Overview

This article examines essential strategies to optimize airflow fan performance, highlighting the critical need to understand fan laws, select the appropriate fan type, and implement effective maintenance and monitoring practices. By detailing methods such as:

- Adjusting fan speed

- Utilizing fan curve charts

- Conducting regular maintenance

it demonstrates how these strategies can significantly enhance cooling efficiency and overall system reliability across various applications. Ultimately, the insights provided are designed to empower professionals to take actionable steps towards improving their systems.

Introduction

In a world increasingly reliant on efficient thermal management, the performance of airflow fans is critical. Overheating continues to be a leading cause of electronic failures, making it essential for engineers to understand the intricacies of fan optimization. This knowledge empowers them to enhance system reliability and longevity. However, with a range of strategies available—from mastering fan laws to selecting the appropriate fan type—navigating the complexities of airflow optimization can be challenging.

This article explores nine essential strategies designed to elevate airflow fan performance, ensuring optimal cooling and efficiency across diverse applications.

Gagner-Toomey Associates: Innovative Solutions for Airflow Optimization

Gagner-Toomey Associates excels in delivering cutting-edge solutions for ventilation optimization that incorporate an airflow fan in the electronics sector. As the world’s largest manufacturer of standard and custom air-movers, Gagner-Toomey provides a broad product line of DC input tube axial airflow fans and centrifugal blowers, meticulously engineered to enhance efficiency and effectiveness across diverse applications. By utilizing advanced cooling technologies and strategic power management, the company empowers engineers to tackle complex ventilation challenges. This commitment to optimal thermal management is crucial, as overheating accounts for 55% of electronic failures, highlighting the importance of such as .

Remarkably, innovative technologies such as NEOcore can reduce heat sink component temperatures by more than 20 degrees, significantly enhancing efficiency and prolonging component lifespan. Furthermore, Gagner-Toomey’s extensive network of local distributors ensures a stable supply of components when and where engineers need them, reinforcing their integral role in the electronics supply chain. Successful projects within the sector showcase the tangible advantages of ventilation optimization, particularly through the implementation of an airflow fan, further solidifying Gagner-Toomey’s status as a leader in delivering innovative thermal management solutions.

Understand the Three Fan Laws for Enhanced Performance

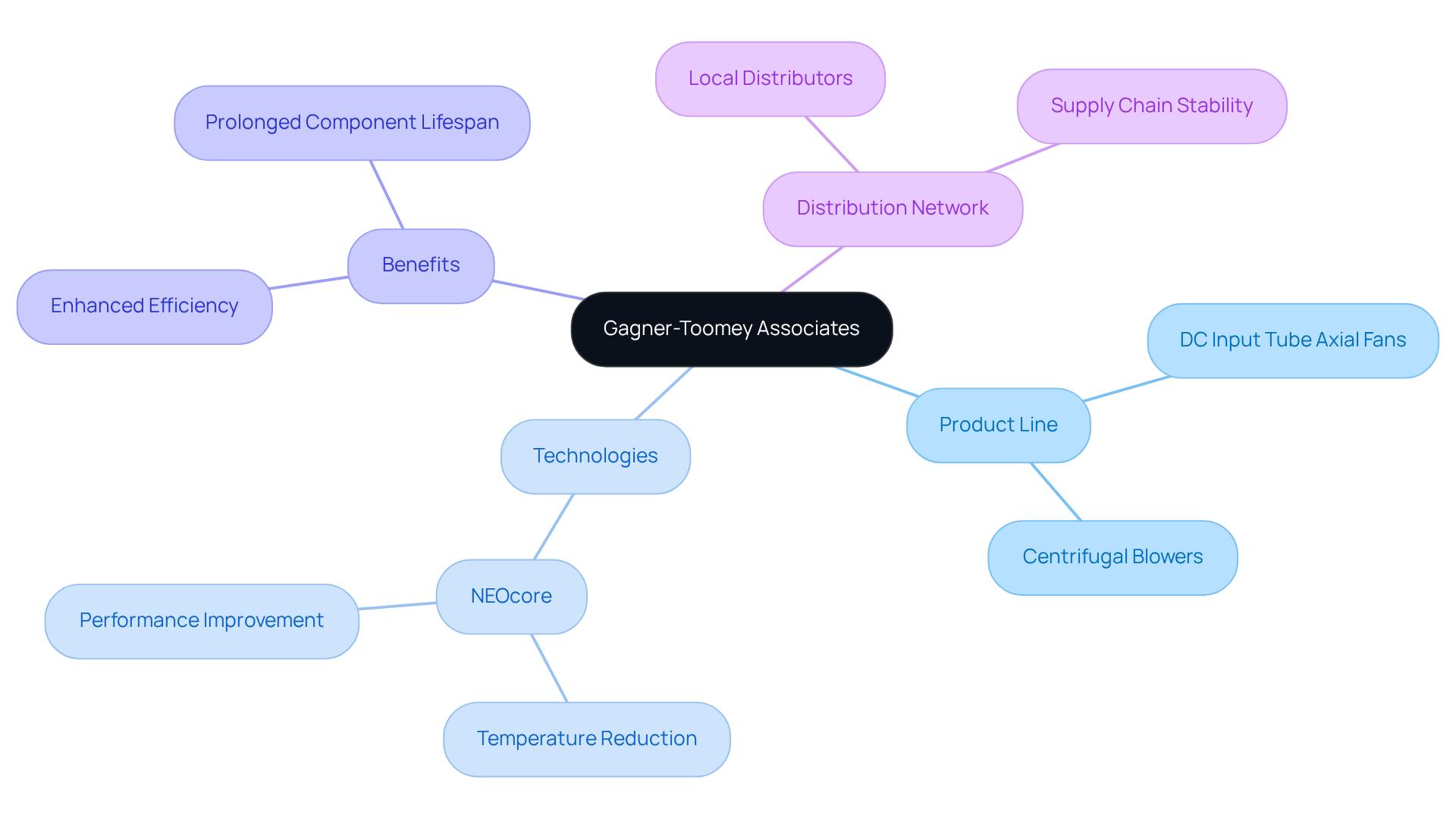

Understanding the three airflow fan laws is crucial for optimizing fan efficiency in engineering design.

