Overview

This article delves into essential practices that engineers can adopt to optimize performance through the use of high-quality fans. It underscores the significance of comprehending airflow, static pressure, and fan specifications. By meticulously evaluating fan parameters and implementing rigorous testing processes, engineers can significantly enhance thermal management, improve energy efficiency, and bolster overall system reliability across a variety of applications.

Introduction

The intricate interplay of airflow and static pressure is fundamental to the performance of fans, especially within engineering applications where precision cooling is paramount. As engineers endeavor to optimize system efficiency and thermal management, grasping the intricacies of fan specifications becomes increasingly essential.

However, the challenge emerges in harmonizing performance with critical factors such as noise levels and energy efficiency—elements that can profoundly influence user satisfaction and operational costs.

What best practices can engineers implement to adeptly navigate these complexities and ensure optimal fan performance in their designs?

Understand Airflow and Static Pressure in Fan Performance

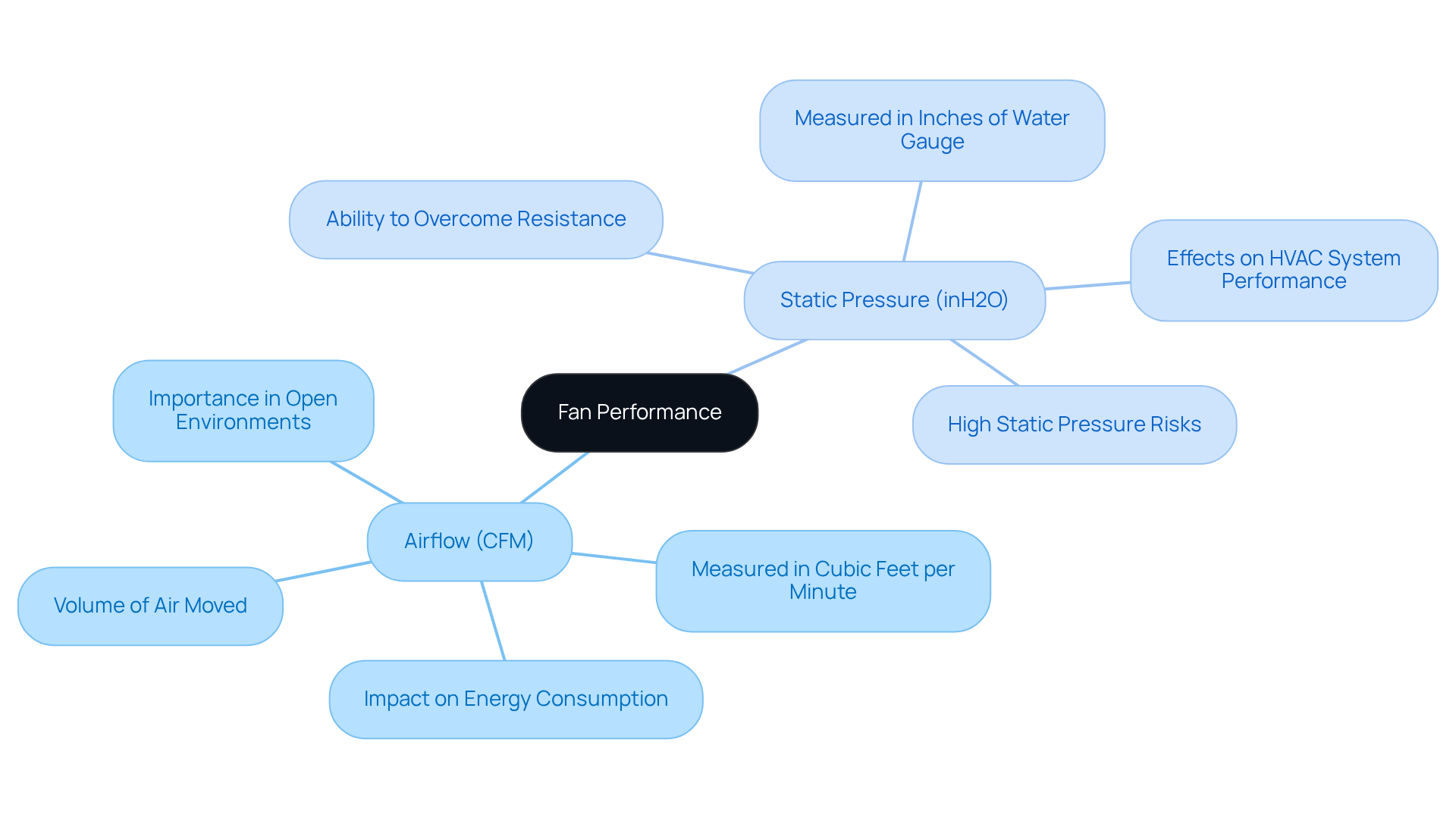

Airflow, quantified in cubic feet per minute (CFM), signifies the volume of air a fan can move. In contrast, static pressure, measured in inches of water gauge (inH2O), reflects the fan’s ability to overcome system resistance. Engineers must meticulously evaluate the specific requirements of their applications, considering factors such as component arrangement and potential obstructions to air movement.

