Overview

The article titled “10 Essential Heat Exchanger Cooler Insights for Engineers” provides critical information and insights pertinent to the design, performance, and selection of heat exchanger coolers specifically for engineers. It underscores the necessity of understanding thermodynamic principles, material selection, and innovative technologies to enhance the efficiency and effectiveness of heat exchangers across various industrial applications.

Introduction

The landscape of thermal management is rapidly evolving, with heat exchangers playing a pivotal role across various industries. Engineers are continuously seeking innovative solutions to enhance efficiency, reduce costs, and meet sustainability goals. This article delves into ten essential insights about heat exchanger coolers, offering engineers valuable knowledge on advanced technologies, design considerations, and application strategies that can significantly impact performance.

What are the latest trends and challenges in optimizing heat exchangers? How can engineers leverage these insights to stay ahead in a competitive market? Understanding these dynamics is crucial for driving progress and achieving excellence in thermal management.

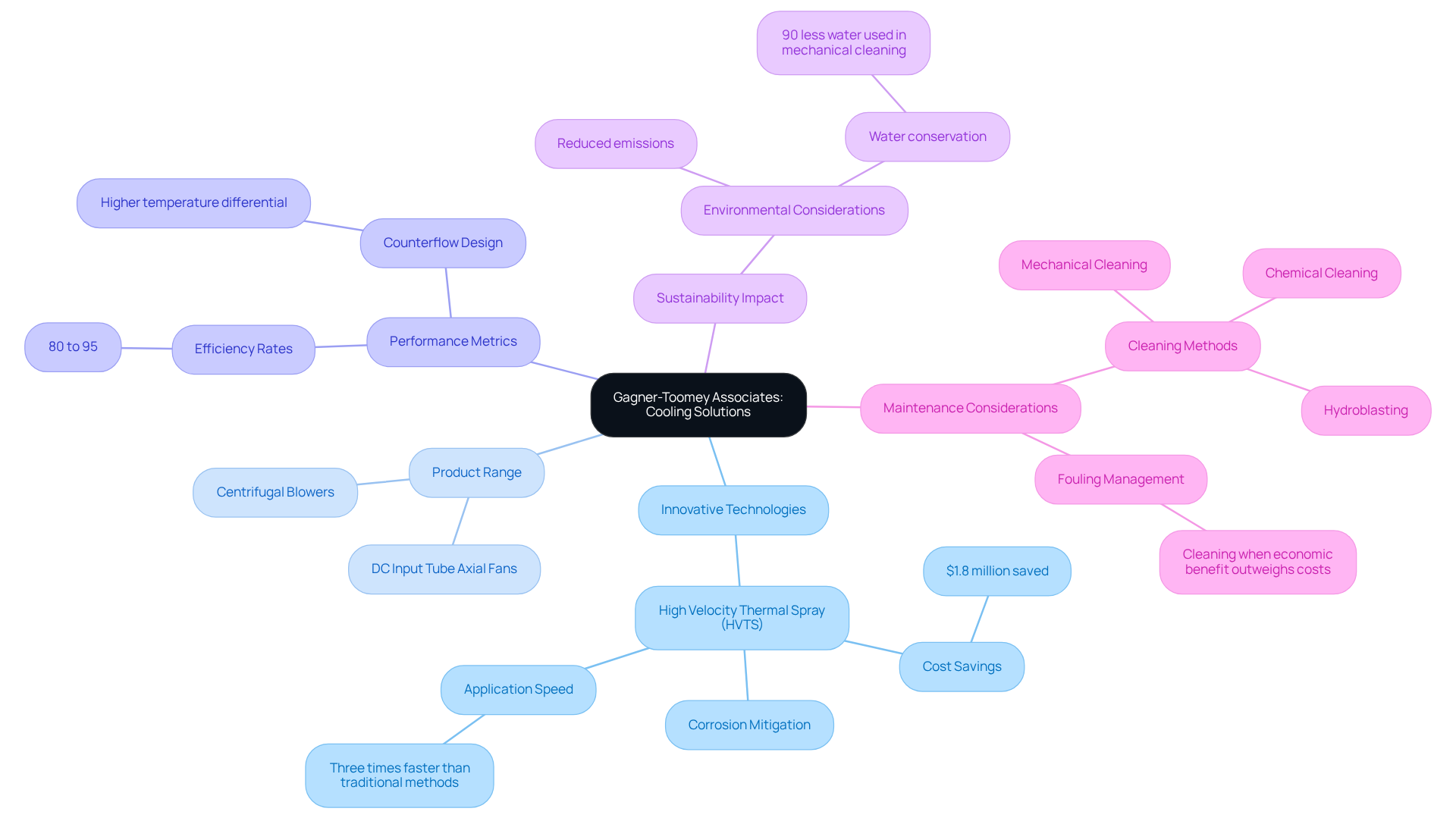

Gagner-Toomey Associates: Innovative Cooling Solutions for Heat Exchangers

Gagner-Toomey Associates excels in delivering specifically tailored for . As the world’s largest manufacturer of standard and custom air-movers, Gagner-Toomey empowers engineers with access to cutting-edge technologies that significantly enhance across diverse applications, including electronics, automotive, and industrial sectors. Their extensive product range encompasses DC input tube axial fans and centrifugal blowers, optimized for performance, effectiveness, and low noise, ensuring with the right tools for effective cooling.

Recent advancements, particularly , showcase a remarkable capability to provide dense, impermeable cladding, effectively preventing of critical components. Notably, HVTS eliminates the need for post-weld thermal treatment (PWHT) and addresses related temperature-affected zones (HAZ) issues, positioning it as an excellent choice for high-temperature environments. This technology has undergone rigorous testing, proving to —up to $1.8 million in specific applications—by mitigating corrosion in high-temperature settings.