Firstly, the volume of air (CFM) is directly proportional to fan speed (RPM). This means that increasing the RPM of the airflow fan will enhance air movement. For example, a reduction of approximately 800 RPM can lead to a 10.7% decrease in air movement, illustrating how even minor adjustments can significantly impact performance.

Secondly, total static pressure is related to the square of the air movement, indicating that small increases in airflow can result in substantial changes in static pressure.

Lastly, the energy required by the fan is proportional to the cube of the air movement, highlighting that greater air movement demands exponentially more power.

By mastering these principles, engineers can make informed decisions regarding the operation and design of airflow fans, ultimately ensuring optimal performance and efficiency in their setups.

Real-world applications show that modifying the speed of can lead to considerable enhancements in cooling efficiency, especially in electronics, where overheating can reduce component lifespan by as much as 50%.

Additionally, factors such as the dimensions of intake and exhaust holes, along with component placement in enclosure ventilation design, are vital for maximizing air movement and minimizing energy consumption. This understanding not only aids in selecting the right fan but also in configuring systems for optimal circulation and energy efficiency.

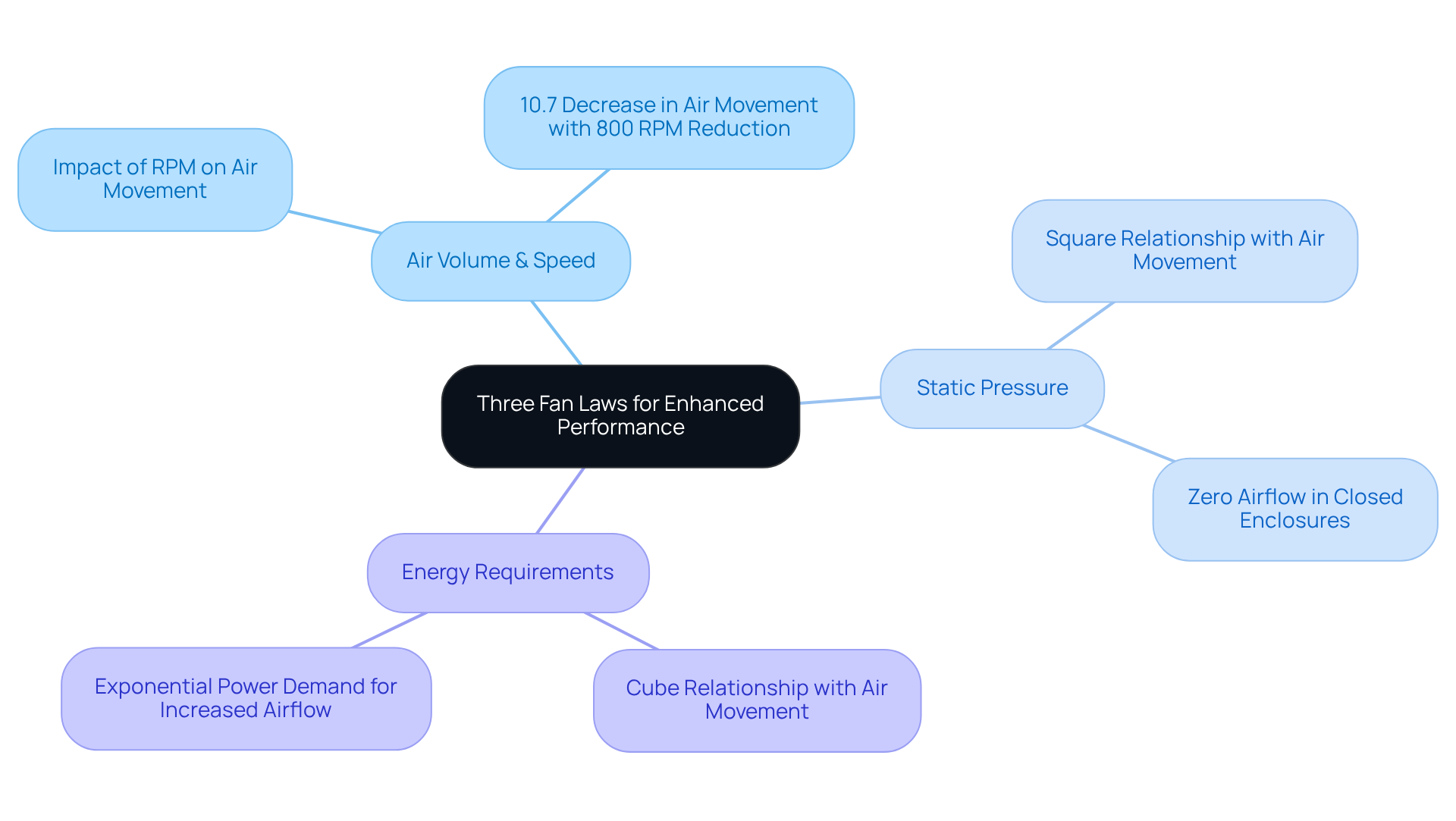

