Overview

This article delves into the diverse types of cooling fans and their critical role in engineering, particularly in the realm of thermal management for electronic devices. It categorizes fans into:

- Axial

- Centrifugal

- Cross-flow

It elaborates on their operational characteristics and performance metrics, including airflow and static pressure. Furthermore, it outlines best practices for selection and installation. By doing so, it equips engineers with the essential knowledge needed to make informed decisions, ensuring efficient cooling solutions.

Introduction

Understanding the intricate world of cooling fans is essential for engineers striving to optimize thermal management in electronic systems. These devices play a pivotal role in dissipating heat, ensuring that components operate efficiently and reliably. This comprehensive guide delves into the various types of cooling fans, their technical specifications, and best practices for selection and installation, equipping engineers with the knowledge to make informed decisions. However, with so many options available, navigating the complexities of cooling fan technology is crucial to ensuring peak performance in diverse applications.

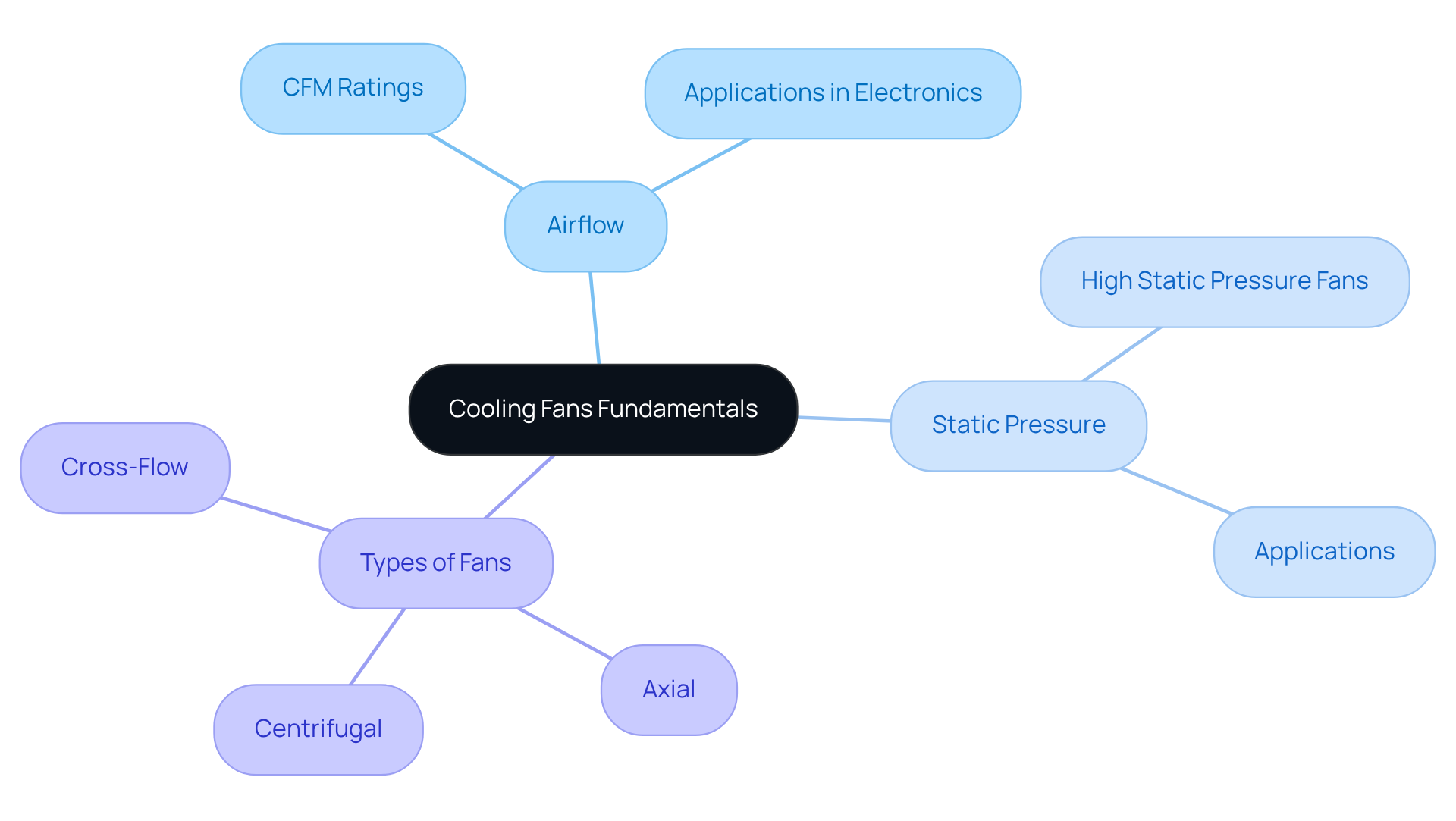

Explore the Fundamentals of Cooling Fans

Cooling fan types are indispensable devices that facilitate heat dissipation across a multitude of applications, particularly within the electronics sector. Operating on convection principles, they transfer heat from hot surfaces to the surrounding air. The primary function of a fan is to enhance ventilation, significantly improving the thermal efficiency of electronic components. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a comprehensive portfolio of temperature control solutions optimized for performance, efficiency, and low noise, solidifying their status as a leading provider in this domain. Key concepts include:

- Airflow: Measured in cubic feet per minute (CFM), airflow quantifies the volume of air a fan can move. In electronics applications, typical average air movement rates range from 30 to 150 CFM, with elevated rates being critical for ventilating high-density components, especially in data centers and telecom infrastructure. Gagner-Toomey’s extensive product range features DC input tube axial devices and centrifugal blowers, providing options tailored to various ventilation requirements.

- Static Pressure: This metric indicates the resistance a fan must overcome to push air through a system. Fans designed for high static pressure are essential in scenarios where airflow is obstructed, ensuring effective cooling in compact or densely packed environments. Gagner-Toomey’s innovative designs cater to these needs, offering solutions that excel in challenging conditions, including options with IP protection.

Understanding the distinctions between various , such as axial, centrifugal, and cross-flow devices, is crucial, as each category possesses unique features tailored for specific applications. For instance, axial blowers, which commanded a significant market share of 38.42% in 2025, are favored for their efficiency in moving large volumes of air at low pressure, making them ideal for consumer electronics and data centers. Gagner-Toomey’s extensive range includes both standard and custom designs, with sizes spanning from 15 to 280mm, ensuring engineers can identify the right fit for their specific needs.