The impact of these advanced cooling systems is underscored by their operational performance, with thermal transfer devices typically achieving . Counterflow thermal devices, in particular, are recognized for their exceptional performance due to their ability to maintain a greater temperature differential, leading to enhanced thermal transfer. However, it is crucial to acknowledge that fouling can reduce effectiveness over time, necessitating cleaning when the economic benefit of cleaning outweighs the associated costs, a critical consideration for sustaining optimal performance.

Gagner-Toomey’s commitment to excellence ensures that engineers can depend on that adhere to stringent industry standards, ultimately facilitating the development of efficient and reliable heat exchangers across various applications. As the thermal exchange sector evolves, the integration of remains essential for meeting the growing demands for sustainability and operational effectiveness. As emphasized by industry specialists, ‘The adoption of intelligent technologies in the exchange sector leads to enhanced operational performance and supports sustainability initiatives.

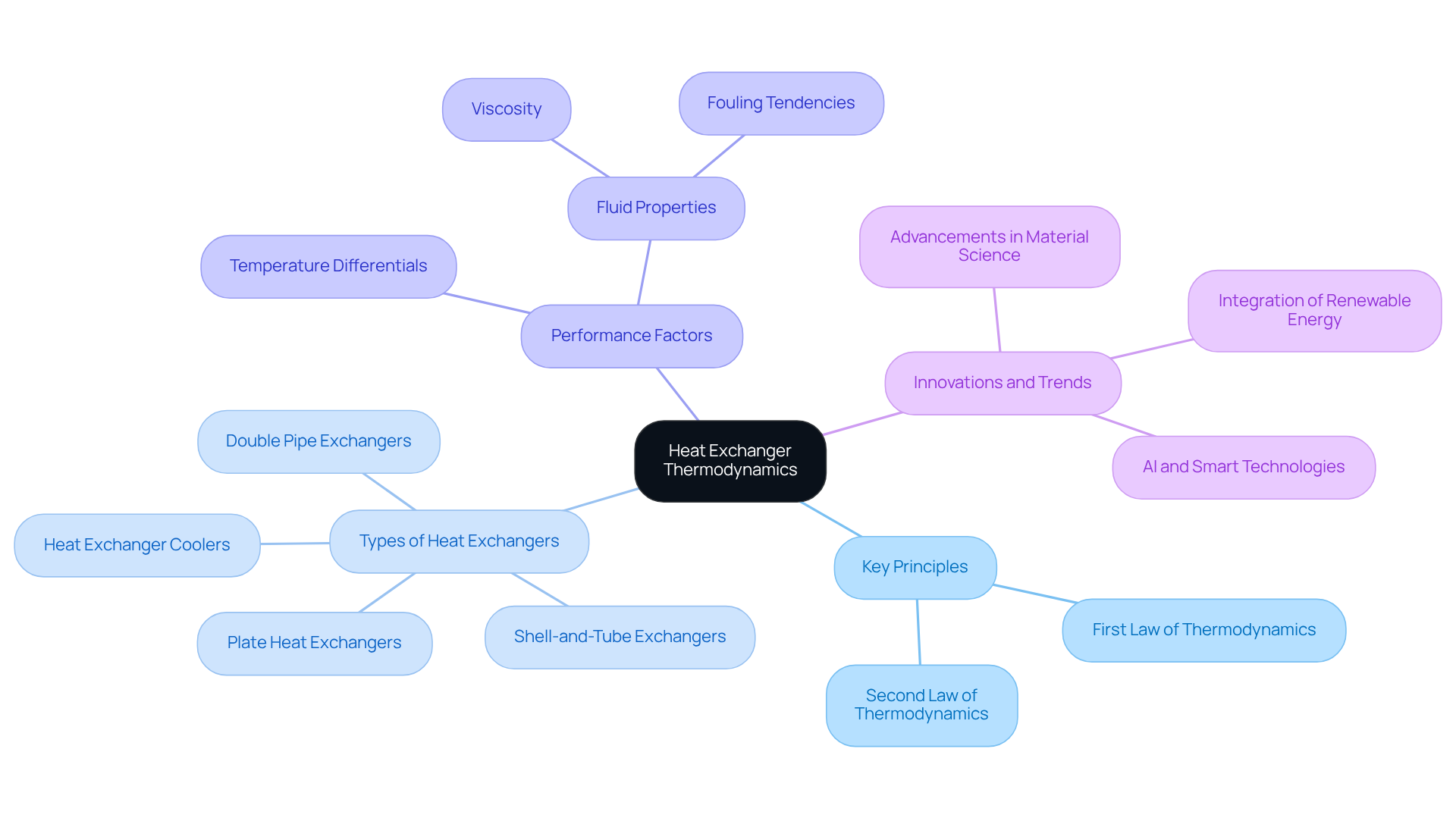

Understanding Heat Exchanger Thermodynamics: Key Principles

operate based on fundamental thermodynamic principles, primarily the , which dictate the movement of thermal energy between fluids. The essential principles include:

- The first law of thermodynamics (energy conservation)

- The second law (entropy)

Both of which significantly influence the design and efficiency of thermal transfer devices. Engineers must account for temperature differentials, thermal transfer coefficients, and to optimize performance. Various types of , such as:

- Double pipe exchangers

- Shell-and-tube exchangers

exemplify these principles in practical applications.

To enhance , engineers scrutinize these elements alongside advancements in material science, leading to innovative designs that markedly improve effectiveness. For instance, the integration of , such as solar thermal collectors, into exchange systems has proven to enhance performance while promoting sustainability. Recent research indicates that exhibit the highest effectiveness and transfer rates, making them a preferred choice in numerous applications.

