Overview

The article examines the fundamental components of cooling fans and their critical role in engineering solutions for effective thermal management. It emphasizes how elements such as fan blade design, motor technology, and operational mechanics directly affect performance and efficiency. This understanding is essential for engineers who are striving to enhance cooling solutions across a variety of applications.

Introduction

Understanding the intricate world of cooling fan components is essential for engineers aiming to enhance thermal management in electronic systems. As technology advances and the demand for efficient cooling solutions escalates, mastering the fundamentals of these components—ranging from fan blades to motors—can lead to significant performance improvements and energy savings.

However, with numerous options available, how can engineers ensure they select the right cooling fan for their specific applications? This article delves into the critical components of cooling fans, their operational mechanics, and key considerations for optimal selection, providing valuable insights for effective engineering solutions.

Explore the Fundamentals of Cooling Fan Components

Cooling devices are essential for effectively managing heat within electronic systems, thereby ensuring optimal performance and extending the longevity of components. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a comprehensive array of temperature management solutions. This includes DC input tube axial devices and centrifugal blowers, all optimized for performance, effectiveness, and low noise.

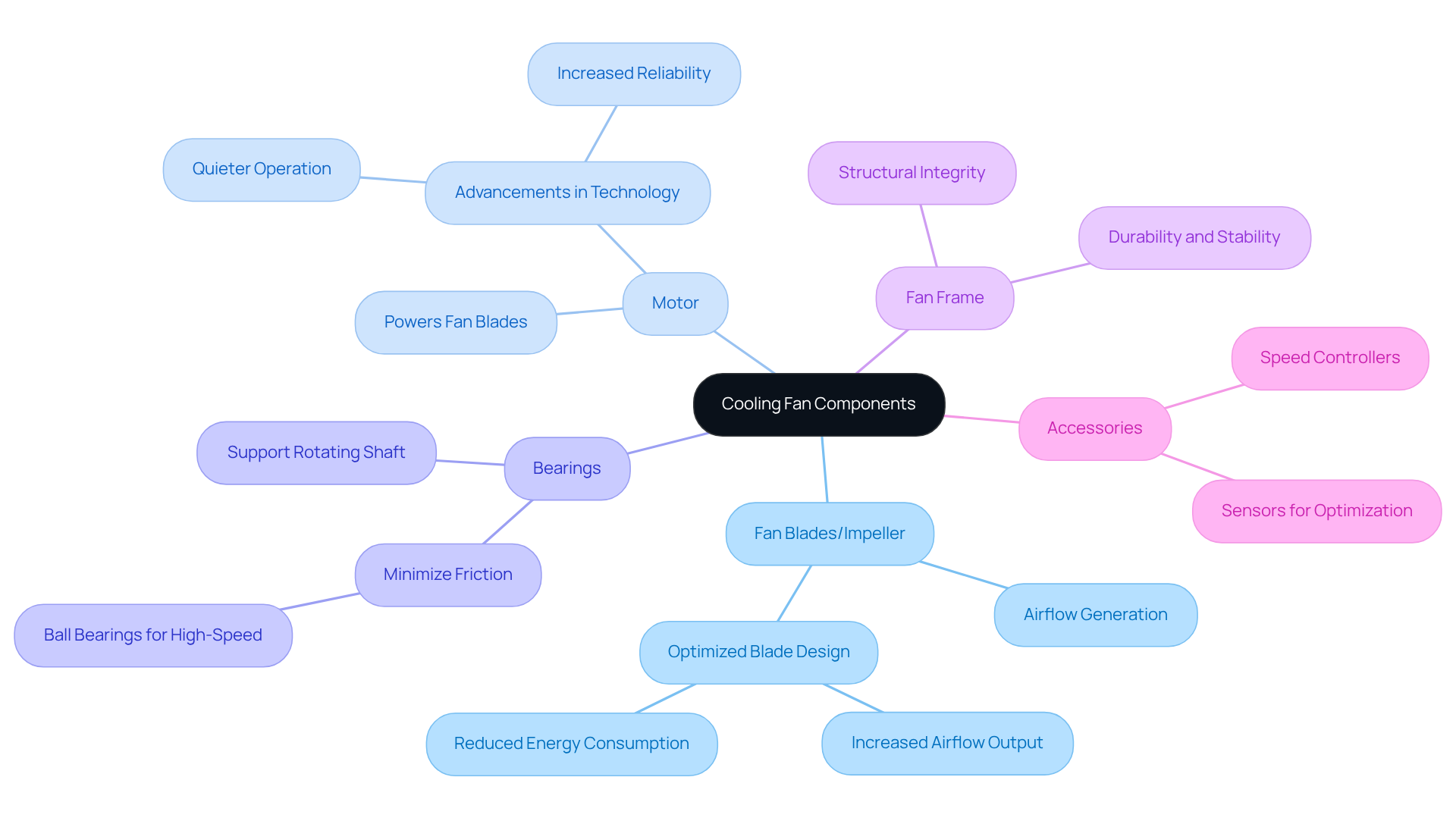

The primary components of cooling fans include:

- Fan Blades/Impeller: These rotating elements are crucial for generating airflow, effectively directing air in a specific manner. Their design significantly influences temperature regulation; research indicates that optimized blade forms can enhance airflow output by as much as 26%, while simultaneously reducing energy consumption by 21%. As highlighted by ZIEHL-Abegg, their aerodynamic blade redesign exemplifies the critical role of blade design in cooling applications.

- Motor: This component powers the fan blades, converting electrical energy into mechanical energy. The choice of motor affects the fan’s speed and overall performance. Recent advancements in motor technology have led to quieter and more reliable operation. Gagner-Toomey Associates’ fans incorporate state-of-the-art motor technology to guarantee optimal performance.

- Bearings: Bearings are integral in supporting the rotating shaft and minimizing friction, essential for smooth operation. Ball bearings, for example, are favored in high-speed applications due to their capacity to handle both radial and axial loads, which contributes to an extended lifespan and reduced noise levels.

- Fan Frame: The frame provides structural integrity and houses essential components, ensuring durability and stability during operation.

- Accessories: These encompass speed controllers and sensors that enhance the fan’s functionality and efficiency. The integration of smart technologies facilitates real-time monitoring and optimization of airflow, a growing necessity in high-performance applications.

Understanding these components is vital for engineers aiming to improve thermal management solutions across various applications, ranging from consumer electronics to industrial machinery. With the global temperature regulation fan market projected to reach USD 29,967.0 million by 2035, and an anticipated size of USD 10,746.0 million by 2025, the demand for is on the rise. This underscores the importance of mastering these essential components.

