Overview

The article delivers critical insights into electric fan motors, emphasizing their design, functionality, and applications—elements that are essential for electronics engineers. It underscores the necessity of grasping:

- Electromagnetic induction

- Various motor types

- Efficiency metrics

- Regulatory compliance

These factors play a significant role in determining the performance and energy efficiency of electric fan motors across diverse applications, including HVAC systems and consumer electronics.

Introduction

In an era where energy efficiency and innovative technology are paramount, electric fan motors have emerged as critical components across various industries, ranging from HVAC systems to consumer electronics. This article delves into ten insightful aspects of electric fan motors, equipping engineers with essential knowledge to navigate the complexities of design and application. As motor technology rapidly evolves, the pressing question arises: how can engineers ensure they remain at the forefront of advancements while optimizing performance and sustainability?

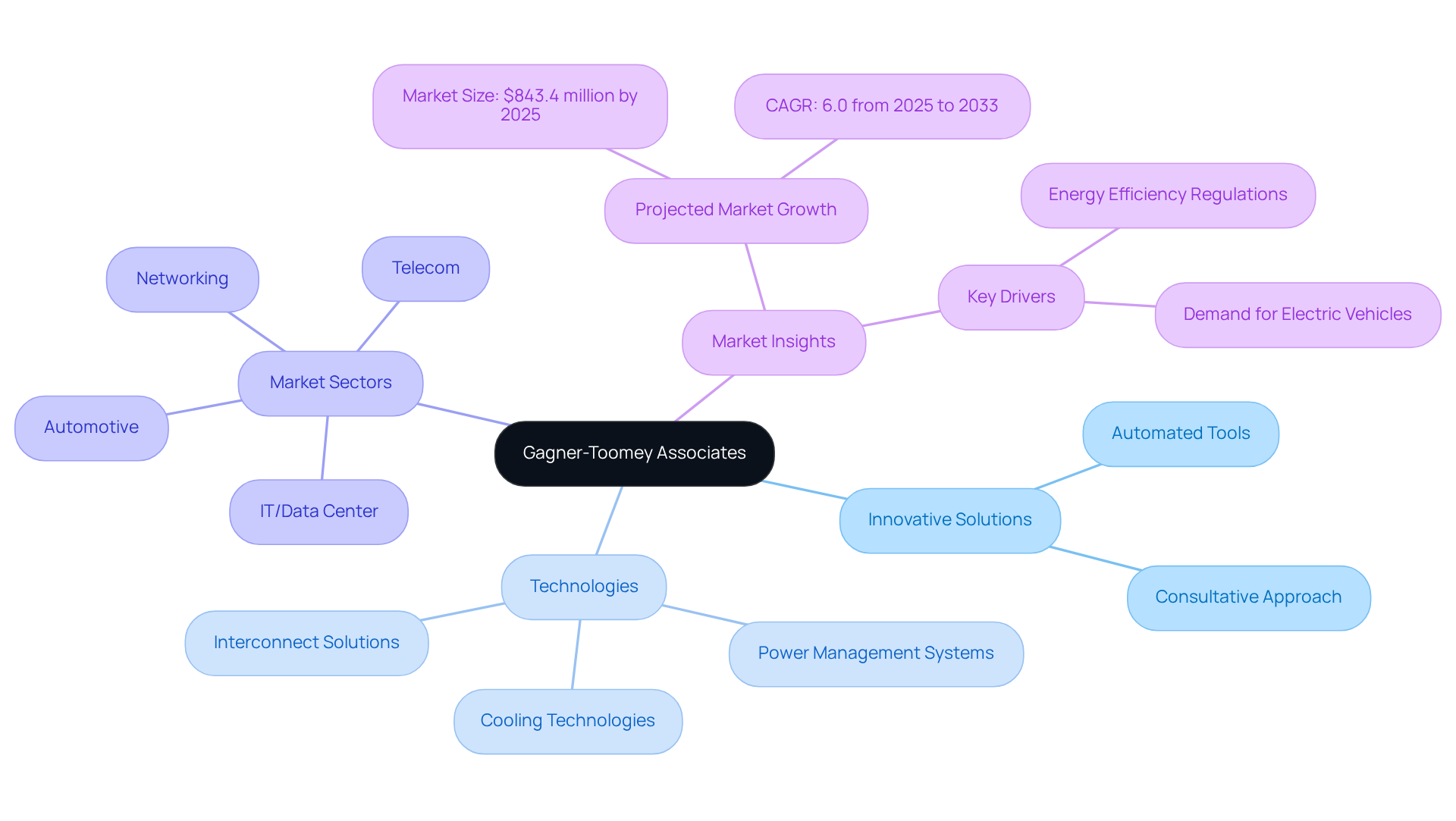

Gagner-Toomey Associates: Innovative Solutions for Electric Fan Motor Applications

Gagner-Toomey Associates stands out as a leader in delivering innovative solutions tailored for electric fan motors applications. By leveraging a diverse portfolio of manufacturers, the company empowers engineers with access to cutting-edge cooling technologies, advanced power management systems, and efficient interconnect solutions. This commitment to innovation is exemplified through the successful implementation of advanced cooling technologies, which markedly enhance the performance and efficiency of electric fan motors.

As the demand for energy-efficient solutions escalates, Gagner-Toomey remains at the forefront, equipping engineers to tackle complex challenges within effectively. The company adopts a consultative approach, employing automated tools to streamline the sales cycle, ensuring engineers receive the necessary guidance.