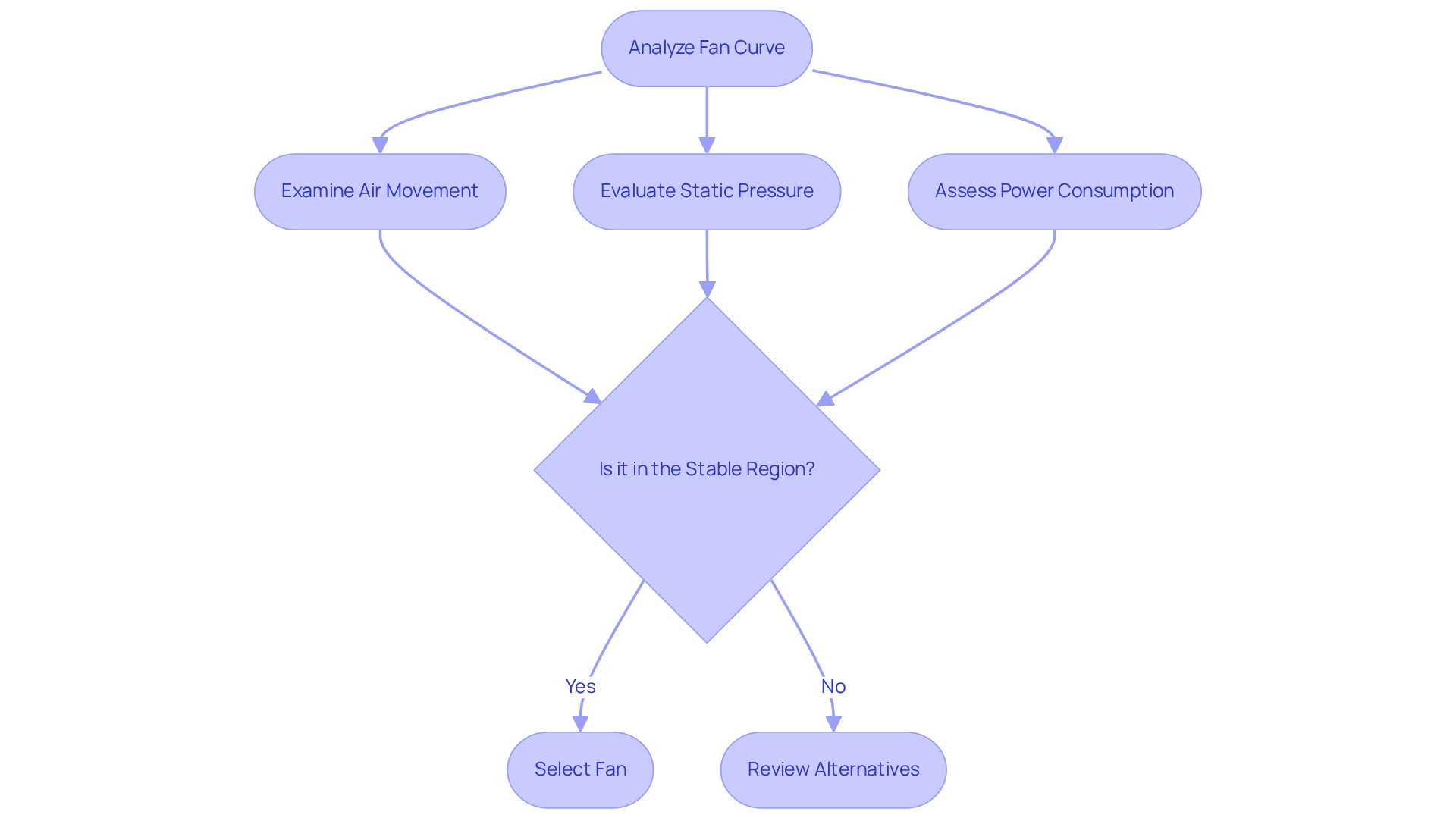

Utilize Fan Curve Charts for Accurate Performance Analysis

Curve charts serve as a powerful visual tool, illustrating the intricate relationship between air movement, static pressure, and power consumption for individual units of the airflow fan. By meticulously examining these curves, engineers can pinpoint the ideal operating point, ensuring that devices fulfill the necessary ventilation and pressure specifications tailored to their specific applications. This analysis is crucial for selecting airflow fans that not only operate efficiently but also align with real-world operational conditions.

Notably, a slight enhancement in air movement can lead to a significant increase in static pressure; for instance, a 10% rise in air movement can result in a staggering 33% increase in the horsepower required. Tim De Stasio, an HVAC and building efficiency consultant, emphasizes that “a creates a significant increase in static pressure,” highlighting the importance of grasping these dynamics.

Engineers who leverage airflow fan curve charts can optimize the selection of airflow fans, thereby enhancing system efficiency and reliability across various electronic applications. Furthermore, it is imperative to acknowledge the ‘unstable region’ depicted on fan curve charts, where fans operate at insufficient speeds for reliable outcomes. By applying this knowledge, engineers can make informed decisions in their projects, ensuring optimal fan performance.

