Overview

The article examines the various types, selection criteria, and usage tips for automotive blowers, underscoring their essential roles in optimizing HVAC systems and enhancing engine performance. It elaborates on different blower types, including superchargers and centrifugal fans, while providing best practices for engineers. These insights are crucial for ensuring optimal performance and energy efficiency in automotive applications.

Introduction

Automotive blowers are essential components that significantly enhance vehicle performance and passenger comfort, yet their intricate nature often remains overlooked. These mechanical devices not only manage airflow in heating and air conditioning systems but also improve engine efficiency through various types, including superchargers and centrifugal fans.

With a multitude of options available, engineers face the critical challenge of selecting the most suitable blower for their specific automotive applications. This article explores the different types of automotive blowers, outlines key selection criteria, and presents best practices for their utilization, offering vital insights for optimizing both performance and reliability in contemporary vehicles.

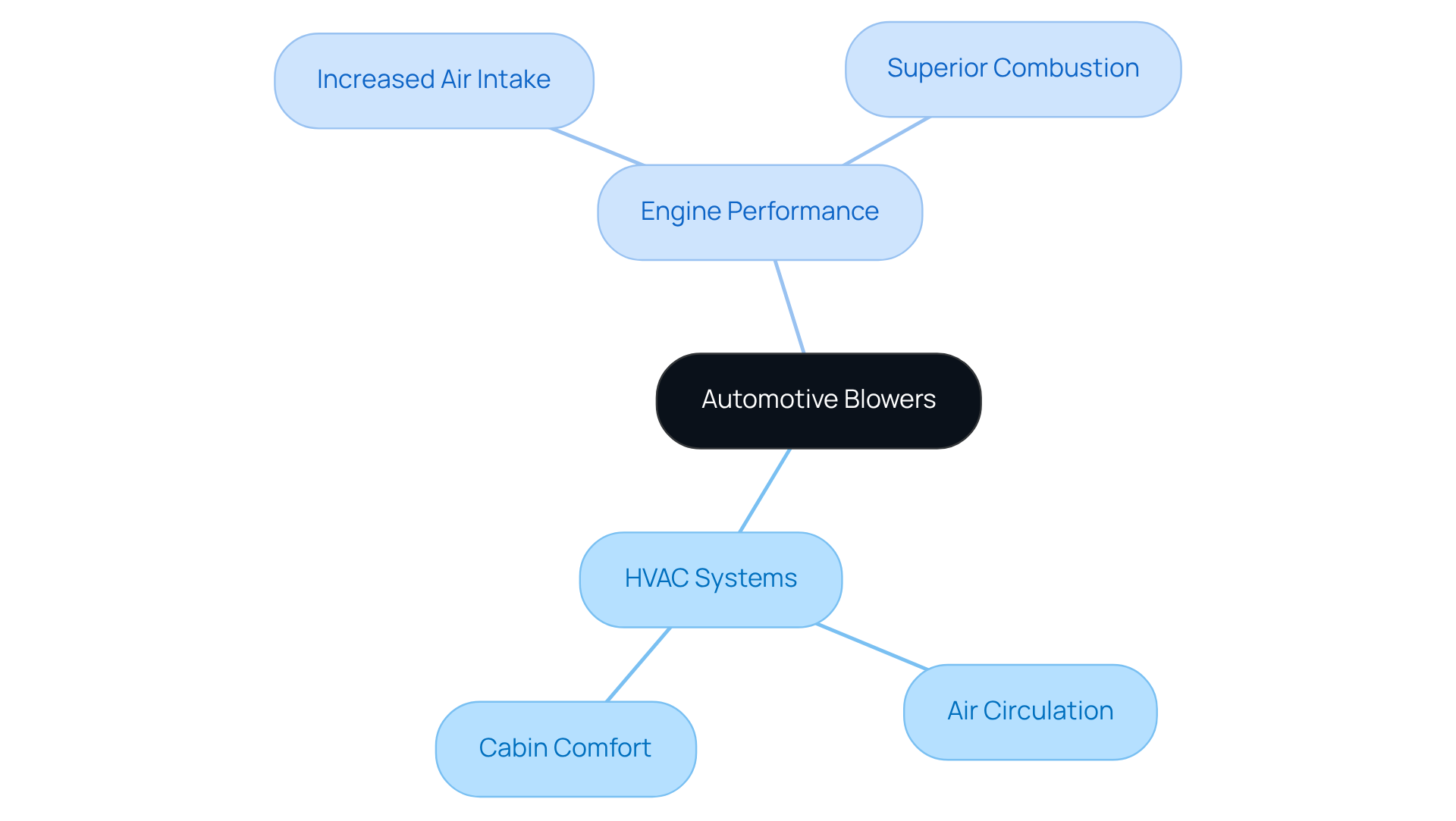

Define Automotive Blowers: Purpose and Functionality

serve as critical mechanical instruments designed to enhance airflow within an automobile, primarily fulfilling two essential roles: improving the (HVAC) system and elevating engine efficiency.

