Overview

Optimizing static fan performance is crucial for enhancing the efficiency of HVAC systems, as it fundamentally involves understanding the dynamics of static pressure, which significantly influences airflow efficiency and energy consumption. This article outlines essential strategies for achieving optimal performance, including:

- Proper duct design

- Regular maintenance

- Appropriate fan selection

- Implementation of variable speed drives

Each of these strategies plays a vital role in reducing resistance within the system and enhancing overall performance, thereby ensuring that HVAC systems operate at their best.

Introduction

Grasping the dynamics of static pressure in HVAC systems is essential for achieving optimal fan performance. As air traverses ductwork, it encounters resistance that can significantly affect energy consumption and airflow efficiency. This article explores effective strategies for optimizing static fan performance, offering insights into measurement techniques, design considerations, and maintenance practices.

With numerous variables influencing performance, the critical question arises: how can one ensure their system operates at peak efficiency while minimizing costs?

Understand Static Pressure in HVAC Systems

Static resistance refers to the opposition that air encounters as it travels through ductwork in HVAC systems. Measured in inches of water column (in WC), this metric is critical in determining the effectiveness of air distribution throughout the system. To grasp the concept of static pressure, consider the following:

- Definition: Static force is the force exerted by air within a duct when it is at rest. This force is essential for maintaining airflow and ensuring the efficient operation of HVAC units.

- Measurement: Utilize a to assess the fixed force at various points within the duct network. This assessment will help identify areas of high resistance that may require intervention.

- Elements Influencing Fixed Force: Factors such as duct dimensions, length, curves, and the presence of filters or barriers can significantly impact fixed force levels. Understanding these variables is crucial for effective design and optimization.

- Significance in HVAC: High resistance can result in increased energy consumption, reduced airflow, and potential system failures. Conversely, excessively low air levels may lead to inadequate heating or cooling.

The optimal fixed airflow range for supply ductwork is between 0.25 – 0.3 in. WC, while for return ductwork, it is 0.2 – 0.25 in. WC. In commercial buildings, approximately 35% of the overall average energy bill is associated with HVAC systems, underscoring the financial impact of effective airflow management. A case study by Clint Orr revealed that cleaning ductwork can reduce resistance by 90%, highlighting the importance of regular maintenance practices. Furthermore, nearly 20% of the average energy bill for U.S. homes is attributed to HVAC equipment, emphasizing the need for airflow control to enhance cost efficiency.

By comprehending these concepts, readers will be better equipped to analyze and improve the performance of static fans within their HVAC systems.

