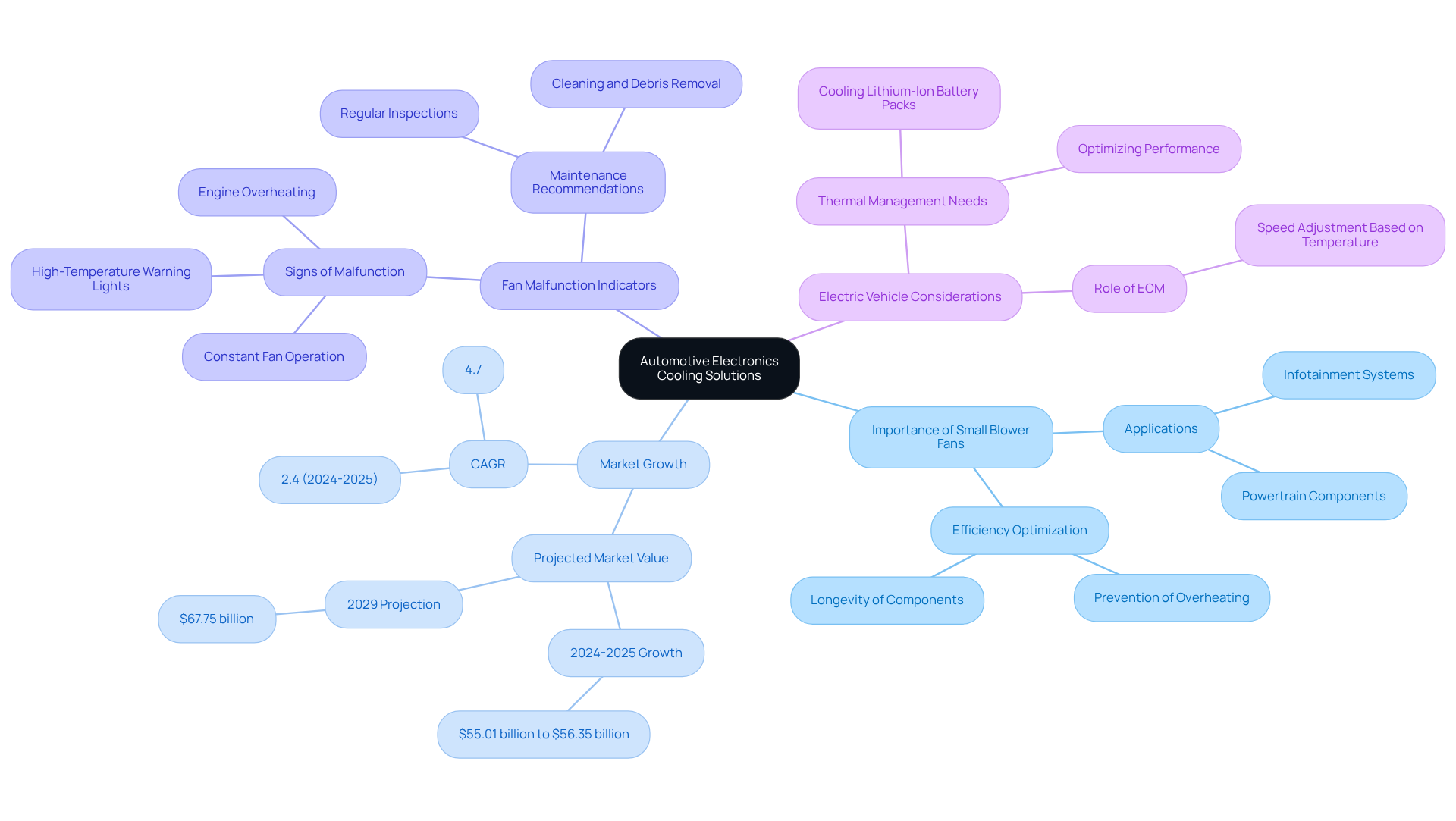

Automotive Electronics: Implementing Small Blower Fans for Effective Cooling

In the automotive sector, electronics operate under severe conditions, necessitating efficient . are employed to manage heat across various , from infotainment systems to powertrain components. Their ability to provide reliable temperature control ensures that function effectively and safely in challenging environments. The is projected to experience significant growth, reaching approximately $67.75 billion by 2029, with a compound annual growth rate (CAGR) of 4.7%. This underscores the increasing within the automotive industry.