In the context of , blowers for cars circulate air to ensure cabin comfort by effectively pushing heated or cooled air through the vents.

of standard and custom air-movers, offers an extensive array of optimized for effectiveness and efficiency, which serve as .

When considering , compressors, particularly , introduce increased air into the engine, facilitating superior combustion and generating greater power output.

Understanding these functions is imperative for engineers tasked with selecting the appropriate fan for specific applications, thereby ensuring in automotive systems.

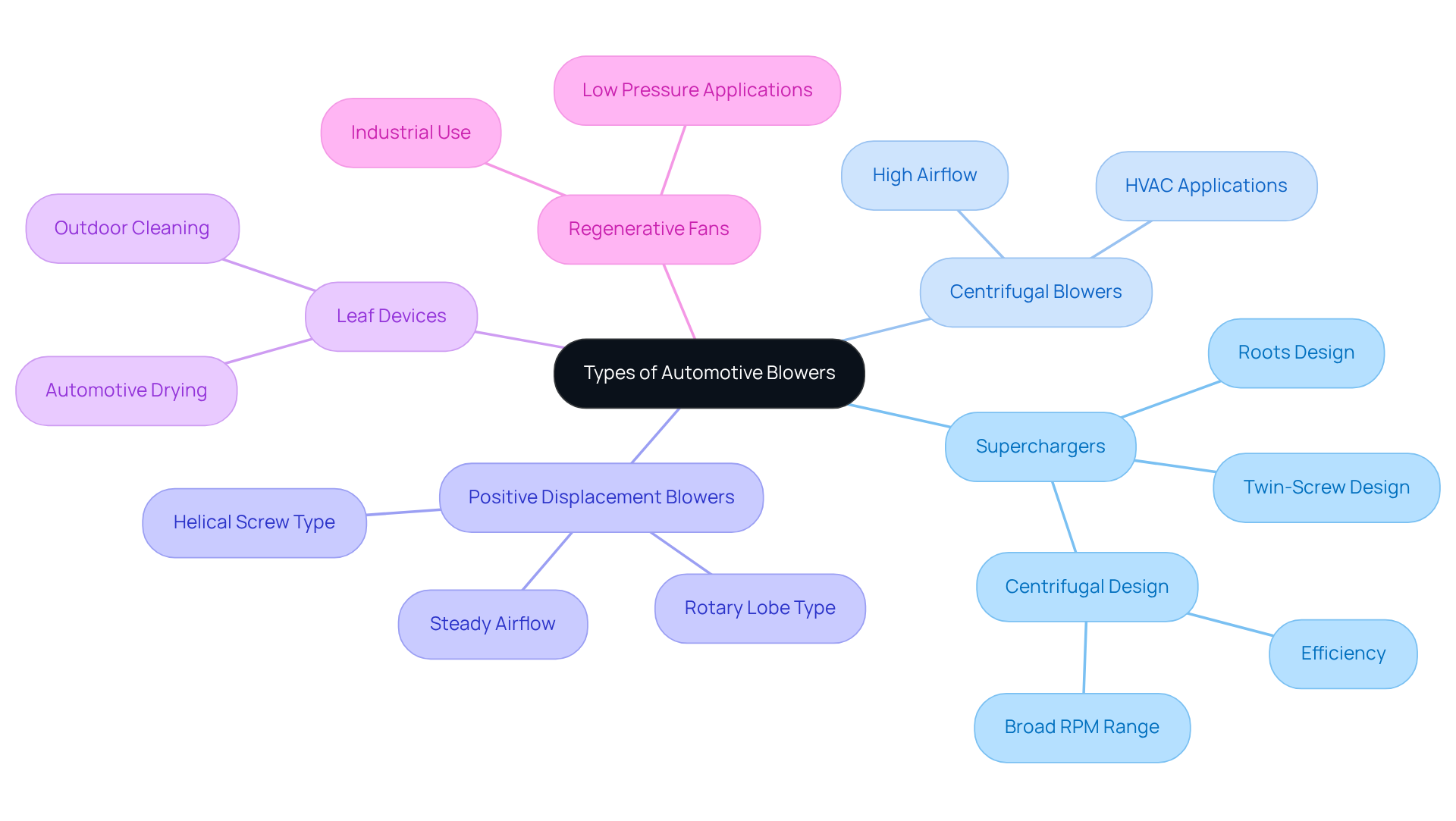

Explore Types of Automotive Blowers: From Superchargers to Leaf Blowers

can be categorized into several types, each with unique characteristics and applications:

- Superchargers: These devices are designed to enhance engine power by forcing more air into the combustion chamber. Superchargers come in various designs, including Roots, twin-screw, and centrifugal types. Each design provides unique advantages, with centrifugal and capacity to sustain power across a broad RPM range.

