Introduction

Blower pressure is a fundamental force in electronics engineering, impacting everything from cooling systems to ventilation processes. Understanding this critical concept allows engineers to optimize airflow and enhance the thermal management of electronic devices, ultimately improving their performance and longevity.

However, the intricate balance between static and dynamic forces presents a significant challenge: how can engineers effectively harness blower pressure to achieve maximum efficiency in their designs? This question not only highlights the importance of blower pressure but also sets the stage for exploring innovative solutions that can drive advancements in the field.

Define Blower Pressure: A Key Concept in Electronics Engineering

Blower pressure is the force generated by a blower as it moves air or gas through a system, playing a crucial role in electronics engineering, especially in cooling and ventilation applications. Typically measured in inches of water column (in WC) or pascals (Pa), blower pressure indicates the strength exerted by the moving air. The blower pressure is vital for overcoming resistance in ducts, ensuring adequate airflow to maintain optimal operating temperatures in electronic components. Understanding blower pressure allows engineers to design systems that efficiently manage heat dissipation, ultimately enhancing the functionality and lifespan of electronic devices.

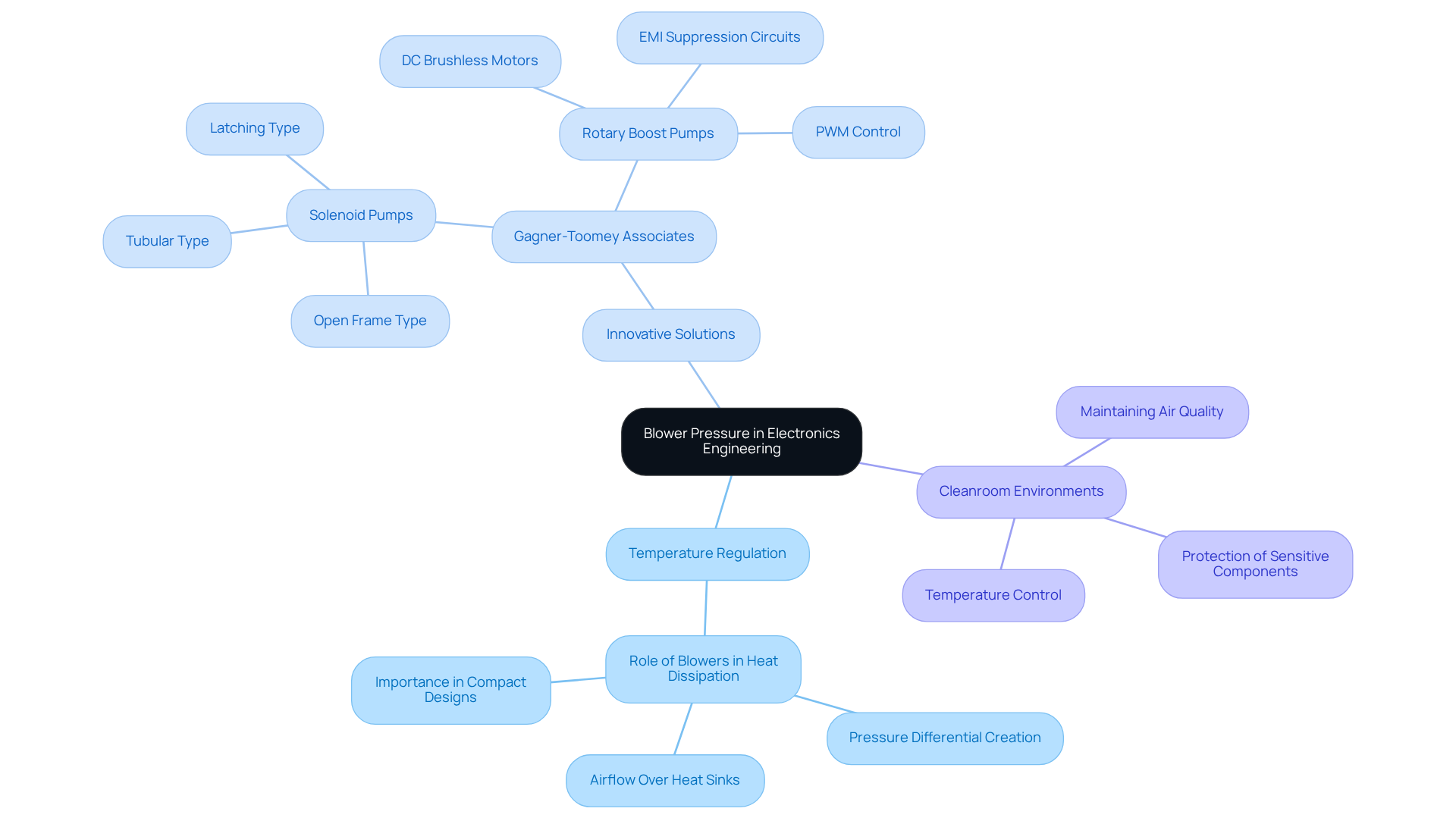

Integrating advanced pump technologies, such as solenoid and rotary boost pumps, significantly impacts blower dynamics. For instance, Gagner-Toomey Associates offers solenoid pumps capable of producing forces up to 16 Bar, ideal for precision applications in electronics thermal management. These pumps are equipped with a DC brushless motor and an EMI suppression circuit, ensuring low noise operation while complying with NSF and WSAS material standards. By leveraging such innovative solutions, engineers can improve airflow and temperature regulation in their designs, leading to more efficient and reliable electronic systems.

