Overview

The brushless DC motor stator plays a pivotal role in generating a rotating magnetic field, which effectively interacts with the rotor’s permanent magnets. This interaction is crucial for enabling efficient motion and precise control across a range of applications.

- Its design is engineered to minimize energy losses and enhance reliability, underscoring its importance in key sectors such as:

- Automotive

- Consumer electronics

- Industrial equipment

The implications of this technology are profound, as it not only drives performance but also contributes to the sustainability and efficiency of modern systems.

Introduction

The evolution of motor technology has ushered in the era of brushless DC motors, representing a significant advancement in efficiency and performance. Central to these sophisticated systems is the brushless DC motor stator, a vital component that not only generates the essential magnetic fields but also enhances reliability and minimizes maintenance requirements. As industries increasingly emphasize energy efficiency and precision, grasping the design, functionality, and importance of the brushless DC motor stator is imperative.

What challenges confront manufacturers in optimizing these components, and how do they influence the future of technology across diverse sectors?

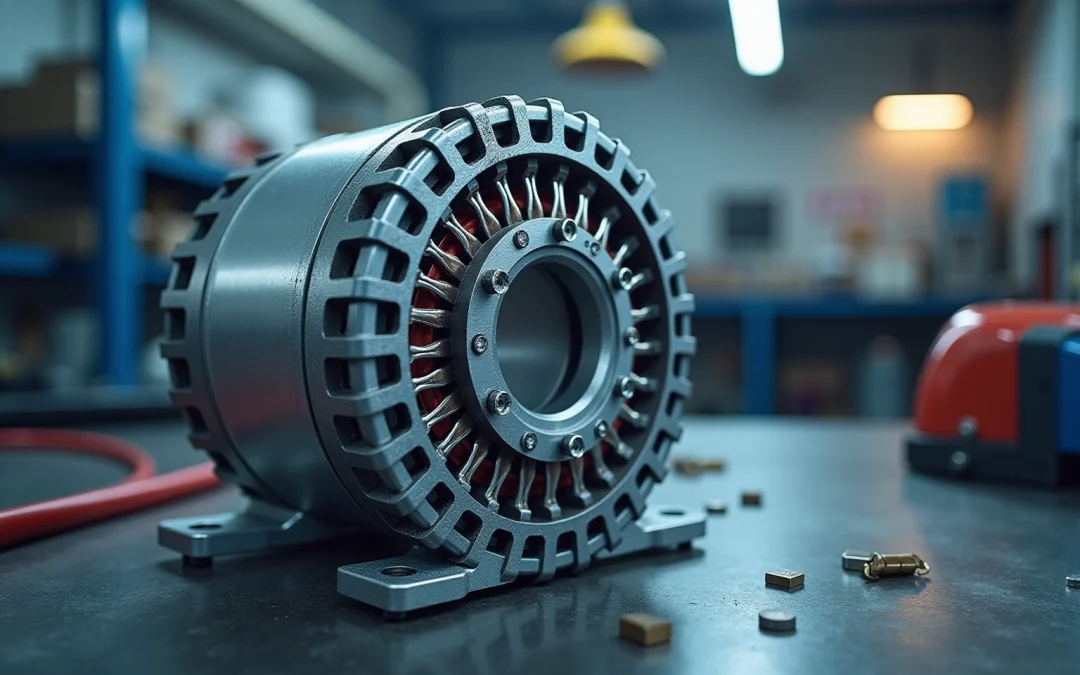

Define Brushless DC Motor Stator

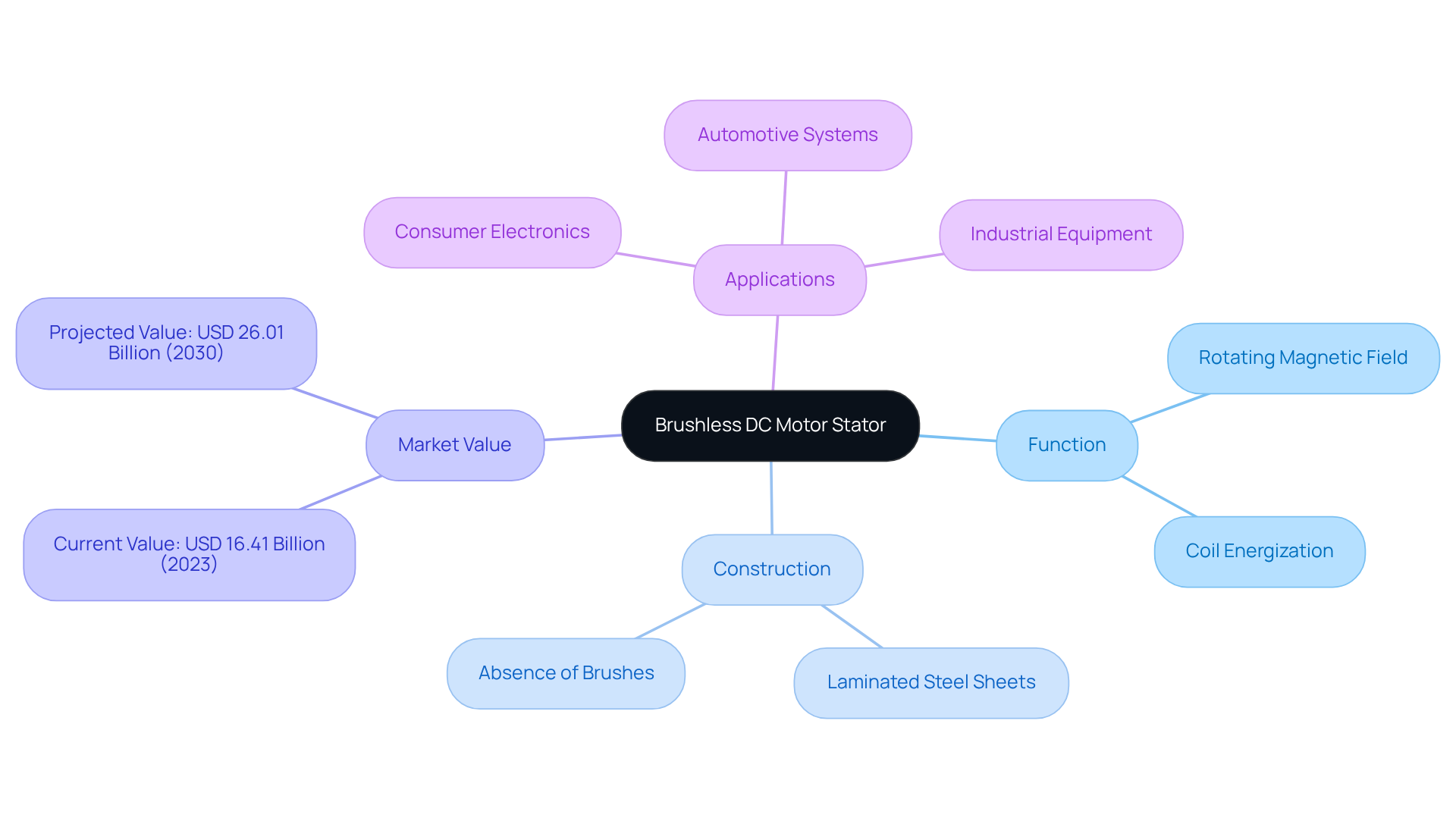

The stationary part of a brushless DC motor stator is crucial, as it contains the windings that generate a rotating magnetic field. In contrast to conventional brushed motors, where the rotor houses the windings, the brushless DC motor stator utilizes a stationary component fitted with coils. In the brushless DC motor stator, these coils are energized in a specific sequence to produce magnetic fields, significantly enhancing performance and reducing maintenance needs due to the absence of brushes that could wear out over time. The magnetic component’s arrangement may vary, typically constructed from laminated steel sheets to minimize energy losses attributed to eddy currents.

According to Next Move Strategy Consulting, the global Brushless DC (BLDC) Motor Market was valued at USD 16.41 billion in 2023 and is projected to reach USD 26.01 billion by 2030. This projection underscores the increasing across various sectors. Brushless DC machinery components, including the brushless DC motor stator, play a vital role in numerous applications, such as:

- Consumer electronics

- Automotive systems

- Industrial equipment

where reliability and efficiency are paramount.