Insights from thermodynamics specialists reveal that optimizing flow configurations and understanding fluid characteristics, including viscosity and fouling tendencies, are crucial for maximizing the overall performance of thermal devices. By leveraging these thermodynamic principles and insights, engineers can design more effective systems that address the growing demands for and environmental responsibility.

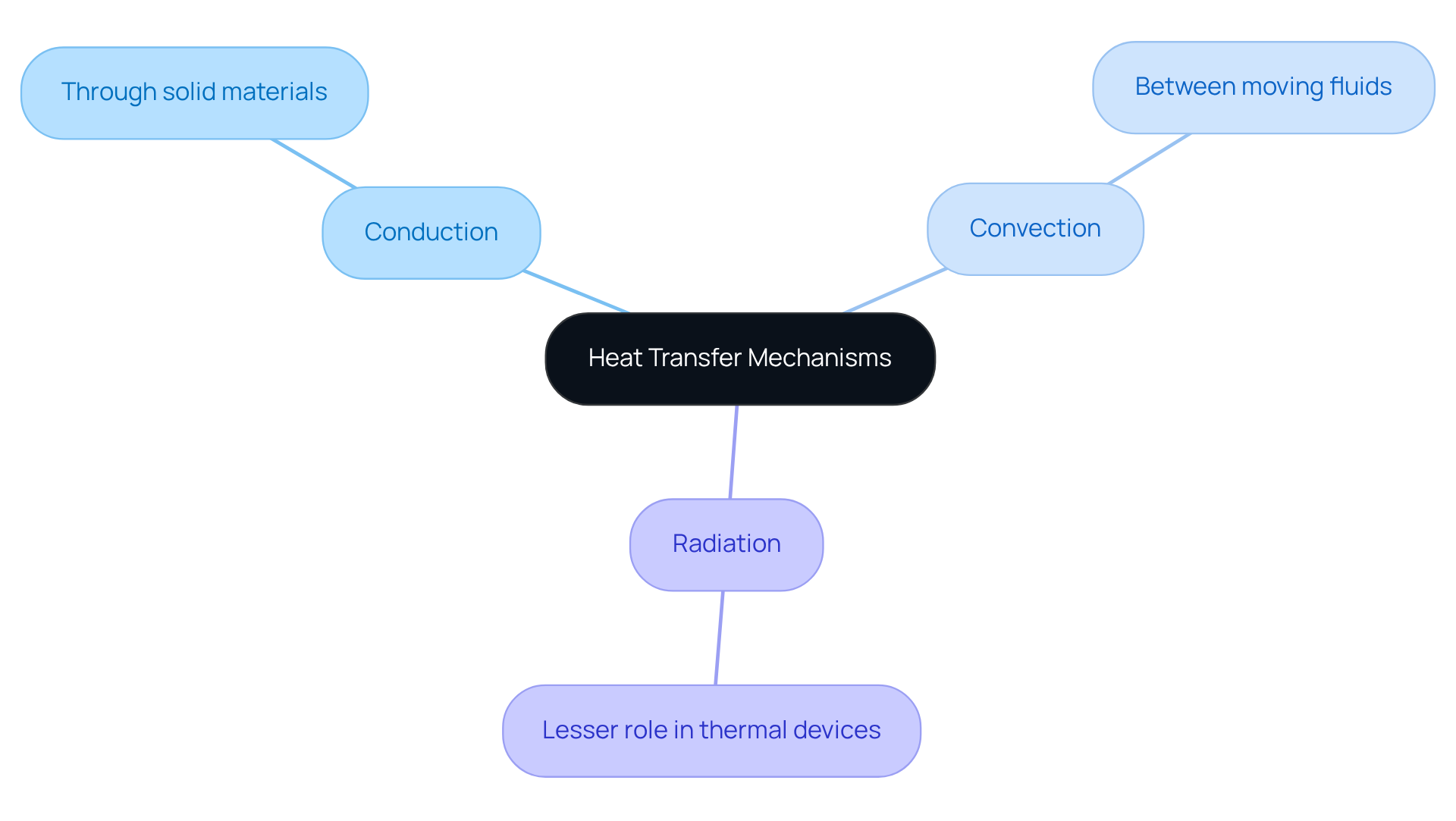

Heat Transfer Mechanisms: Conduction, Convection, and Radiation

in thermal devices occurs primarily through three distinct processes:

- Conduction is the mechanism of thermal transfer through solid materials.

- Convection pertains to the transfer of heat between moving fluids.

- Although radiation plays a lesser role in most thermal devices, it can still contribute to effective temperature transfer.

For , a thorough is crucial for and that optimize .