Not only do enhance the efficiency of electronic systems, but they also contribute to the longevity of components by preventing overheating. Indicators of a malfunctioning fan, such as engine overheating or high-temperature warning lights, signal potential issues that require attention. As electric vehicles gain traction, the demand for solutions becomes increasingly critical, as these vehicles rely heavily on proper thermal management to ensure optimal functionality. Electric ventilators, governed by the Engine Control Module (ECM), adjust their speed based on temperature sensor data, further optimizing efficiency in temperature regulation.

By integrating small ventilation units, manufacturers can ensure that their automotive electronics remain functional and reliable, safeguarding against possible malfunctions and enhancing overall vehicle efficiency. Regular assessments of are recommended to maintain optimal performance and prevent overheating.

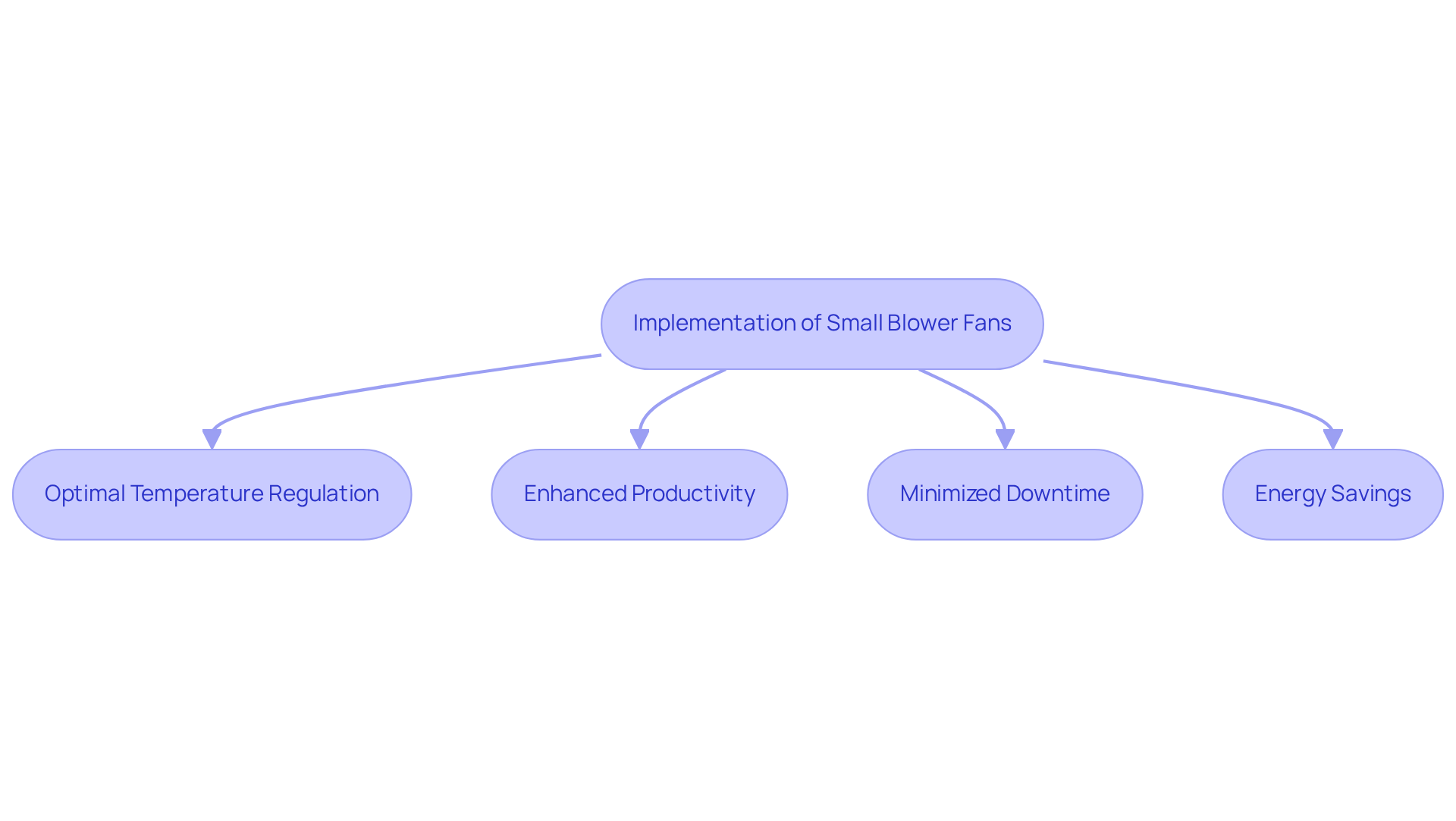

Industrial Applications: Utilizing Small Blower Fans for Process Efficiency

In industrial applications, the maintenance of is essential for maximizing process efficiency. are strategically employed to provide in machinery and equipment, thereby preventing overheating and ensuring seamless operations. By integrating these devices, companies can significantly associated with thermal issues.