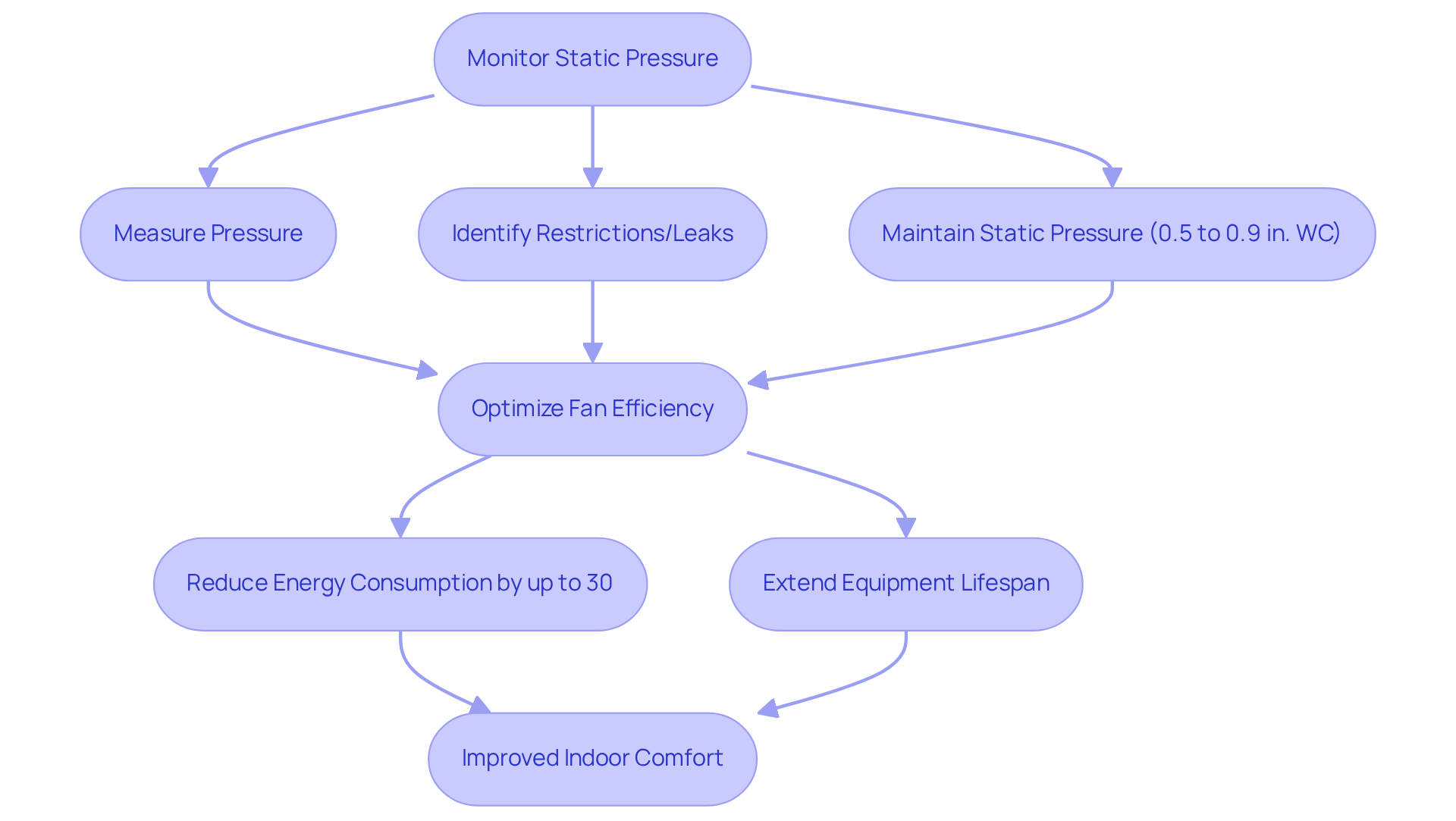

Monitor Static Pressure to Maximize Fan Efficiency

Monitoring static pressure is essential for optimizing the efficiency of an airflow fan. By measuring pressure at various points within , engineers can identify restrictions or leaks that obstruct airflow. Maintaining static pressure within the recommended range of 0.5 to 0.9 inches of water column (in. WC) is ideal for most homes, enabling fans to operate efficiently and significantly reducing energy consumption—potentially by up to 30%—while extending the lifespan of the equipment.

Elevated static pressure can lead to increased wear on components and cause HVAC units to consume up to 30% more electricity. Conversely, reduced static pressure may result in insufficient air distribution, undermining heating and cooling efficiency. Engineers have effectively enhanced the efficiency of the airflow fan by conducting regular static pressure measurements, as highlighted in the case study ‘Impact of Static Pressure on Energy Consumption,’ which illustrates how consistent monitoring can prevent elevated static pressure levels and improve overall operation.

Frequent monitoring aids in the prompt detection of issues, ensuring that HVAC units operate smoothly and efficiently, ultimately resulting in reduced operational expenses and improved indoor comfort. Furthermore, specific air movement data, such as the average movement for a 12-inch fan at 0.05 inH O static pressure being 1,654 cfm, exemplifies the evaluation criteria that engineers should consider. It is also crucial to acknowledge that nearly 50% of HVAC systems are oversized, leading to inefficiencies that further affect the airflow fan’s operation.