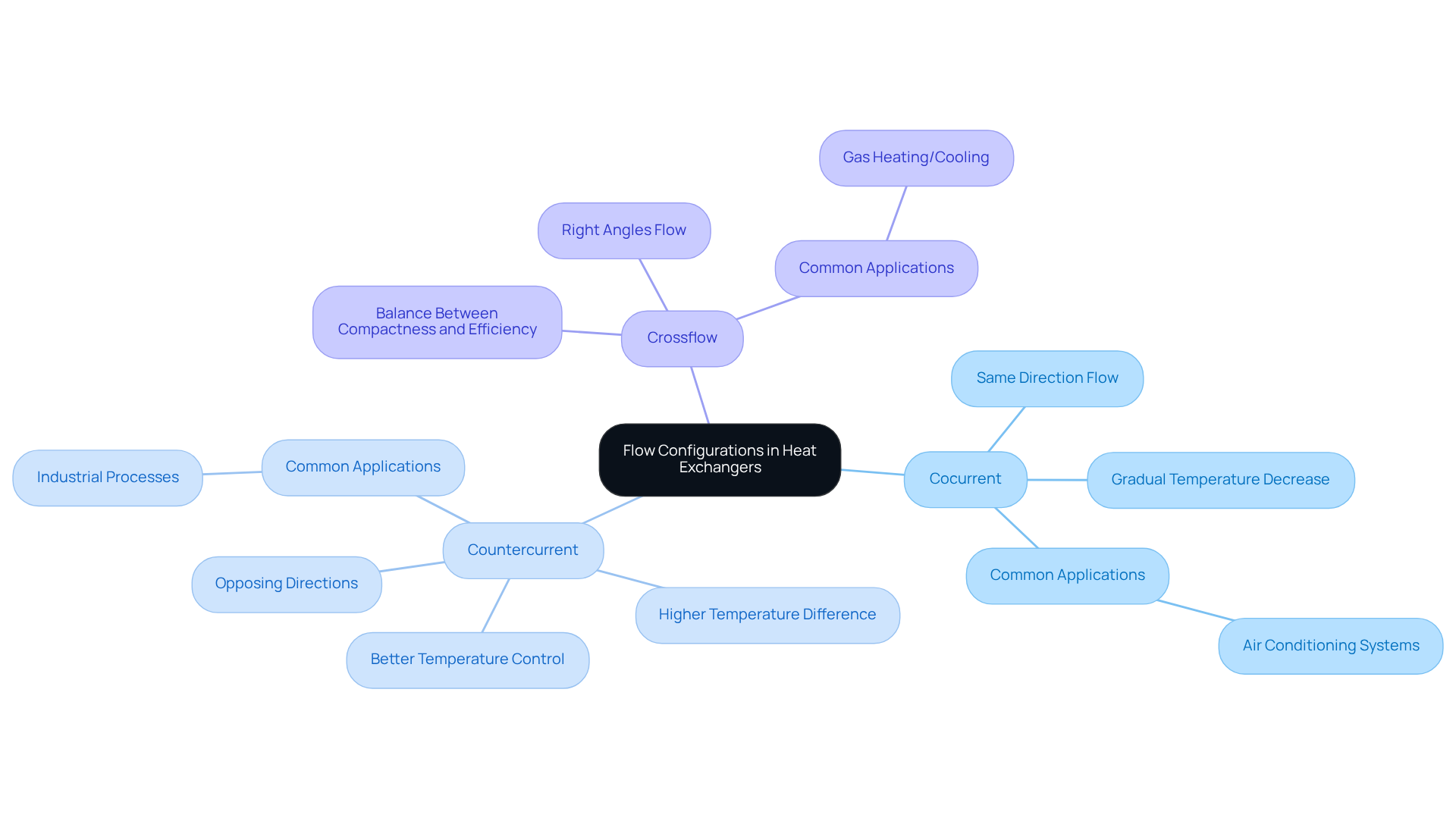

Flow Configurations in Heat Exchangers: Cocurrent, Countercurrent, and Crossflow

s can be designed with various flow configurations, including:

- Cocurrent

- Countercurrent

- Crossflow

sees both fluids traveling in the same direction, while involves fluids moving in opposing directions, often resulting in improved in a heat exchanger cooler due to a greater temperature gradient. In , the heat exchanger cooler allows fluids to flow at right angles to one another, striking a balance between compact structure and efficiency. to select the most .