Recent statistics indicate that is projected to reach approximately $843.4 million by 2025, underscoring the growing importance of these technologies across various sectors, including:

- Telecom

- Networking

- IT/Data Center

- Automotive

With a steadfast focus on continuous improvement and responsiveness to emerging trends, Gagner-Toomey Associates is dedicated to supporting engineers in achieving optimal results in their projects.

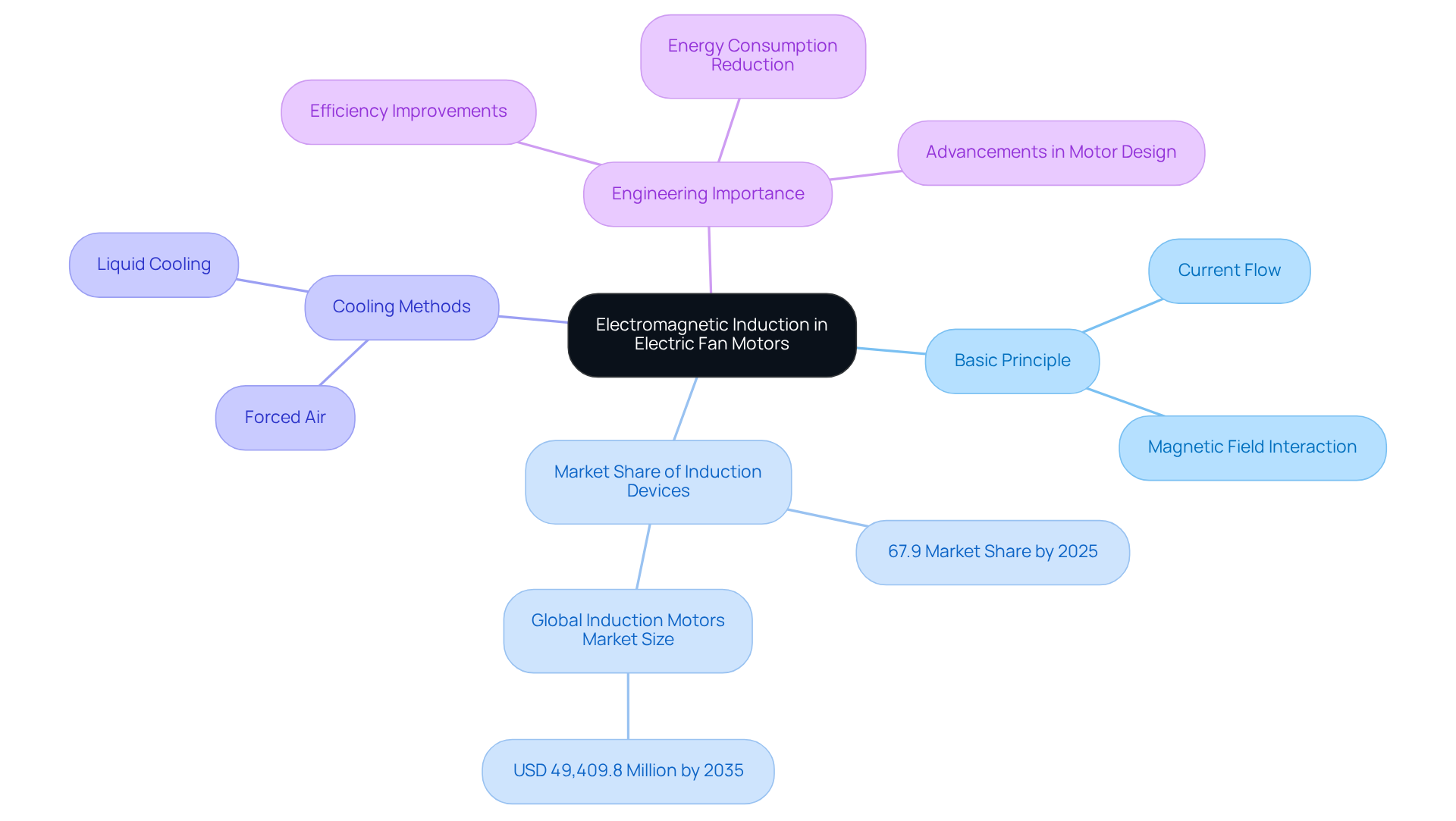

Electromagnetic Induction: The Core Principle Behind Electric Fan Motors

Fans fundamentally rely on the principle of electromagnetic induction, wherein a current flowing through a coil generates a magnetic field. This magnetic field interacts with the rotor, resulting in its rotation and the creation of airflow. Engineers recognize that this principle is crucial for developing efficient and effective fan devices, as it directly influences both performance and energy consumption.

Recent case studies underscore the operational efficiency of three-phase induction devices, which dominate the market due to their reliability and suitability for heavy-duty applications. These engines are projected to capture a 67.9% market share by 2025, underscoring their significance in the fan industry. Additionally, advancements in cooling methods, such as forced air and liquid cooling, are essential for maintaining optimal performance in fan systems, preventing overheating during operation.

The importance of electromagnetic induction extends beyond basic functionality; it is integral to the design and enhancement of electric fan motors. Engineers emphasize that understanding the nuances of this principle fosters advancements that enhance machine performance and reduce energy losses. As the industry moves towards improved efficiency benchmarks, the relevance of electromagnetic induction in design becomes increasingly critical, aligning with global sustainability initiatives.

In discussions among engineers, a clear consensus emerges: mastery of electromagnetic induction principles is not merely beneficial but essential for advancing electric fan motors technology. This understanding catalyzes the development of that meet the demands of modern applications, spanning from HVAC systems to consumer electronics.