Analyze Key Components and Their Functions in Cooling Fans

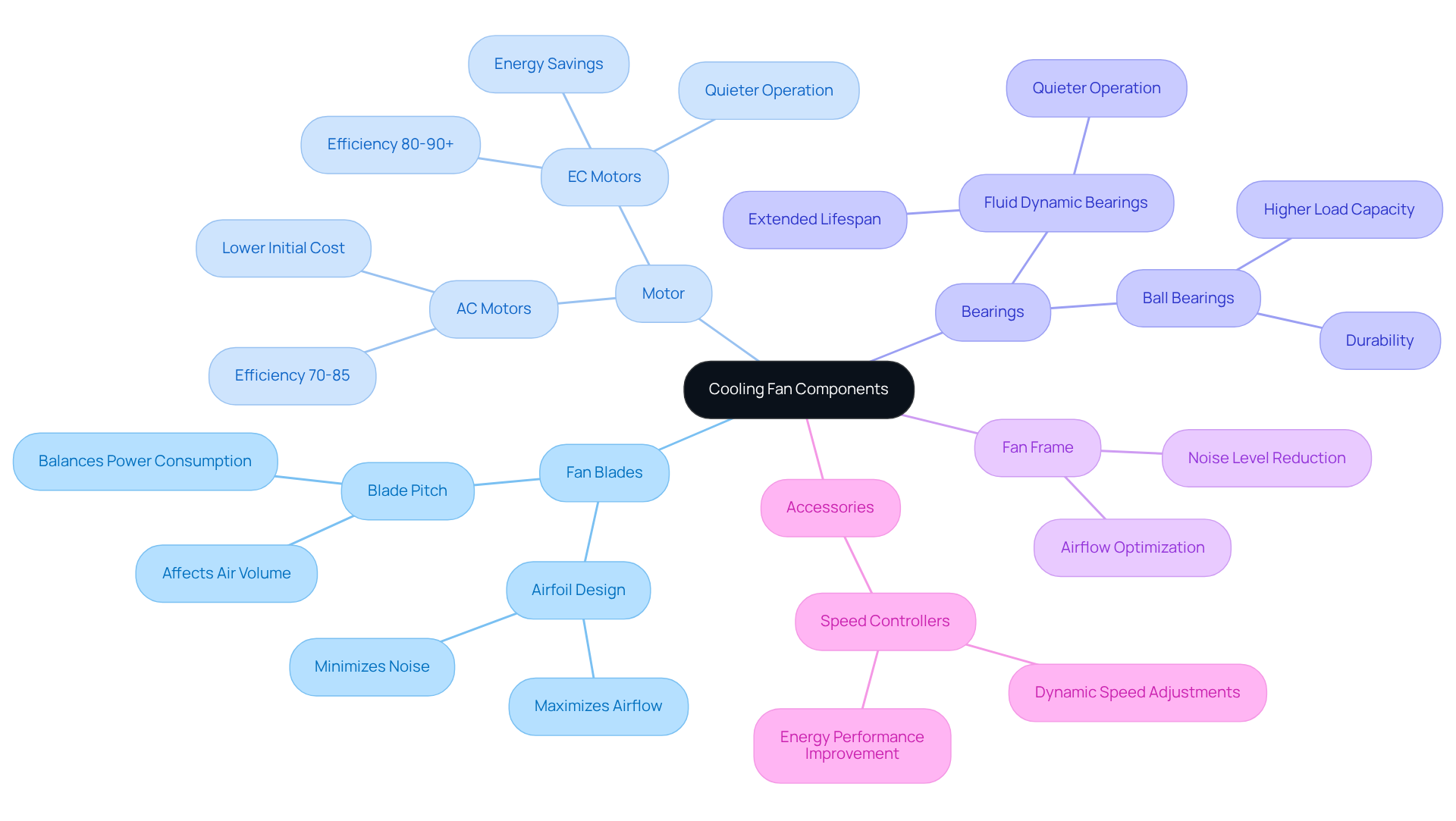

Each of the cooling fan components is integral to its overall performance.

- Fan Blades: The design of fan blades is essential for maximizing airflow while minimizing noise. Airfoil-style blades, which emulate aircraft wings, significantly reduce drag and enhance airflow performance.

- Motor: The choice of motor has a profound impact on fan performance. AC motors typically exhibit a performance rating of 70-85%, whereas EC motors can achieve performance levels of 80-90% or higher. This distinction is particularly critical in applications necessitating continuous operation, as utilizing EC motors in cooling fans can yield substantial energy savings and lower operating costs over time.

- Bearings: Different types of bearings, including sleeve, ball, and fluid dynamic bearings, offer unique advantages. For example, fluid dynamic bearings facilitate quieter operation and extended lifespans, making them ideal for noise-sensitive environments.

- Fan Frame: The design of the fan frame influences airflow patterns and noise levels. A thoughtfully designed frame can enhance the fan’s overall performance by optimizing airflow and minimizing turbulence.

- Accessories: Speed controllers are vital accessories that enable dynamic adjustments of fan speed based on temperature and demand. This functionality not only improves energy performance but also extends the lifespan of the fan components by preventing unnecessary wear.

In practical applications, the selection of motor types can significantly influence performance. While AC motors may be favored for their lower initial costs, EC motors frequently offer due to their enhanced efficiency and quieter operation. Weak EC units can operate for up to 70,000 hours, making them suitable for environments where noise reduction is paramount, such as residential HVAC systems. Grasping the cooling fan components and their respective functions is essential for engineers aspiring to optimize cooling solutions across various applications.