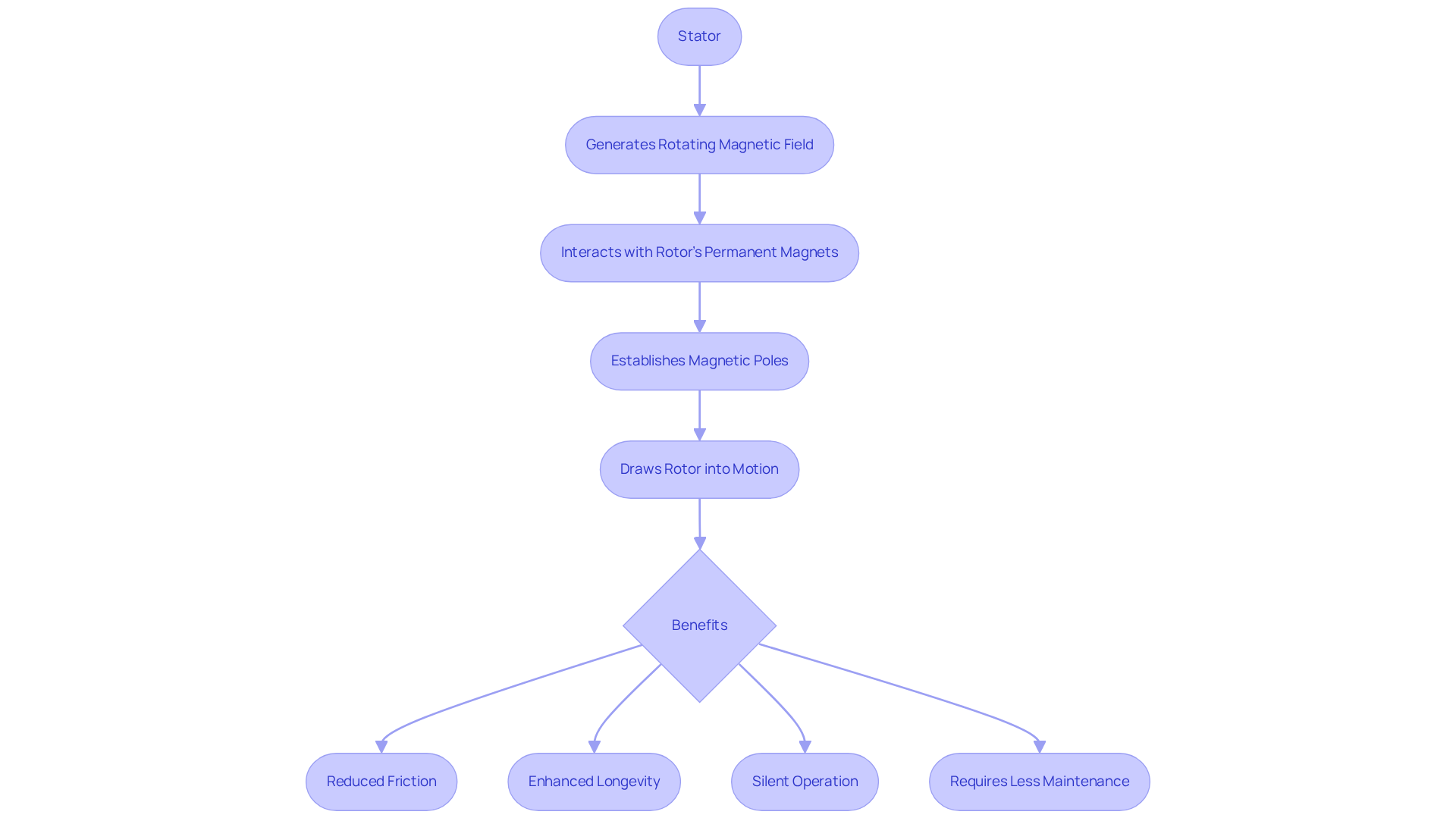

Explain the Functionality of the Stator in Brushless DC Motors

In a non-brush type DC machine, the component plays a pivotal role by generating a rotating magnetic field that interacts with the rotor’s permanent magnets. When electrical current traverses the stator windings, it establishes magnetic poles that sequentially switch, effectively drawing the rotor into motion. This electronic commutation allows for precise control of speed and torque, making DC machines both efficient and responsive.

The absence of brushes not only reduces friction but also enhances the longevity and reliability of the engine, rendering it suitable for diverse applications, from electric vehicles to industrial machinery. Moreover, the silent operation of these engines is particularly beneficial for sensitive applications, such as patient lifts. While they require , they demand less overall care compared to traditional brushed devices.