Types of Electric Motors: AC vs. DC in Fan Applications

Electric fan motors are primarily categorized into AC (Alternating Current) and DC (Direct Current) types. AC engines are recognized for their durability and cost-effectiveness, making them suitable for larger fans. Their simpler maintenance requirements compared to direct current devices contribute to their widespread application in both home appliances and industrial settings. Conversely, DC motors excel in performance and speed regulation, rendering them ideal for scenarios that demand variable airflow.

Notably, DC fans can consume up to 70% less energy than their AC counterparts while delivering equivalent airflow—an essential advantage in commercial environments where operational costs are paramount. For instance, operating may cost as little as $3 for the same airflow that an AC fan would cost $10, underscoring the efficiency of DC technology.

However, it is crucial to note that DC ceiling devices necessitate specialized wiring and controls, complicating installation processes. Engineers must consider these factors, including the electromagnetic interference produced by AC fans in contrast to DC fans, when selecting drives for their designs.

Industry specialists emphasize that the choice between AC and DC devices, such as electric fan motors, should be guided by specific application requirements, encompassing budget constraints, energy efficiency, and desired performance characteristics. This nuanced understanding is vital for engineers striving to optimize their designs within the ever-evolving realm of electric fan motors.

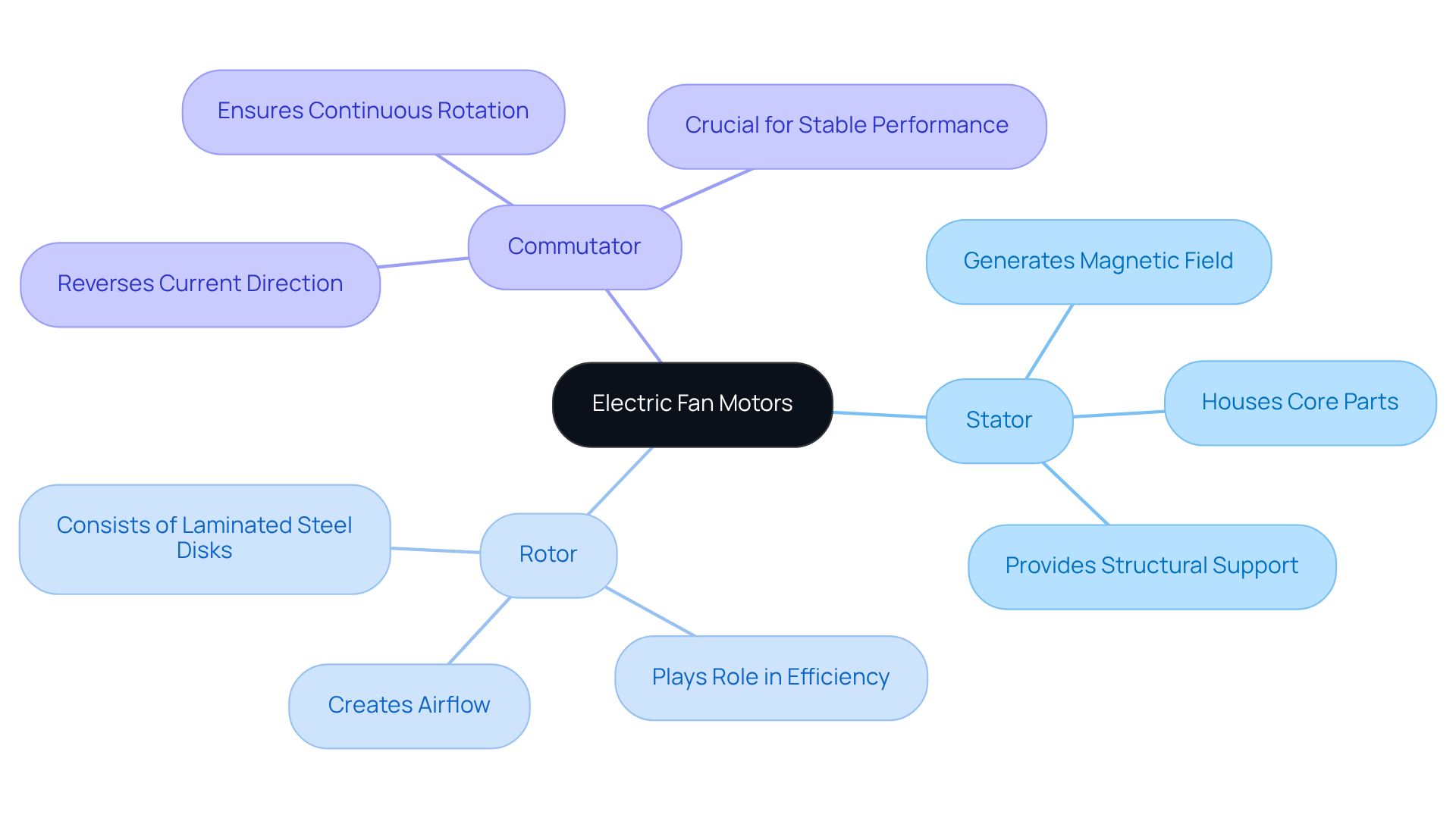

Key Components of Electric Fan Motors: Understanding Stators, Rotors, and Commutators

consist of several critical components: the stator, rotor, and commutator. The stator, the stationary component, generates a magnetic field essential for operation. In contrast, the rotor in electric fan motors is the rotating element that creates airflow, playing a vital role in the fan’s efficiency and effectiveness. In DC devices, the commutator is crucial as it reverses the current direction, ensuring continuous rotation and stable performance. Understanding the interaction among these elements is imperative for engineers aiming to enhance machinery performance.

