Overview

Thermoelectric coolers are pivotal in a range of electronic applications, including:

- smartphones

- automotive systems

- data centers

- medical devices

- renewable energy

- industrial processes

- aerospace technology

- gaming consoles

- telecommunications

- smart home devices

These coolers significantly enhance performance, energy efficiency, and reliability across diverse sectors by effectively managing heat. This management not only improves device longevity but also enriches user experience. Such advancements underscore the growing market demand and technological progress, establishing thermoelectric coolers as essential components in modern electronics.

Introduction

In a world increasingly driven by technology, thermoelectric coolers (TECs) are emerging as unsung heroes across various industries, from smartphones to aerospace. These innovative devices are pivotal in enhancing performance, extending battery life, and optimizing energy efficiency, transcending their basic function of keeping things cool. As high-performance electronics generate more heat, the demand for effective thermal management solutions has never been greater.

This article delves into the transformative impact of TECs, exploring their applications in sectors such as gaming, telecommunications, and renewable energy. It highlights advancements that promise to redefine how devices operate in a heat-intensive landscape. The integration of TEC technology represents not just a trend; it is a critical evolution that shapes the future of modern technology and sustainability.

Thermoelectric Coolers in Smartphones: Enhancing Performance and Battery Life

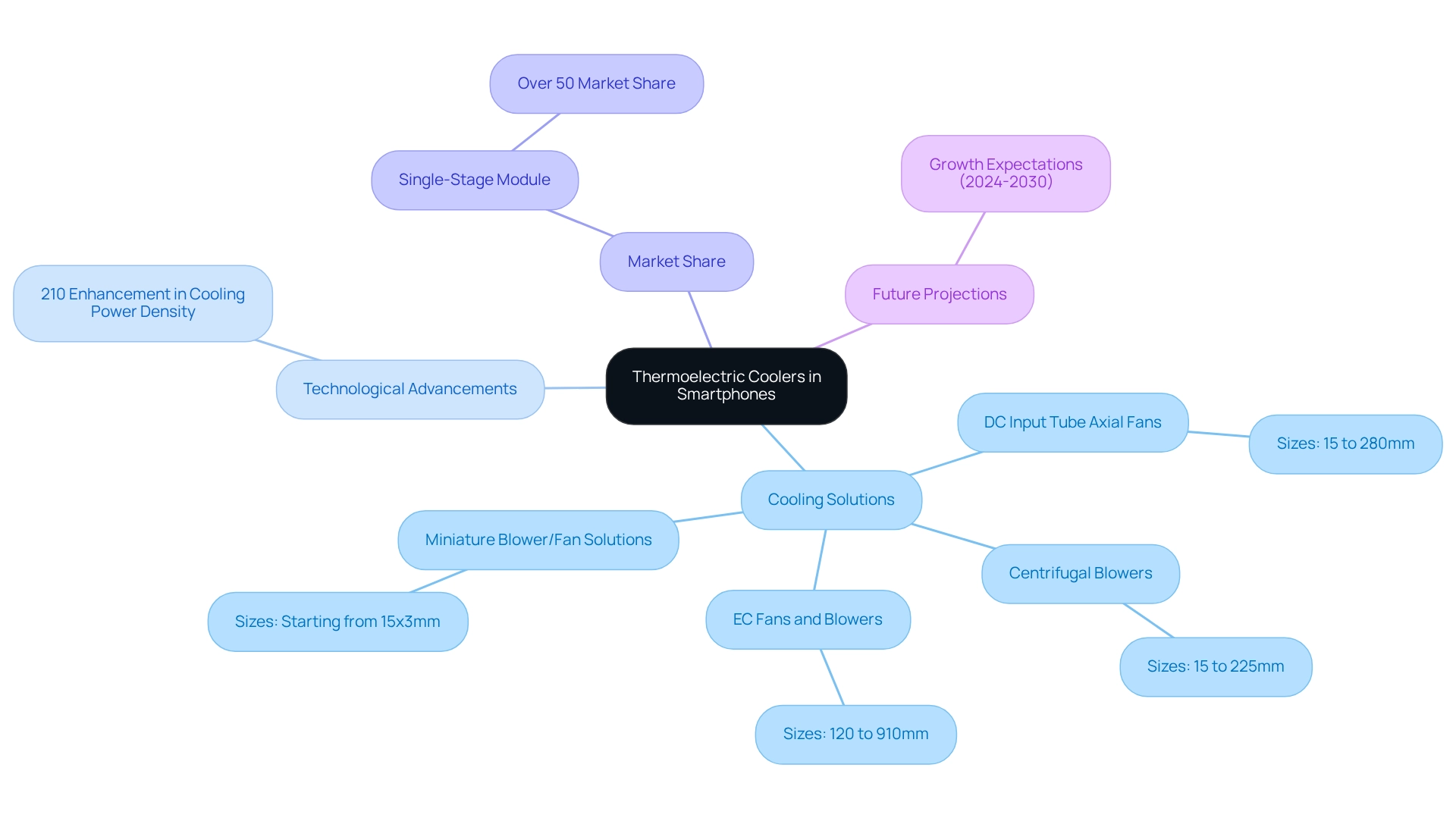

In smartphones, have become essential for effectively managing the heat generated by . By sustaining ideal operating temperatures, these coolers significantly enhance device functionality and prolong battery life. , the world’s largest manufacturer of standard and custom air-movers, provides a comprehensive portfolio of tailored for electronics applications, including:

- : Available in sizes from 15 to 280mm.

- Centrifugal Blowers: Ranging from 15 to 225mm.

- EC Fans and Blowers: Sizes from 120 to 910mm.

- Miniature Blower/Fan Solutions: Starting from 15x3mm for consumer applications.

- : Including extruded aluminum heatsinks, copper-based heat sinks, heat sinks with embedded heat pipes, vapor chambers, cold plates, and integrated cooling solutions.

Recent studies indicate that demonstrates a 210% enhancement in compared to leading commercial devices. This advancement minimizes the risk of thermal throttling and maximizes efficiency. Such technology not only improves user experience but also contributes to device longevity by preventing overheating. Notably, the single-stage module represents the , holding over 50% market share, underscoring its significance in smartphone applications. As the consumer electronics segment continues to evolve, the integration of thin film TEC modules in smartphones is projected to drive substantial growth, with expectations of the highest compound annual growth rate (CAGR) in the coming years. The influence of technology components on smartphone battery longevity is significant, as they enable devices to sustain optimal performance without excessive energy consumption, ultimately resulting in a more dependable and enjoyable user experience. As Bed Poudel, a Research Professor in the Department of Materials Science and Engineering at Penn State, notes, addressing the challenges of high-power density in microelectronics is crucial as devices become smaller and operate at higher power. Furthermore, suggest a promising future for thermoelectric coolers in the smartphone sector, offering valuable insights for stakeholders.

Automotive Electronics: Utilizing Thermoelectric Coolers for Temperature Regulation

In , the plays a pivotal role in , such as sensors and control units. By ensuring these components remain within their optimal temperature range, the thermoelectric cooler significantly boosts the reliability and performance of automotive systems.

For example, in electric vehicles, are essential for managing battery temperatures, which not only but also prolongs battery life. This capability is increasingly critical as the automotive industry shifts towards electrification and automation.

Recent advancements have shown that optimized thermoelectric devices can improve maximum refrigeration capacity by 1.95% compared to standard models, underscoring the importance of in modern vehicles. Furthermore, studies reveal that the average coefficient of performance (COP) of thermoelectric coolers declines as current increases, emphasizing the need for a balanced approach to cooling efficiency and energy consumption.

As the market for thermoelectric coolers continues to grow, valued at $624.8 million in 2021, as reported by industry expert Sonia Mutreja, the integration of thermoelectric coolers in automotive electronics is poised to become increasingly prevalent, fostering innovations in and . Additionally, findings from the case study ‘Thermal Modeling of Battery Cells’ illustrate the thermal dynamics of battery cells, further emphasizing the critical role of thermoelectric coolers in optimizing systems for electric vehicles.

Data Centers: Implementing Thermoelectric Coolers for Energy-Efficient Cooling Solutions

Data centers are increasingly adopting to enhance temperature regulation and decrease power usage. Unlike traditional refrigeration systems that rely on compressors, thermoelectric coolers utilize a solid-state design, resulting in reduced power consumption and minimal upkeep needs.

, a prominent supplier of cutting-edge , offers an extensive selection of and centrifugal blowers that can significantly improve the efficiency of data centers. The utilization of these can lead to , with studies indicating potential reductions in cooling consumption by as much as 30%.

Moreover, , underscoring the critical need for in this sector. This transition not only supports sustainable operations but also aligns with the escalating demand for energy-efficient solutions in the data center industry.

For instance, Japan’s data center market generated $18.18 billion in revenue in 2023, with forecasts predicting an increase to $21.96 billion by 2025, reflecting a robust need for data services and the significance of technology enablers in meeting that demand.

As U.S. Secretary of Energy Jennifer M. Granholm noted, across American sectors. As the market evolves, the integration of , alongside Gagner-Toomey Associates‘ comprehensive portfolio of cooling solutions, is becoming a strategic imperative for data centers seeking to enhance their operational efficiency while addressing the rising energy demands anticipated in the coming years.