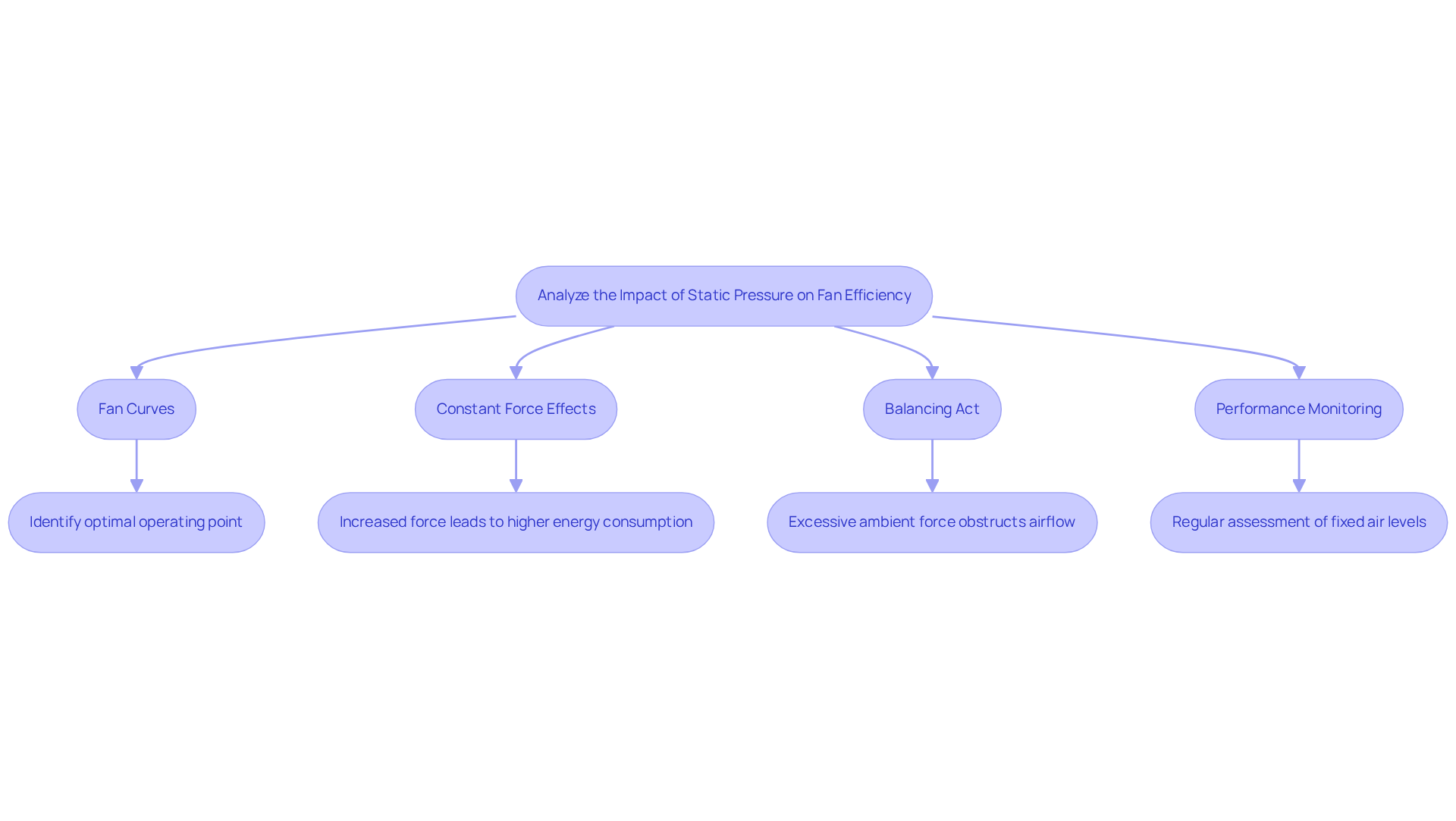

Analyze the Impact of Static Pressure on Fan Efficiency

The effectiveness of a fan is significantly influenced by the fixed force within the system. Understanding this impact is crucial for optimizing performance:

- Fan Curves: Familiarize yourself with fan performance graphs that illustrate the relationship between airflow (CFM) and atmospheric resistance. These curves are essential for identifying the optimal operating point for a static fan, ensuring efficient functionality across various conditions.

- Constant Force Effects: As the constant force increases, so does the workload on the fan. This escalation can lead to higher energy consumption and potential overheating if the fan is not rated for the required force. For instance, a 10% increase in airflow can necessitate a 33% rise in horsepower, underscoring the importance of selecting the appropriate static fan for optimal performance. Moreover, maintaining consistent tension at approximately 0.5 psi minimizes the risk of leak-related issues and damage to HVAC air ducts.

- Balancing Act: Achieving a balance between airflow and the performance of a static fan is vital. Excessive ambient force can obstruct airflow, while insufficient force may result in inadequate air distribution, compromising system performance. For reference, the typical airflow for a static fan measuring 12″ at 0.05 inH O resistance is 1,654 CFM, serving as a benchmark for evaluating fan performance.

- Performance Monitoring: Regularly assess fixed air levels to confirm that fans operate within their ideal range. Employ measurement instruments, including a static fan, to track changes and implement adjustments as necessary. For example, if a fan is delivering 6500 CFM at 4″ w.c. and requires adjustment to 6000 CFM, the new static pressure can be calculated using Fan Law 1 to ensure continued effectiveness. Additionally, it is crucial to adhere to AMCA Standard 205, which recommends no more than a 15-percentage-point deviation below the fan’s total peak efficiency when selecting an efficient fan.

By comprehending these dynamics, engineers can effectively evaluate their fan configurations and implement necessary modifications to enhance efficiency and performance.

Implement Strategies to Optimize Fan Performance

To optimize fan performance, consider implementing the following strategies:

- Duct Design: Prioritize ductwork that minimizes bends and obstructions. Utilizing larger ducts can significantly reduce resistance, enhancing airflow and overall efficiency. A well-designed duct system can balance airflow, ensuring consistent temperatures across all rooms, which is crucial for maintaining comfort and efficiency. Additionally, sealing and insulating ducts can prevent air leaks and heat loss, further improving performance.