The global Industrial and Commercial Fan and Blower Market is projected to experience substantial growth, reflecting the increasing demand for efficient . Moreover, small ventilation devices can achieve an evaporative cooling effect of up to ten degrees, which is critical for sustaining machinery performance during peak operational periods. This capability effectively , fostering a more reliable production environment.

Additionally, the strategic implementation of small blower fans not only enhances operational efficiency but also contributes to , aligning with the heightened emphasis on and adherence to environmental regulations in contemporary industrial practices.

As noted by Baghouse America, “An industrial fan or device can help your business enhance energy efficiency and reduce operating expenses,” underscoring the vital role these instruments play in achieving .

Laboratory Equipment: Ensuring Temperature Control with Small Blower Fans

In , the regulation of temperature is paramount for both experimental integrity and equipment functionality. To achieve this, are employed as ventilation devices, ensuring that various laboratory apparatus—ranging from incubators to analytical tools—maintain . These small play a critical role by providing , which is essential for sensitive equipment to operate within designated temperature ranges. This consistency not only enhances the reliability of experimental results but also underscores the importance of precise in scientific research.

help regulate temperature, ensuring that laboratory equipment functions properly. Each box represents a key step in the temperature management process. Follow the arrows to understand how small blower fans help regulate temperature, ensuring that laboratory equipment functions properly. Each box represents a key step in the temperature management process.](https://images.tely.ai/telyai/bruklfgk-follow-the-arrows-to-understand-how-small-blower-fans-help-regulate-temperature-ensuring-that-laboratory-equipment-functions-properly-each-box-represents-a-key-step-in-the-temperature-management-process.webp)

