Overview

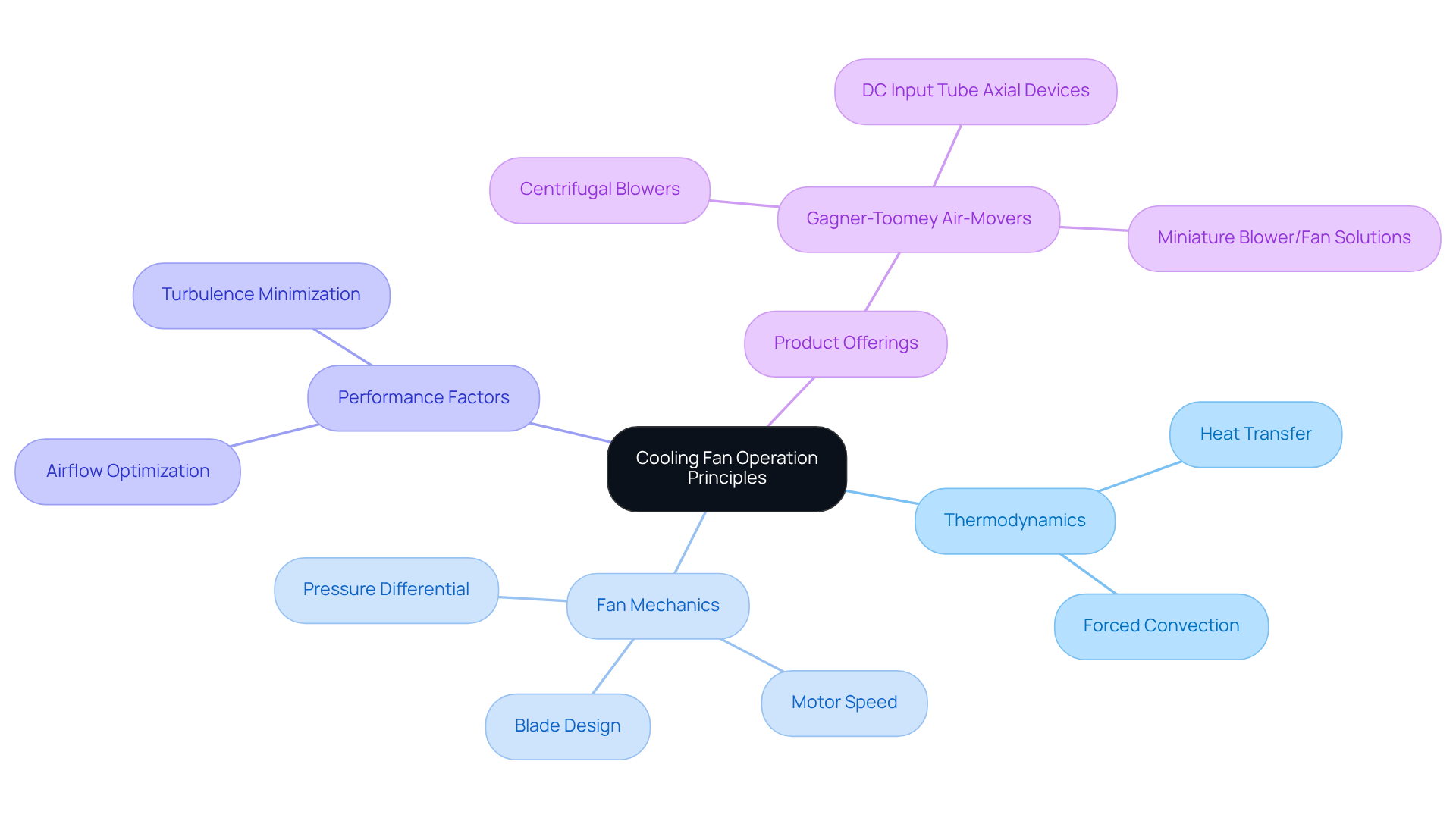

Cooling fans operate by leveraging thermodynamic principles to facilitate heat transfer through convection. This process effectively draws in cooler air while expelling warmer air, thereby enhancing cooling efficiency. The article elaborates on this mechanism, highlighting how factors such as:

- Blade design

- Motor speed

- Proper placement

are crucial for achieving optimal fan performance. These elements are particularly significant in applications requiring effective thermal management, such as in electronics and industrial systems. Understanding these principles not only underscores the importance of fan design but also emphasizes the need for careful consideration in their application to maximize cooling effectiveness.