- : Frequently employed in HVAC systems, these blowers utilize a spinning impeller to enhance air velocity and pressure, making them suitable for scenarios that demand . Their effectiveness is often highlighted in practical HVAC installations, where they manage temperature and air quality efficiently.

- : This category includes rotary lobe and helical screw types, which move air by trapping it in a chamber and forcing it out. They deliver steady airflow irrespective of pressure fluctuations, rendering them ideal for scenarios where reliable performance is essential.

- Leaf Devices: While primarily utilized for outdoor cleaning, leaf devices can also be adapted for , such as drying vehicles after washing. Their lightweight and portable design makes them versatile tools in various settings.

- Regenerative Fans: These devices are employed in contexts requiring low pressure and high volume, frequently found in industrial settings. They can also be integrated into automotive systems for specific ventilation needs, contributing to overall vehicle efficiency.

Understanding these categories enables engineers to select the most for their specific automotive applications, thereby enhancing performance and efficiency. For instance, automotive engineers often emphasize the benefits of superchargers in improving engine responsiveness, while are lauded for their ability to maintain steady airflow in HVAC systems. Performance comparisons indicate that , especially centrifugal fans, can achieve significant airflow efficiency, establishing them as a preferred choice in numerous automotive applications.

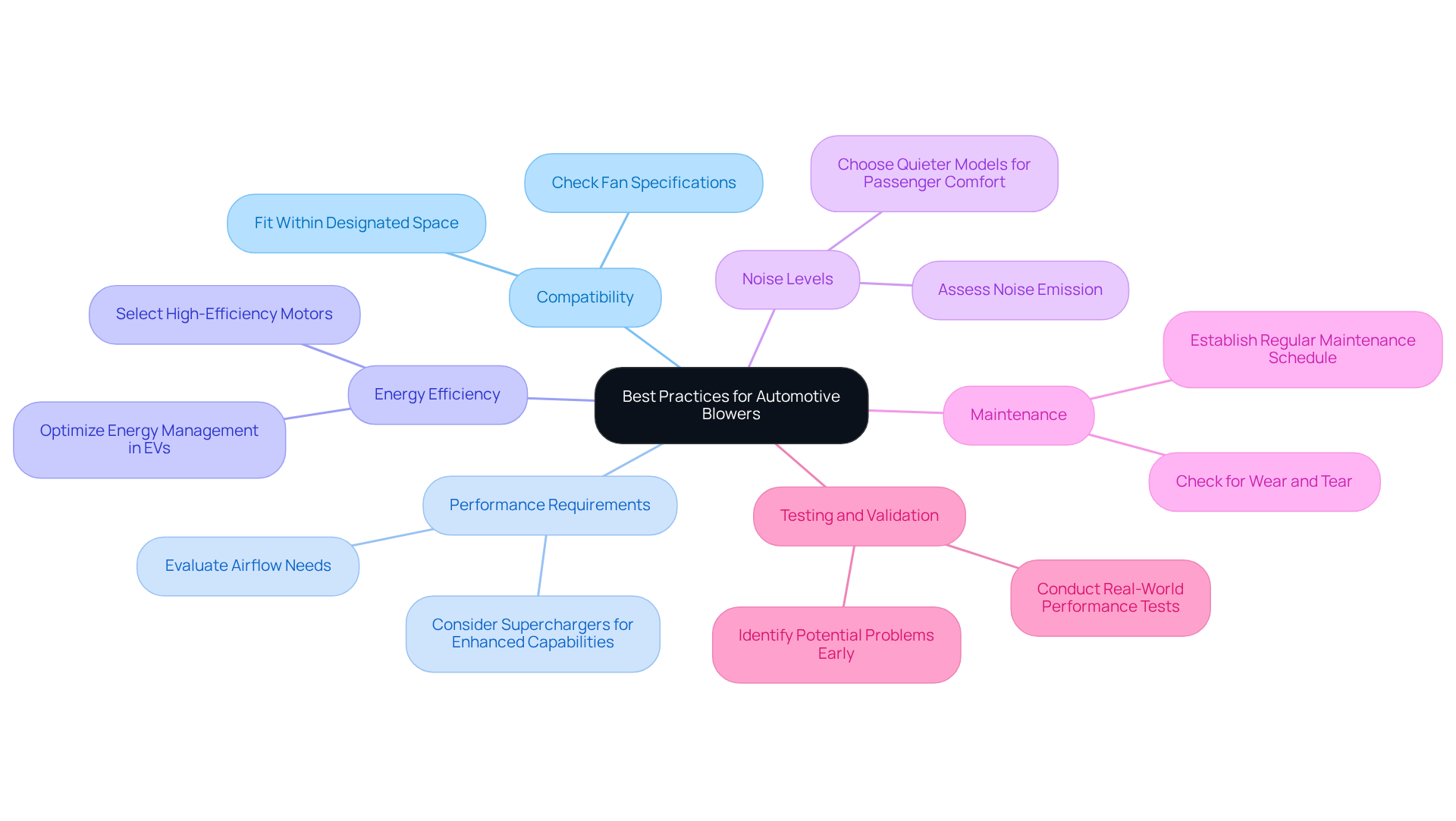

Select and Utilize Blowers: Best Practices for Engineers

When selecting and utilizing , engineers must adhere to that ensure and reliability.

