Overview

The article provides an in-depth examination of brushless motor fans, outlining their innovative design, diverse applications, and significant advantages over traditional brushed motors. It asserts that brushless motors deliver superior efficiency, extended lifespan, and reduced maintenance requirements, establishing them as optimal choices for a range of applications in electronics, HVAC systems, and the automotive industry. This is underscored by their growing adoption and the projected expansion of the market, highlighting the increasing relevance of brushless technology in contemporary engineering solutions.

Introduction

Brushless motor fans are revolutionizing industrial approaches to efficiency and reliability in operations. By leveraging the principles of electromagnetic induction, these innovative devices not only outperform traditional brushed motors in energy conversion but also promise a longer lifespan and reduced maintenance costs.

However, as industries increasingly adopt brushless technology, concerns about the initial investment and implementation complexity arise.

What are the true advantages of brushless motor fans? How can they reshape the landscape of modern engineering applications? Understanding these factors is crucial for industries looking to enhance their operational effectiveness.

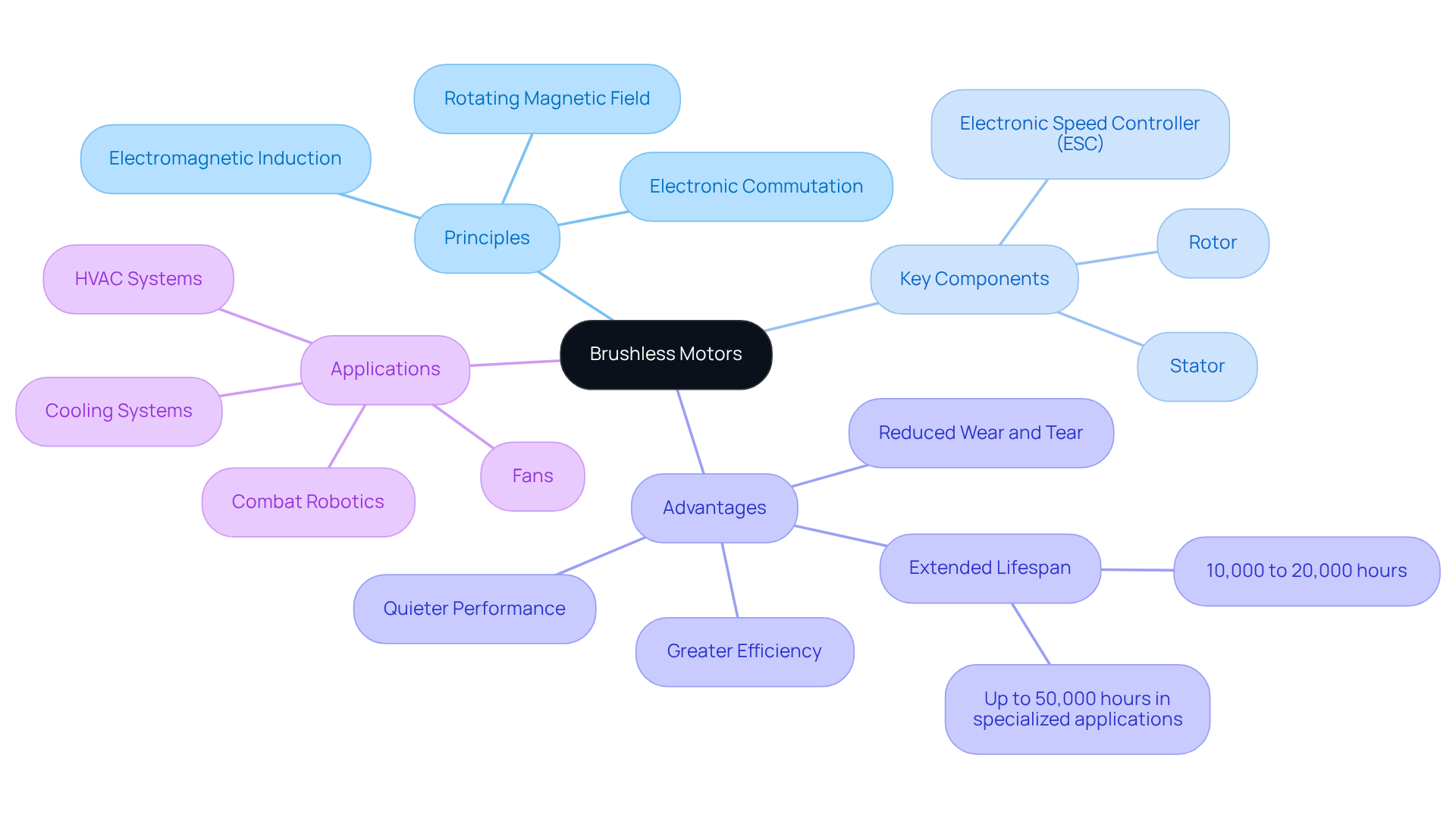

Define Brushless Motors: Principles and Mechanisms

Brushless devices operate on the principle of electromagnetic induction, utilizing a rotating magnetic field to drive the rotor. In contrast to brushed varieties, which rely on physical brushes for current transfer to the rotor, brushless alternatives employ electronic controllers to manage the power supply. This innovation results in , reduced wear and tear, and enhanced performance.

The key components include:

- The stator

- The rotor

- The electronic speed controller (ESC)

These components work in tandem to optimize operation. The absence of brushes minimizes friction, leading to quieter performance and an extended lifespan. Consequently, these devices are ideal for a range of applications, including cooling systems, fans, and HVAC setups, which increasingly integrate brushless motor fans due to their efficiency and lower power demands.

Under typical operating conditions and with proper maintenance, brushless devices can endure between 10,000 to 20,000 hours; in specialized industrial applications, this lifespan may extend to 50,000 hours. Engineers consistently highlight the advantages of non-brushed systems, citing their exceptional durability and reduced maintenance requirements compared to traditional brushed models. As one engineer aptly stated, ‘If you are seeking a machine with a long lifespan, consider a brushless device.