Introduction

Understanding the mechanics behind cooling fans is essential for engineers striving to enhance thermal management in various applications. These devices operate on fundamental thermodynamic principles and play a crucial role in maintaining optimal temperatures across a wide range of settings, from consumer electronics to industrial machinery. The challenge, however, lies in selecting the right type of fan and implementing effective strategies for their operation and maintenance.

Engineers must navigate the complexities of cooling fan design and application to ensure peak performance and reliability. This article will explore these intricacies, providing actionable insights for engineers seeking to optimize thermal management solutions.

Understand the Principles of Cooling Fan Operation

To understand how a cooling fan works, it’s essential to know that they operate based on thermodynamic principles, particularly heat transfer through convection. The operation of the fan blades, which rotate to create a pressure differential, illustrates how a cooling fan works by drawing cooler air into the system while expelling warmer air. This ongoing exchange significantly enhances the chilling effect, as heated air is replaced with cooler surrounding air. The performance of a fan is influenced by several factors, including blade design, motor speed, and environmental conditions. For instance, blades optimized for specific applications can improve cooling performance by maximizing airflow and minimizing turbulence.

Gagner-Toomey Associates stands as the globe’s largest producer of standard and custom air-movers, offering a comprehensive range of DC input tube axial devices from 15 to 280mm and centrifugal blowers from 15 to 225mm. Their extensive portfolio encompasses solutions such as EC fans and blowers from 120 to 910mm, as well as miniature blower/fan solutions starting from 15x3mm. This ensures that engineers have access to the right tools for effective thermal management.

Understanding how a cooling fan works is crucial for engineers aiming to optimize fan performance across various applications, from consumer electronics to industrial machinery. The effectiveness of forced convection heat transfer is particularly evident in high-density electronic devices, where efficient heat dissipation is essential. Without sufficient temperature regulation, processors can generate enough heat to impact performance, underscoring the importance of for specific thermal management requirements. As Naghman Khan observes, “Forced convection ventilation is a crucial element of contemporary electronics where high power density devices and enclosures produce heat that requires dissipation.” By leveraging these principles and utilizing Gagner-Toomey’s innovative cooling solutions, engineers can ensure effective cooling that enhances the reliability and longevity of electronic components.