Contextualize Blower Pressure in Electronics Engineering Applications

In electronics engineering, fan force is essential for various applications, including temperature regulation for high-performance components, ventilation in enclosures, and air control in manufacturing processes.

Temperature Regulation Applications

Blowers are utilized to create a pressure differential that promotes airflow over heat sinks and circuit boards, effectively dissipating heat produced by electronic components. This is particularly crucial in tightly packed arrangements where conventional temperature regulation techniques may fall short.

Innovative Solutions from Gagner-Toomey Associates

Gagner-Toomey Associates offers advanced solenoid and rotary boost pump solutions that significantly enhance these applications. Their solenoid pumps, available in open frame, tubular, and latching types, can operate up to 16 Bar, making them suitable for a range of electronic cooling needs. The rotary boost pumps, equipped with DC brushless motors and EMI suppression circuits, provide precise control through PWM, ensuring low noise operation and compliance with automotive standards such as SAE and VDA.

Importance in Cleanroom Environments

These pumps are vital in cleanroom environments, maintaining air quality and temperature control to protect sensitive electronic components from contamination and overheating.

By understanding and optimizing blower pressure alongside Gagner-Toomey’s advanced pumping solutions, engineers can enhance the reliability and efficiency of electronic frameworks. This ultimately leads to improved product performance and greater customer satisfaction.