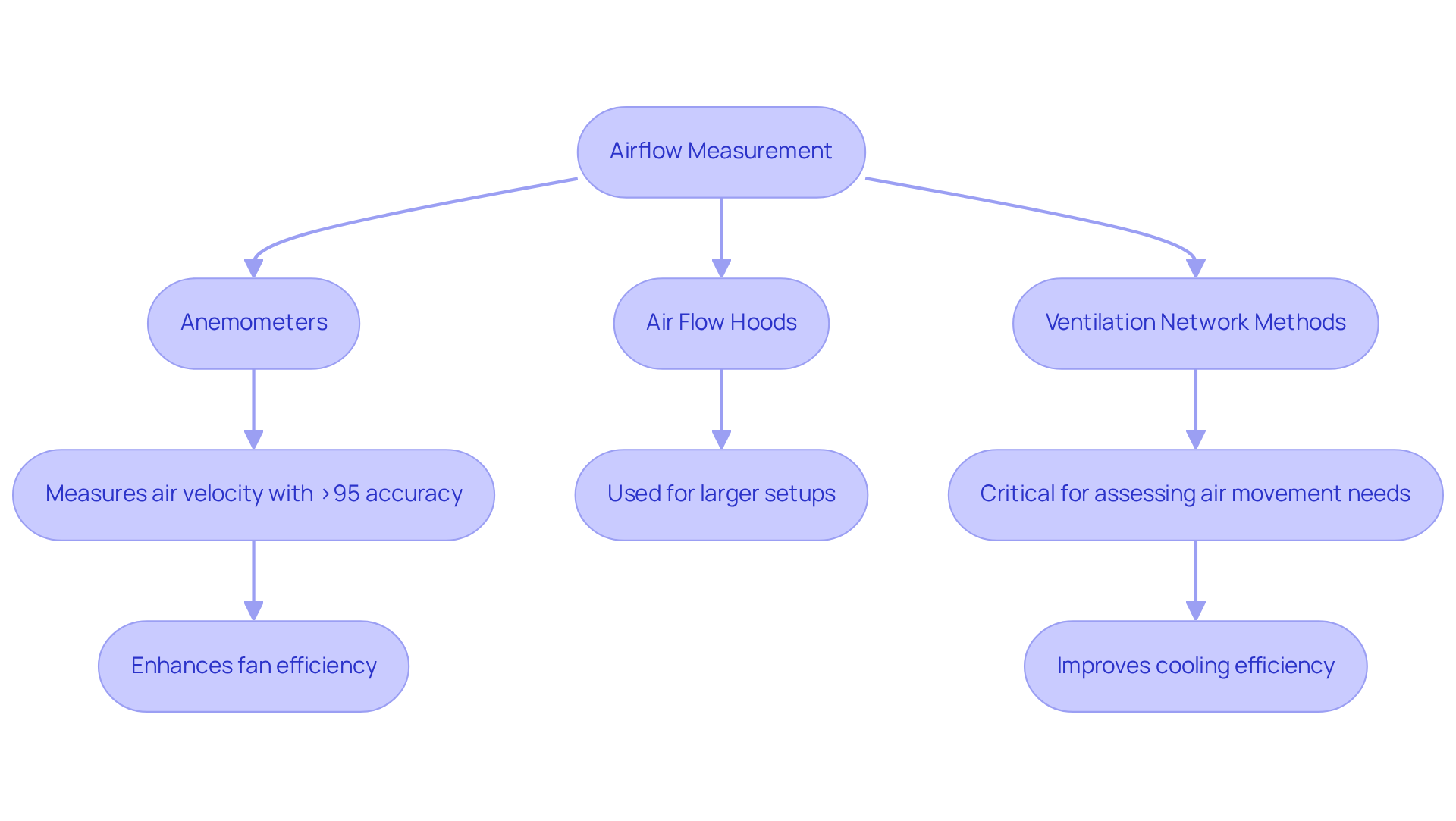

Measure Airflow Effectively to Enhance Fan Output

Accurate air movement measurement is essential for enhancing fan efficiency, with instruments such as anemometers and air flow hoods playing a vital role in this process. Anemometers, which measure air velocity, have undergone significant advancements, resulting in improved accuracy and reliability across various applications. Recent statistics indicate that modern anemometers can achieve accuracy levels exceeding 95%, rendering them indispensable for engineers who assess fan output. It is crucial to recognize that air velocity must remain below 7 m/s to ensure sufficient movement, thereby establishing optimal conditions for fan operation.

By accurately quantifying the volume of air moved by a fan, engineers can ascertain whether the fan operates within its expected performance parameters. This data is essential for making informed adjustments to fan speed or configuration, ultimately . A case study focusing on estimating necessary ventilation for cooling underscores the significance of precise air movement measurement concerning heat dissipation, illustrating that even minor modifications can yield considerable improvements in thermal management. Techniques such as experimental measurement, ventilation network methods, and computational fluid dynamics (CFD) are critical for assessing real air movement needs.

Furthermore, ventilation hoods provide a practical method for gauging air movement in larger setups, facilitating comprehensive evaluations of fan efficiency. These tools assist in identifying inefficiencies and optimizing configurations, ensuring that cooling systems operate at peak efficiency. Moreover, understanding fan laws is essential for assessing fan efficiency under varying circumstances, which is pertinent for enhancing air movement measurement. By leveraging these advanced measurement tools and considering factors such as fan positioning within a pressurized enclosure, engineers can significantly improve fan efficiency and ensure effective cooling in electronic applications. As the upcoming ECTC 2025 event approaches, it presents an exceptional opportunity for engineers to engage with the latest advancements in air movement measurement and fan efficiency.