Medical Devices: Ensuring Precision Cooling with Thermoelectric Technology

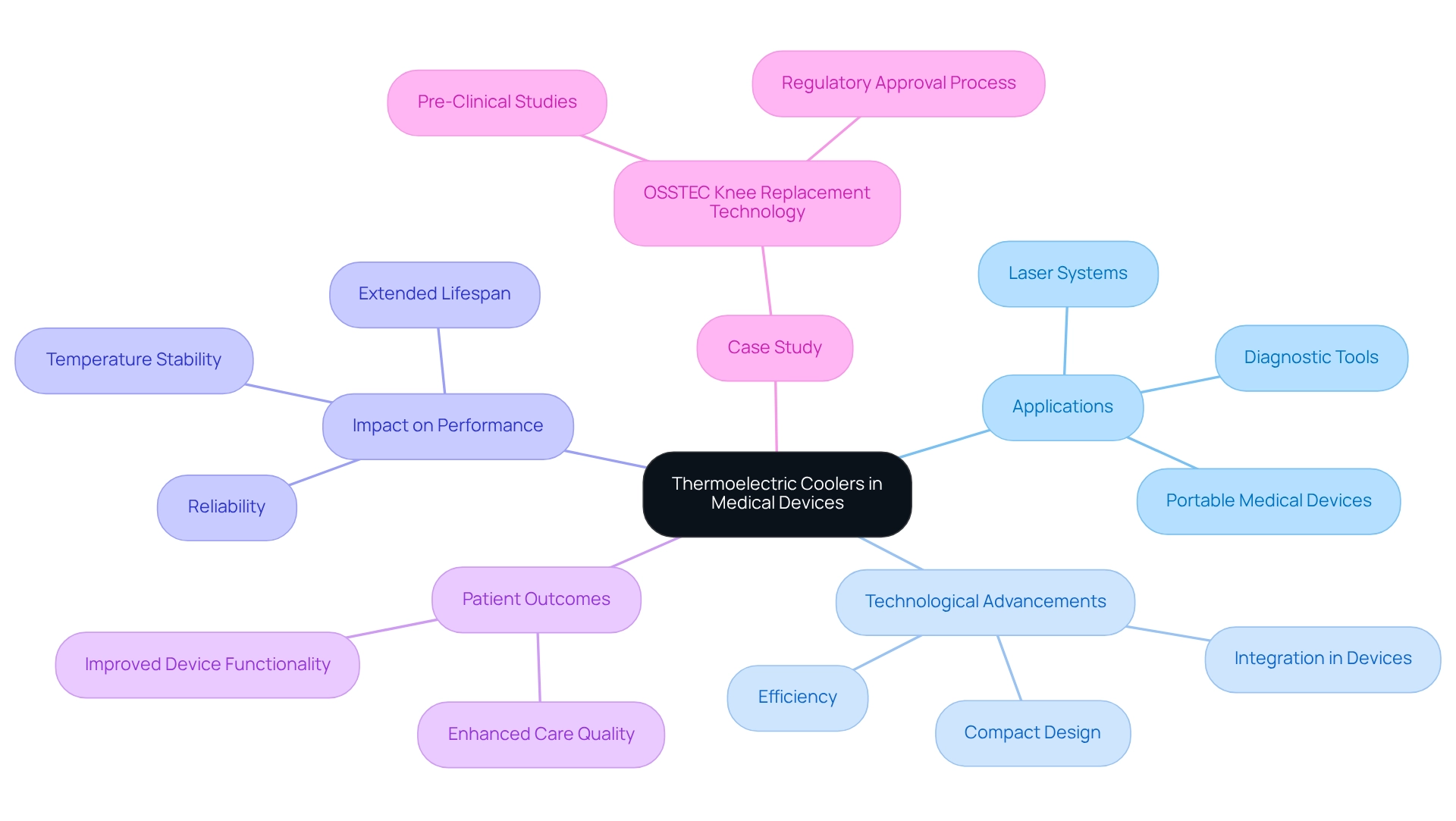

In , are indispensable, particularly for applications that demand precise . Devices such as laser systems and diagnostic tools rely on thermoelectric coolers to sustain stable temperatures, which is essential for optimal performance. For instance, in portable medical devices, the implementation of thermoelectric coolers effectively cools sensitive components, significantly enhancing their reliability and accuracy. This capability is especially critical in environments where temperature fluctuations can jeopardize readings or result in device malfunctions.

Recent advancements in thermoelectric cooler (TEC) technology have further underscored their . As the industry transitions towards more compact and efficient medical devices, the integration of is becoming increasingly prevalent. These innovations not only but also contribute to improved patient outcomes by ensuring that devices function within their specified temperature ranges.

