Overview

The key differences between vapor chambers and heat pipes are rooted in their design and application. Vapor chambers excel in rapid thermal distribution across surfaces, making them ideal for compact, high-performance devices like smartphones. This capability allows them to manage high power inputs and provide uniform thermal distribution. In contrast, heat pipes are optimized for energy transfer over longer distances and are preferred in larger systems such as laptops and data centers, where cost-effectiveness and versatility are paramount. Understanding these distinctions is crucial for selecting the appropriate thermal management solution in various technological contexts.

Introduction

In today’s electronics landscape, the demand for efficient thermal management solutions is paramount, as even minor temperature fluctuations can significantly affect performance and longevity.

At the forefront of this technological evolution are vapor chambers and heat pipes, each presenting distinct advantages that cater to specific applications.

As engineers confront the complexities of cooling high-performance devices, a pivotal question arises: which technology truly excels in efficiency, adaptability, and cost-effectiveness?

This exploration examines the fundamental differences between vapor chambers and heat pipes, illuminating their respective functionalities and guiding the decision-making process for optimal thermal management in contemporary electronics.

Understand Vapor Chambers and Heat Pipes

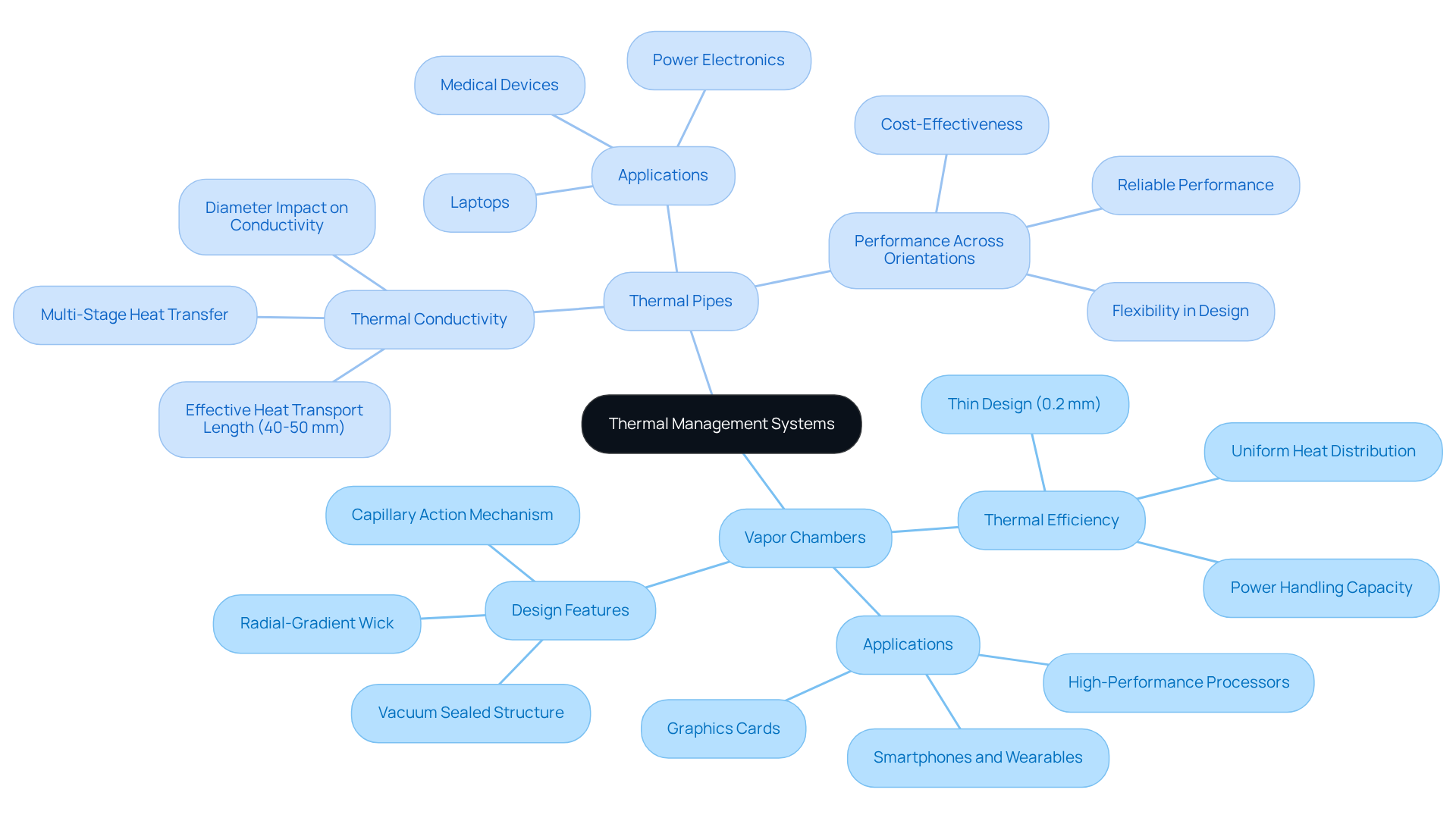

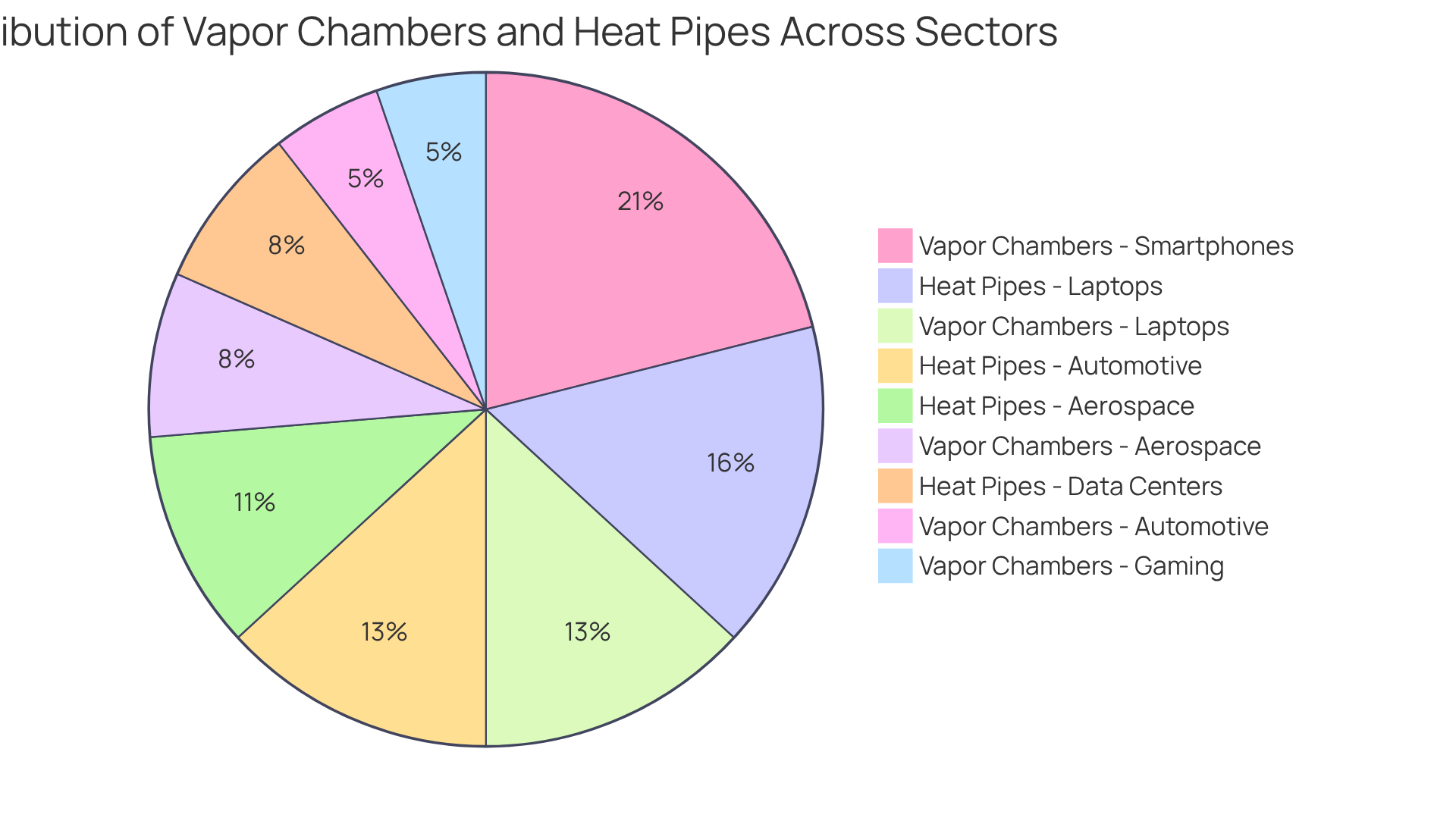

Vapor units and represent essential passive temperature control devices that leverage phase change for effective warmth transfer. A steam compartment functions similarly to a flat heat pipe, enabling —critical for maintaining optimal temperatures in compact electronic devices. It consists of a sealed container filled with a minimal amount of liquid; upon heating, this liquid evaporates, generating gas that migrates to cooler regions, where it condenses back into liquid. This mechanism facilitates efficient thermal spreading, rendering for and gaming consoles, which constitute over 40% of vapor chamber utilization.