Explore Different Types of Cooling Fans

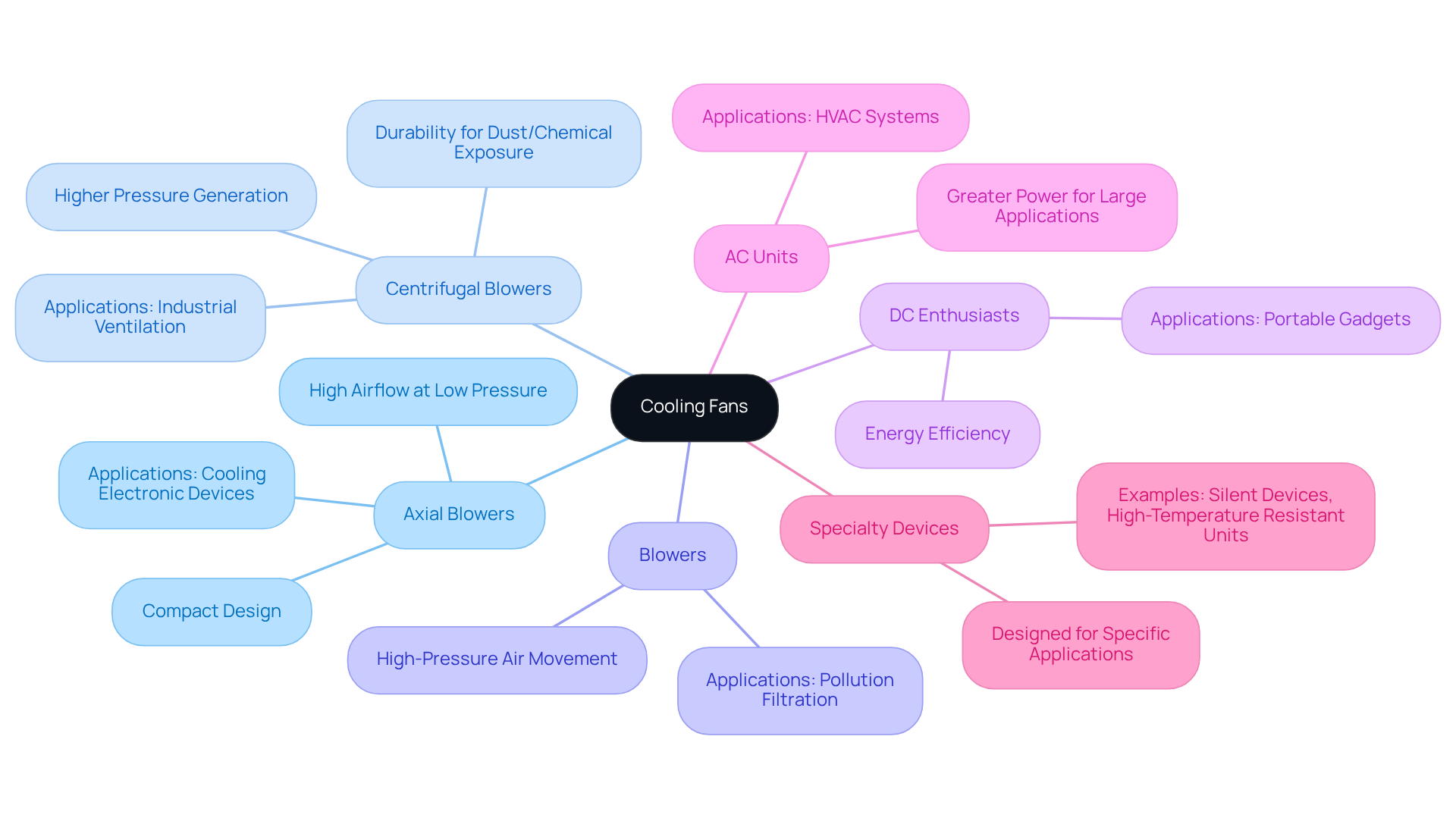

Cooling fans can be categorized into several types based on their design and application:

- Axial Blowers: These devices move air parallel to the shaft, making them suitable for applications requiring high airflow at low pressure. Their compact design and efficiency render them particularly effective for cooling electronic devices, such as computers and HVAC systems.

- [Centrifugal Blowers](https://gagner-toomey.com/10-key-insights-on-axial-vs-centrifugal-fan-performance): Also referred to as blowers, centrifugal blowers draw air into the center and expel it at a right angle, generating higher pressure. This design is essential for applications that necessitate moving air through ducts or against resistance, such as in industrial ventilation systems and air conditioning units. They excel in environments with dust or chemical exposure due to their durability and ability to handle higher static pressures.

- Blowers: Comparable to centrifugal devices, blowers are designed to generate high-pressure air movement, making them ideal for industrial applications where air must be directed specifically, such as in pollution filtration systems.

- DC Enthusiasts: Powered by direct current, these devices are recognized for their energy efficiency and are commonly utilized in computer systems and portable gadgets, where low power consumption is crucial.

- AC Units: Alternating current devices are typically employed in larger applications, such as HVAC systems, where greater power is necessary to maintain airflow and temperature regulation.

- Specialty Devices: This category includes devices designed for specific applications, such as high-temperature environments or noise-sensitive areas. Examples consist of silent devices for quiet operation and high-temperature resistant units for industrial processes.

Understanding how a cooling fan works allows engineers to make informed choices when selecting for their projects, ensuring optimal performance and efficiency.

Apply Cooling Fans in Electronics and Thermal Management

To effectively apply cooling fans in electronics and thermal management, engineers must consider several critical strategies:

- Placement: Position ventilators strategically to optimize airflow across heat-generating components. For instance, placing intake vents near heat sources can significantly enhance cooling efficiency. Proper fan placement can lead to a notable reduction in Power Usage Effectiveness (PUE) in data centers, decreasing from 1.55 to 1.42, which translates to improved energy efficiency and substantial operational cost savings.

- Motor Speed Control: Implementing variable speed control, such as Pulse Width Modulation (PWM), enables units to adjust their speed according to thermal demands. This not only enhances energy efficiency but also reduces noise levels. PWM devices can decrease power usage by as much as 30% compared to conventional models, making them an excellent choice for energy-conscious designs.