Moreover, the influence of TECs on the reliability of medical devices cannot be overstated. By providing consistent temperature control, they help mitigate risks associated with overheating, thus extending the lifespan of essential equipment. As the medical field continues to evolve, the demand for reliable and precise will only intensify, positioning thermoelectric coolers as a cornerstone of modern medical technology. This is particularly relevant with the upcoming IP switch to digital phone networks scheduled for January 2027, emphasizing the critical importance of advanced cooling technologies in medical devices. The adoption of technology-enhanced components not only improves the functionality of medical devices but also aligns with the broader movement towards technology-enabled care, which aims to enhance outcomes for patients and healthcare systems alike.

A significant illustration of technology application can be seen in OSSTEC’s pre-clinical studies, where their groundbreaking knee replacement technology is currently under evaluation. This case exemplifies how via a thermoelectric cooler can bolster the reliability and efficiency of medical devices, ultimately . As the industry progresses, the importance of thermoelectric coolers in sustaining the reliability and efficiency of medical equipment will remain a focal point in healthcare technology.

Renewable Energy: Boosting Solar Panel Efficiency with Thermoelectric Coolers

s play a critical role in enhancing by effectively regulating heat. Excessive heat can severely compromise the functionality of photovoltaic cells, resulting in diminished power output. By integrating , solar panels can sustain optimal operating temperatures, leading to significant improvements in their overall performance. Recent research conducted in Shimla, Himachal Pradesh, India, has demonstrated that the incorporation of can elevate solar panel efficiency by up to 27%, highlighting their vital role in renewable energy systems.

Experts assert that not only enhance but also contribute to increased electrical and overall exergy gains in photovoltaic systems. Neha Dimri emphasized, “Finally, the derived thermal model has been utilized to assess the efficiency of with air duct regarding thermal gain, electrical gain, and overall exergy gain,” underscoring the benefits of such systems in boosting .

Moreover, research suggests the development of that include a thermoelectric cooler, tailored to specific climatic conditions, which could further enhance efficiency. Real-world examples illustrate the effectiveness of technology in , showcasing its potential to revolutionize solar technology. As research continues to advance, the emphasis on optimizing TEC designs for diverse environments is likely to yield even greater improvements in solar panel efficiency.