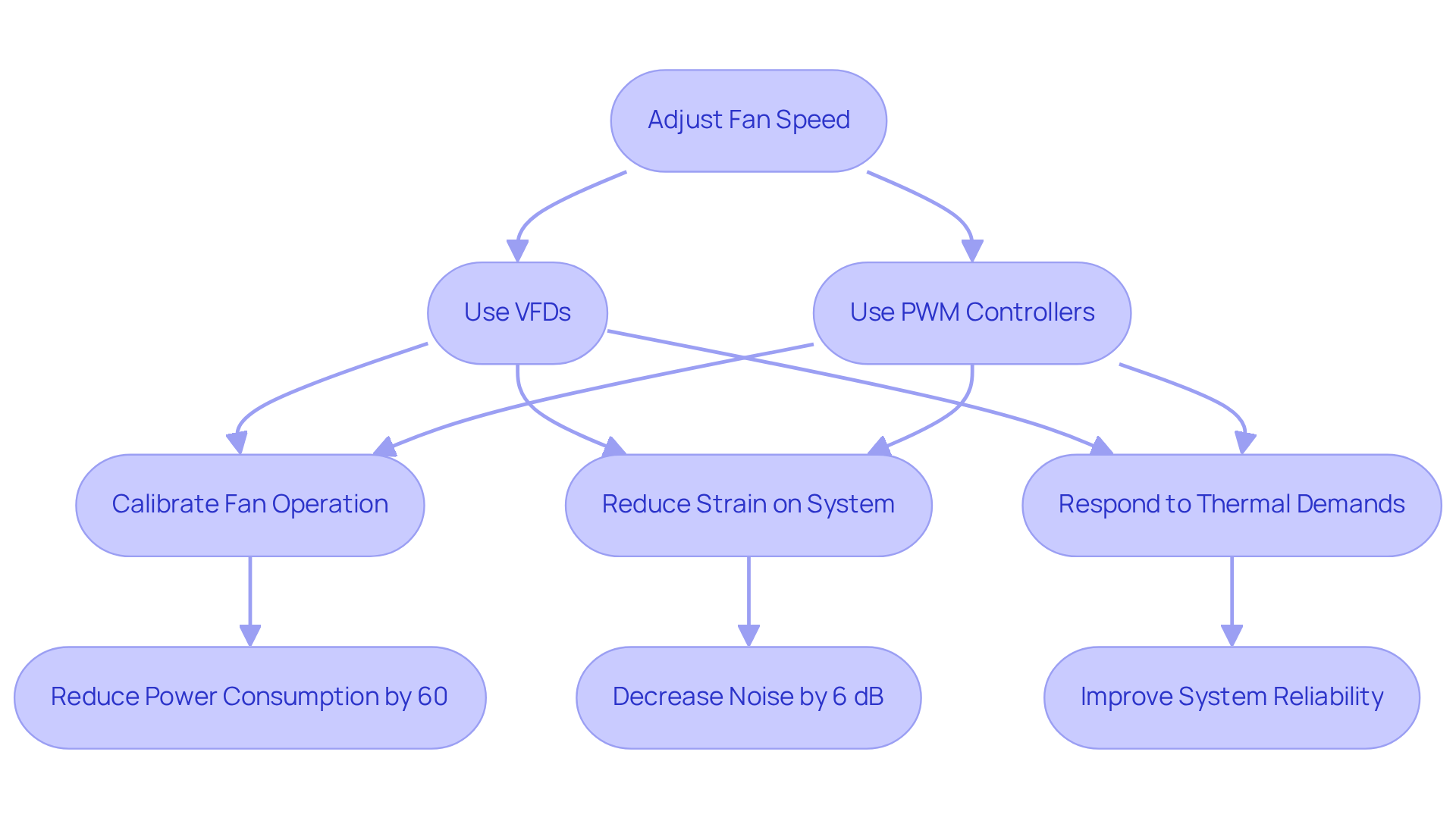

Adjust Fan Speed for Optimal Airflow Control

Modifying fan speed is a crucial technique for enhancing air movement in electronic devices. By utilizing variable speed drives (VFDs) or pulse-width modulation (PWM) controllers, engineers can accurately calibrate fan operation to align with real-time thermal demands. This adaptability significantly boosts cooling efficiency, as VFDs facilitate gradual adjustments in fan speed, thereby reducing strain on the system and extending motor life.

For instance, a mere 25% reduction in fan speed can yield an impressive 60% decrease in power consumption, a corresponding decline in noise levels by approximately 6 dB, and a 25% reduction in air movement. Moreover, the latest VFD technologies are engineered to respond dynamically to fluctuations in temperature and airflow requirements, ensuring optimal performance in high-demand applications.

Industry experts note that implementing these advanced control methods not only enhances system reliability but also fosters energy savings, rendering electronic systems more sustainable and efficient. Additionally, enables motors to function at speeds as low as 10% of maximum velocity while maintaining improved acoustics and efficiency compared to linear control techniques.

The effective operating window for a 12-V fan typically spans between 8 V and 12 V, underscoring the practical advantages of VFDs in boosting cooling efficiency.

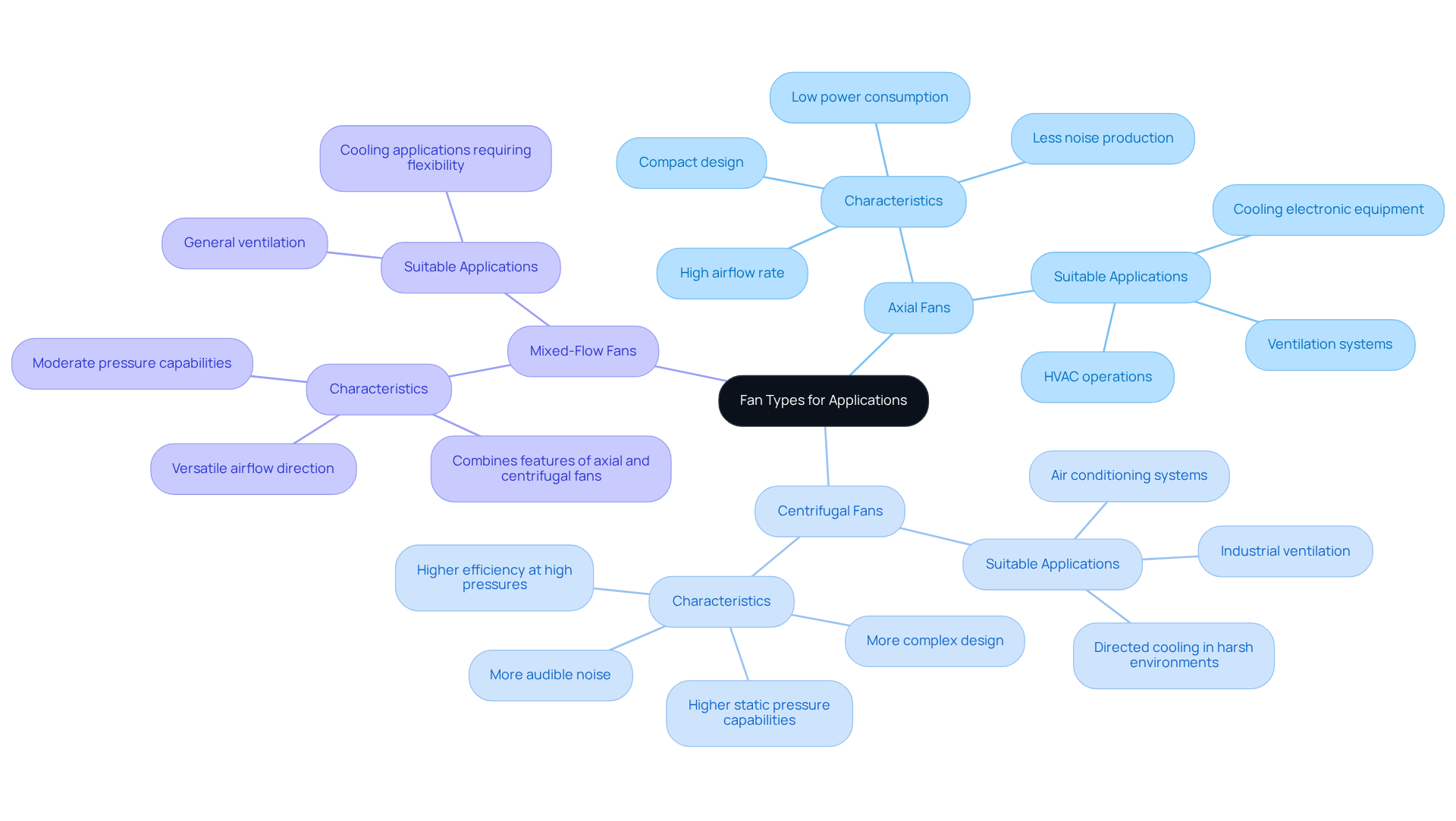

Select the Right Fan Type for Your Application

Selecting —be it axial, centrifugal, or mixed-flow—is crucial for fulfilling . Each type of fan possesses distinct characteristics that render it suitable for various scenarios. For instance, airflow fans such as axial blowers are particularly effective in , while centrifugal models thrive in high-pressure environments. By comprehending these differences, engineers can make informed decisions that significantly enhance system performance.