For instance, engineers can improve airflow and energy efficiency by fine-tuning the design of the stator and rotor. Practical applications demonstrate that well-engineered stators and rotors can significantly enhance the overall performance of electric fan motors, making them indispensable in numerous electronic devices. Insights from industry specialists indicate that focusing on the enhancement of these elements can lead to substantial advancements in performance and durability, ultimately benefiting the end-user experience.

Efficiency Metrics: Evaluating Performance in Electric Fan Motors

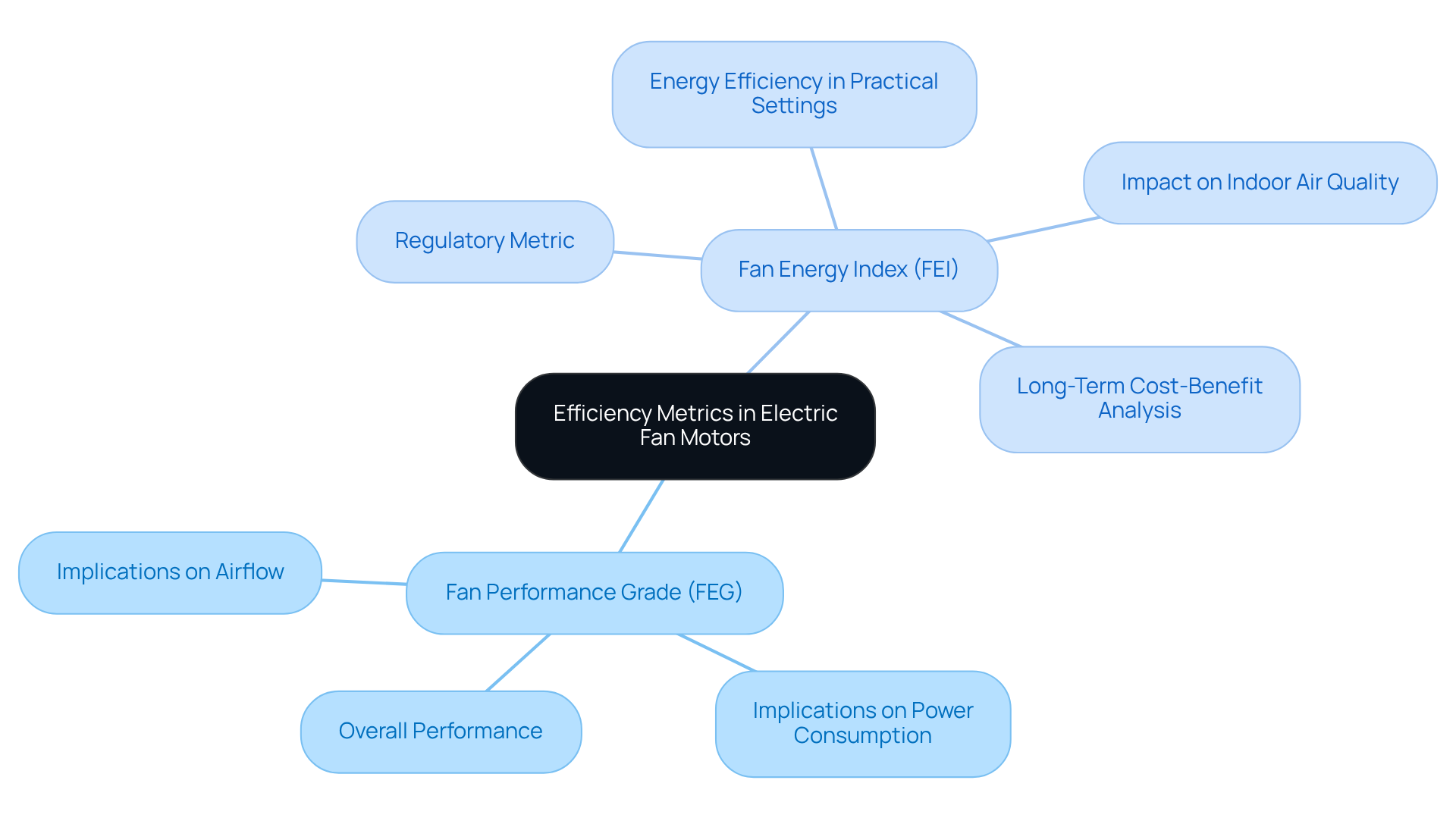

Assessing the performance of is critical for optimizing energy use and system efficiency. Key metrics such as the Fan Performance Grade (FEG) and the Fan Energy Index (FEI) serve as essential tools in this evaluation. These metrics provide insights into the relationship between airflow, power consumption, and overall performance, highlighting the need for careful consideration in design and operational choices.

Engineers must prioritize high-efficiency machines like electric fan motors not only to reduce energy consumption but also to enhance overall system performance. By focusing on these metrics, professionals can drive advancements in technology and sustainability.