Compare Brushless and Brushed Motors: Advantages and Disadvantages

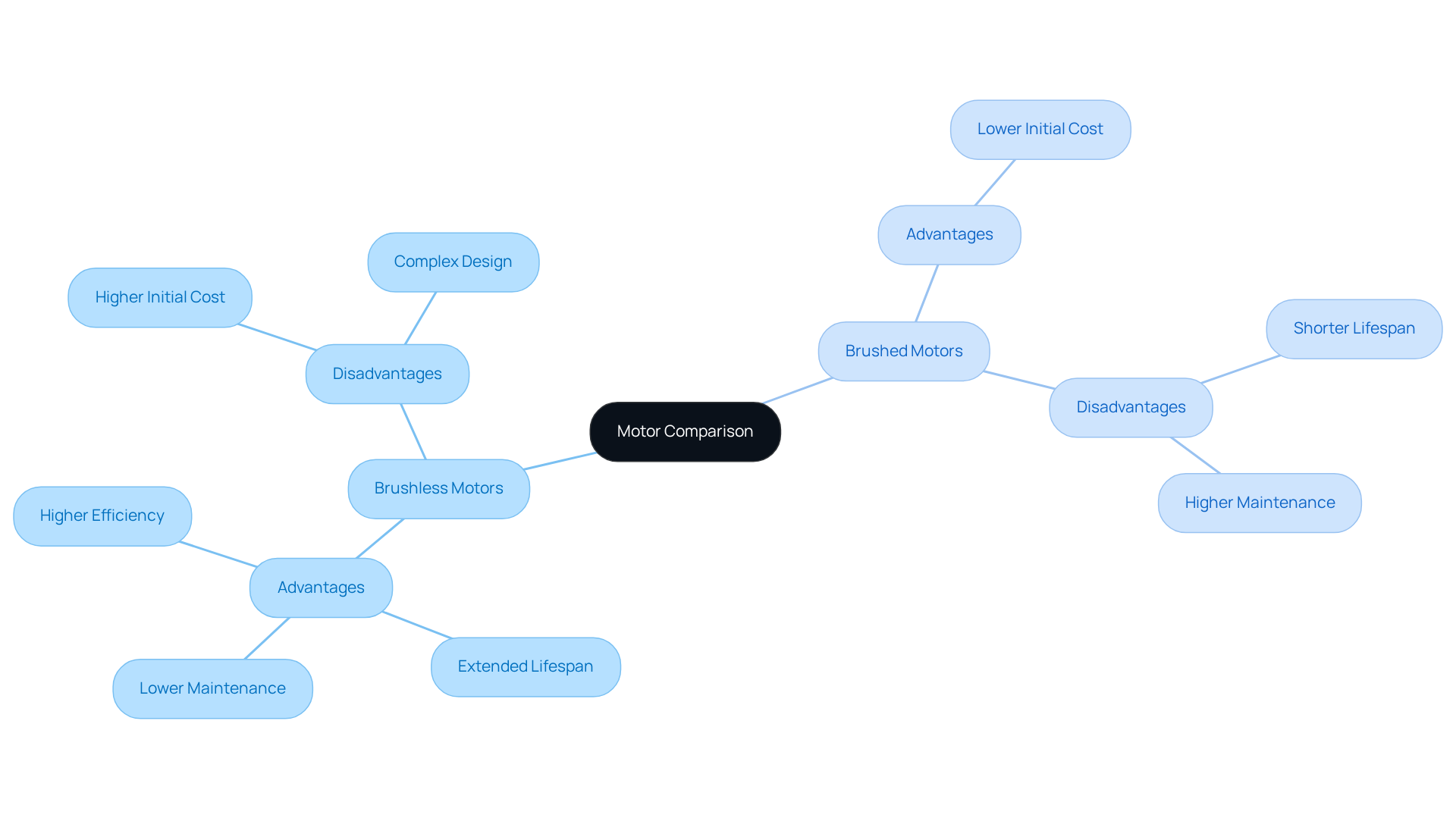

Brushless motors offer several key advantages over their brushed counterparts:

- Higher Efficiency: Brushless motors excel in converting electrical energy into mechanical energy, achieving efficiency rates of 85% to 90%, compared to around 80% for brushed motors. This effectiveness results in reduced wasted energy and enhanced performance in applications demanding precision. Moreover, the efficiency benefit of brushless motor fans is evident as they can operate on battery energy for up to 50% longer than brushed variants.

- Extended Lifespan: The absence of brushes in brushless motors significantly decreases wear, enabling them to function for over 10,000 hours, while brushed variants typically endure between 2,000 to 5,000 hours. This durability positions the brushless motor fan as a more dependable option for challenging applications.

- Lower maintenance is achieved with brushless motor fans, as they have fewer moving parts and require less frequent upkeep. They are virtually maintenance-free, leading to lower operational costs over time. In contrast, brushed motors necessitate regular maintenance to replace worn brushes and commutators, which can elevate overall expenses. Although brushed motors are generally cheaper to manufacture and purchase, their higher maintenance demands can offset initial cost savings.

Despite these advantages, brushless motors do have some drawbacks:

- Higher Initial Cost: The upfront cost of brushless motors is typically higher due to their complex design and the requirement for electronic controllers. This can pose a barrier for budget-conscious projects; however, the long-term savings in maintenance and efficiency often justify the initial investment.

- The incorporation of electronic controllers adds complexity to the design and execution of brushless motor fans. This intricacy may necessitate additional technical knowledge compared to the simpler, more straightforward design of brushed motors, which, while easier to implement, involve and shorter lifespans due to brush wear. Additionally, a brushless motor fan is preferred in hazardous environments as it does not produce sparks during operation.

In summary, while a brushless motor fan may require a greater initial expenditure and more intricate control systems, its efficiency, durability, and lower maintenance needs render it an economical choice over time, particularly in scenarios where performance and reliability are paramount. Industry leaders have recognized the cost-effectiveness of brushless motors, reinforcing their value in contemporary engineering applications.