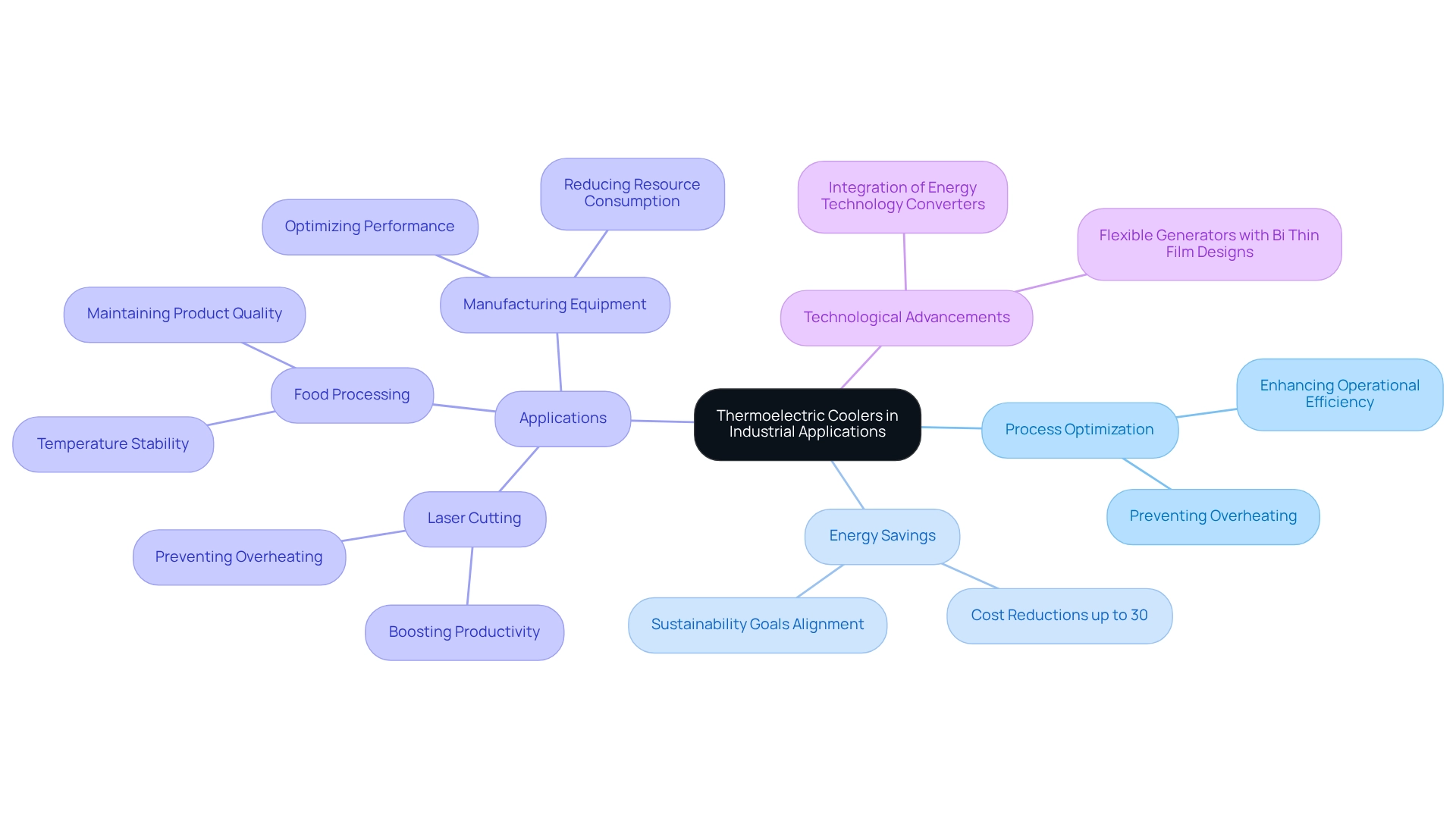

Industrial Applications: Leveraging Thermoelectric Coolers for Process Optimization

In industrial settings, provided by are crucial for and enhancing operational efficiency. Industries such as manufacturing and food processing rely on to maintain optimal conditions for both equipment and products. For instance, in , a thermoelectric cooler is utilized to cool machinery, ensuring consistent performance and preventing overheating. This not only boosts productivity but also significantly reduces resource consumption, aligning with sustainability goals.

Recent advancements in thermoelectric technology have yielded promising results, particularly with that improve the efficiency of thermoelectric coolers. Moreover, studies reveal that integrating can lead to , illustrating their potential for substantial impact on manufacturing energy consumption.

Real-world applications of thermoelectric coolers in industrial environments showcase their versatility; they maintain temperature stability in sensitive food processing settings and optimize the performance of high-precision manufacturing equipment. As industries continue to digitize their operations, the integration of thermoelectric coolers for is becoming increasingly essential for maintaining a competitive edge in a rapidly evolving landscape. Expert insights suggest that the adaptability and efficiency of thermal energy converters will be pivotal in shaping the future of industrial cooling technologies. Furthermore, the potential for underscores the importance of technology-enabled concepts in process optimization, as improving the adaptability and flexibility of robotic systems is recognized as a critical indicator of a system’s intelligence.

Aerospace Technology: Advancing Thermal Management with Thermoelectric Coolers

are transforming thermal management in aerospace technology, playing a crucial role in maintaining optimal temperatures for sensitive electronic components in spacecraft and aircraft. These coolers are essential for managing heat produced by onboard electronics, particularly in satellite systems, where they enhance reliability and efficiency under extreme conditions.

Recent innovations, such as Laird Thermal Systems’ OptoTEC MBX Series and TEC Microsystems’ Aluminium series, exemplify advancements aimed at improving performance in —an essential factor for the success of aerospace missions. The integration of thermoelectric coolers not only mitigates the risk of overheating—an issue that can lead to mission failure—but also enhances the overall efficiency of thermal management systems.

As the aerospace industry progressively adopts these technologies, expert opinions highlight their growing significance, particularly in where utilizing waste heat for power generation is increasingly appealing. As noted by European Editors, ” using thermoelectric modules is becoming more attractive for a range of applications, but especially in the military and aerospace sectors.”

In 2023, the IT and telecom segment led the thermoelectric cooler market, reflecting a broader trend towards innovative across various industries. as a premier supplier of , offering a wide array of products including DC input fans ranging from 15 to 280mm, centrifugal blowers from 15 to 225mm, and customized cooling solutions that .

The is paramount, as they ensure that critical systems operate within safe temperature limits, thereby safeguarding mission success.