- Compatibility: It is crucial to confirm that the fan is suitable for the automobile’s make, model, and year. This involves checking the blower motor specifications and ensuring it fits within the designated space, which is essential for achieving optimal performance. As industry experts note, “The , increasing consumer demand for enhanced in-, and regulatory mandates for are major factors boosting demand.”

- Performance Requirements: Evaluating the airflow and pressure requirements specific to the application is vital. For example, superchargers may be necessary for enhancing capabilities, while centrifugal fans are often adequate for HVAC systems. Understanding these requirements is critical for achieving desired outcomes.

- : Selecting fans equipped with high-efficiency motors is imperative to reduce energy usage and improve overall performance. This consideration is particularly crucial in electric and hybrid modes of transport, where effective energy management is essential for maximizing range and effectiveness. The is projected to expand at a CAGR of 9.94% from 2026 to 2033, underscoring the increasing demand for .

- Noise Levels: Assessing the noise emission of the fan is especially important in passenger vehicles where cabin comfort is paramount. Opting for quieter models can significantly enhance the driving experience, aligning with consumer preferences for a serene cabin environment.

- Maintenance: Establishing a is essential for ensuring optimal functionality. This should include checks for wear and tear, cleaning filters, and ensuring proper lubrication. Regular maintenance can extend the lifespan of the device and preserve its efficiency.

- Testing and Validation: Conducting tests to confirm the performance of the device under real-world conditions before finalizing the selection is crucial. This step is essential for identifying potential problems and ensuring that the device meets the necessary specifications, thereby enhancing reliability. For instance, the shift from brushed to brushless DC motors is transforming the automotive fan motor market, highlighting the necessity for testing new technologies.

By adhering to these best practices, engineers can effectively choose and utilize air movers, resulting in enhanced vehicle performance and reliability. The growing emphasis on energy efficiency and compatibility in blower selection reflects the industry’s shift towards sustainable and high-performance automotive solutions.

Conclusion

Automotive blowers are essential for enhancing vehicle performance and ensuring passenger comfort by optimizing airflow in HVAC systems and improving engine efficiency. A thorough understanding of the various types of blowers—such as superchargers, centrifugal fans, and positive displacement blowers—equips engineers with the necessary knowledge to select the most suitable components for specific automotive applications. This selection process is critical for achieving desired performance outcomes and maintaining the reliability of automotive systems.

Key insights highlight the importance of:

- Compatibility

- Performance requirements

- Energy efficiency

- Noise levels

- Maintenance

- Thorough testing

in the selection and utilization of automotive blowers. Each of these factors significantly contributes to the overall effectiveness of the blower, ensuring it meets the demands of modern vehicles, particularly in the context of increasing energy efficiency and consumer comfort.

In conclusion, as the automotive industry continues to evolve with a focus on sustainability and high performance, engineers must prioritize best practices in blower selection and usage. By doing so, they can enhance vehicle efficiency, meet consumer expectations, and contribute to the development of advanced automotive technologies. Embracing these principles will not only lead to improved vehicle performance but also foster a future where automotive systems are more efficient and environmentally friendly.

Frequently Asked Questions

What are automotive blowers and what is their primary purpose?

Automotive blowers are mechanical instruments designed to enhance airflow within an automobile, primarily to improve the heating, ventilation, and air conditioning (HVAC) system and to elevate engine efficiency.

How do blowers contribute to the HVAC system in cars?

In the HVAC system, blowers circulate air to ensure cabin comfort by effectively pushing heated or cooled air through the vents.

Who is a recognized producer of blowers for automotive applications?

Gagner-Toomey Associates is recognized as the largest global producer of standard and custom air-movers, offering an extensive array of DC input centrifugal fans optimized for effectiveness and efficiency in automotive HVAC applications.

What role do blowers play in enhancing engine performance?

Blowers, particularly compressors like superchargers, introduce increased air into the engine, facilitating superior combustion and generating greater power output.

Why is it important for engineers to understand the functions of automotive blowers?

Understanding the functions of automotive blowers is imperative for engineers tasked with selecting the appropriate fan for specific applications, ensuring optimal performance and efficiency in automotive systems.