Engineers consistently emphasize the importance of airflow in ventilation systems, noting that optimal airflow is vital for sustaining the performance and longevity of electronic components. Furthermore, research indicates that over 80% of high-end electronic devices incorporate sophisticated temperature management technologies, underscoring the necessity of efficient thermal solutions. The market size for temperature regulation devices was USD 10,746.0 Million in 2025, highlighting the economic impact and significance of refrigeration technologies. By mastering these fundamentals and leveraging Gagner-Toomey’s innovative cooling solutions, engineers can make informed decisions when selecting cooling solutions for their projects, ensuring compatibility and efficiency in their designs.

Categorize Different Types of Cooling Fans

Cooling fans can be categorized into several types based on their design and operational characteristics:

- Axial Blowers: These devices move air parallel to the shaft, making them highly efficient for low-pressure applications. Frequently employed in cooling towers and for electronic component temperature management, axial devices can attain airflow rates of up to 5,000 cubic feet per minute (CFM) with a static pressure of 0.5 inches of water gauge (inwg). Their compact design allows for installation in confined spaces, making them versatile for various applications. The cooling devices market is anticipated to reach USD 29,967.0 Million in 2035, emphasizing the increasing significance of these units in the industry.

- [Centrifugal Units](https://gagner-toomey.com/9-benefits-of-centrifugal-industrial-fans-for-electronics-cooling): Also referred to as blowers, these devices draw air into the center and expel it at a right angle, generating higher static pressure. They are perfect for uses needing concentrated ventilation, such as , where they can generate pressures of up to 10 inwg with a volumetric movement of 1,000 CFM. HVAC professionals often prefer centrifugal units for their durability and effectiveness in high-pressure environments, although they typically consume more power than axial systems.

- Cross-flow Blowers: These devices push air through a narrow channel, providing uniform airflow across a surface. Their design is particularly advantageous in compact spaces where even cooling is essential, such as in floor heaters and air walls in commercial settings. Cross-flow blowers are preferred for their low noise levels and efficiency, making them suitable for both workplace and home environments.

- Mixed-flow Devices: Combining characteristics of both axial and centrifugal types, mixed-flow devices provide versatility in managing differing airflow and pressure needs. They are particularly useful in applications where space is limited but high performance is still necessary.

By understanding these categories, engineers can make informed choices when selecting the suitable cooling fan types based on specific temperature control needs, project constraints, and performance requirements. Moreover, confirming that chosen devices meet UL certification standards is essential for product safety and reliability.