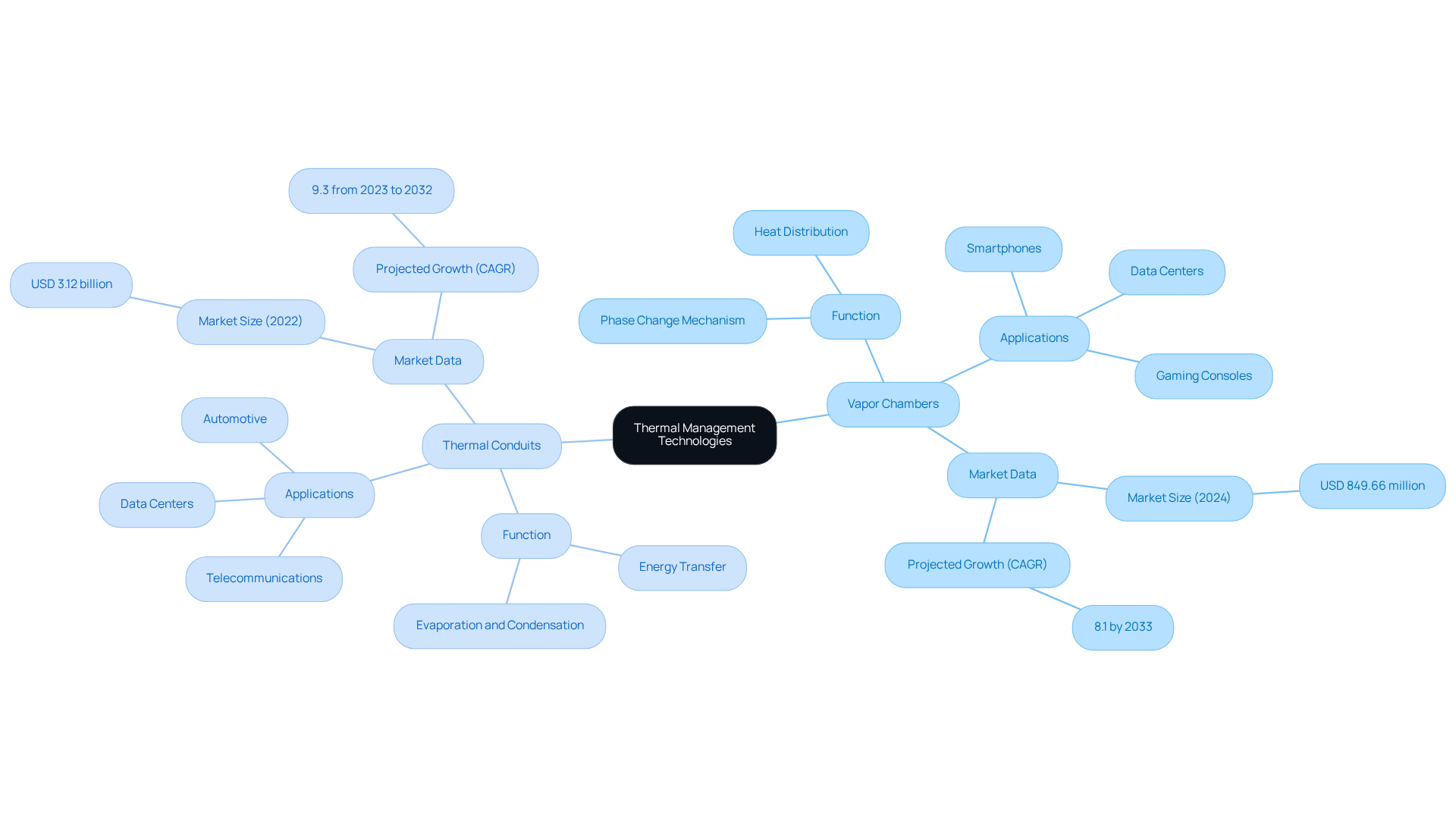

Conversely, designed to transfer energy predominantly along their length. They too contain a working fluid that undergoes evaporation and condensation; however, their configuration is optimized for energy transfer over extended distances rather than uniform distribution. This characteristic makes thermal conduits ideal for larger electronic systems, including data centers and telecommunications devices, where managing high thermal loads is paramount.

Both technologies, specifically , play a pivotal role in , with the market for thermal conduits and gaseous containers poised for significant expansion. For instance, the global market size for was estimated at approximately USD 3.12 billion in 2022, with a projected CAGR of 9.3% from 2023 to 2032. Case studies underscore their effectiveness: Cooler Master’s integration of heat sinks in gaming PCs accounted for 18% of their sales in 2024, illustrating the demand for advanced cooling solutions in high-performance environments. Engineers consistently highlight that fluid containers provide , which are vital for ensuring the reliability and functionality of modern electronic devices.

Compare Performance Metrics: Thermal Efficiency and Heat Transfer

In the domain of thermal effectiveness, steam reservoirs generally outperform in scenarios demanding rapid temperature distribution across surfaces. Their design facilitates efficient thermal conductivities that can exceed those of copper, making them particularly suitable for . For instance, a steam containment unit can manage power inputs exceeding 450 watts, exemplifying its capability in high-performance environments.

when to a sink foundation that is at least ten times larger than the energy source. Furthermore, s can be fabricated as thin as 0.2 mm, rendering them ideal for ultra-thin devices such as smartphones and wearables. Conversely, thermal pipes are optimized for energy transfer over extended distances, showcasing high thermal conductance along their axis. They excel in applications where thermal energy must be conveyed from one location to another, such as in laptops and power electronics, especially when the .