Understand the Operational Mechanics of Cooling Fans

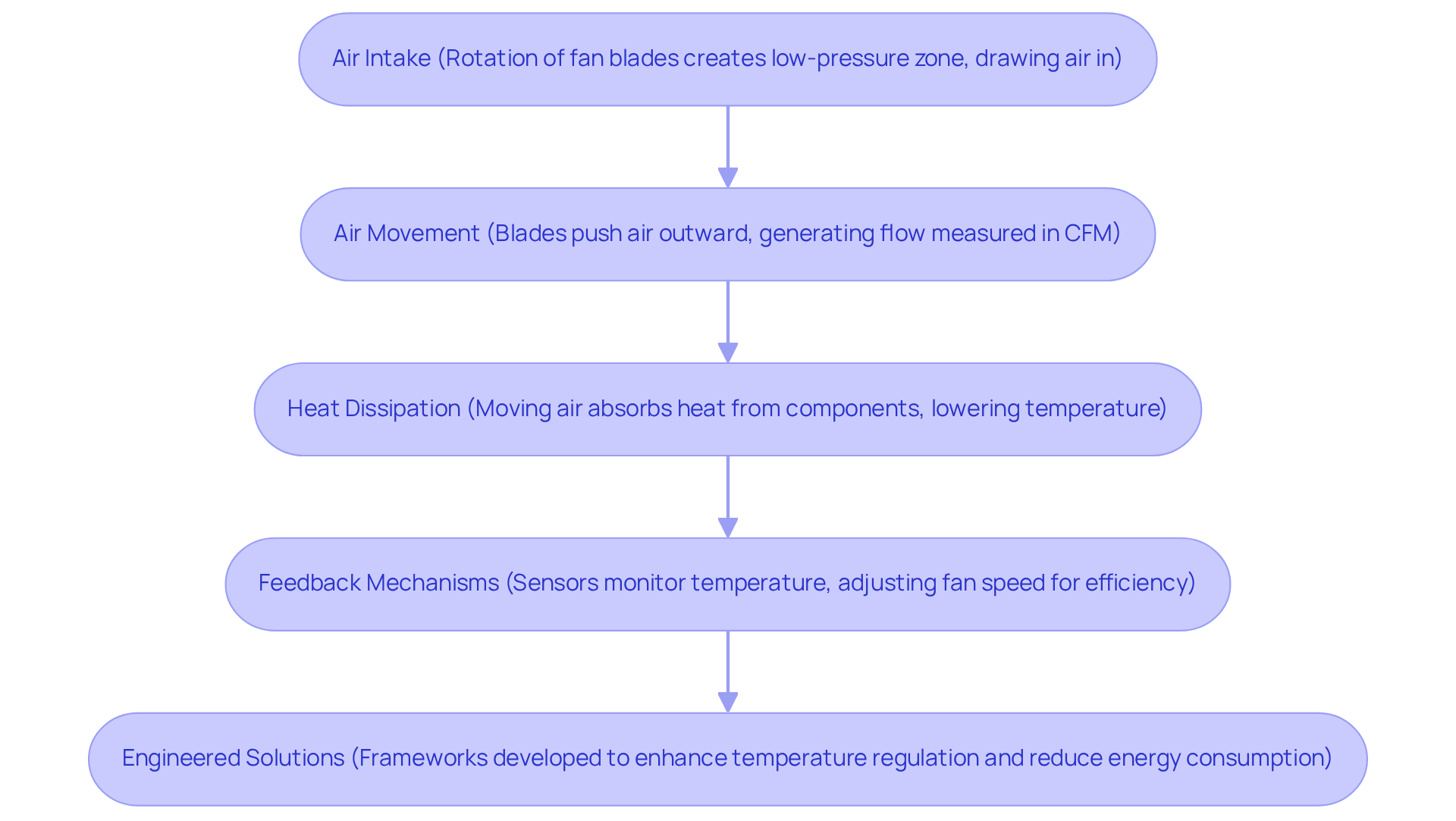

Cooling fan components generate airflow through a systematic process that is crucial for effective heat management in electronic systems.

- Air Intake: The rotation of fan blades creates a low-pressure zone, drawing air into the fan. This initial step is vital for initiating airflow.

- Air Movement: As the blades continue to spin, they push the air outward, generating a flow that cools surrounding components. This movement is measured in cubic feet per minute (CFM), with often surpassing 100 CFM, ensuring swift air circulation. The highest rotor speed verified in tests can attain 94%, demonstrating the capabilities of contemporary refrigeration systems.

- Heat Dissipation: The moving air absorbs heat from electronic components, effectively lowering their temperature. Research shows that cooling devices can keep CPU temperatures up to 3 degrees Celsius lower than conventional ventilation techniques, greatly improving system reliability. The effective management of temperature, particularly through cooling fan components, is vital for lowering operational expenses and enhancing energy performance.

- Feedback Mechanisms: Numerous contemporary devices are equipped with sensors that monitor temperature and adjust their speed accordingly. This dynamic reaction not only enhances temperature regulation but also aids in energy savings, with energy-saving fans decreasing power usage by up to 70% in comparison to traditional models. Moreover, regular maintenance activities, like replacing air filters, can additionally lower air conditioner energy consumption by 5 to 15%, improving overall performance.

By understanding these operational mechanics, engineers can create frameworks that enhance temperature regulation while reducing energy consumption, ultimately resulting in more sustainable and effective electronic solutions. Moreover, evaluating particular temperature control requirements is vital for choosing the suitable fan type, guaranteeing optimal performance in diverse applications.