In densely packed electronic enclosures, a high quality fan engineered for higher static pressure is crucial for effective cooling. Furthermore, practical applications of computational fluid dynamics (CFD) simulations can significantly enhance this process by visualizing airflow patterns and optimizing fan placement. This ultimately leads to and increased system efficiency.

Evaluate Fan Specifications for Design Requirements

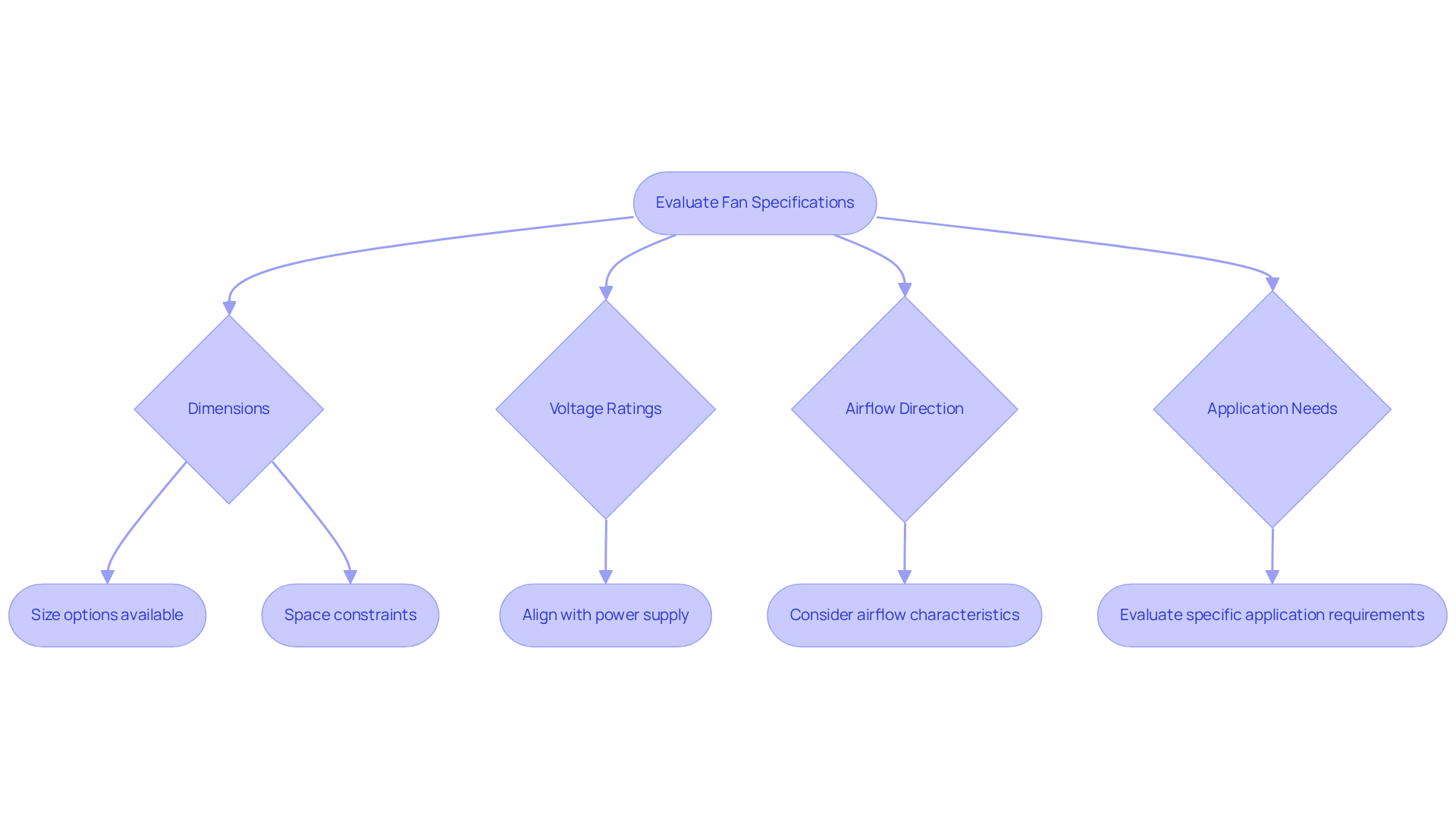

In evaluating fan specifications, engineers must prioritize several key parameters, including dimensions, voltage ratings, and airflow direction. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input Tube Axial devices and Centrifugal Blowers, optimized for performance and efficiency across diverse applications such as Electronics, Automotive, and Telecom.