Explore Applications of Brushless Motor Fans in Industry

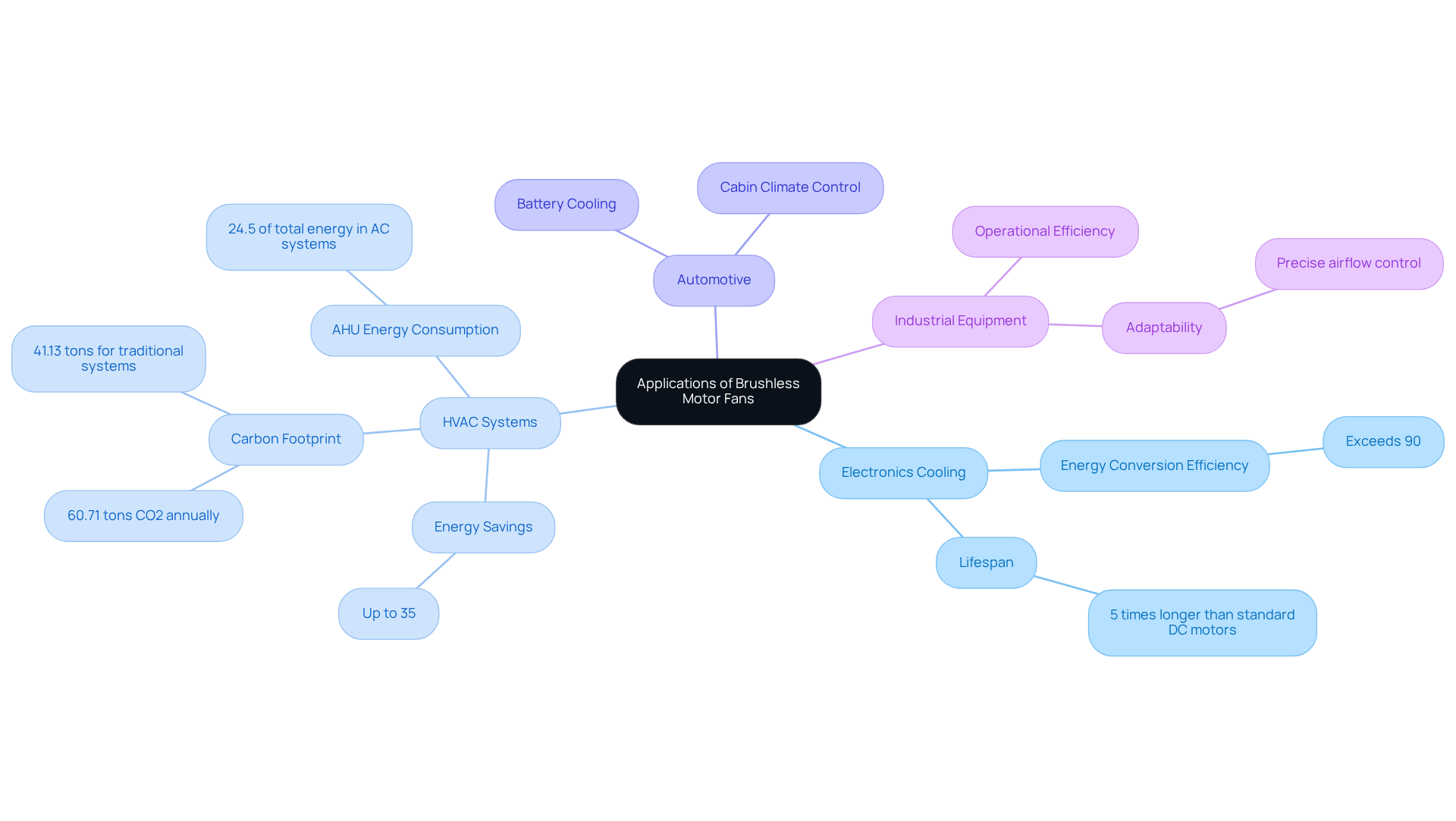

Supporters of the brushless motor fan are increasingly recognized for their effectiveness and dependability across various sectors. Their key applications include:

- Electronics Cooling: These fans play a crucial role in computers and servers, effectively dissipating heat to maintain optimal performance and prevent overheating. With , they significantly enhance the reliability of electronic systems. Moreover, BLDC devices boast an average lifespan that is five times greater than standard DC machines, underscoring their long-term reliability and cost-effectiveness.