Types of Heat Exchangers: Shell and Tube, Plate, and More

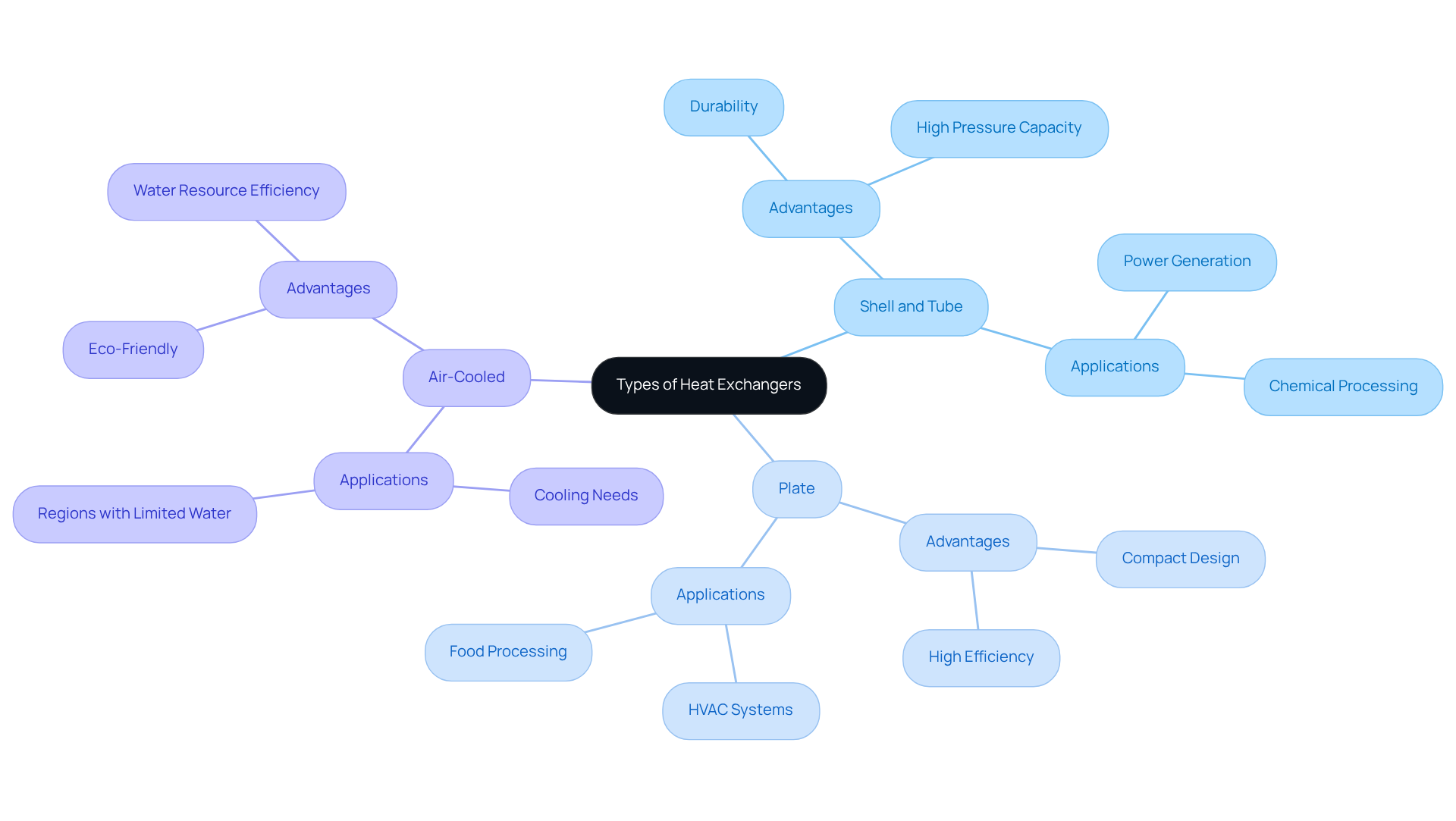

Heat transfer devices come in various forms, including shell and tube, plate, and types, each designed for specific applications.

- are favored for their durability and capacity to withstand high pressures, making them ideal for demanding industrial environments. Their effectiveness is particularly notable in power generation and chemical processing, where reliability is paramount.

- Conversely, plate thermal devices stand out for their , achieving performance levels up to five times greater than traditional shell-and-tube models. This efficiency is especially beneficial in applications with limited space, such as HVAC systems and food processing, where precise temperature control is critical.

- Air-cooled thermal devices, such as heat exchanger coolers, serve as an optimal solution in regions with limited water resources, providing an .

When selecting a , such as available space, fluid characteristics, thermal requirements, and operational conditions. Recent innovations in thermal transfer designs, including enhanced sealing systems and advanced materials, continue to improve the performance of these vital components across various sectors.

Heat Exchanger Components and Materials: Selection Criteria

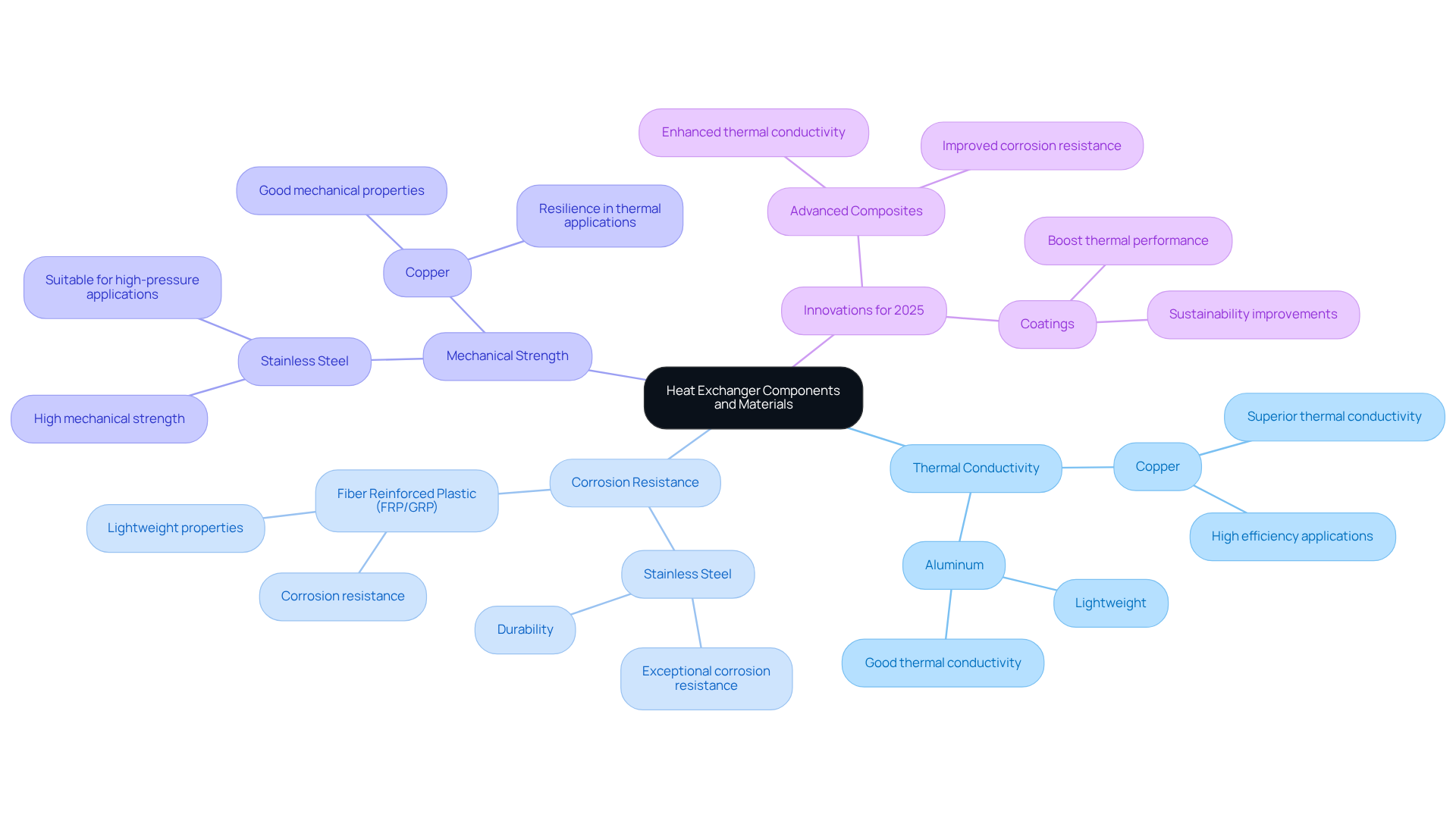

Selecting the right materials and components for thermal transfer devices is critical for and longevity. Engineers must prioritize key factors such as:

in their decision-making processes. Materials like stainless steel, copper, and aluminum each offer distinct advantages tailored to specific applications. For example, stainless steel is preferred for its exceptional corrosion resistance and durability, while copper is recognized for its superior thermal conductivity, making it particularly suitable for high-efficiency applications.

Moreover, the choice of gaskets, seals, and other ancillary components can significantly impact the of the device. Engineers are advised to conduct a comprehensive assessment of the —including temperature, pressure, and fluid characteristics—to ensure that the selected materials can endure the environment without compromising functionality.

Innovations in materials for 2025 include engineered to boost thermal conductivity while delivering outstanding corrosion resistance. These advancements are essential in addressing the increasing demands for effectiveness and sustainability in . For instance, mitigating steam leaks can lead to , underscoring the financial ramifications of material selection. By integrating these insights into their development processes, engineers can markedly enhance the of thermal devices.

Design Characteristics of Heat Exchangers: Key Considerations

The design features of the are pivotal for achieving . Key factors encompass surface area, flow arrangement, and . Engineers must strategically balance these elements to enhance thermal transfer while minimizing pressure drop and . Notably, are recognized for their superior efficiency, enabling higher transfer rates compared to other configurations. Additionally, optimizing surface area through , such as topology optimization and additive manufacturing, can significantly enhance performance.

Fouling resistance, ease of maintenance, and operational flexibility are also essential considerations for ensuring . Engineers at the University of Wisconsin-Madison have demonstrated that complex shapes in can yield a 27% improvement in power density, underscoring the potential of sophisticated development methods. Furthermore, the selection of materials is crucial, as it directly impacts thermal performance and durability. Various types of thermal devices, including recuperative and regenerative systems, offer multiple advantages based on specific application needs. A thorough understanding of these features empowers engineers to design thermal devices, including a heat exchanger cooler, tailored to particular application requirements, ultimately fostering innovation in thermal management solutions. As Dr. Mahder Tewolde articulates, “The design of a heat transfer device is an exercise in thermodynamics, the science that deals with heat energy flow, temperature, and their relationships to other forms of energy.