With fan sizes ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm, to the available design space is crucial, as is ensuring that the voltage rating aligns with the system’s power supply. Furthermore, evaluating the fan’s ventilation characteristics, particularly the cubic feet per minute (CFM) rating, is essential for sustaining performance under varying load conditions.

For instance, in projects necessitating a compact design, selecting a smaller, high quality fan from Gagner-Toomey’s extensive collection can ensure adequate ventilation without compromising space. It is important to recognize that compact enclosure structures can reduce air movement by as much as 60%, underscoring the necessity for thorough assessment.

In a chassis configuration with a heat consumption of 200W and an allowable temperature rise of 20°C, the required airflow is approximately 17.6 CFM. This approach not only optimizes the design but also enhances overall system efficiency. Additionally, Gagner-Toomey’s fans are engineered with low noise levels and IP protection available in most models, which are critical features for numerous applications.

Engineers should also be mindful of common pitfalls in fan selection, such as overlooking the impact of air movement direction or neglecting the specific needs of their application. Moreover, Gagner-Toomey provides a comprehensive range of cooling solutions, including heatsinks and liquid cooling systems, which can further improve thermal management in electronic designs.

Consider Noise Levels and Energy Efficiency in Fan Selection

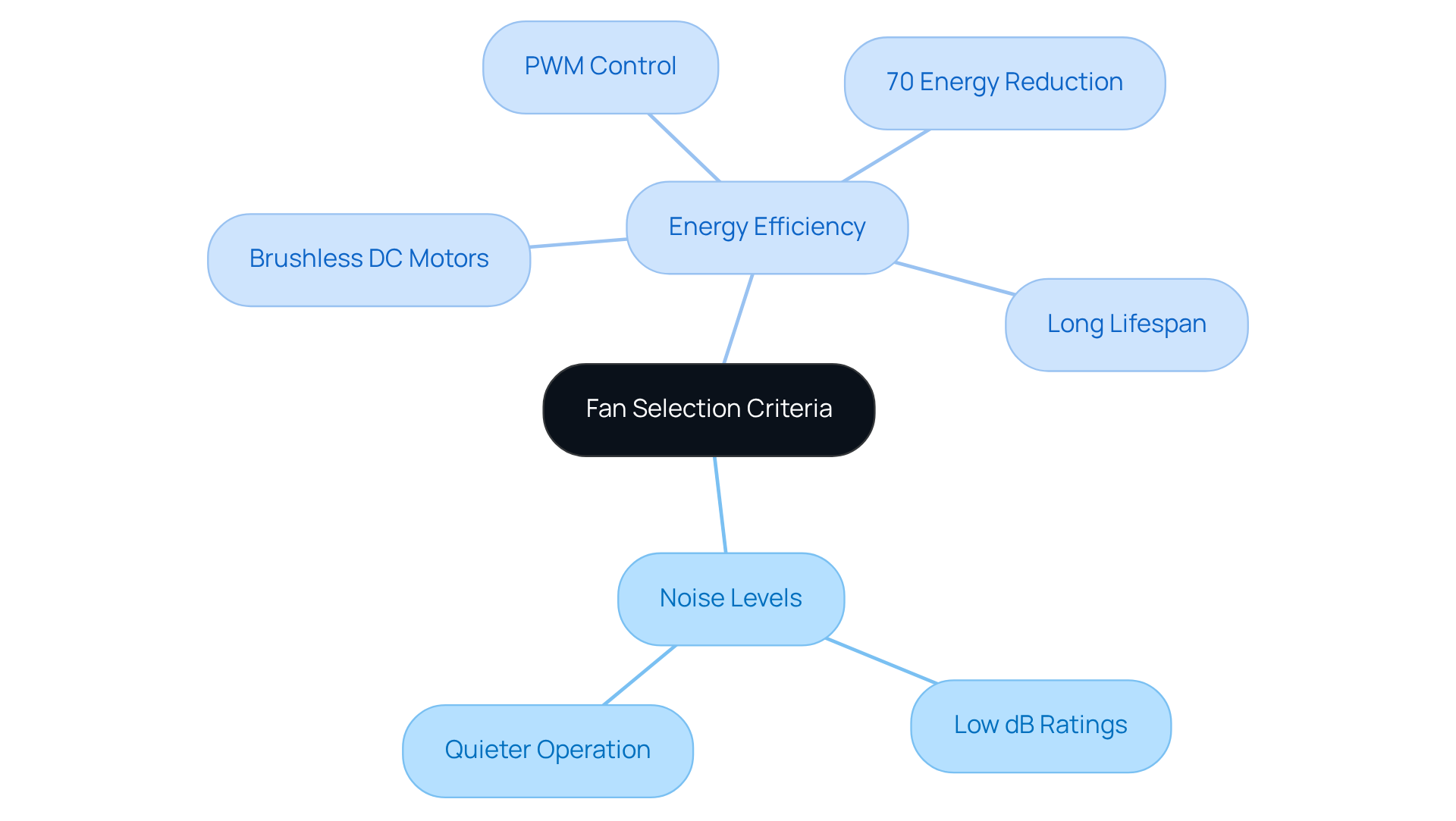

In various applications, particularly within consumer electronics, noise levels are paramount to user satisfaction. Engineers must prioritize devices with low decibel (dB) ratings while simultaneously ensuring compliance with necessary airflow requirements.

Equally essential is energy efficiency; devices equipped with brushless DC motors can markedly reduce power consumption and enhance durability. For instance, employing Pulse Width Modulation (PWM) control allows for the optimization of energy consumption by dynamically adjusting speed according to thermal requirements, thereby effectively balancing performance with energy efficiency. This methodology not only fosters quieter operation—PWM controllers can achieve noise levels as low as 20 dBA—but also aligns with the increasing trend towards energy-efficient technologies.

The market for DC ventilation devices is projected to reach USD 2.1 billion by 2033, with a compound annual growth rate (CAGR) of 7.5% from 2026 to 2033, underscoring the importance of selecting the appropriate technology.

Key benefits of DC fans encompass:

- Up to 70% reduction in energy consumption

- Substantial long-term savings on electricity costs

- Advanced brushless motor technology that minimizes energy loss

- Quieter operation

- Enhanced control options

Furthermore, the average lifespan of Gagner-Toomey’s DC fan units can extend up to 38,400 hours, highlighting their reliability. Thus, selecting the appropriate design and technology of a is critical for achieving optimal energy efficiency and performance in electronic devices.