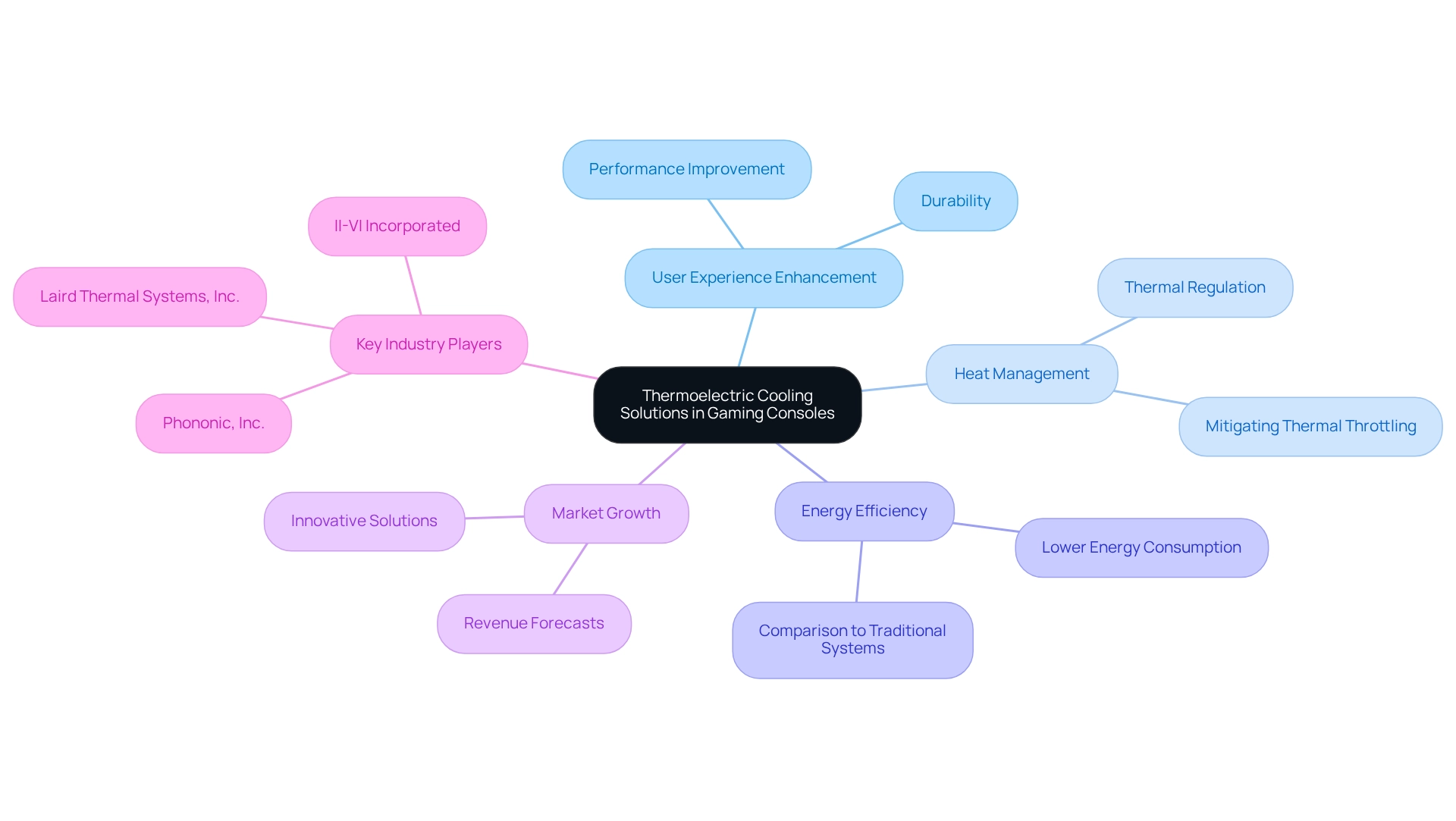

Gaming Consoles: Enhancing User Experience with Thermoelectric Cooling Solutions

In the gaming industry, the integration of is revolutionizing gaming consoles by significantly enhancing user experience through efficient heat management. As gaming consoles evolve into increasingly powerful systems, the challenge of becomes paramount, particularly during extended gaming sessions.

Thermoelectric coolers actively cool critical components, thereby mitigating the risk of thermal throttling that can hinder performance. This innovative technology not only enhances gameplay but also contributes to the durability of the console, establishing it as a vital element of modern gaming systems.

Recent advancements in solid-state refrigeration have shown that thermoelectric coolers offer lower energy consumption compared to traditional temperature control methods, further solidifying their role in contemporary gaming. Notably, companies like Phononic, Inc. and Laird Thermal Systems, Inc. are leading the charge in this technology, driving innovation and market expansion.

According to market analysis, is projected to experience significant growth, with key players strengthening their market positions through . As Aarti Dhapte observes, “This is due to the development of new and improved materials and manufacturing techniques that have led to a significant reduction in the cost of single-stage thermoelectric modules, further increasing their popularity and market.”

Consequently, the incorporation of thermoelectric temperature control solutions is becoming increasingly essential for and user satisfaction.

