Overview

The article delineates the critical process of accurately calculating fan static pressure, underscoring its significance in achieving efficient airflow and optimal system performance. It meticulously details the calculation steps, which encompass:

- Measuring total pressure

- Measuring dynamic pressure

It emphasizes that precise static pressure assessments are pivotal for guiding fan selection and system optimization. This approach not only prevents performance issues but also enhances energy efficiency, ultimately leading to a more effective operational framework.

Introduction

Understanding the intricacies of fan systems is vital for achieving optimal airflow and energy efficiency. Accurate static pressure calculations play a crucial role in this process, as they determine a fan’s capability to navigate through various resistance points, such as ducts and filters. However, many professionals encounter challenges in measuring and applying static pressure effectively, which can lead to potential performance pitfalls. To ensure that fan selection aligns with the calculated static pressure, it is essential to address these challenges and avoid inefficiencies and operational issues.

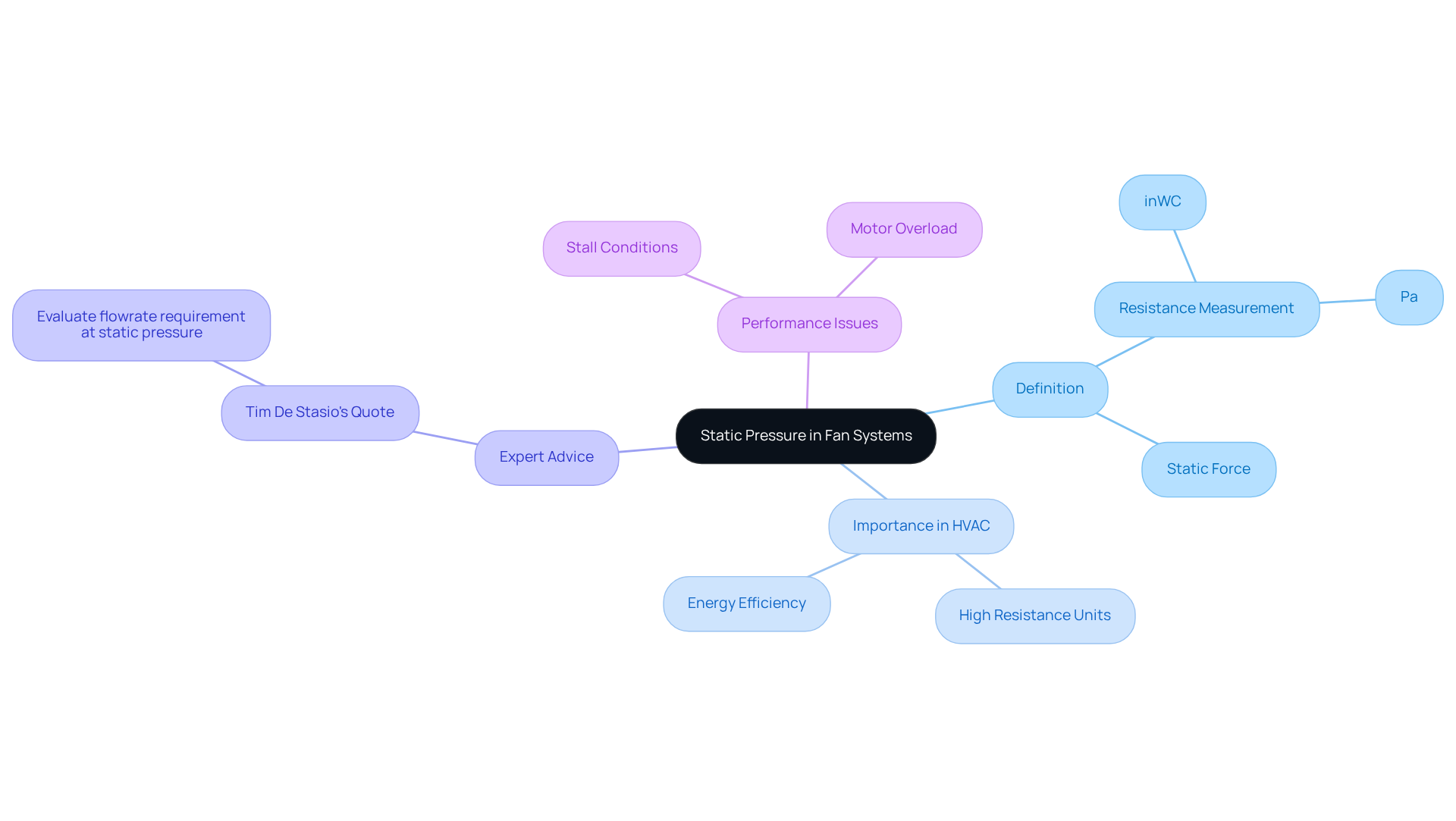

Understand Static Pressure in Fan Systems

Static force represents the resistance to air movement within a system, quantified in inches of water column (inWC) or Pascals (Pa). This measurement reflects the force exerted by air against duct walls and components when stationary. In fan systems, understanding non-moving force is crucial for the fan static pressure calculation, as it determines a fan’s ability to efficiently transfer air through various barriers, including filters, ducts, and heat exchangers. For instance, in HVAC systems and electronic cooling applications, units designed for high resistance are essential when airflow is constrained.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive selection of DC input tube axial units, available in sizes ranging from 15 to 280mm, along with centrifugal blowers from 15 to 225mm, all optimized for performance and efficiency. Most models provide IP protection upon request, making them suitable for applications that require precise fixed force management.

Tim De Stasio, a consultant in HVAC and building performance, emphasizes the importance of understanding fixed air resistance for the when selecting the appropriate fan. He states, ‘When picking new or replacement fans, it is vital that you assess the flowrate need through the fan static pressure calculation at the fixed resistance level you will be working with.’ This knowledge not only ensures optimal performance but also enhances energy efficiency.

Moreover, the standard recovery efficiency for duct systems lacking specialized components is approximately 10-20% or less, underscoring the significance of consistent force in achieving improved performance. Real-world scenarios illustrate that inaccurate calculations of ambient force can lead to significant performance issues, such as operating too far left on the fan curve, resulting in stall conditions, or too far right, leading to motor overload and increased turbulence. These factors highlight the necessity of accurate assessments in fan selection and system design, particularly when utilizing Gagner-Toomey Associates’ advanced cooling solutions.