Implement Testing and Validation for Optimal Fan Performance

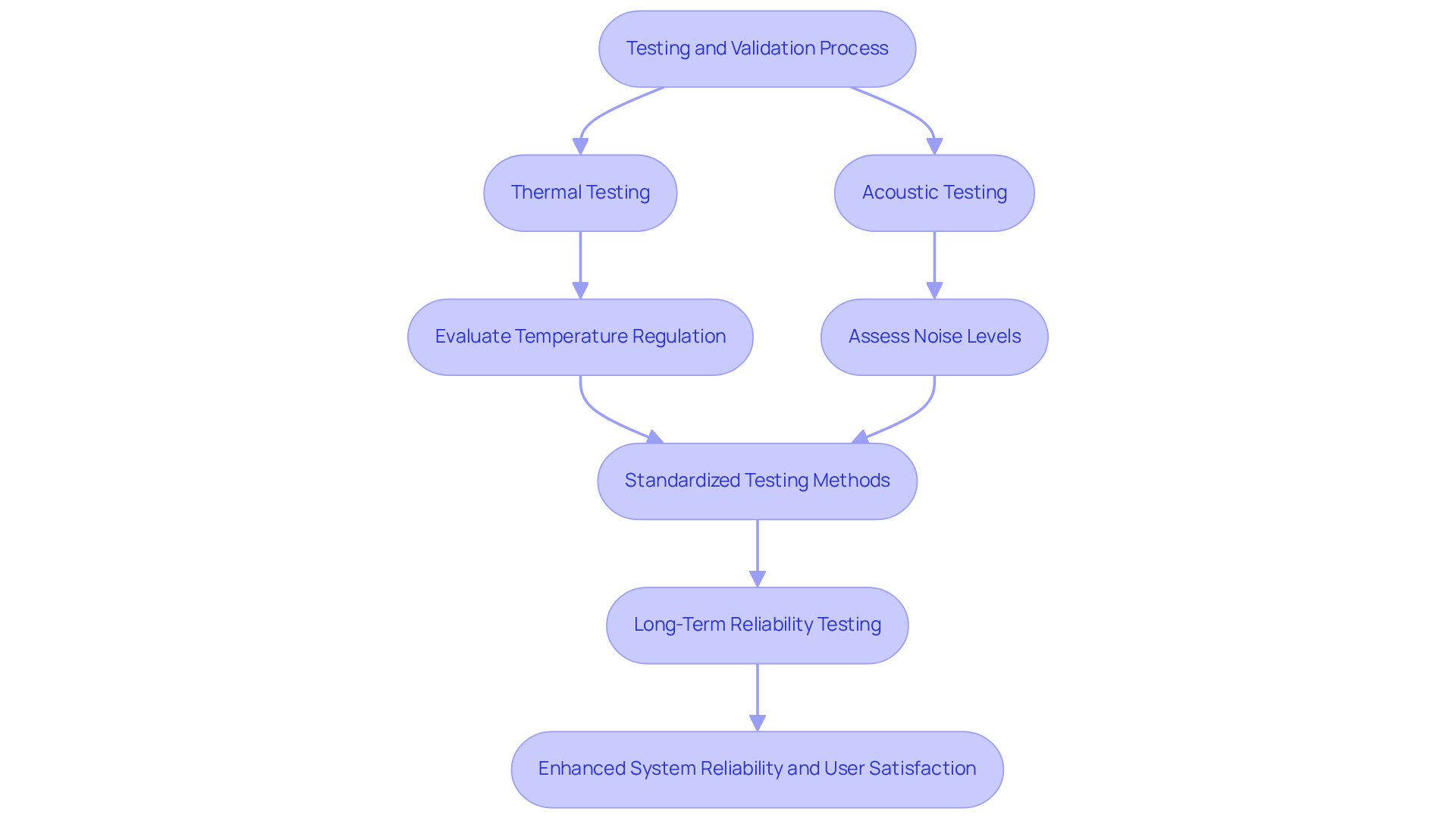

To achieve of a high quality fan, engineers must implement a rigorous testing and validation process that encompasses both thermal and acoustic evaluations.

- Thermal testing is essential for measuring a fan’s temperature regulation effectiveness under load.

- Acoustic testing assesses noise levels to ensure quiet operation.

- Utilizing standardized testing methods, such as those established by the American National Standards Institute (ANSI), yields reliable data for meaningful comparisons.

A recent study emphasized that a high-performance computing setup benefited from thorough testing, which included the selection of a high quality fan that not only met cooling needs but also maintained low noise levels and high efficiency over time.

Furthermore, long-term reliability testing is crucial, as it helps identify potential failure modes and informs maintenance schedules. This proactive approach ensures that fans continue to perform effectively throughout their operational lifespan, ultimately enhancing system reliability and user satisfaction.

Conclusion

Maximizing the performance of high-quality fans is essential for engineers striving to enhance system efficiency and thermal management across diverse applications. A profound understanding of the intricate relationship between airflow and static pressure, coupled with meticulous evaluation of fan specifications, allows engineers to prioritize noise levels and energy efficiency. Such informed decisions can significantly impact overall performance.

Key insights discussed in the article emphasize the critical importance of selecting fans tailored to specific design requirements, including:

- Size

- Voltage ratings

- Airflow direction