Recent Innovations in Electric Fan Motor Technology

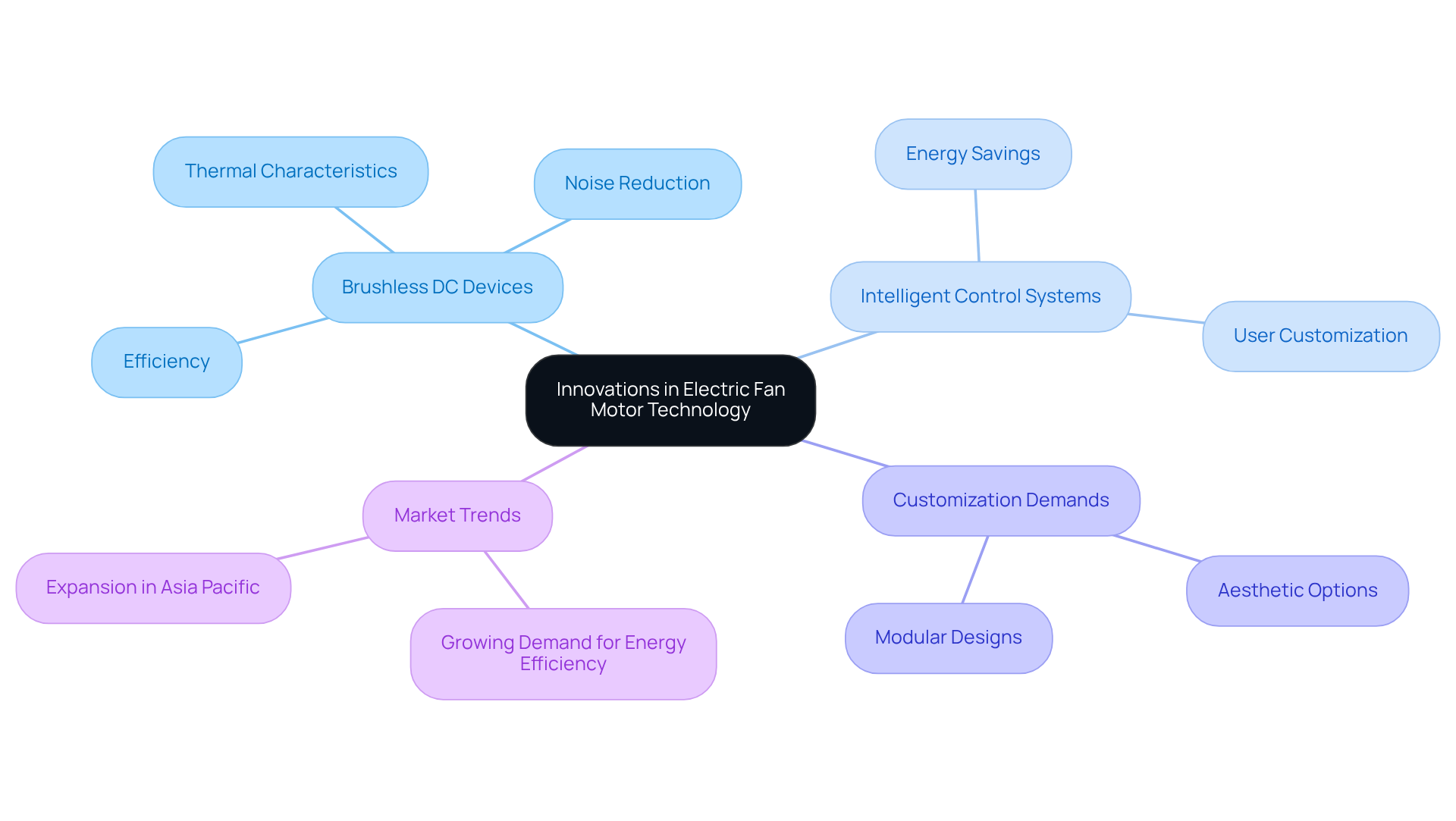

Recent innovations in electric fan motors technology have prominently featured the rise of brushless DC devices, celebrated for their superior efficiency and significantly reduced noise levels. These devices operate without brushes, effectively minimizing electrical and mechanical noise, thereby enhancing user comfort and product performance.

Furthermore, advancements in intelligent control systems have revolutionized the way engineers can adjust fan speed with precision, yielding substantial energy savings. For instance, smart fans equipped with remote controls and programmable settings enable users to customize their cooling experience according to real-time environmental conditions.

Statistics indicate that these innovations can reduce noise levels by up to 50%, rendering them ideal for applications in both residential and commercial settings. However, the high initial cost of brushless DC devices may pose a barrier to adoption, a consideration engineers should keep in mind when designing their systems.

Additionally, there is an increasing demand for customization in fan designs, reflecting consumer preferences for products that resonate with their personal style. Brushless DC devices also exhibit superior thermal characteristics compared to their brushed counterparts, further enhancing their appeal.

Engineers are encouraged to harness these cutting-edge technologies to enhance the performance and sustainability of their designs, including electric fan motors, ensuring they meet the growing demand for energy-efficient and quiet solutions in the marketplace.

is projected to expand significantly, particularly in the Asia Pacific region, driven by technological advancements and increasing applications across various sectors, including automotive and healthcare.