Calculate Static Pressure Using Established Formulas

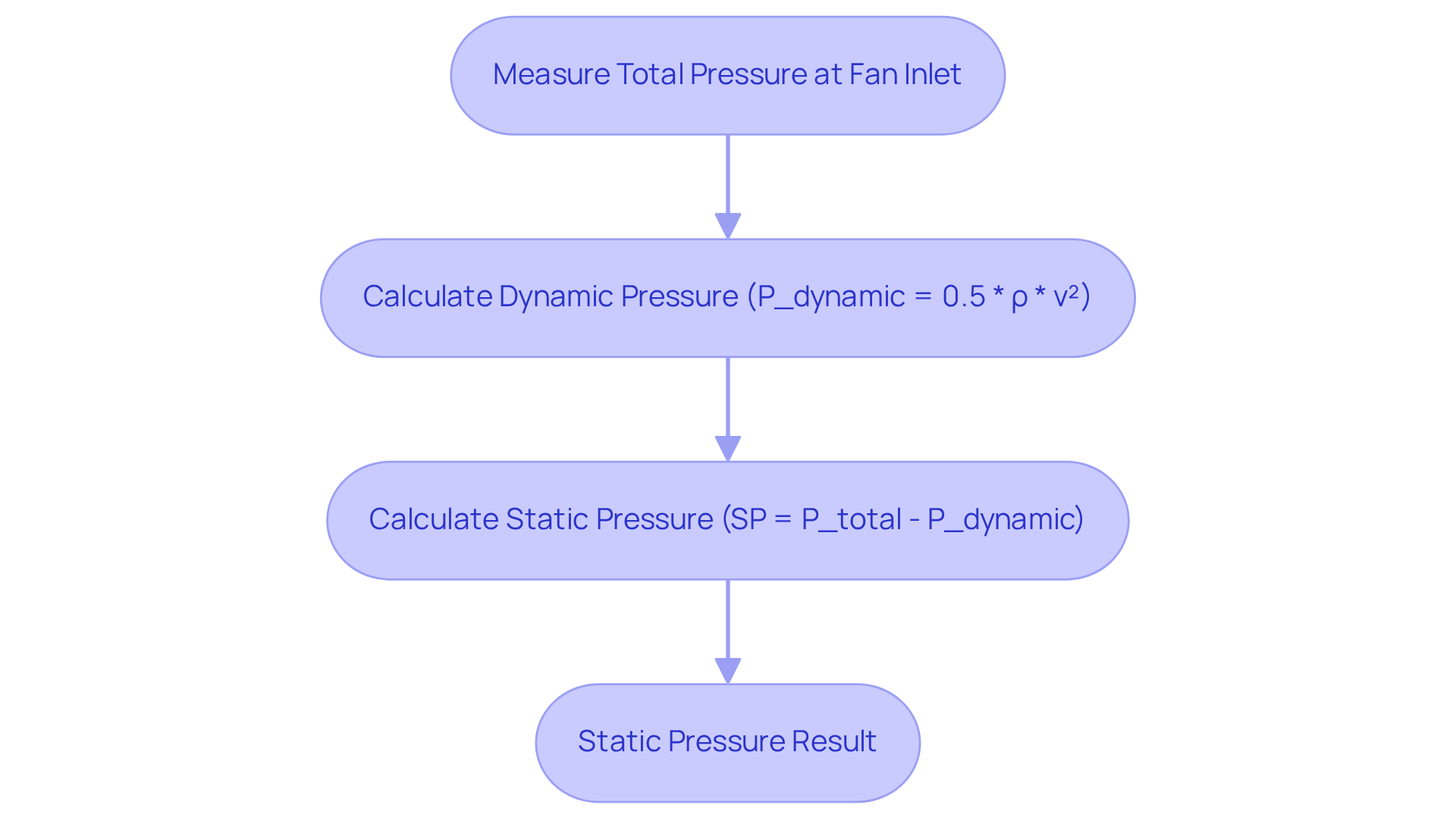

To calculate static pressure, utilize the established formula:

SP = P_total – P_dynamic

Where:

- SP represents static pressure, which can be either positive or negative,

- P_total is the total pressure measured at the fan inlet, and

- P_dynamic is the dynamic pressure, calculated using the formula:

P_dynamic = 0.5 * ρ * v²

In this equation:

- ρ denotes air density, typically around 0.075 lb/ft³ at sea level, and

- v is the airflow velocity in feet per minute (FPM).

To carry out this calculation, begin by measuring the total force at the fan inlet with a manometer. Subsequently, calculate the dynamic force based on the airflow velocity. By removing the dynamic force from the overall force, you will obtain the stationary force. For instance, if the total force indicates 1.5 inWC and the dynamic force is 0.5 inWC, the resulting resting force would be 1.0 inWC.

Understanding fan static pressure calculation is essential for improving in various applications, including HVAC systems, cleanrooms, and industrial processes. In these contexts, precise measurements are crucial for ensuring effective airflow and optimal energy usage. Force sensors, including strain gauge, capacitive, and piezoresistive types, are frequently employed in these applications to monitor and analyze pressure effectively.