Additionally, non-brushed engines rely on electronic speed controllers (ESC) for their operation, which further amplifies their advanced capabilities. The design of the component is crucial in minimizing electromagnetic interference (EMI), thereby reinforcing the advantages of brushless technology.

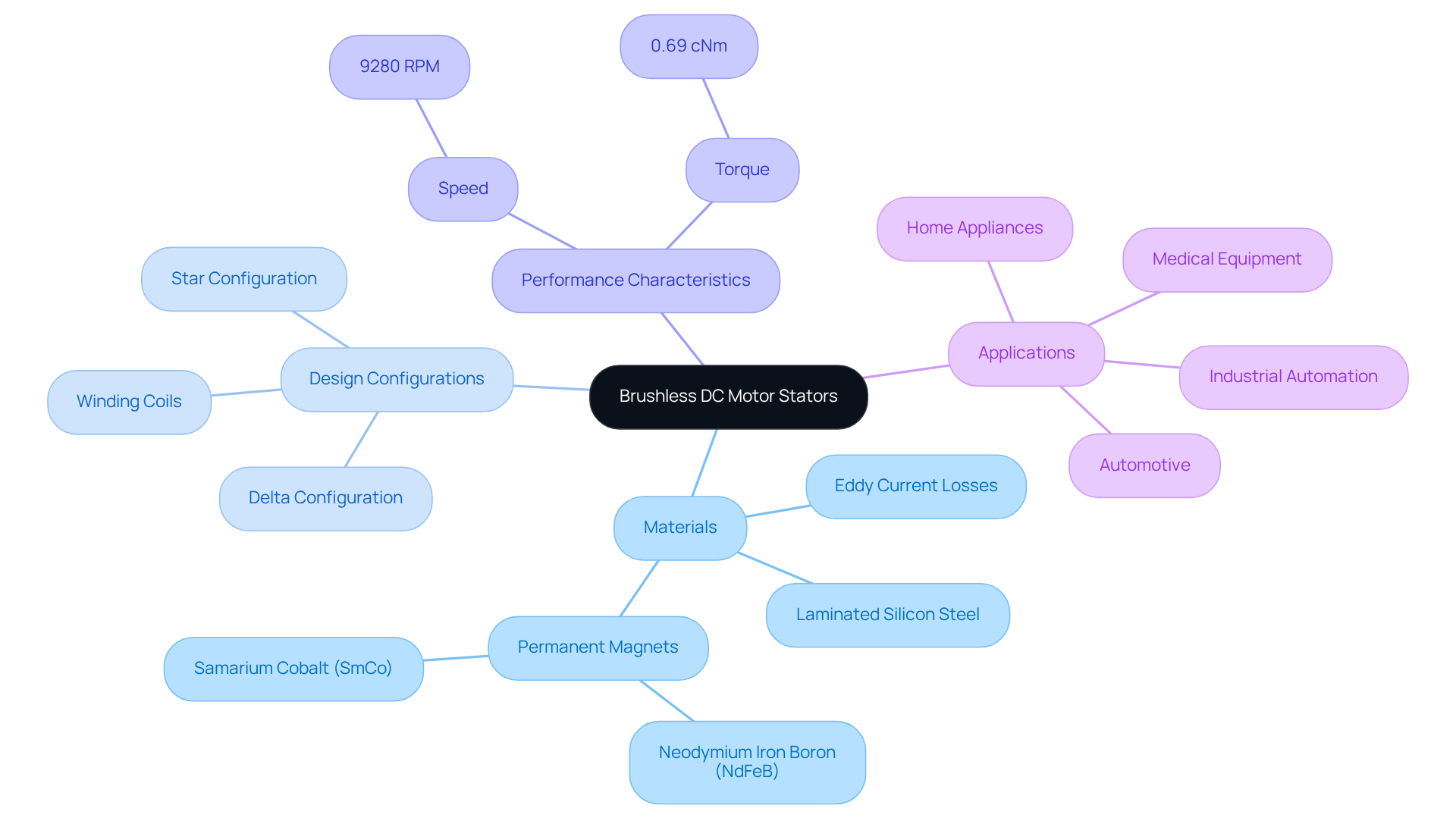

Describe the Construction and Design of Brushless DC Motor Stators

Brushless DC machine cores are primarily constructed from laminated silicon steel, a material choice that significantly minimizes eddy current losses and enhances magnetic efficiency. The design of the [brushless DC motor stator](https://gagner-toomey.com/10-advantages-of-using-frameless-bldc-motors-in-electronics) typically incorporates multiple slots for winding coils, which can be arranged in various configurations, such as star or delta. The number of poles and the specific winding arrangement are critical design elements that directly influence the machine’s performance, particularly its torque and speed characteristics.