Acoustic Performance: Managing Noise in Electric Fan Motors

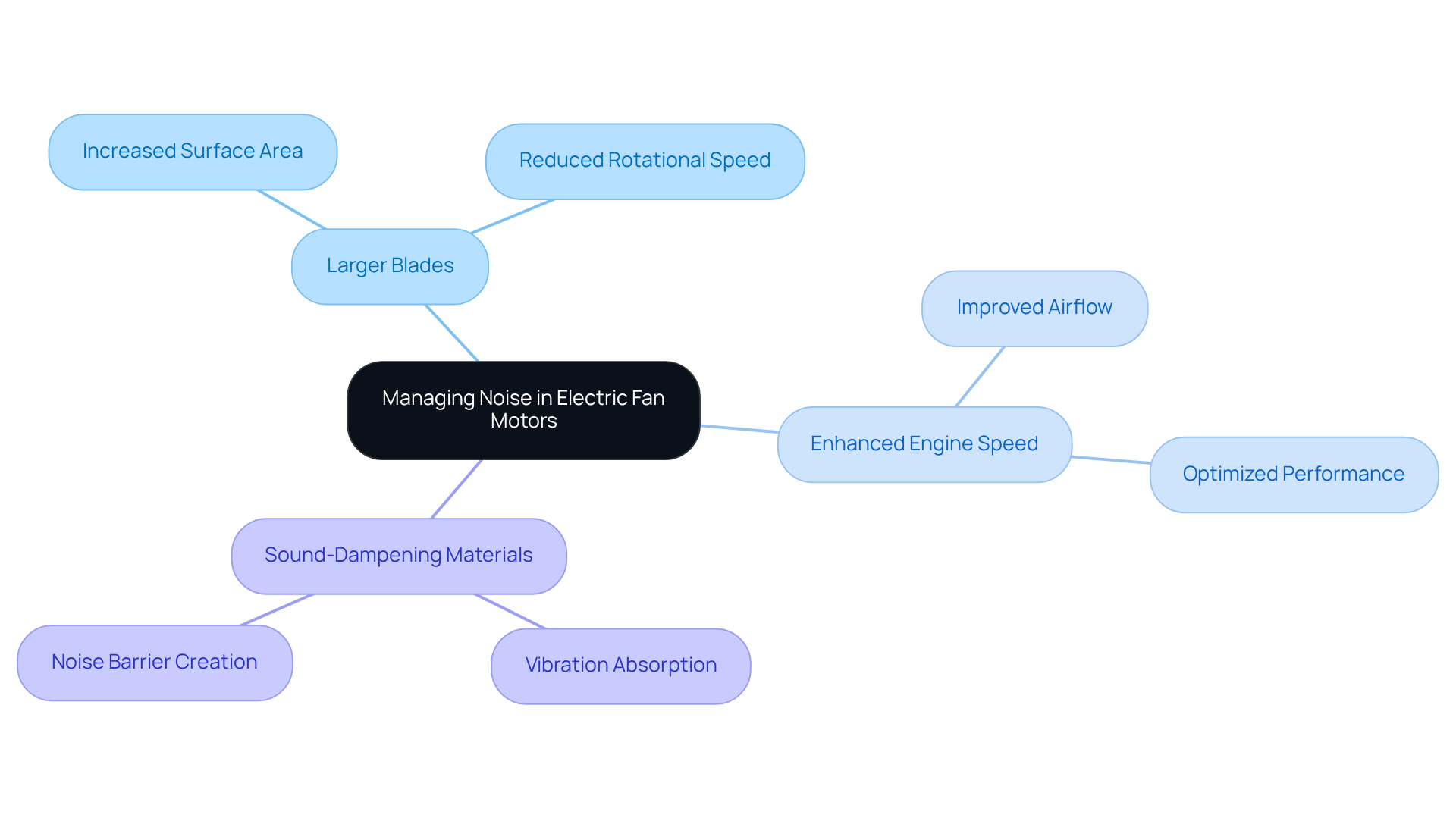

Controlling noise in fan systems is crucial, especially in applications like HVAC setups and residential environments. The challenge of can be effectively addressed through several methods.

- Utilizing larger blades

- Enhancing engine speed

- Incorporating sound-dampening materials

These are proven strategies that significantly reduce noise levels. Engineers must prioritize acoustic performance in their designs to not only meet operational standards but also enhance user comfort. By focusing on these aspects, the industry can ensure a more pleasant auditory experience for users.