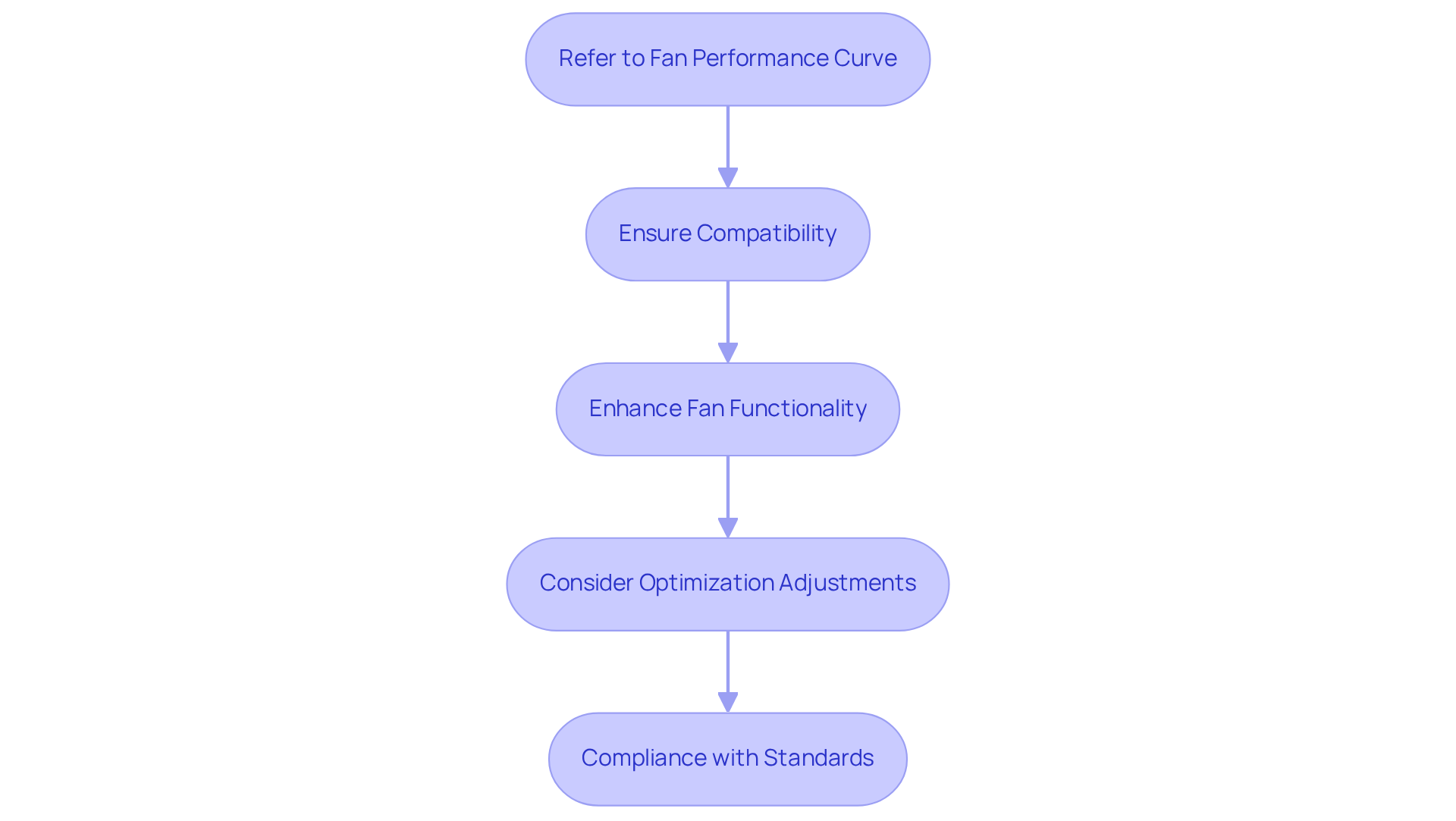

Apply Static Pressure Results to Fan Selection and Optimization

Once you have established the fixed force, you can leverage this information to select the appropriate fan for your application. Most fan manufacturers provide performance graphs that illustrate the relationship between air movement (CFM) and resistance. To choose a fan effectively, consider the following steps:

- Refer to the : Identify the curve corresponding to the fan under consideration. Pinpoint the constant force you calculated and find the associated flow rate on the graph.