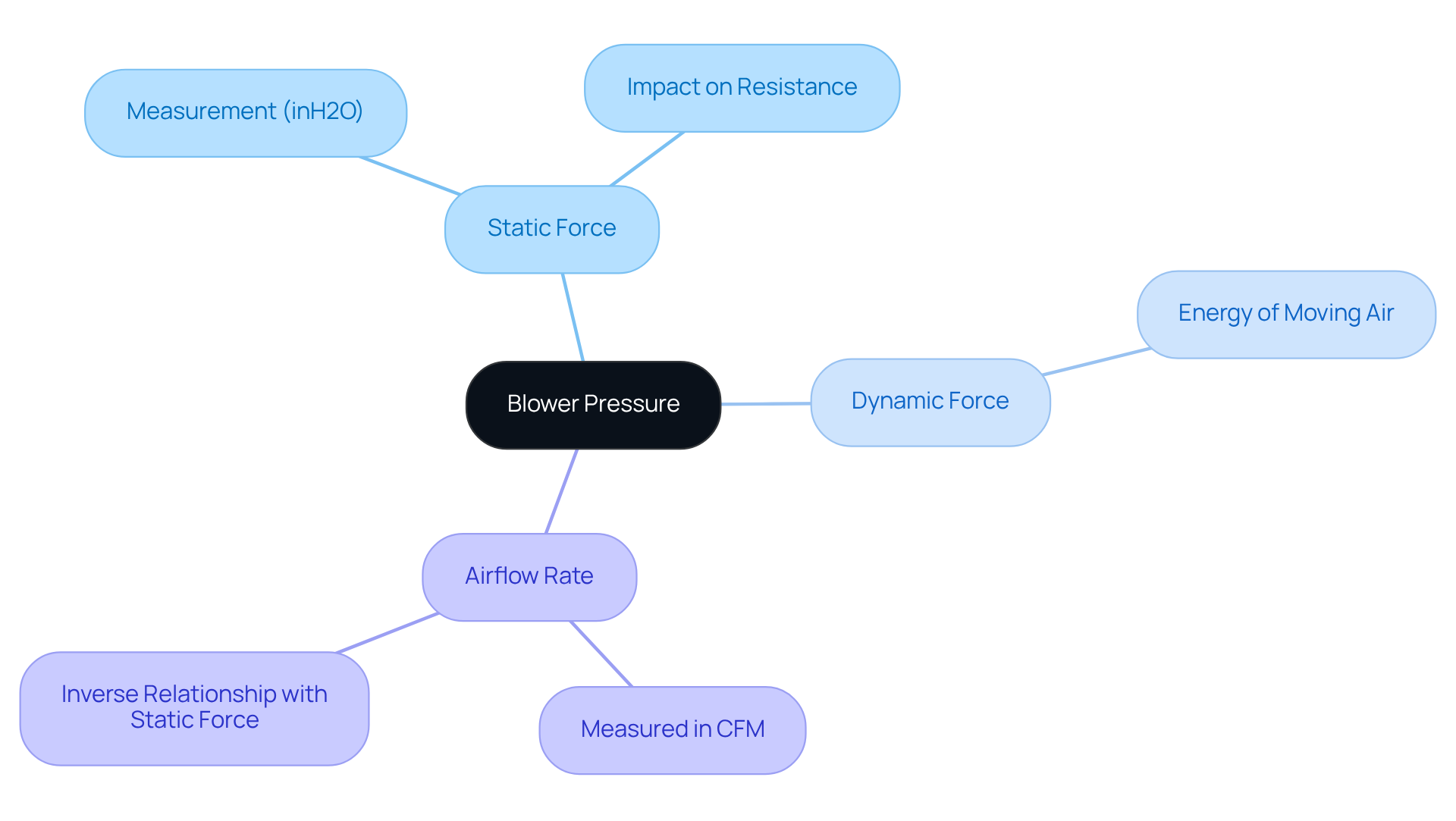

Key Characteristics of Blower Pressure

Blower pressure includes several critical characteristics, such as static force, dynamic force, and airflow rate. Understanding these elements is essential for engineers aiming to optimize thermal management in electronic devices.

Static force refers to the force exerted by the fan when airflow is stagnant. This measurement, expressed in inches of water column (inH2O), is vital for assessing the fan’s ability to overcome resistance within a system. Conversely, blower pressure relates to the energy of moving air, indicating how effectively the blower can facilitate airflow. The interplay between these forces is significant; as static force increases, the airflow rate – typically measured in cubic feet per minute (CFM) – may decrease. This inverse relationship underscores the importance of meticulous design considerations to maintain optimal performance in electronic temperature regulation applications.

For instance, a mere 10% reduction in fan RPM can lead to a corresponding 10% decrease in airflow. This example highlights the necessity for engineers to strike a balance between static and dynamic forces to achieve efficient thermal management. Moreover, static fans can maintain CPU temperatures up to 3 degrees Celsius lower than ventilation fans in a radiator setup, illustrating the practical implications of static force in electronics thermal management.