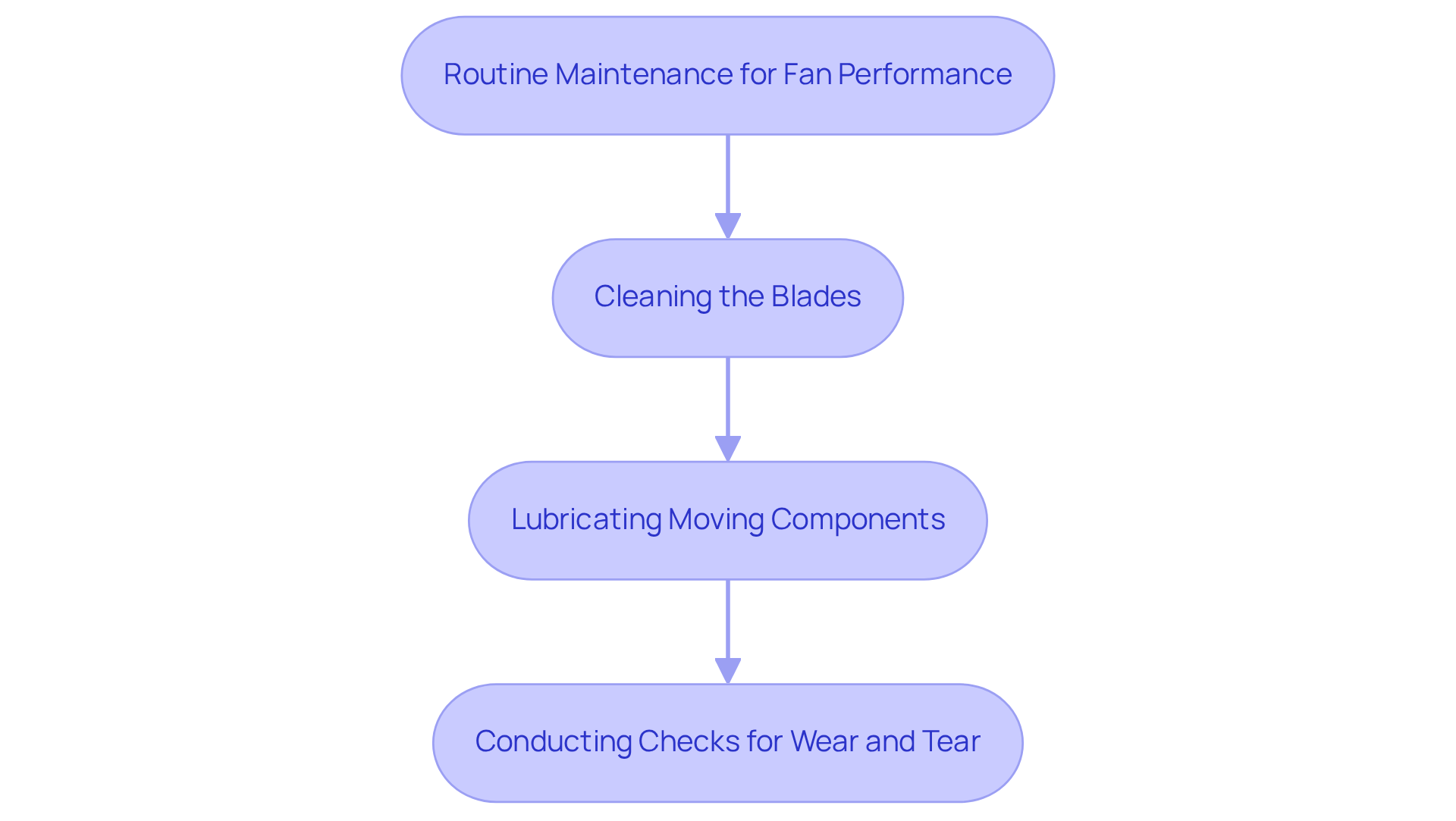

Perform Regular Maintenance to Sustain Fan Performance

Routine upkeep of the airflow fan is essential for optimal performance, which includes:

- Cleaning the blades

- Lubricating moving components

- Conducting thorough checks for wear and tear

By establishing , one can effectively prevent dust buildup and mechanical failures, thereby ensuring that fans operate at peak efficiency. This proactive strategy not only extends the lifespan of the equipment but also significantly enhances overall reliability. Implementing these practices is crucial for maintaining operational integrity and should be prioritized in any maintenance protocol.

Control Noise and Vibration for Improved User Experience

Effectively managing noise and vibration in fan setups is crucial for optimizing performance and user satisfaction. This challenge can be addressed through several methods, including:

- The use of vibration dampeners

- Selecting

- Ensuring meticulous installation practices

By implementing these strategies, engineers can significantly enhance the user experience and foster a more pleasant operating environment. Furthermore, regular monitoring of noise levels serves as a proactive measure, enabling the identification of potential issues before they escalate into significant problems. Adopting these practices not only improves operational efficiency but also reinforces the commitment to quality and user comfort.