Control Systems: Enhancing Functionality in Electric Fan Motors

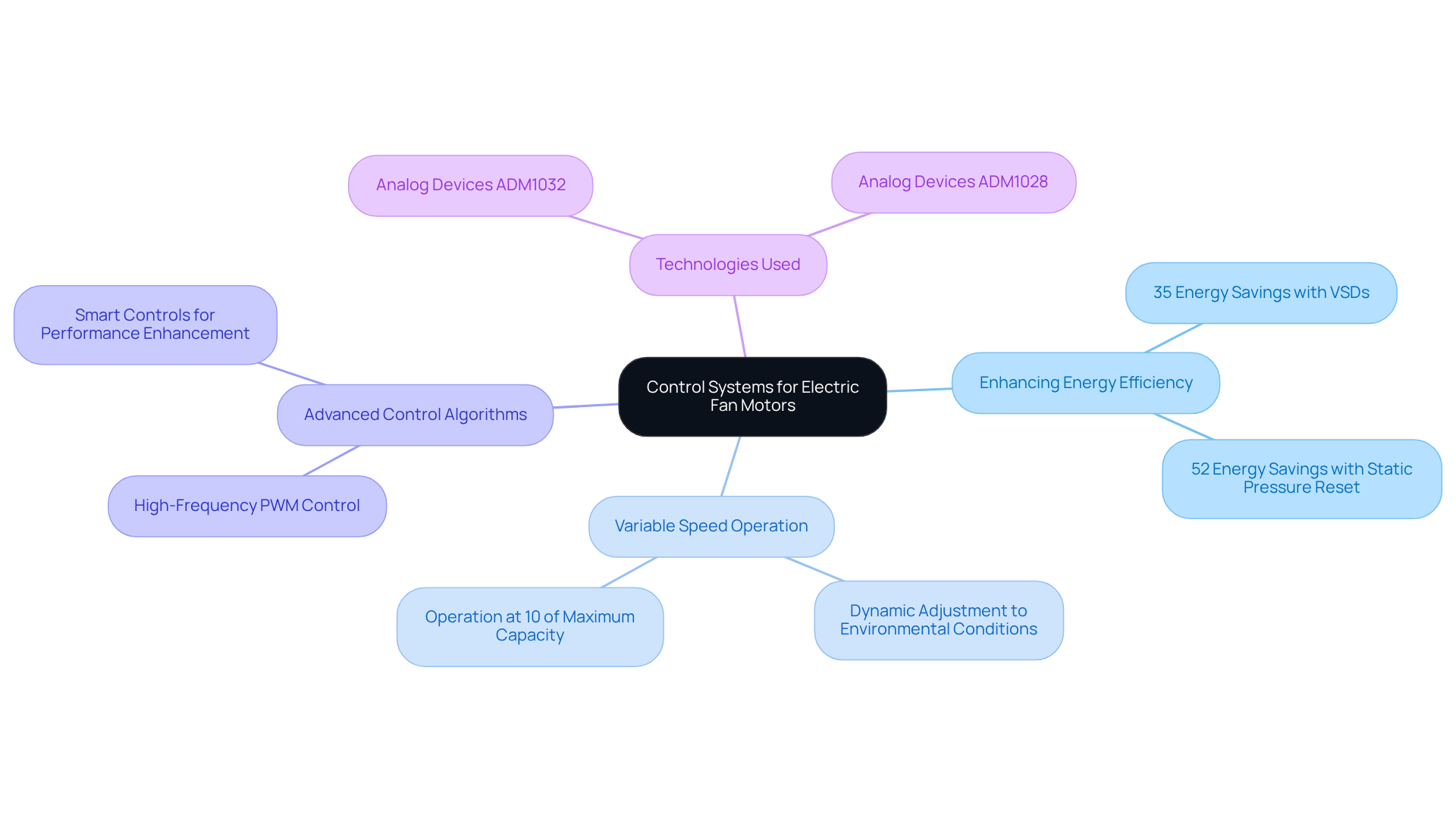

Control systems are crucial for optimizing the performance of electric fan motors, enabling advanced functionalities that significantly enhance energy efficiency. By employing sophisticated control algorithms, these systems support variable speed operation, allowing ventilators to adjust dynamically to fluctuating environmental conditions.

For example, studies demonstrate that the implementation of variable speed drives (VSDs) can yield energy savings of up to 35% in commercial applications, with potential increases to 52% when combined with static pressure reset strategies. Engineers are urged to incorporate smart controls for electric fan motors, which not only enhance their performance but also contribute to decreased energy consumption.

The adoption of , operating at frequencies surpassing 20 kHz, enables devices to function at speeds as low as 10% of their maximum capacity, thereby improving reliability and minimizing noise. Insights from engineers underscore the significance of these advanced control algorithms in contemporary fan technology, particularly for electric fan motors, highlighting their role in achieving both operational efficiency and sustainability in electronic cooling solutions.

Furthermore, the Analog Devices ADM1032 and ADM1028 are recognized for their suitability in fan control applications, further bolstering the technical credibility of these systems.

Regulatory Compliance: Standards for Electric Fan Motor Design

Compliance with stringent regulatory standards is imperative for fan designs, particularly UL 507, which governs the safety and performance criteria for fans. This adherence is crucial not only for ensuring the safety and reliability of devices but also for enhancing energy efficiency. The Department of Energy (DOE) has set forth energy efficiency guidelines that elevate performance expectations for fan units. Notably, the latest regulatory standards for 2025 underscore the necessity of maximizing energy savings while minimizing environmental impact.

Current statistics reveal that approximately 88% of fans lack load control, indicating a significant opportunity for improving compliance rates. Real-world cases of UL 507 compliance illustrate how manufacturers have effectively integrated these standards into their designs, which has led to improved product reliability and increased consumer trust.

Industry leaders emphasize that compliance with transcends mere regulatory obligation; it serves as a pathway to innovation and enhanced market competitiveness within the electric fan sector.