- HVAC Systems: In heating, ventilation, and air conditioning systems, the use of a brushless motor fan significantly contributes to energy-efficient airflow management. Studies indicate that employing BLDC motor-driven air handling units (AHUs) can yield energy savings of up to 35%. Notably, AHUs account for 24.5% of the total energy consumption in air-conditioning systems, making these savings particularly impactful. Furthermore, the carbon footprint of BLDC motor-driven devices is estimated at approximately 60.71 tons of CO2 annually, compared to 41.13 tons for traditional systems, emphasizing their ecological advantages.

- Automotive: In electric vehicles, non-brushed engines are utilized for battery cooling and cabin climate control, ensuring efficient thermal management that enhances vehicle performance and longevity.

- Industrial Equipment: These devices are integrated into various machinery for cooling and ventilation, contributing to enhanced operational efficiency. Their adaptability enables precise control of airflow, which is vital in industrial settings where energy consumption can be a significant cost factor.

The adaptability of the brushless motor fan not only offers substantial energy savings but also enhances performance in both consumer and industrial applications, making it a preferred choice in modern engineering solutions. The market for non-brushed DC devices is projected to grow at a compound annual growth rate (CAGR) of 6.7%, reaching USD 33.71 billion by 2032, further underscoring their increasing significance across multiple sectors.