The of heat exchangers is significantly influenced by the fill ratio; as this ratio increases, thermal resistance decreases, thereby enhancing overall efficiency. In contrast, thermal conduits exhibit reliable performance across various orientations, making them versatile in design applications.

Ultimately, when considering vapor chamber vs heat pipe, vapor systems are favored in situations where , such as in large processors and graphics cards, while thermal pipes are optimal for in designs requiring adaptability and cost-effectiveness. This nuanced understanding of their respective strengths is essential for engineers when selecting the appropriate thermal management solution tailored to specific applications.

Evaluate Applications: Where to Use Vapor Chambers vs Heat Pipes

Vapor systems, particularly in the context of , play a pivotal role in , graphics cards, and mobile devices, where spatial constraints demand . Their innovative design enables effective , such as CPUs and GPUs, by evenly distributing heat across a larger surface area, highlighting the advantages of vapor chamber vs heat pipe.

Notably, over 40% of are found in the smartphone sector, underscoring their critical function in within mobile devices. Conversely, when examining vapor chamber vs heat pipe technologies, find extensive application in laptops, power electronics, and aerospace sectors, excelling at transferring heat from temperature-generating components to remote thermal sinks. Their operational versatility across various orientations renders them ideal for diverse design requirements.

More than 50% of utilize thermal conduits for temperature regulation, emphasizing their importance in sustaining performance. Additionally, in aerospace applications, engineers have demonstrated that thermal pipes can effectively manage thermal loads in satellite systems, thereby enhancing reliability and efficiency.