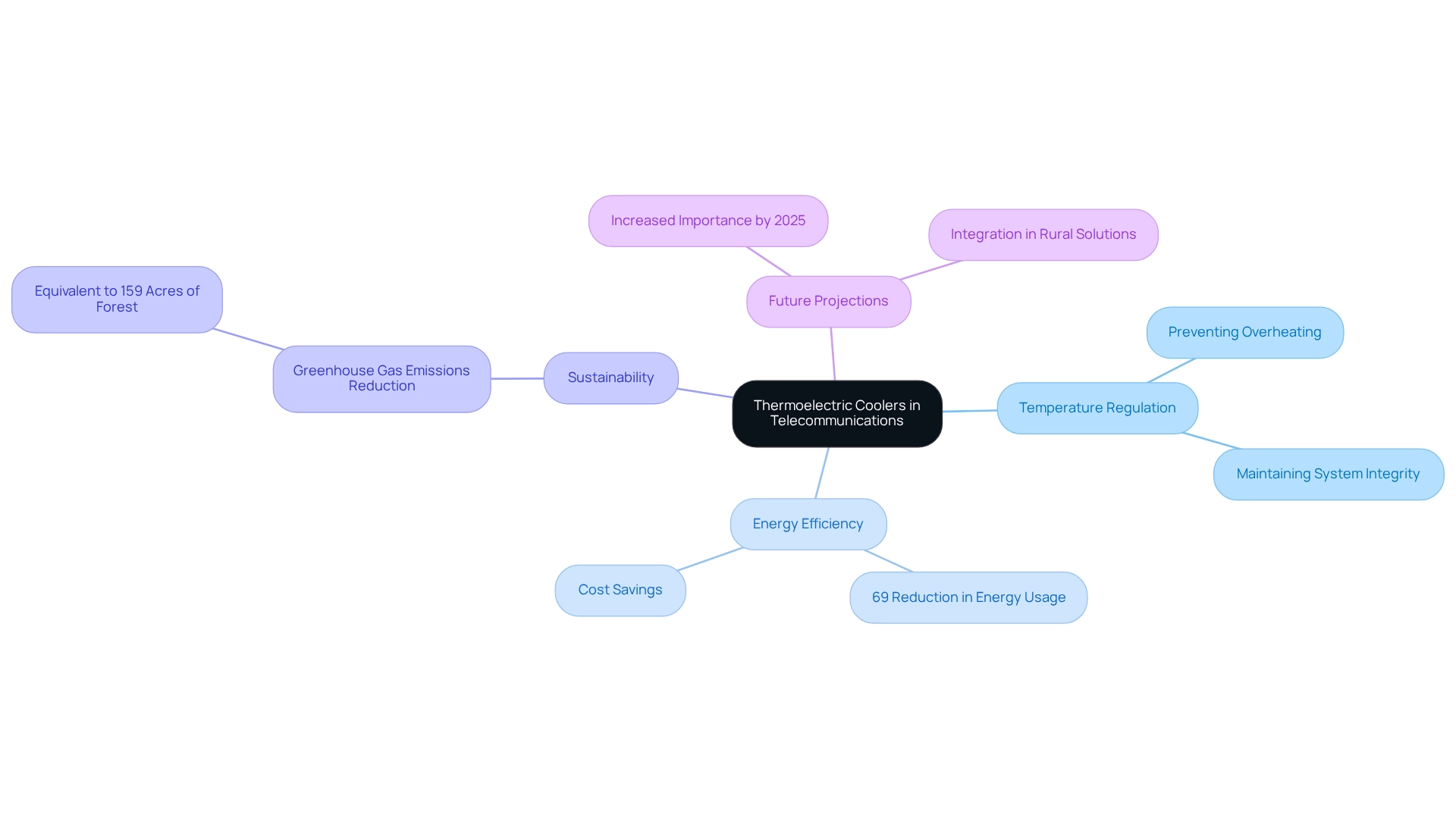

Telecommunications: Maintaining Optimal Conditions with Thermoelectric Coolers

In the , play a crucial role in maintaining for essential equipment. As systems grow increasingly intricate, effective temperature regulation methods become indispensable to prevent overheating and ensure reliable performance. Particularly in remote or outdoor environments where traditional temperature control methods may be impractical, thermoelectric coolers provide effective solutions. By facilitating precise temperature regulation, these coolers help maintain the integrity of telecommunications systems, thereby guaranteeing uninterrupted service for users.

While the Kingsdown, Inc. case study primarily focused on LED illumination, it underscores the importance of efficiency in operational enhancements. Although not directly related to technology energy converters, the emphasis on improving aligns with the goals of in telecommunications, where can lead to significant reductions in energy consumption.

Statistics reveal that efficient cooling can yield , with some implementations achieving up to a 69% reduction in annual energy usage. This not only translates to cost savings but also supports sustainability initiatives, such as , which can equate to preserving 159 acres of forest. As the telecommunications industry continues to advance, expert opinions highlight the critical need for incorporating thermoelectric coolers to enhance . By 2025, sustaining optimal conditions for telecom devices will be more vital than ever, emphasizing of thermoelectric coolers in the future of telecommunications.

Smart Home Devices: Improving Energy Efficiency with Thermoelectric Cooling

are transforming , particularly within smart refrigerators and HVAC systems. By leveraging , these devices can sustain optimal temperatures while significantly reducing power consumption. For instance, intelligent refrigerators equipped with thermoelectric coolers can minimize energy use by effectively managing internal temperatures, which not only reduces electricity costs but also mitigates environmental impact. Recent advancements reveal that have improved the coefficient of operation (COP) by 15.0% to 19.7% compared to , thereby enhancing the overall efficiency of these systems.