Applications of Heat Exchangers: Industries and Use Cases

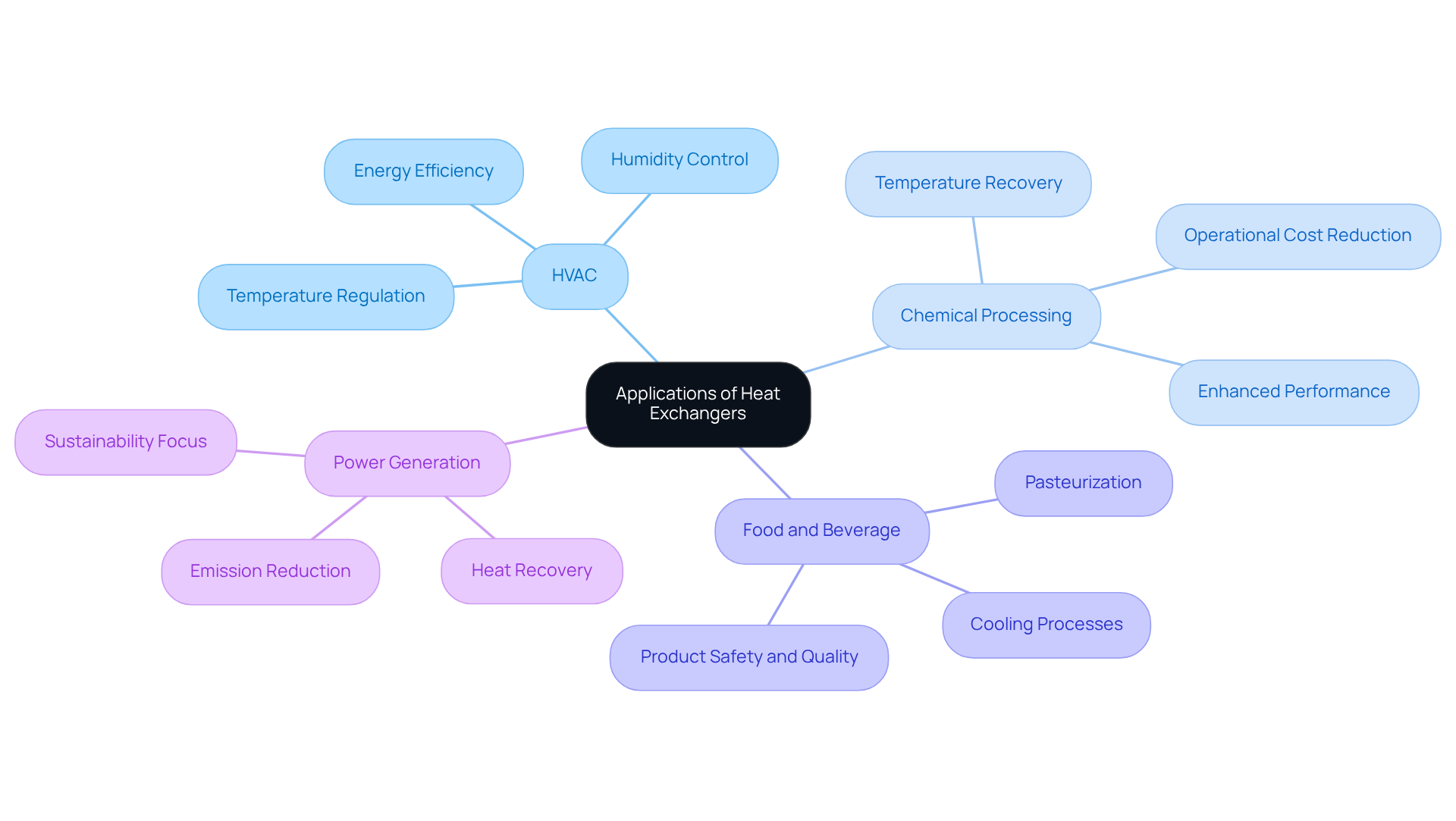

are indispensable devices for heat transfer across various industries, including HVAC, chemical processing, food and beverage, and power generation. In HVAC systems, heat exchanger coolers are essential devices for regulating temperature and humidity, thereby ensuring both comfort and . In the realm of chemical processing, heat exchanger coolers facilitate temperature recovery, significantly . For instance, a Type 304L stainless steel thermal device is commonly employed for condensing gases and heating water, exemplifying its effectiveness in demanding environments.

The food and beverage industry relies heavily on , particularly heat exchanger coolers, for critical processes such as pasteurization and cooling, which are vital for maintaining product safety and quality. Recent trends highlight an increasing focus on and materials capable of withstanding high temperatures and corrosive conditions. Alloys containing , are increasingly utilized in thermal transfer devices due to their exceptional resistance to corrosion and high temperatures, making them ideal for rigorous processing environments.

Data from 2025 reveals a rising adoption of heat exchanger coolers in HVAC systems, driven by technological innovations and a heightened focus on sustainability. Meanwhile, the chemical processing sector continues to embrace to enhance performance and reduce emissions. Understanding the of each industry empowers engineers to for optimal performance, ultimately leading to enhanced operational efficiency and a reduced environmental footprint.