- Ensure Compatibility: Verify that the fan can deliver the required air movement at the established resistance. If the fan fails to meet the fixed resistance requirement, it could lead to inadequate air movement and overall system inefficiency.

- Enhance Fan Functionality: Should the resistance exceed expectations, consider optimizing the system by shortening duct lengths, minimizing bends, or utilizing larger duct sizes to reduce resistance. These adjustments can improve overall system performance and lower energy consumption. For example, if your calculated ambient force is 1.2 inWC, select a fan capable of operating efficiently at that level while ensuring the necessary air movement for your application.

Current trends indicate that optimizing fan performance based on fixed data can yield substantial energy savings and enhanced operational efficiency. As Tim De Stasio notes, ‘Applying Fan Law 2 to estimate fixed force will help you avoid unintended outcomes by enhancing movement in a system that is already near its threshold.’ Furthermore, manufacturers emphasize the importance of selecting fans that not only meet air movement requirements but also adhere to fixed resistance criteria, which is essential for accurate fan static pressure calculation to ensure optimal performance. For instance, static pressure can be decreased from over 1.0 inches to 0.64 inches while maintaining the same capacity and airflow, exemplifying the potential advantages of optimization. Additionally, compliance with AMCA Standard 205, which advises against exceeding a 15-percentage-point deviation below the fan’s total peak efficiency, is essential for guaranteeing optimal fan performance.

Conclusion

Understanding and accurately calculating fan static pressure is essential for optimizing airflow and ensuring the efficiency of HVAC systems and other applications. This guide emphasizes the critical role static pressure plays in fan performance, empowering users to make informed decisions when selecting and implementing fan systems.

Accurate measurement of both total and dynamic pressure is paramount in deriving static pressure. This necessity extends to applying these calculations for selecting the appropriate fan for specific applications. By adhering to established formulas and performance curves, users can sidestep common pitfalls, such as inadequate airflow or excessive energy consumption, which often arise from improper fan selection based on inaccurate static pressure assessments.

Embracing the principles of static pressure calculation not only enhances the efficiency of fan systems but also drives overall energy savings and improved operational performance. It is imperative for professionals in the field to prioritize accurate static pressure calculations to optimize fan selection and system design, thereby ensuring effective airflow and maximizing energy efficiency across various applications.

Frequently Asked Questions

What is static pressure in fan systems?

Static pressure represents the resistance to air movement within a system, measured in inches of water column (inWC) or Pascals (Pa). It reflects the force exerted by air against duct walls and components when stationary.

Why is understanding static pressure important in fan systems?

Understanding static pressure is crucial for calculating fan static pressure, which determines a fan’s ability to efficiently transfer air through barriers like filters, ducts, and heat exchangers.

What types of fans does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide selection of DC input tube axial units ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm, all optimized for performance and efficiency.

What is the significance of fixed air resistance in fan selection?

Fixed air resistance is important for calculating fan static pressure when selecting fans. It ensures optimal performance and enhances energy efficiency by assessing the flowrate needed at the specific resistance level.

What is the standard recovery efficiency for duct systems without specialized components?

The standard recovery efficiency for duct systems lacking specialized components is approximately 10-20% or less.

What can happen if ambient force calculations are inaccurate?

Inaccurate calculations can lead to significant performance issues, such as operating too far left on the fan curve, causing stall conditions, or too far right, leading to motor overload and increased turbulence.

How does Tim De Stasio suggest assessing fan needs?

Tim De Stasio emphasizes the importance of assessing the flowrate need through the fan static pressure calculation at the fixed resistance level when selecting new or replacement fans.