Grasping the principles of static and dynamic forces is crucial for engineers to ensure reliable thermal management in electronic devices, particularly in high-resistance environments where adequate blower pressure ratings around 3.0 inH2O are often required to sustain airflow. Furthermore, effective air circulation management can yield energy savings of up to 20%. This statistic emphasizes the critical need to balance static and dynamic forces in fan design and operation.

The Importance of Blower Pressure in Thermal Management

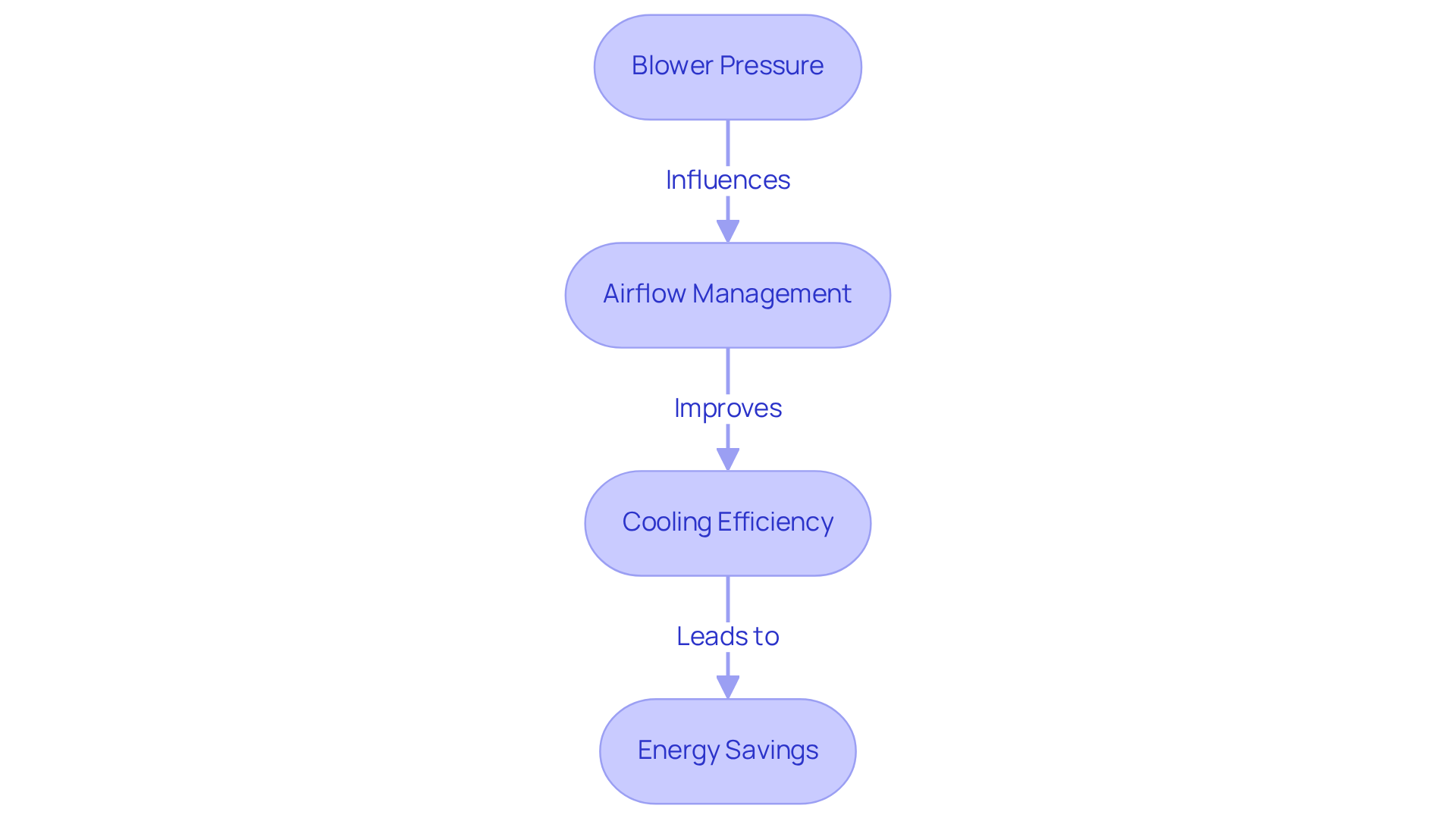

Blower force is essential for effective thermal regulation in electronics, directly impacting temperature control efficiency in various systems. High-performance electronic components generate significant heat that must be dissipated to prevent damage and ensure optimal functionality. By generating sufficient fan force, engineers can effectively direct airflow over heat sinks and other critical areas, enhancing heat transfer and temperature regulation.

In data centers, for instance, fans play a vital role in managing airflow around servers, preventing hotspots and maintaining consistent performance. This optimization of fan force not only boosts cooling efficiency but also leads to substantial energy savings, allowing devices to operate more effectively with reduced energy consumption.

For engineers dedicated to designing reliable and efficient electronic systems, understanding and managing blower pressure is crucial. By focusing on these aspects, professionals can ensure that their systems not only perform optimally but also contribute to energy conservation efforts.

Conclusion

Understanding blower pressure is fundamental for engineers in electronics, as it directly influences the efficiency of thermal management systems. This concept encapsulates the force exerted by blowers to facilitate airflow, which is essential for cooling electronic components and ensuring optimal performance. By grasping the nuances of blower pressure, engineers can design systems that not only manage heat effectively but also enhance the longevity of electronic devices.

The article delves into several key aspects of blower pressure, including its:

- Definition

- Measurement

- Significance in various applications