- Breeze Direction: Ensure that the direction of airflow aligns with the cooling requirements of the system. For example, exhaust fans should be effectively positioned to remove hot air from the environment.

- Ducting: In larger systems, utilizing ducting can facilitate the efficient movement of air, ensuring that cool air reaches critical components while expelling hot air effectively.

- Monitoring: Integrate temperature sensors to continuously monitor system temperatures and adjust fan operations accordingly. This proactive approach can prevent overheating, thereby .

By implementing these strategies, engineers can significantly enhance the understanding of how does a cooling fan work in their designs, ensuring both reliability and efficiency. As Matt Safford noted, “The accuracy of PWM devices enables engineers to enhance temperature management strategies efficiently, which is crucial in high-performance settings.” Furthermore, understanding air movement measurement in cubic feet per minute (CFM) is vital for optimizing fan performance. Consideration of fan size and design is equally important to achieve higher air movement rates while minimizing noise.

Maintain and Troubleshoot Cooling Fans for Optimal Performance

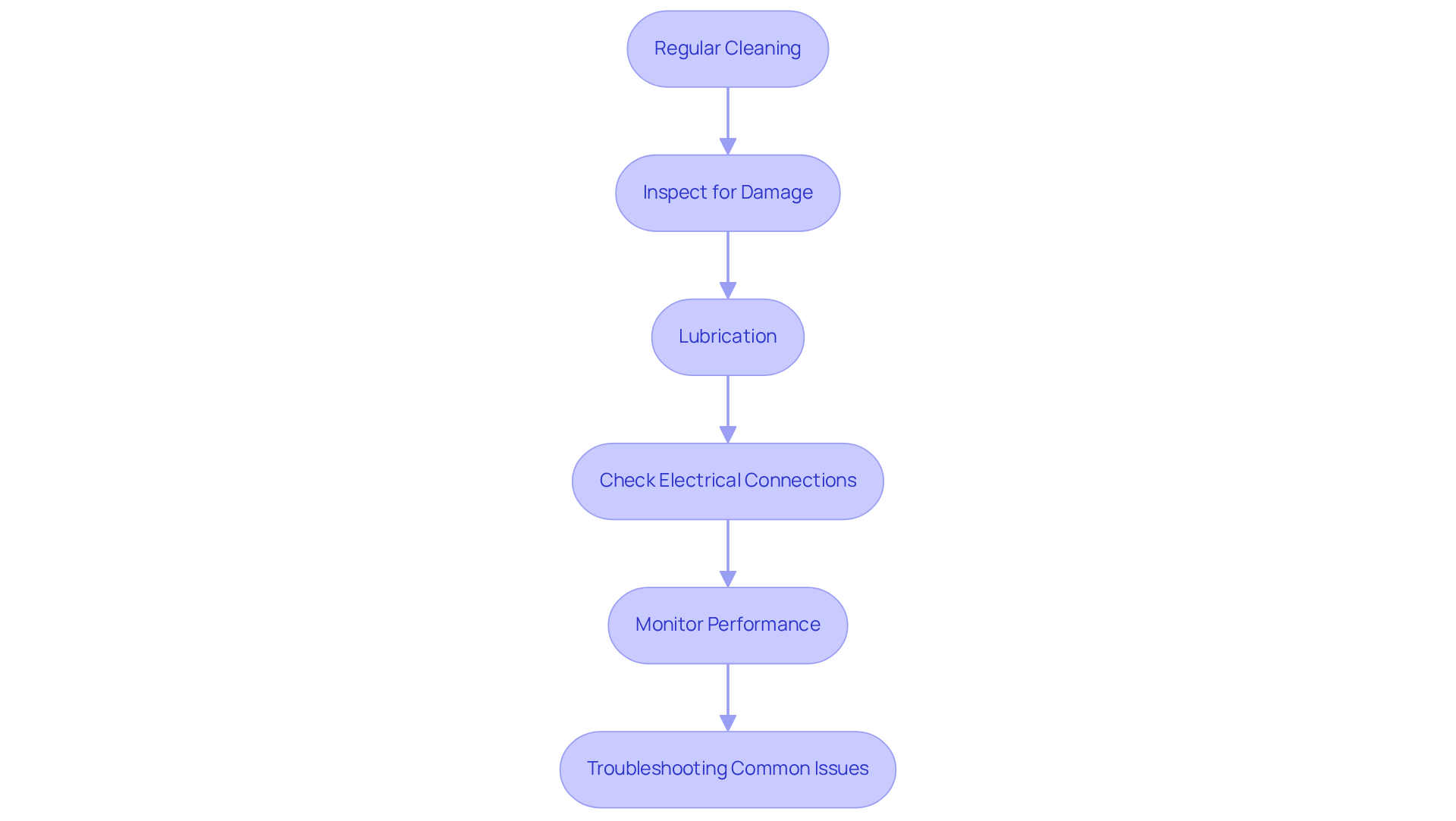

To ensure optimal performance and longevity of cooling fans, engineers must adhere to the following maintenance and troubleshooting guidelines:

- Regular Cleaning: Dust and debris accumulation on fan blades and housing can significantly obstruct ventilation. Regular cleaning is essential to maintain peak performance and efficiency.

- Inspect for Damage: Regularly examining fan blades for cracks or signs of wear, and verifying that the motor operates correctly, is crucial. Promptly addressing any damage prevents potential failures.

- Lubrication: Where applicable, lubricate fan bearings according to the manufacturer’s guidelines to minimize friction and wear, which can lead to overheating and reduced efficiency.

- Check Electrical Connections: Ensure all electrical connections are secure and free from corrosion. Faulty connections can cause intermittent operation, leading to performance issues.

- Monitor Performance: Utilize temperature sensors to track the efficiency of cooling devices. An increase in temperatures may suggest problems such as insufficient fan speed or blockages that require examination.

- Troubleshooting Common Issues: For devices that fail to operate, , fuses, and control signals. If a fan runs but fails to cool effectively, inspect for airflow blockages or mechanical failures.

Statistics indicate that inadequate maintenance can result in failure rates of refrigeration units exceeding 30%, underscoring the significance of routine care. By implementing these practices, engineers can enhance the efficiency of cooling fans while also exploring how does a cooling fan work, prolong their operational lifespan, and ensure effective thermal management across various applications.

Conclusion