Analyze Technical Specifications and Performance Metrics

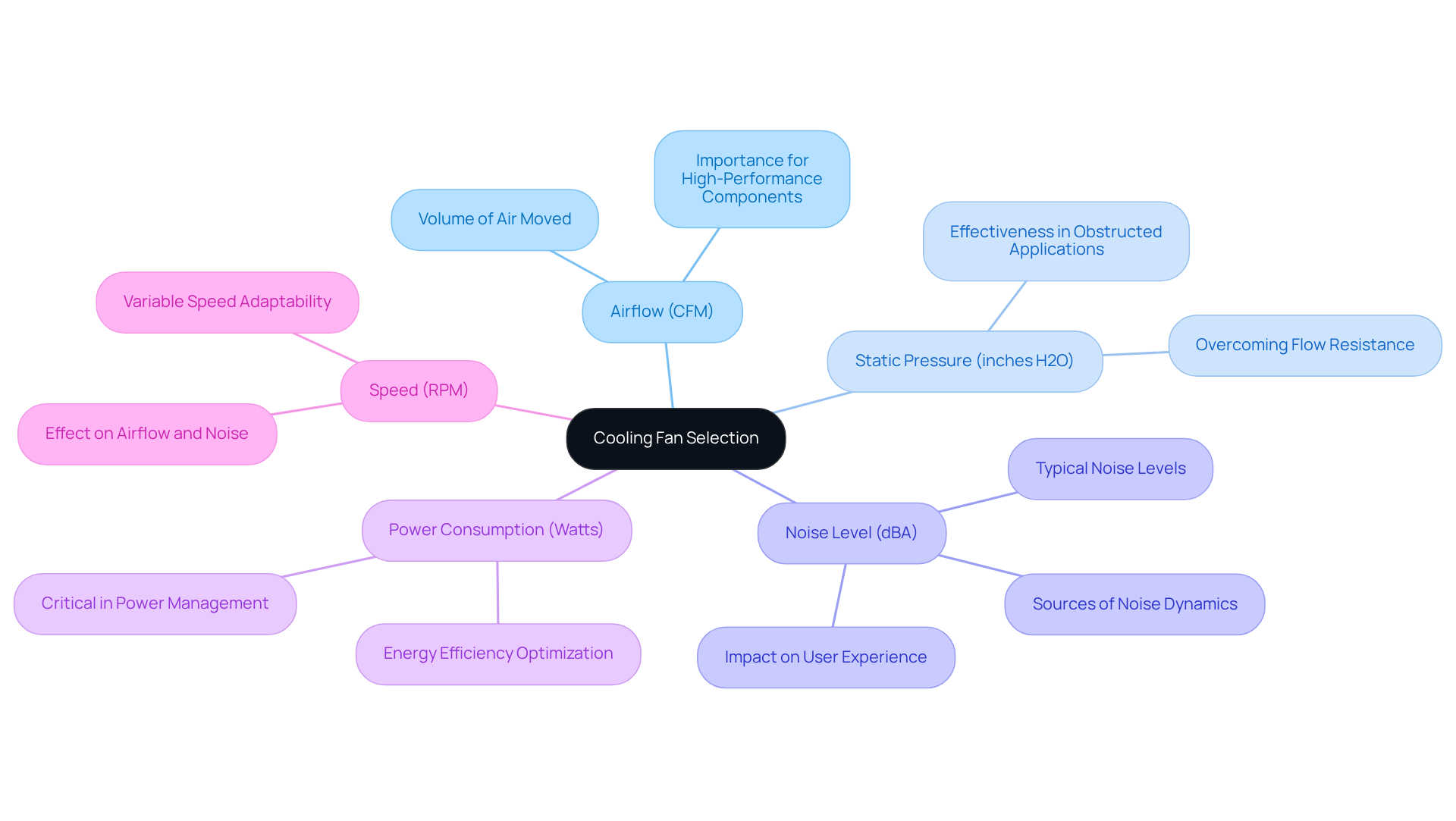

When selecting cooling fan types, engineers must evaluate several key and performance metrics that are critical to ensuring optimal thermal management in their systems.

- Airflow (CFM): This metric measures the volume of air a fan can move, directly influencing cooling efficiency. For high-performance components, higher CFM ratings are essential to ensure adequate cooling.

- Static Pressure (inches H2O): This specification indicates the fan’s capability to overcome resistance in the flow path. Fans with elevated static pressure ratings are particularly effective in applications with obstructions, ensuring consistent airflow.

- Noise Level (dBA): This factor is crucial for applications where sound is a concern, such as consumer electronics. Fans operating at sound levels as low as 10-20 dBA can significantly enhance user experience, while typical models may reach noise levels of 40 dBA or higher. Selecting fans with lower dBA ratings is vital for maintaining a comfortable acoustic environment. Richard H. Lyon observes that ‘the noise generated by chilled air flowing through electronics packages originates from two sources,’ highlighting the significance of comprehending noise dynamics in fan selection.