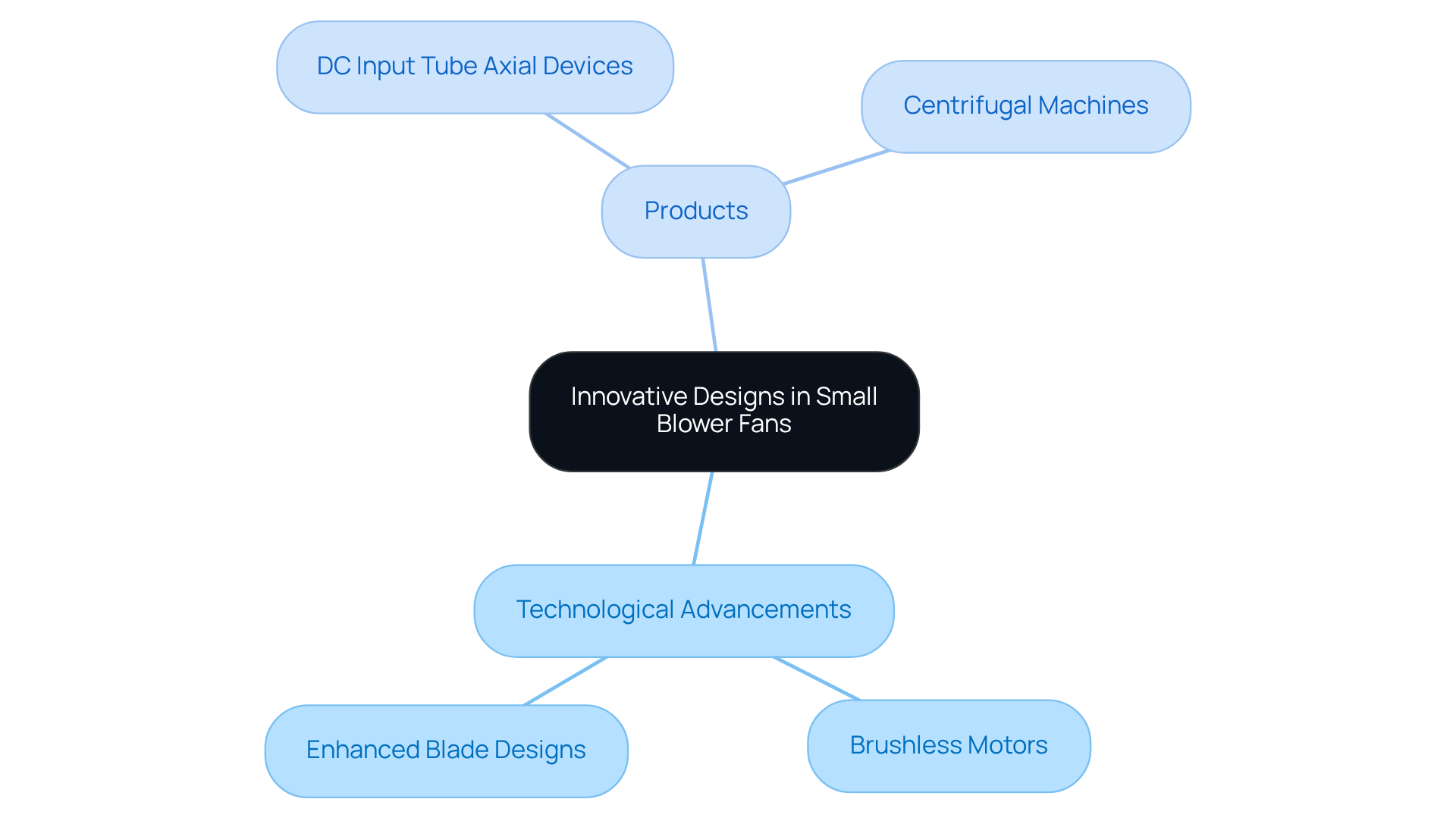

Innovative Designs: Advancements in Small Blower Fans for Electronics Applications

Recent advancements in technology have , efficiency, and noise reduction. This is particularly evident in the solutions provided by , the world’s largest producer of standard and custom air-movers. Innovations such as brushless motors and facilitate greater airflow while minimizing . ‘ extensive portfolio includes:

- DC input tube axial devices

- Centrifugal machines

These are , including electronics and automotive sectors. These advancements empower engineers to select small blower fans that not only fulfill their but also enhance the of their .

Conclusion

The integration of small blower fans into electronic systems represents a pivotal advancement in thermal management strategies, effectively addressing the escalating challenges associated with component miniaturization and increasing power demands. These compact devices not only enhance cooling efficiency but also play a critical role in extending the lifespan and reliability of electronic components across diverse applications, ranging from consumer electronics to industrial machinery.

Key benefits of small blower fans are underscored throughout this discussion, including their capacity to optimize airflow, prevent overheating, and maintain stable operating temperatures. Innovations in fan technology, such as enhanced blade designs and brushless motors, further amplify their effectiveness, rendering them indispensable tools for engineers striving to elevate system performance. The wide-ranging applications of these fans—from portable devices to automotive electronics—highlight their versatility and essential role in contemporary design.

Given these insights, it is imperative for engineers and designers to prioritize effective thermal management solutions in their projects. By leveraging the capabilities of small blower fans, optimal performance can be achieved, significantly enhancing the longevity and reliability of electronic systems. Embracing these innovative cooling technologies will ensure that electronics can flourish in increasingly demanding environments, paving the way for future advancements in the industry.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates excels in delivering advanced temperature control solutions tailored for the electronics industry, particularly through the integration of small ventilation units into thermal control strategies.

How do small blower fans impact electronic component temperature?

Small blower fans can lower component temperatures by as much as 20°C, which helps prevent thermal throttling and prolongs hardware lifespan.

What are some recent trends in the small temperature regulation devices market?

Recent trends include the miniaturization of components and increasing power demands from applications such as data centers and electric vehicles.

What innovative technologies are being used for thermal management?

Innovative technologies include microconvective temperature regulation and direct-to-chip thermal management, which facilitate targeted temperature regulation of processor hotspots.

What is the significance of high-performance computing systems in thermal management?

High-performance computing systems can generate heat outputs exceeding 300 watts per chip, making effective thermal management essential to maintain performance and prevent overheating.

What types of cooling solutions does Gagner-Toomey Associates offer?

Their portfolio includes DC input tube axial devices ranging from 15 to 280mm, centrifugal units from 15 to 225mm, and bespoke cooling solutions.

Why are small blower fans essential in thermal management?

Small blower fans enhance airflow, maintain optimal operating temperatures, and prevent thermal accumulation, which can lead to component failure.

How can airflow optimization improve electronic system performance?

Enhancing airflow within electronic enclosures through compact air circulation devices can improve cooling efficiency, leading to better overall system performance and reliability.

What factors should engineers consider when integrating small blower fans?

Engineers should consider fan placement, airflow direction, and the specific thermal demands of the system to optimize cooling performance.

How can integrating solenoid and rotary boost pumps enhance thermal management?

These devices can provide precise control over fluid dynamics, amplifying thermal management efforts and improving overall thermal regulation in electronic systems.