Implement Design Strategies for Brushless Motor Fans

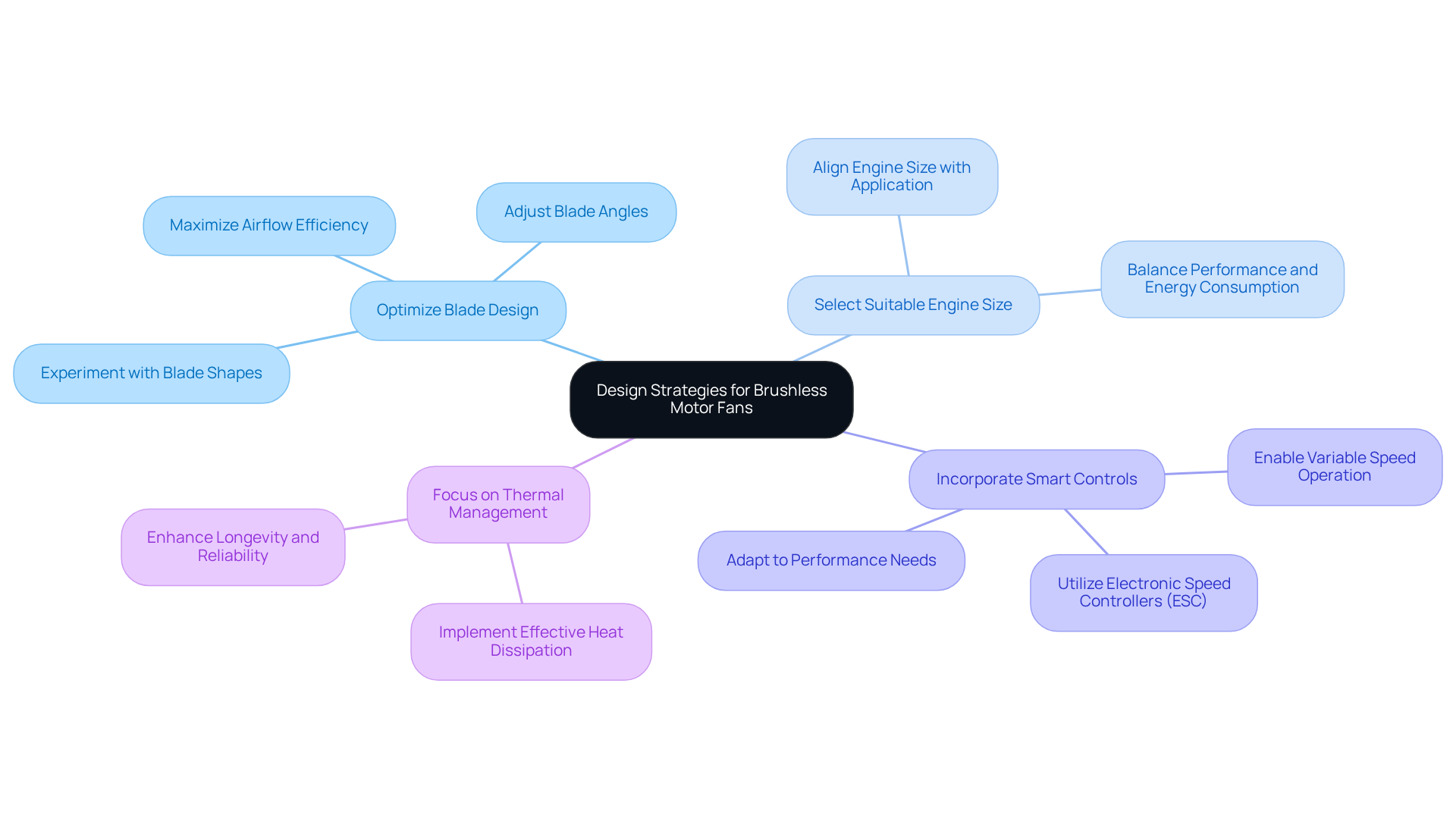

When designing a , it is essential to implement effective strategies that enhance performance and efficiency.

- Optimize Blade Design: The shape and angle of the blades play a crucial role in determining airflow and efficiency. Engineers should experiment with various designs to identify the optimal configuration that maximizes performance.

- Select Suitable Engine Size: It is vital to ensure that the engine size aligns with the application requirements. This alignment is key to achieving a balance between performance and energy consumption, which is critical in today’s energy-conscious environment.

- Incorporate Smart Controls: Utilizing electronic speed controllers (ESC) enables variable speed operation, which significantly enhances both energy conservation and overall performance. This technology allows for tailored operation, adapting to specific performance needs.

- Focus on Thermal Management: Designing the fan system to effectively manage heat dissipation is paramount. By ensuring adequate thermal management, engineers can enhance the longevity and reliability of the fan systems.

By implementing these strategies, engineers can develop a new standard in fan design with brushless motor fans that not only meet specific performance criteria but also maximize efficiency.

Conclusion

Brushless motor fans signify a remarkable leap in fan technology, demonstrating enhanced efficiency, durability, and decreased maintenance requirements. Their innovative design, which eliminates brushes, facilitates smoother operation and extends lifespans, rendering them an optimal choice for a wide range of applications, including electronics cooling, HVAC systems, and industrial equipment.

This article explores the principles underlying brushless motors, emphasizing their essential components such as the stator, rotor, and electronic speed controller. It contrasts their advantages over traditional brushed motors, highlighting superior efficiency rates, extended operational life, and reduced maintenance costs. Furthermore, it underscores the increasing market demand for brushless motor fans, propelled by their exceptional performance and energy-saving attributes.