- Power Consumption (Watts): Understanding the power requirements of a fan is essential for optimizing energy efficiency and system design, particularly in applications where power management is critical.

- Speed (RPM): The rotational speed of the fan blades affects both airflow and noise levels. Variable speed ventilators provide adaptability, enabling engineers to modify performance according to particular temperature management requirements.

By thoroughly analyzing these specifications, engineers can ensure that the selected cooling fan types effectively meet the thermal management requirements of their systems, balancing performance with user comfort. Furthermore, it is crucial to recognize that the irreducible noise from turbulent air movement is a key element in thermal dynamics, as it plays a vital role in heat transfer between components and the air stream.

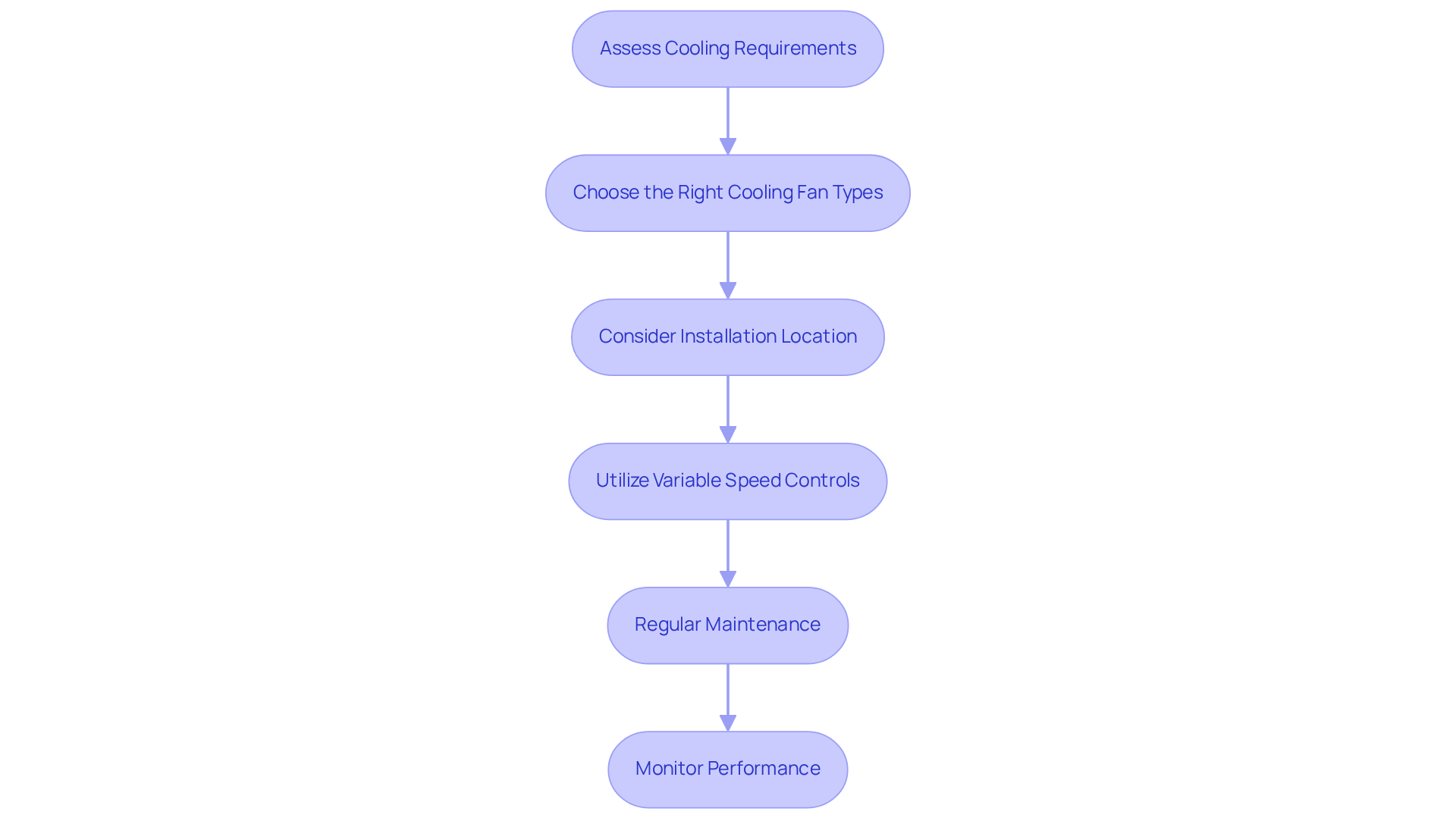

Implement Best Practices for Cooling Fan Selection and Installation

To ensure effective cooling fan performance, engineers must adhere to the following best practices:

- Assess Cooling Requirements: Accurately determining the heat load and ventilation needs of the system is essential. This evaluation is crucial, as improper selection of cooling fan types can lead to system failures, frequently associated with insufficient air movement.