For example, the Mechtex BO32(6W) device achieves an impressive speed of 9280 RPM and a torque of 0.69 cNm, demonstrating the potential of well-engineered BLDC systems. Additionally, contemporary electrical machines frequently utilize Hall effect sensors, which offer real-time feedback on rotor position, thereby improving control and operational efficiency.

The careful selection of materials and design parameters is essential for maximizing the performance and reliability of the brushless DC motor stator. Moreover, employing design for six-sigma methods can enhance manufacturing quality, ensuring that components meet rigorous performance standards. The versatility of BLDC devices is evident in their , including automotive and medical equipment, where their performance and reliability are paramount.

Applications of Brushless DC Motor Stators

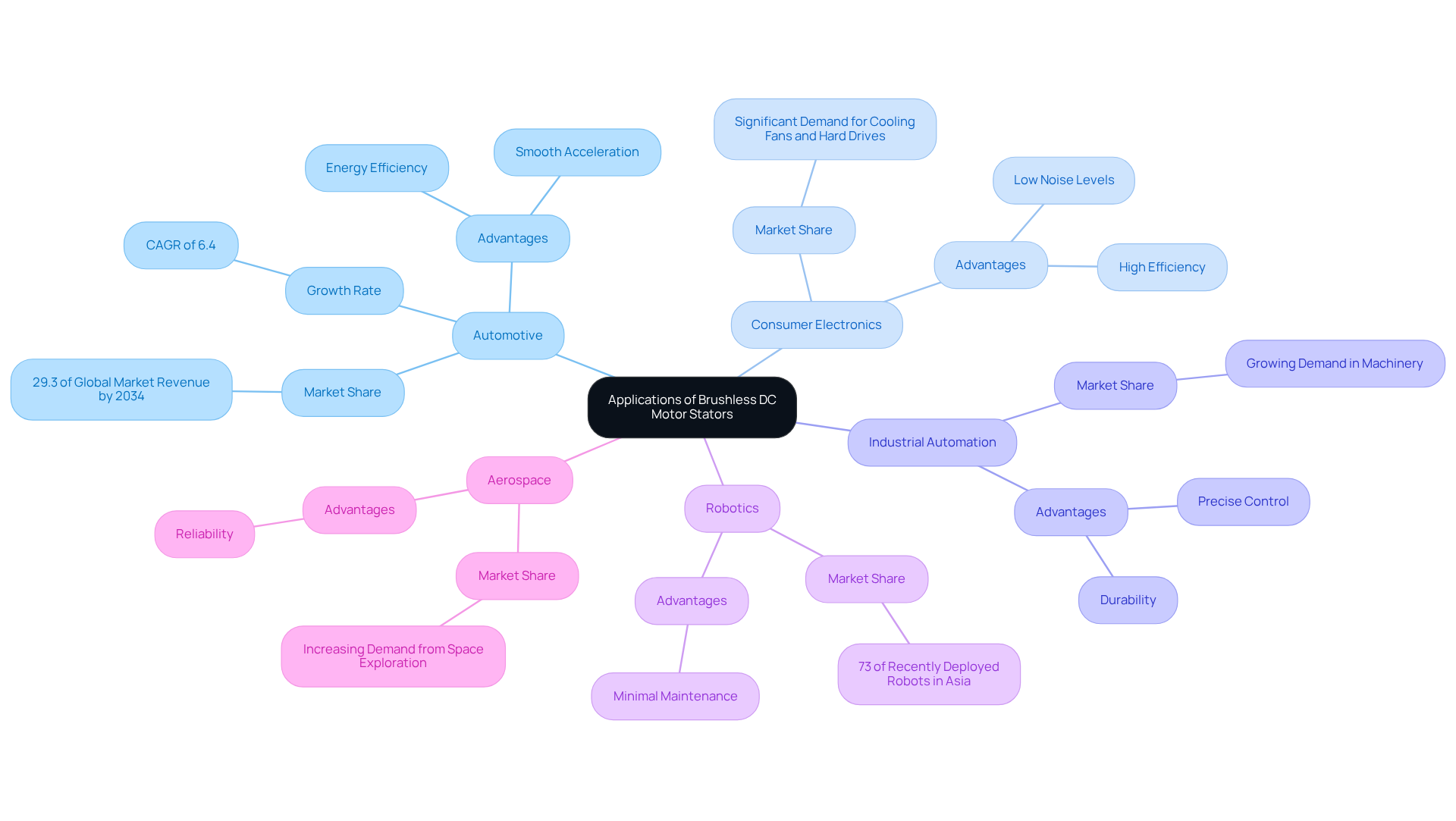

Brushless direct current device components are pivotal to a myriad of applications, celebrated for their effectiveness and reliability. In the realm of electric vehicles, these components enable smooth and responsive acceleration, significantly enhancing the performance of hybrid and electric models. Notably, the automotive sector is projected to account for 29.3% of the global market earnings for DC devices, which is anticipated to reach US$ 38.49 billion by 2034.

In consumer electronics, including computer cooling fans and hard drives, these components are prized for their low noise levels and high efficiency, making them ideal for devices where sound and energy consumption are critical factors. Their application further extends to industrial automation systems, robotics, and aerospace, where precise control and durability are essential.

The demand for energy-efficient solutions within the automotive sector is expected to grow at a CAGR of 6.4%, while the South Korean market is projected to advance at a CAGR of 6.3%. However, manufacturers encounter challenges such as high initial costs and competition from low-cost alternatives in grey markets. Overall, the increasing focus on energy-efficient solutions is driving the adoption of brushless DC motor stators across various sectors. This trend highlights the importance of brushless DC motor stators in meeting the needs of .

Conclusion

The significance of the brushless DC motor stator is paramount, serving as the backbone of modern electric motor technology. By utilizing a stationary component to generate a rotating magnetic field, the brushless DC motor stator enhances efficiency and reliability while minimizing maintenance requirements. This innovative design represents a significant evolution from traditional brushed motors, showcasing advancements in electric motor systems that cater to diverse applications across various industries.