It is essential to recognize the challenges faced by manufacturers in adapting vapor units to new models in mobile phones and gaming devices, as well as the elevated production costs associated with vapor units, which may impact their market acceptance. By understanding these applications, engineers can select the most appropriate technology for their specific , comparing vapor chamber vs heat pipe to ensure optimal performance and longevity of electronic systems.

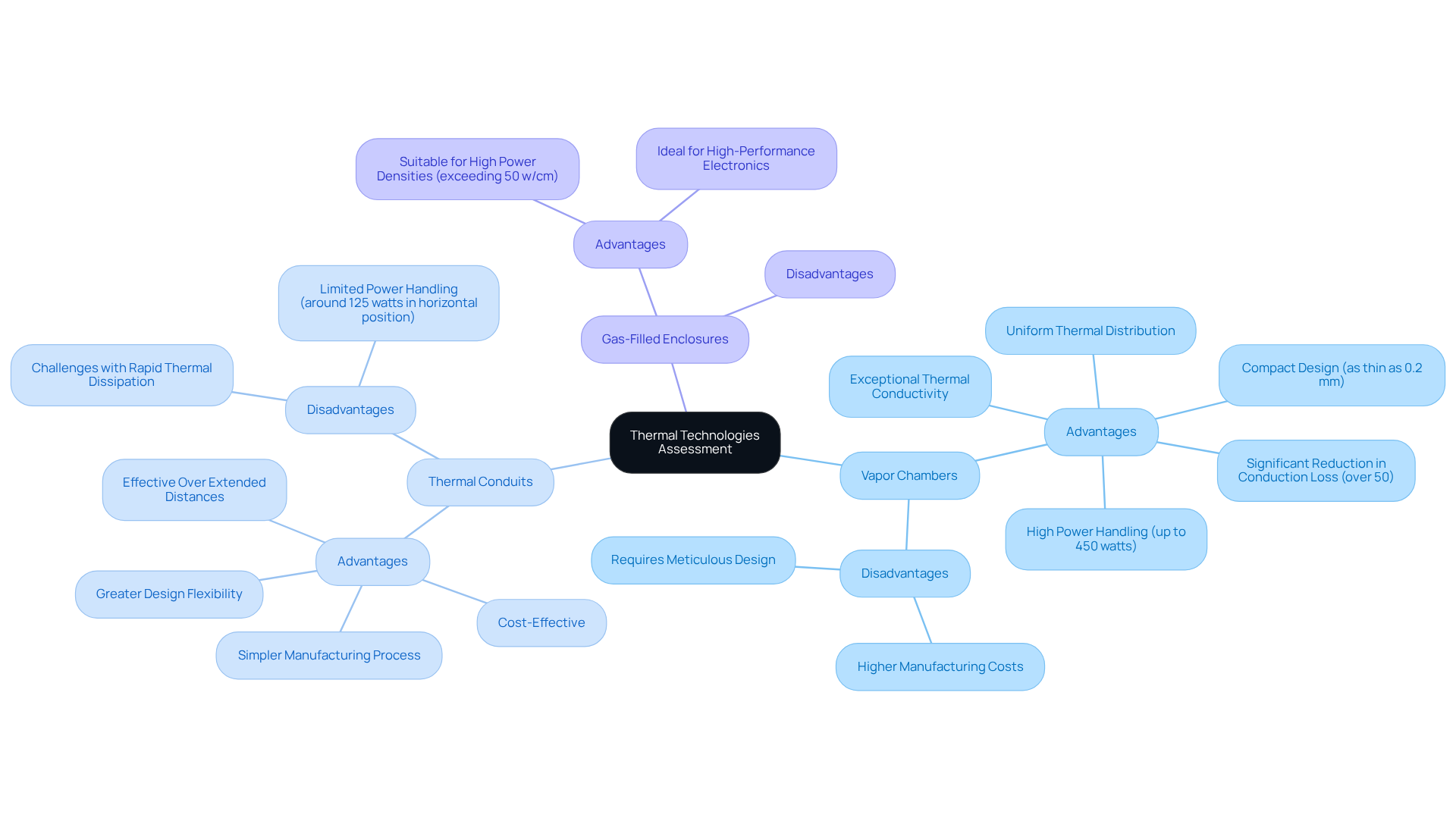

Assess Advantages and Disadvantages of Each Technology

Vapor chambers present distinct advantages, including , uniform thermal distribution, and a compact design that can , making them particularly suitable for applications with limited space. They are capable of managing and can significantly reduce conduction loss by over 50%. However, the manufacturing costs are typically higher, and they require meticulous design to achieve peak performance.