Design Optimization for Heat Exchangers: Strategies for Improvement

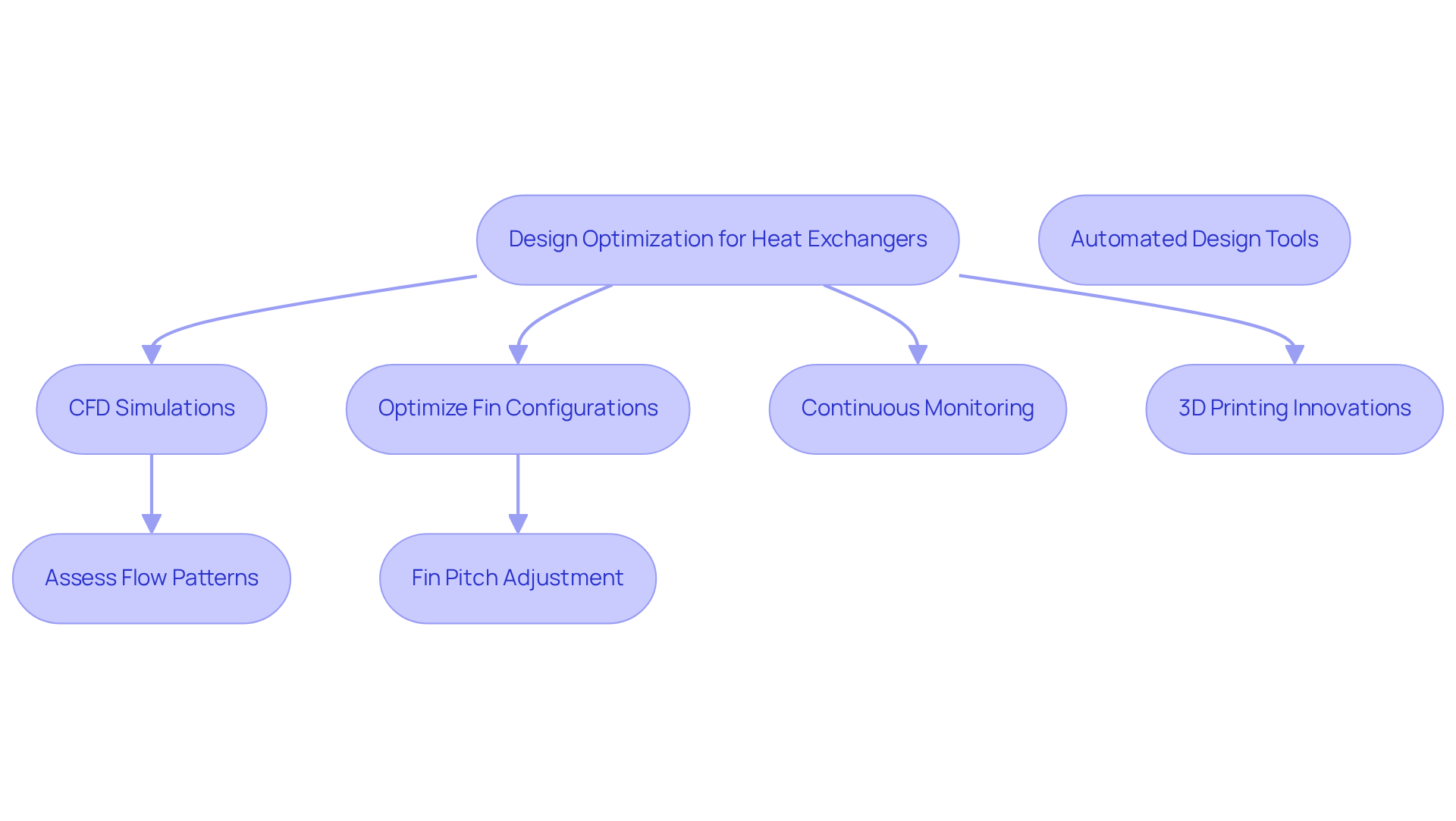

Design optimization for the is a critical endeavor that leverages , , and to enhance performance. By employing CFD tools, engineers can meticulously examine flow patterns and thermal transfer rates, facilitating precise modifications that lead to significant . For instance, enable the assessment of various fin configurations, including elliptical and serrated fins, optimizing thermal transfer while minimizing pressure drop. Through to fin pitch, height, and thickness, engineers can substantially increase surface area, thereby further enhancing .

Moreover, constant observation and provide valuable insights for continuous improvement, ensuring that at optimal performance levels. The IAMHEX project exemplifies these advancements, focusing on the integration of 3D printing methods and automated design tools to revolutionize thermal device production and performance. As the industry evolves, the role of CFD simulations will remain essential in driving innovations and improving the overall efficiency of thermal transfer systems, particularly with heat exchanger coolers.

Heat Exchanger Selection Considerations: Factors to Evaluate

When selecting a , engineers face a that requires careful evaluation of several key factors. These include:

- requirements

- Fluid properties

- Space constraints

- Budget considerations

Furthermore, operational conditions such as temperature, pressure, and flow rates must be meticulously assessed. By understanding the specific application needs and potential challenges, engineers can make informed decisions that not only optimize performance but also ensure long-term reliability.

Recent guidelines for 2025 underscore the importance of assessing equipment for:

- Safety

These elements are essential in the selection process. Successful assessments, as highlighted in the case study on ‘High-Performing Innovation,’ demonstrate how .

Moreover, appropriate exchanger sizing necessitates a thorough determination of the required transfer surface based on the temperature variance between liquids, which is crucial for meeting thermal performance standards. Engineers must also account for specific structural factors, including:

- Heat transfer coefficient

- Heat exchange area

- Fouling control

to guarantee optimal performance.

The integration of renewable energy sources further complicates the selection process, making it imperative for engineers to adapt their designs to accommodate varying fluid characteristics. By embracing these considerations, engineers can navigate the complexities of heat exchanger selection with confidence and expertise.

Conclusion

The exploration of heat exchanger coolers underscores their critical role in enhancing thermal management across various industries. By delving into the intricacies of heat transfer mechanisms, flow configurations, and material selection, engineers can significantly elevate the efficiency and reliability of these essential devices. The insights presented underscore the necessity of adopting advanced technologies and innovative designs that align with the evolving demands of sustainability and operational effectiveness.

Key arguments emphasize:

- The importance of thermodynamic principles in optimizing performance

- The advantages of diverse heat exchanger types

- The critical factors shaping design and material choices

The integration of cutting-edge technologies, such as High Velocity Thermal Spray (HVTS), highlights the potential for substantial cost savings while extending the lifespan of heat exchangers. Moreover, the focus on thorough evaluation during the selection process reinforces the need for tailored solutions that address specific application requirements.

As industries increasingly prioritize energy efficiency and environmental responsibility, engineers are urged to embrace these insights and innovations. By leveraging advanced design strategies and optimizing material selection, the potential for enhanced performance in heat exchanger systems is immense. Ultimately, the commitment to continuous improvement and adaptation will not only drive operational excellence but also contribute to a more sustainable future in thermal management.

Frequently Asked Questions

What does Gagner-Toomey Associates specialize in?

Gagner-Toomey Associates specializes in delivering innovative cooling solutions specifically tailored for heat exchanger coolers, making them the world’s largest manufacturer of standard and custom air-movers.

What types of products does Gagner-Toomey offer?

Gagner-Toomey offers a range of products including DC input tube axial fans and centrifugal blowers, optimized for performance, effectiveness, and low noise.

What is High Velocity Thermal Spray (HVTS) technology?

HVTS technology provides dense, impermeable cladding that prevents corrosion and prolongs the lifespan of critical components, eliminating the need for post-weld thermal treatment and addressing temperature-affected zones in high-temperature environments.

How does HVTS technology impact costs?

HVTS technology has been proven to save substantial costs—up to $1.8 million in specific applications—by mitigating corrosion in high-temperature settings.

What is the typical performance rate of thermal transfer devices?

Thermal transfer devices typically achieve performance rates between 80% and 95%, with counterflow thermal devices recognized for their exceptional performance due to their ability to maintain a greater temperature differential.

What is fouling, and how does it affect thermal devices?

Fouling refers to the accumulation of unwanted material on solid surfaces, which can reduce the effectiveness of thermal devices over time, necessitating cleaning when the economic benefit of cleaning outweighs the associated costs.

What principles govern the operation of thermal transfer devices?

Thermal transfer devices operate based on the first law of thermodynamics (energy conservation) and the second law (entropy), which influence their design and efficiency.

What types of thermal exchangers are mentioned in the article?

The article mentions several types of thermal exchangers, including heat exchanger coolers, double pipe exchangers, and shell-and-tube exchangers.

How can engineers enhance thermal transfer performance?

Engineers can enhance thermal transfer performance by optimizing temperature differentials, thermal transfer coefficients, fluid properties, and leveraging advancements in material science.

What are the three primary heat transfer mechanisms?

The three primary heat transfer mechanisms are conduction (through solid materials), convection (between moving fluids), and radiation (which plays a lesser role in most thermal devices).