- Regular Maintenance: Establish a routine upkeep schedule to clean filters, check ducts for leaks, and ensure that ventilation systems are clear of dust and debris. Predictive maintenance has been demonstrated to yield quantifiable cost reductions and enhanced efficiency, assisting in preserving optimal airflow and consistent force levels.

- Fan Selection: Choose fans that are appropriately sized for your specific application. It is essential to evaluate both airflow needs and the static fan ratings to guarantee compatibility, as incorrect sizing can lead to inefficiencies and higher operational expenses. Properly sized ducts ensure adequate airflow to each room, preventing issues related to undersized ducts, such as increased pressure and noise.

- Variable Speed Drives (VSDs): Implementing VSDs allows for based on demand. This not only enhances energy efficiency but also reduces wear on fan components, extending their lifespan and improving reliability.

- System Balancing: Conduct a thorough balancing of the HVAC setup to ensure even airflow distribution throughout the space. This may involve adjusting dampers and registers, which can prevent over- or under-heating and improve overall performance. Proper installation of duct materials is essential to avoid issues like condensation and mold growth.

By applying these strategies, you can significantly enhance fan performance, leading to improved system efficiency and longevity. Real-world examples demonstrate that optimized duct design and regular maintenance can prevent costly repairs and unplanned downtime, ultimately supporting sustainability initiatives and reducing energy consumption.

Conclusion

Optimizing static fan performance is crucial for maximizing efficiency in HVAC systems. Understanding the dynamics of static pressure and its influence on fan operation reveals that effective airflow management is essential, not only for comfort but also for cost savings. This guide underscores the importance of static pressure in ensuring optimal HVAC system functionality, ultimately resulting in reduced energy consumption and enhanced system reliability.

Key insights include:

- The definition and measurement of static pressure

- The impact of fan performance on energy efficiency

- Actionable strategies for optimizing fan operation

Strategies such as:

- Proper duct design

- Regular maintenance

- Selecting the right fans

- Implementing variable speed drives

are integral to enhancing airflow and minimizing resistance. Furthermore, recognizing the financial implications of HVAC efficiency emphasizes the necessity of addressing static pressure in system design and maintenance.

The significance of static pressure extends beyond technical specifications; it plays a vital role in sustainability and energy conservation efforts. By prioritizing the optimization of static fan performance, stakeholders can contribute to a more efficient future while enjoying the benefits of lower operational costs and enhanced comfort. Embracing these strategies not only improves individual systems but also supports broader initiatives aimed at reducing energy consumption in HVAC applications.

Frequently Asked Questions

What is static pressure in HVAC systems?

Static pressure refers to the opposition that air encounters as it travels through ductwork in HVAC systems, measured in inches of water column (in WC). It is critical for determining the effectiveness of air distribution throughout the system.

How is static pressure defined?

Static pressure is the force exerted by air within a duct when it is at rest, which is essential for maintaining airflow and ensuring the efficient operation of HVAC units.

How can static pressure be measured?

A manometer can be used to assess the static pressure at various points within the duct network, helping to identify areas of high resistance that may require intervention.

What factors influence static pressure in HVAC systems?

Factors that influence static pressure include duct dimensions, length, curves, and the presence of filters or barriers.

Why is static pressure significant in HVAC systems?

High static pressure can lead to increased energy consumption, reduced airflow, and potential system failures, while excessively low static pressure may result in inadequate heating or cooling.

What are the optimal static pressure ranges for supply and return ductwork?

The optimal static pressure range for supply ductwork is between 0.25 – 0.3 in. WC, while for return ductwork, it is 0.2 – 0.25 in. WC.

What is the financial impact of HVAC systems on energy bills?

Approximately 35% of the overall average energy bill in commercial buildings is associated with HVAC systems, while nearly 20% of the average energy bill for U.S. homes is attributed to HVAC equipment.

How can maintenance affect static pressure in HVAC systems?

Regular maintenance, such as cleaning ductwork, can significantly reduce static pressure resistance; a case study revealed that cleaning can reduce resistance by 90%.

How can understanding static pressure improve HVAC system performance?

By comprehending static pressure concepts, individuals can analyze and improve the performance of static fans within their HVAC systems, leading to better airflow management and cost efficiency.