A case study examining the energy consumption of fan systems in thermoelectric refrigeration devices has shown that while increased airflow speeds can enhance thermal efficacy, they also lead to higher fan energy consumption. This finding underscores the necessity for a comprehensive evaluation of and resource utilization. Moreover, the latest finned heat sinks demonstrate an impressive 42.6% reduction in thermal resistance, further optimizing the efficiency of thermoelectric coolers in smart appliances.

As the demand for , the integration of thermoelectric coolers (TECs) in is becoming increasingly vital. Insights from Ferrotec indicate that thermoelectric coolers not only bolster the performance of smart refrigerators but also contribute to the overarching trend of in smart home devices. The continuous advancements in thermoelectric cooler technology, particularly in , are poised to play a pivotal role in shaping the future of energy-efficient appliances.

Conclusion

The transformative impact of thermoelectric coolers (TECs) across various industries is undeniable. These innovative devices enhance the performance and battery life of smartphones while optimizing energy consumption in data centers. TECs prove essential in effectively managing heat, improving the reliability of electronic components in automotive applications, and ensuring precise temperature control critical for device performance in the medical sector. Their integration into renewable energy systems, particularly solar panels, showcases their potential to significantly enhance efficiency, demonstrating remarkable versatility in addressing the challenges posed by excessive heat.

As industries continue to evolve, the role of TECs in improving thermal management will only grow. In gaming consoles and telecommunications, these coolers facilitate optimal operating conditions, thereby enhancing user experience and system reliability. The push towards sustainability further emphasizes the need for energy-efficient solutions, positioning TECs as a cornerstone of modern technological advancements. With ongoing innovations and a projected increase in market demand, the future of thermoelectric cooling technology is bright, promising to redefine standards across multiple sectors.

In conclusion, the integration of thermoelectric coolers represents a critical evolution in technology, addressing the pressing challenges of heat management while contributing to energy efficiency and sustainability. As industries increasingly adopt these solutions, the potential benefits for performance, reliability, and environmental impact will be profound, shaping the future landscape of modern technology. Embracing TECs is not merely a trend; it is an essential step towards a more efficient and sustainable future.

Frequently Asked Questions

What role do thermoelectric coolers play in smartphones?

Thermoelectric coolers are essential for managing heat generated by high-performance processors and GPUs in smartphones. They help maintain ideal operating temperatures, enhancing device functionality and prolonging battery life.

What types of cooling solutions does Gagner-Toomey Associates offer for electronics?

Gagner-Toomey Associates provides a range of cooling solutions, including: – DC Input Tube Axial Fans (15 to 280mm) – Centrifugal Blowers (15 to 225mm) – EC Fans and Blowers (120 to 910mm) – Miniature Blower/Fan Solutions (starting from 15x3mm) – Thermal Management Products (including various types of heatsinks and integrated cooling solutions).

What recent advancements have been made in thermoelectric devices?

Recent studies indicate a new thermoelectric device that shows a 210% enhancement in cooling power density compared to leading commercial devices, which helps minimize thermal throttling and maximize efficiency.

What is the significance of the single-stage module in the thermoelectric cooler market?

The single-stage module is the largest segment in the thermoelectric cooler market, holding over 50% market share, highlighting its importance in smartphone applications.

How is the integration of thermoelectric coolers projected to impact the smartphone market?

The integration of thin film TEC modules in smartphones is expected to drive substantial growth, with the highest compound annual growth rate (CAGR) projected in the coming years.

How do thermoelectric coolers benefit automotive applications?

In automotive applications, thermoelectric coolers regulate the temperature of electronic components, enhancing the reliability and performance of systems, especially in electric vehicles where they manage battery temperatures.

What improvements have been observed in thermoelectric devices for automotive use?

Optimized thermoelectric devices can improve maximum refrigeration capacity by 1.95% compared to standard models, emphasizing the importance of efficient thermal management in vehicles.

What is the market value of thermoelectric coolers, and what are the growth expectations?

The thermoelectric cooler market was valued at $624.8 million in 2021, and it is expected to grow as the integration of these coolers in automotive electronics becomes more prevalent.

How are data centers utilizing thermoelectric coolers?

Data centers are increasingly adopting thermoelectric coolers for better temperature regulation and reduced power usage, which leads to substantial cost savings and aligns with the demand for energy-efficient solutions.

What are the projected impacts of data centers on the U.S. power grid?

Data centers are projected to account for up to 12-13% of the U.S. power grid’s output by 2030, highlighting the need for energy-efficient cooling solutions in this sector.