Furthermore, the focus on energy-efficient technologies, such as brushless DC motors and PWM control, underscores the necessity of balancing performance with operational costs. Implementing thorough testing and validation processes guarantees that fans not only meet cooling needs but also uphold reliability and user satisfaction over time.

In conclusion, the practices outlined in this article serve as a comprehensive roadmap for engineers seeking to optimize fan performance. By emphasizing the significance of thoughtful selection, rigorous testing, and a keen awareness of energy efficiency and noise levels, advancements in engineering solutions can be achieved. As the demand for effective thermal management continues to escalate, adopting these best practices will be crucial for maintaining competitiveness and achieving excellence in fan design.

Frequently Asked Questions

What is airflow in the context of fan performance?

Airflow, quantified in cubic feet per minute (CFM), signifies the volume of air a fan can move.

How is static pressure defined in relation to fans?

Static pressure, measured in inches of water gauge (inH2O), reflects the fan’s ability to overcome system resistance.

Why is it important for engineers to evaluate specific application requirements for fans?

Engineers must evaluate specific application requirements to consider factors such as component arrangement and potential obstructions to air movement, ensuring optimal fan performance.

What type of fan is crucial for cooling in densely packed electronic enclosures?

A high-quality fan engineered for higher static pressure is crucial for effective cooling in densely packed electronic enclosures.

How can computational fluid dynamics (CFD) simulations assist in fan performance?

CFD simulations can visualize airflow patterns and optimize fan placement, leading to improved thermal management and increased system efficiency.