In summary, adopting brushless motor technology not only enhances performance across diverse sectors but also fosters sustainability through energy efficiency. As industries persist in pursuing innovative solutions to operational challenges, the integration of brushless motor fans emerges as a strategic investment that promises long-term advantages. Embracing these advanced systems can yield substantial cost savings and improved reliability, solidifying their position as a cornerstone of contemporary engineering practices.

Frequently Asked Questions

What are brushless motors and how do they operate?

Brushless motors operate on the principle of electromagnetic induction, using a rotating magnetic field to drive the rotor. Unlike brushed motors, which use physical brushes for current transfer, brushless motors utilize electronic controllers to manage the power supply.

What are the key components of brushless motors?

The key components of brushless motors include the stator, the rotor, and the electronic speed controller (ESC). These components work together to optimize the motor’s operation.

What advantages do brushless motors have over brushed motors?

Brushless motors offer greater efficiency, reduced wear and tear, enhanced performance, quieter operation, and an extended lifespan compared to brushed motors. The absence of brushes minimizes friction, leading to these benefits.

What applications commonly use brushless motors?

Brushless motors are ideal for various applications, including cooling systems, fans, and HVAC setups. They are increasingly integrated into these systems due to their efficiency and lower power demands.

What is the typical lifespan of brushless motors?

Under typical operating conditions and with proper maintenance, brushless motors can last between 10,000 to 20,000 hours. In specialized industrial applications, this lifespan may extend to 50,000 hours.

Why do engineers recommend brushless motors?

Engineers recommend brushless motors due to their exceptional durability and reduced maintenance requirements compared to traditional brushed models. They are considered a better choice for machines that require a long lifespan.