This article has explored key insights into the functionality, construction, and applications of brushless DC motor stators. The stator’s critical role in generating a rotating magnetic field facilitates precise control of speed and torque, making it an ideal choice for electric vehicles, consumer electronics, and industrial machinery. Furthermore, the importance of materials, such as laminated silicon steel, in reducing energy losses and improving performance has been underscored, highlighting the intricate design considerations that contribute to the stator’s effectiveness.

As the demand for energy-efficient solutions continues to escalate, the brushless DC motor stator emerges as a pivotal component in advancing technology and sustainability. Its applications are poised for further expansion, propelled by the automotive sector’s emphasis on electric vehicles and the increasing need for reliable, efficient machinery. By embracing the advantages of brushless DC technology, industries not only enhance operational performance but also align with the global shift towards sustainable practices. It is imperative for industries to consider the integration of brushless DC motor stators in their future developments.

Frequently Asked Questions

What is the role of the brushless DC motor stator?

The brushless DC motor stator is the stationary part of the motor that contains the windings to generate a rotating magnetic field.

How does the brushless DC motor stator differ from conventional brushed motors?

In brushless DC motors, the stator is stationary and houses the coils, while in conventional brushed motors, the rotor contains the windings. This design enhances performance and reduces maintenance needs.

What is the significance of the winding arrangement in the brushless DC motor stator?

The coils in the brushless DC motor stator are energized in a specific sequence to produce magnetic fields, which significantly improves the motor’s performance.

Why are laminated steel sheets used in the construction of the brushless DC motor stator?

Laminated steel sheets are used to minimize energy losses associated with eddy currents, enhancing the efficiency of the motor.

What was the value of the global Brushless DC Motor Market in 2023, and what is it projected to reach by 2030?

The global Brushless DC Motor Market was valued at USD 16.41 billion in 2023 and is projected to reach USD 26.01 billion by 2030.

In which sectors are brushless DC motor components, including the stator, commonly used?

Brushless DC motor components are commonly used in consumer electronics, automotive systems, and industrial equipment, where reliability and efficiency are critical.