Conversely, thermal conduits are often more cost-effective and simpler to produce, utilizing a manufacturing process that allows for greater design flexibility. They excel in transferring heat over extended distances, yet may encounter challenges with rapid thermal dissipation across surfaces, particularly in orientations that do not align with their design. For instance, the largest thermal conduit available can accommodate approximately 125 watts in a horizontal position, which is notably less than the capacity of vapor chambers.

Furthermore, gas-filled enclosures are preferred for exceeding 50 w/cm, underscoring their suitability for . Ultimately, the choice between depends on specific application demands, such as budget limitations, spatial constraints, and the necessity for efficient . Recognizing these factors is essential for engineers seeking to identify the most effective thermal solution for their projects.

Conclusion

Vapor chambers and heat pipes represent essential components in the domain of thermal management, each presenting distinct advantages tailored to specific applications. Grasping the differences between these technologies is vital for engineers aiming to optimize cooling solutions in high-performance electronics. Vapor chambers are distinguished by their rapid thermal distribution and compact design, rendering them ideal for devices with stringent space constraints. Conversely, heat pipes excel in effective heat transfer over extended distances, proving advantageous in larger systems.

This article has delved into key insights regarding the operational mechanisms, performance metrics, and contextual applications of both vapor chambers and heat pipes. Vapor chambers are particularly favored in compact devices such as smartphones and gaming consoles, where efficient thermal spreading is critical. In contrast, heat pipes find widespread application in laptops and aerospace sectors, where their design facilitates effective thermal transport. The burgeoning market for these technologies highlights the escalating demand for advanced cooling solutions across diverse electronic systems.

As the electronics industry continues to advance, the significance of selecting the appropriate thermal management solution cannot be overstated. Engineers and designers must carefully evaluate the benefits and drawbacks of each technology, taking into account factors such as cost, spatial limitations, and performance requirements. By making informed decisions between vapor chambers and heat pipes, they can enhance the reliability and efficiency of modern electronic devices, ultimately contributing to the technological advancement across various sectors.

Frequently Asked Questions

What are vapor chambers and heat pipes?

Vapor chambers and heat pipes are passive temperature control devices that utilize phase change to transfer heat effectively. Vapor chambers distribute heat across two dimensions, while heat pipes primarily transfer energy along their length.

How do vapor chambers work?

Vapor chambers consist of a sealed container filled with a small amount of liquid. When heated, the liquid evaporates, turning into gas that moves to cooler areas, where it condenses back into liquid. This process facilitates efficient thermal spreading.

What applications benefit from vapor chambers?

Vapor chambers are particularly advantageous for high-performance applications such as smartphones and gaming consoles, which account for over 40% of their utilization.

What are thermal conduits?

Thermal conduits are cylindrical tubes designed to transfer energy mainly along their length. They also contain a working fluid that evaporates and condenses, optimized for energy transfer over longer distances.

Where are thermal conduits typically used?

Thermal conduits are ideal for larger electronic systems, such as data centers and telecommunications devices, where managing high thermal loads is crucial.

What is the market outlook for thermal conduits and vapor chambers?

The global market for thermal conduits and gas-filled units was estimated at approximately USD 3.12 billion in 2022, with a projected compound annual growth rate (CAGR) of 9.3% from 2023 to 2032.

How effective are vapor chambers and heat pipes in cooling electronics?

Both vapor chambers and heat pipes play a crucial role in electronics cooling methodologies, with case studies showing significant demand for advanced cooling solutions in high-performance environments, such as Cooler Master’s heat sinks in gaming PCs, which accounted for 18% of their sales in 2024.

What advantages do fluid containers offer in thermal management?

Fluid containers provide superior thermal distribution capabilities, which are essential for ensuring the reliability and functionality of modern electronic devices.