- Choose the right cooling fan types: Selecting the appropriate cooling fan types—such as axial or centrifugal—based on the specific application is vital. Each type possesses distinct characteristics that influence performance and compatibility with cooling needs.

- Consider Installation Location: Strategically positioning air circulators optimizes airflow and minimizes obstructions. Clear intake and exhaust paths are imperative for maximizing efficiency, ensuring that cool air enters from the bottom while hot air is expelled from the top.

- Utilize Variable Speed Controls: Implementing variable speed controls, such as those offered by SmartFan Nimbus II, significantly enhances energy efficiency. These controls allow for dynamic modifications according to thermal loads, ensuring that the equipment operates at while maintaining a stable environment.

- Regular Maintenance: Scheduling routine inspections and upkeep is essential for ensuring ventilation systems operate efficiently. Regular maintenance can prevent failures and extend the lifespan of cooling systems, which typically range from 3 to 5 years under normal conditions. Notably, fans with sleeve bearings generally last around 30,000 hours, while those with double ball bearings can endure between 50,000 to 100,000 hours.

- Monitor Performance: Employing sensors to continuously monitor airflow and temperature provides real-time information, allowing engineers to make necessary adjustments to maintain optimal temperature conditions and prevent overheating.

By following these best practices, engineers can enhance the performance and reliability of cooling systems in their designs, ultimately leading to improved thermal management and longevity of electronic devices.

Conclusion

In conclusion, understanding the various types of cooling fans and their technical specifications is paramount for engineers seeking to optimize thermal management in electronic systems. Mastering these concepts enables professionals to ensure that their designs not only meet performance demands but also enhance the longevity and reliability of devices. The significance of selecting the right cooling fan type—be it axial, centrifugal, or cross-flow—cannot be overstated, as each serves unique applications and performance needs.

Critical metrics such as airflow and static pressure directly influence cooling efficiency and system performance. Furthermore, the importance of installation practices, including proper placement and maintenance, plays a vital role in maximizing fan effectiveness. With the cooling devices market projected to grow significantly, engineers must remain informed about advancements and best practices to harness the full potential of cooling technologies.

Ultimately, the insights provided in this guide underscore the necessity for engineers to make informed decisions when selecting cooling fans. By prioritizing efficiency, performance, and adherence to best practices, they can contribute to the development of robust systems that effectively manage heat dissipation. Embracing these principles will not only enhance device performance but also pave the way for innovation in thermal management solutions across various industries.

Frequently Asked Questions

What is the primary function of cooling fans?

The primary function of cooling fans is to enhance ventilation, significantly improving the thermal efficiency of electronic components by facilitating heat dissipation.

How do cooling fans operate?

Cooling fans operate on convection principles, transferring heat from hot surfaces to the surrounding air.

What is airflow, and how is it measured?

Airflow, measured in cubic feet per minute (CFM), quantifies the volume of air a fan can move. In electronics applications, typical airflow rates range from 30 to 150 CFM.

Why is static pressure important in cooling fans?

Static pressure indicates the resistance a fan must overcome to push air through a system. Fans designed for high static pressure are essential in scenarios where airflow is obstructed, ensuring effective cooling in compact environments.

What types of cooling fans are available?

There are various types of cooling fans, including axial, centrifugal, and cross-flow devices, each with unique features tailored for specific applications.

What is the market share of axial blowers, and what are their advantages?

Axial blowers commanded a significant market share of 38.42% in 2025 and are favored for their efficiency in moving large volumes of air at low pressure, making them ideal for consumer electronics and data centers.

How does airflow affect the performance of electronic components?

Optimal airflow is vital for sustaining the performance and longevity of electronic components, as it helps in effective cooling.

What percentage of high-end electronic devices use temperature management technologies?

Research indicates that over 80% of high-end electronic devices incorporate sophisticated temperature management technologies.

What was the market size for temperature regulation devices in 2025?

The market size for temperature regulation devices was USD 10,746.0 Million in 2025.

How can engineers benefit from understanding cooling fan fundamentals?

By mastering the fundamentals of cooling fans and leveraging innovative cooling solutions, engineers can make informed decisions when selecting cooling solutions for their projects, ensuring compatibility and efficiency in their designs.