It highlights how advanced technologies, such as solenoid and rotary boost pumps, improve airflow and thermal regulation. The interplay between static and dynamic forces is also emphasized, illustrating the importance of balancing these elements to achieve efficient thermal management. Furthermore, the role of blower pressure in maintaining air quality in cleanroom environments and its impact on energy savings are discussed, underscoring its critical importance in the design of electronic systems.

Ultimately, a comprehensive understanding of blower pressure is essential for engineers striving to create reliable and energy-efficient electronic devices. By prioritizing this concept, professionals can not only enhance the performance of their systems but also contribute to broader energy conservation goals. Embracing innovative solutions and optimizing blower pressure will lead to advancements in electronics engineering, benefiting both manufacturers and consumers alike.

Frequently Asked Questions

What is blower pressure?

Blower pressure is the force generated by a blower as it moves air or gas through a system, which is crucial for cooling and ventilation applications in electronics engineering.

How is blower pressure measured?

Blower pressure is typically measured in inches of water column (in WC) or pascals (Pa).

Why is blower pressure important in electronics engineering?

Blower pressure is vital for overcoming resistance in ducts and ensuring adequate airflow, which helps maintain optimal operating temperatures in electronic components.

How does understanding blower pressure benefit engineers?

Understanding blower pressure allows engineers to design systems that efficiently manage heat dissipation, enhancing the functionality and lifespan of electronic devices.

What technologies can impact blower dynamics?

Advanced pump technologies, such as solenoid and rotary boost pumps, significantly impact blower dynamics in electronic thermal management.

What are the capabilities of solenoid pumps offered by Gagner-Toomey Associates?

Solenoid pumps from Gagner-Toomey Associates can produce forces up to 16 Bar, making them ideal for precision applications in electronics thermal management.

What features do these solenoid pumps include?

These pumps are equipped with a DC brushless motor and an EMI suppression circuit, ensuring low noise operation while complying with NSF and WSAS material standards.

How do innovative pump solutions improve electronic systems?

By leveraging advanced pump technologies, engineers can enhance airflow and temperature regulation in their designs, leading to more efficient and reliable electronic systems.