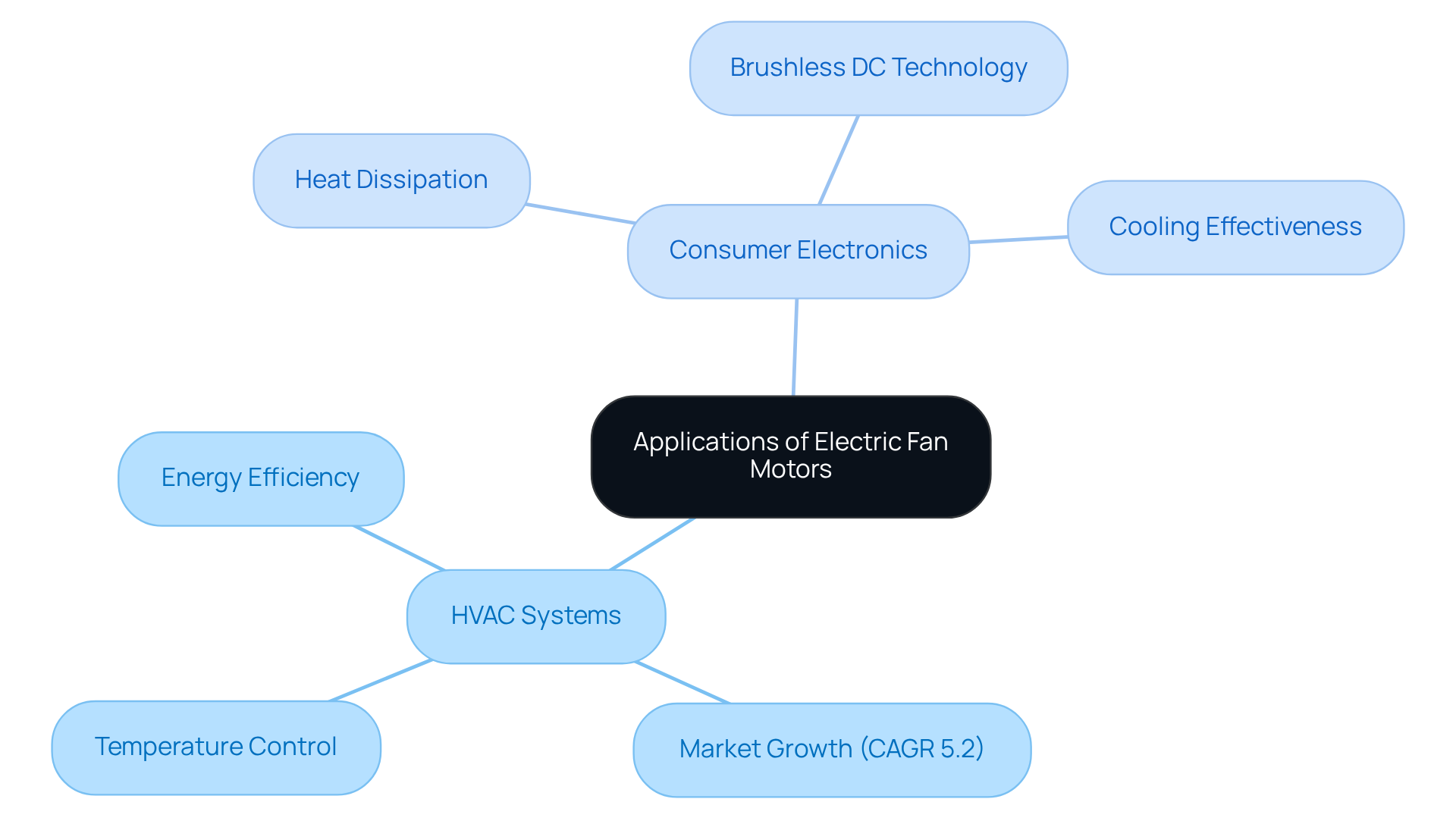

Applications of Electric Fan Motors: From HVAC to Electronics

play a crucial role in various applications, especially in HVAC systems and consumer electronics. In HVAC, these devices are crucial for enabling air circulation and ensuring optimal temperature control, which significantly influences energy efficiency. The global market for fan engines in HVAC applications is projected to grow at a CAGR of 5.2%, driven by an increasing demand for energy-efficient solutions.

In the realm of consumer electronics, electric fan mechanisms are vital for managing heat dissipation in devices such as computers, gaming consoles, and home appliances. Engineers are increasingly focused on enhancing engine performance to improve cooling effectiveness. Current trends reveal a movement towards brushless DC devices, known for their superior efficiency and quieter operation compared to traditional AC units.

Real-world examples underscore the efficacy of electric fan engines in thermal management. For instance, in high-performance gaming PCs, strategically positioned fans can lower internal temperatures by up to 30%, thereby preventing thermal throttling and ensuring peak performance. Insights from engineers indicate that selecting the appropriate size and speed of the device is critical for optimizing airflow while minimizing energy consumption.

Ultimately, the significance of electric fan motors in contemporary engineering applications is highlighted by their versatility in both HVAC and electronics. This makes them a crucial consideration for engineers striving to enhance system performance and energy efficiency.

Conclusion

In the realm of modern engineering, electric fan motors are pivotal components that drive energy efficiency and innovation across diverse applications. This article has explored ten critical insights into the technology, design, and application of electric fan motors, emphasizing the necessity of staying updated with current trends and advancements that shape the industry.

Key discussions have included:

- The foundational principles of electromagnetic induction

- The distinctions between AC and DC motors

- The essential components that contribute to the functionality of electric fan motors

Furthermore, the exploration of efficiency metrics, recent technological innovations, and regulatory compliance has underscored the necessity for engineers to prioritize performance while adhering to industry standards.

As the demand for energy-efficient solutions continues to rise, engineers are encouraged to embrace the latest advancements in electric fan motor technology. By leveraging innovative designs and understanding the intricacies of motor functionality, professionals can significantly enhance system performance and sustainability. The future of electric fan motors will undoubtedly be shaped by these insights, making it imperative for engineers to remain informed and adaptable in this evolving landscape.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized as a leader in providing innovative solutions for electric fan motor applications, offering access to advanced cooling technologies, power management systems, and interconnect solutions.

How does Gagner-Toomey Associates support engineers in the electronics industry?

The company employs a consultative approach and utilizes automated tools to streamline the sales cycle, ensuring engineers receive the necessary guidance to tackle complex challenges effectively.

What is the projected market value of the fan engine market by 2025?

The fan engine market is projected to reach approximately $843.4 million by 2025.

In which sectors is the demand for electric fan motor technologies growing?

The demand is growing across various sectors, including Telecom, Networking, IT/Data Center, and Automotive.

What principle do electric fan motors fundamentally rely on?

Electric fan motors rely on the principle of electromagnetic induction, where a current flowing through a coil generates a magnetic field that interacts with the rotor to create airflow.

What type of electric motors dominate the fan market?

Three-phase induction devices dominate the market due to their reliability and suitability for heavy-duty applications, projected to capture a 67.9% market share by 2025.

What are the advantages of AC motors in fan applications?

AC motors are known for their durability, cost-effectiveness, and simpler maintenance, making them suitable for larger fans used in home appliances and industrial settings.

How do DC motors compare to AC motors in terms of energy consumption?

DC motors can consume up to 70% less energy than AC motors while delivering equivalent airflow, making them more efficient in commercial environments.

What installation considerations should engineers keep in mind when using DC fans?

DC fans require specialized wiring and controls, which can complicate installation processes, and engineers must also consider electromagnetic interference produced by AC fans.

What factors should guide the choice between AC and DC electric fan motors?

The choice should be guided by specific application requirements, including budget constraints, energy efficiency, and desired performance characteristics.