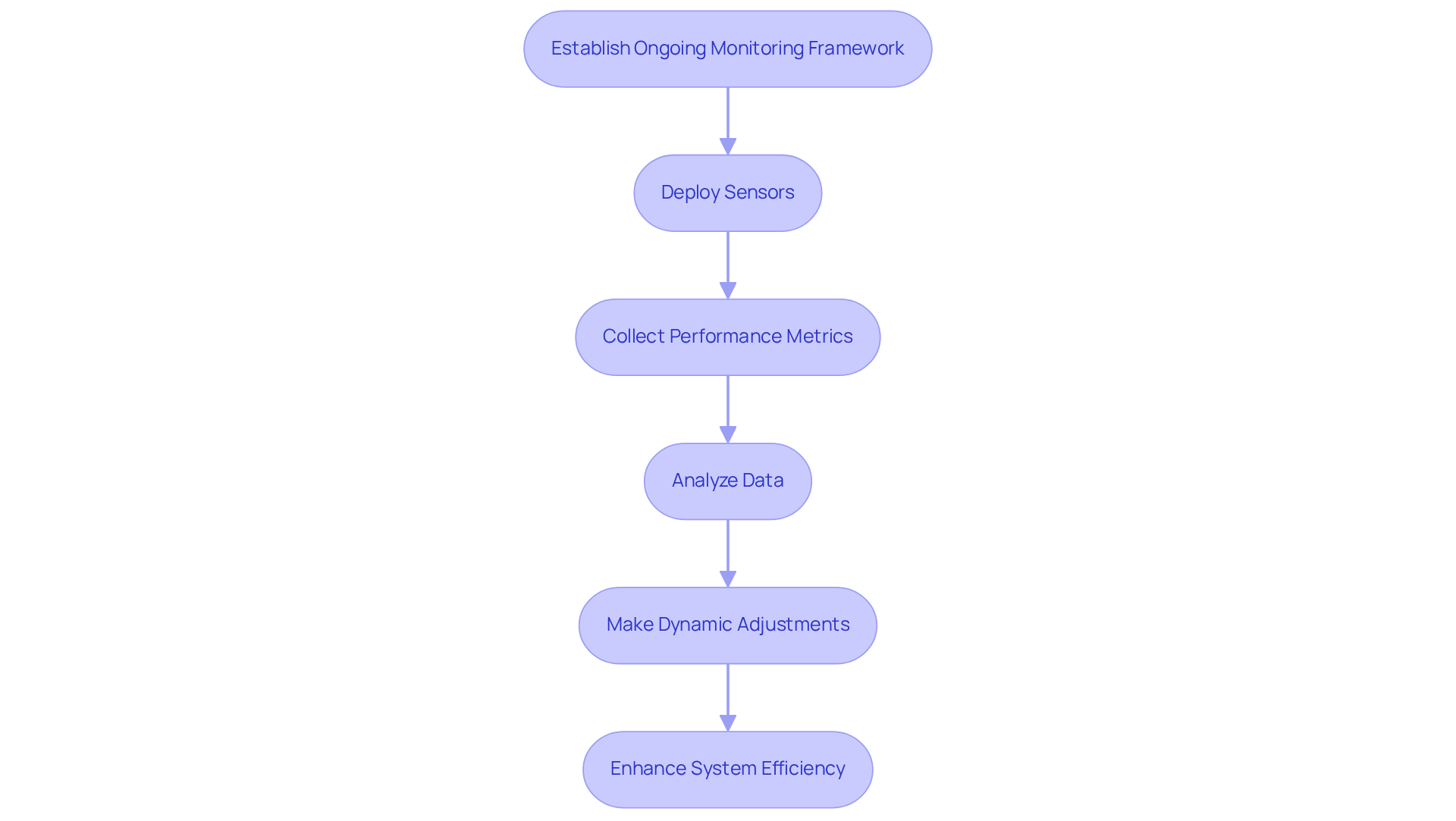

Implement Continuous Monitoring for Adaptive Performance Management

Establishing ongoing monitoring frameworks is essential for engineers to observe fan performance metrics in real-time. This proactive strategy leverages sensors and , allowing for dynamic adjustments that optimize both airflow and energy consumption. Such an adaptive approach not only enhances system efficiency but also significantly contributes to overall operational sustainability.

Conclusion

In the realm of thermal management, optimizing airflow fan performance is not merely beneficial; it is essential. The strategies outlined in this article underscore the importance of understanding fan laws, leveraging advanced technologies, and implementing best practices to ensure efficient cooling solutions. By mastering these techniques, engineers can significantly enhance system reliability and extend the lifespan of electronic components, ultimately mitigating the risks associated with overheating.

Key insights include:

- The critical role of fan speed adjustments

- The use of fan curve charts for precise performance analysis

- The necessity of regular maintenance to sustain optimal functionality

Moreover, monitoring static pressure and measuring airflow effectively are crucial for identifying potential inefficiencies and ensuring that cooling systems operate at their best. Each of these strategies contributes to a comprehensive approach to airflow optimization, enabling engineers to successfully navigate the complexities of thermal management.

As the demand for efficient thermal solutions continues to grow, embracing these strategies becomes increasingly vital. Engineers are encouraged to adopt a proactive mindset, utilizing innovative tools and techniques to enhance airflow fan performance. By doing so, they not only improve operational efficiency but also contribute to the sustainability of electronic systems, paving the way for a future where effective cooling solutions are the standard across all applications.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative solutions for ventilation optimization, particularly through the use of airflow fans in the electronics sector.

What is the significance of airflow fans in electronic applications?

Airflow fans are crucial for effective cooling solutions, as overheating accounts for 55% of electronic failures. They enhance efficiency and thermal management in electronic devices.

How does the NEOcore technology benefit component performance?

NEOcore technology can reduce heat sink component temperatures by more than 20 degrees, which significantly enhances efficiency and prolongs the lifespan of components.

What are the three fan laws that engineers should understand?

The three fan laws are: 1. The volume of air (CFM) is directly proportional to fan speed (RPM). 2. Total static pressure is related to the square of the air movement. 3. The energy required by the fan is proportional to the cube of the air movement.

How can modifying the speed of an airflow fan impact cooling efficiency?

Modifying the speed of an airflow fan can lead to considerable enhancements in cooling efficiency, especially in electronics, where overheating can reduce component lifespan by as much as 50%.

What role do fan curve charts play in performance analysis?

Fan curve charts illustrate the relationship between air movement, static pressure, and power consumption, helping engineers identify the ideal operating point for airflow fans to meet ventilation and pressure specifications.

What can happen with a slight increase in air movement regarding static pressure?

A 10% increase in air movement can result in a 33% increase in the horsepower required, highlighting the importance of understanding airflow dynamics.

What is the ‘unstable region’ on fan curve charts?

The ‘unstable region’ refers to the area where fans operate at insufficient speeds, which can lead to unreliable outcomes. Recognizing this region is crucial for ensuring optimal fan performance.