Understanding the operation of cooling fans is fundamental for engineers tasked with optimizing thermal management across various applications. By grasping the principles of heat transfer and airflow mechanics, engineers can select and implement the right cooling solutions tailored to their specific needs, ensuring that electronic devices and industrial machinery operate efficiently and reliably.

The article delves into the essential components of cooling fan operation, highlighting the significance of blade design, motor speed, and environmental factors. It categorizes different types of cooling fans, such as axial and centrifugal blowers, and discusses their applications in both consumer electronics and industrial settings. Furthermore, it provides practical strategies for effectively applying cooling fans, emphasizing the importance of placement, motor speed control, and regular maintenance to enhance performance and longevity.

Ultimately, the insights presented underscore the critical role that cooling fans play in maintaining optimal temperatures and preventing overheating in high-density electronic devices. Engineers are encouraged to leverage these principles and adopt proactive maintenance practices to ensure the reliability of their thermal management systems. By doing so, they can not only enhance the performance of their designs but also contribute to the longevity and efficiency of the technologies that power our daily lives.

Frequently Asked Questions

How does a cooling fan operate?

A cooling fan operates based on thermodynamic principles, particularly heat transfer through convection. It uses rotating blades to create a pressure differential, drawing cooler air into the system while expelling warmer air, thus enhancing the chilling effect.

What factors influence the performance of a cooling fan?

The performance of a cooling fan is influenced by several factors, including blade design, motor speed, and environmental conditions. Optimized blades can improve cooling performance by maximizing airflow and minimizing turbulence.

What products does Gagner-Toomey Associates offer?

Gagner-Toomey Associates offers a wide range of air-movers, including DC input tube axial devices from 15 to 280mm, centrifugal blowers from 15 to 225mm, EC fans and blowers from 120 to 910mm, and miniature blower/fan solutions starting from 15x3mm.

Why is understanding cooling fan operation important for engineers?

Understanding how a cooling fan works is crucial for engineers to optimize fan performance across various applications, particularly in high-density electronic devices where efficient heat dissipation is essential for maintaining performance and reliability.

What is the significance of forced convection in electronics?

Forced convection ventilation is vital in contemporary electronics, especially for high power density devices and enclosures that produce heat requiring dissipation. It helps ensure effective cooling, enhancing the reliability and longevity of electronic components.