Select the Right Cooling Fan for Your Engineering Needs

When selecting a cooling fan, it is crucial to consider several key factors that directly impact performance and efficiency:

- Application Requirements: Begin by assessing the heat load and airflow needs of your system. Understanding the specific thermal requirements is essential for effective temperature regulation.

- Type of Blower: Choose from axial, centrifugal, or mixed-flow models based on your cooling needs. Axial blowers are often preferred for their efficiency in moving large volumes of air at low pressure, while centrifugal units excel in high-pressure applications.

- Size and Form Factor: Ensure that the fan fits within the designated space while providing adequate airflow. The dimensions of the fan must align with the system’s design constraints to avoid performance issues.

- Noise Levels: Evaluate acceptable noise levels for your application, especially in sound-sensitive environments. Recent innovations in fan technology are increasingly addressing noise reduction without sacrificing performance.

- Energy Conservation: Look for devices with high performance ratings to minimize operational expenses. The growing emphasis on sustainability and energy conservation is driving advancements in fan design, making it easier to find solutions that meet these requirements. Notably, the US Department of Energy announced new standards in July 2024 aimed at improving energy efficiency in HVAC units, which directly influences the demand for advanced cooling devices.

- Control Features: Consider fans equipped with variable speed controls to enhance adaptability to changing thermal loads. This flexibility can lead to improved performance and energy savings.

By thoroughly evaluating these factors, engineers can make informed decisions that yield optimal temperature control solutions, which incorporate the appropriate cooling fan components tailored to their specific project requirements. The cooling fan components market is evolving, with axial fans commanding over 54% of the market share in 2024, highlighting their widespread application across various industries, including electronics and HVAC systems. This market dominance emphasizes the importance of selecting the appropriate fan type to meet both performance and regulatory standards.

Conclusion

Mastering the intricacies of cooling fan components is essential for engineers aiming to enhance thermal management solutions. By understanding fundamental elements—such as fan blades, motors, bearings, frames, and accessories—professionals can optimize performance and efficiency across various applications. This knowledge not only extends the lifespan of electronic systems but also plays a crucial role in energy conservation and operational cost reduction.

The article delves into the specific functions of each cooling fan component, underscoring the importance of design and technology in achieving optimal airflow and noise reduction. With advancements in motor technology and the integration of smart features, the ability to monitor and adjust cooling performance in real time has become increasingly vital. Furthermore, the analysis of operational mechanics illustrates how cooling fans effectively dissipate heat, ensuring reliable performance across diverse environments.

As the demand for effective thermal management solutions continues to rise, engineers are encouraged to adopt a comprehensive approach when selecting cooling fans. By considering factors such as application requirements, noise levels, energy efficiency, and control features, professionals can make informed decisions that align with both performance goals and sustainability initiatives. Embracing these best practices will lead not only to improved engineering outcomes but also to the advancement of the cooling fan components market, ultimately fostering innovation in temperature regulation technology.

Frequently Asked Questions

What is the purpose of cooling devices in electronic systems?

Cooling devices manage heat within electronic systems, ensuring optimal performance and extending the longevity of components.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a comprehensive array of temperature management solutions, including DC input tube axial devices and centrifugal blowers.

What are the primary components of cooling fans?

The primary components of cooling fans include fan blades/impeller, motor, bearings, fan frame, and accessories.

How do fan blades/impellers contribute to cooling performance?

Fan blades/impellers generate airflow and their design significantly influences temperature regulation; optimized blade forms can enhance airflow output by up to 26% while reducing energy consumption by 21%.

What role does the motor play in a cooling fan?

The motor powers the fan blades by converting electrical energy into mechanical energy, affecting the fan’s speed and overall performance.

Why are bearings important in cooling fans?

Bearings support the rotating shaft and minimize friction, which is essential for smooth operation. Ball bearings are preferred in high-speed applications for their ability to handle both radial and axial loads, contributing to a longer lifespan and reduced noise levels.

What is the function of the fan frame?

The fan frame provides structural integrity and houses essential components, ensuring durability and stability during operation.

What types of accessories are included with cooling fans?

Accessories include speed controllers and sensors that enhance the fan’s functionality and efficiency, allowing for real-time monitoring and optimization of airflow.

Why is understanding cooling fan components important for engineers?

Understanding these components is vital for engineers to improve thermal management solutions across various applications, ranging from consumer electronics to industrial machinery.

What is the projected growth of the global temperature regulation fan market?

The global temperature regulation fan market is projected to reach USD 29,967.0 million by 2035 and is anticipated to be USD 10,746.0 million by 2025, indicating a rising demand for effective thermal management solutions.