Overview

Small fan blowers play a pivotal role in enhancing the performance of electronics by improving airflow and facilitating effective heat dissipation. This is crucial for maintaining optimal operating temperatures, which in turn prevents component failure. These devices have been shown to significantly reduce temperatures, thereby increasing the reliability and lifespan of electronic components across various applications, from automotive to laboratory settings. The implications of this technology are profound, as they not only ensure the longevity of components but also enhance overall system performance.

Introduction

Compact cooling solutions have become indispensable in the realm of electronics, where the management of heat is crucial for optimal performance and reliability. Small fan blowers, in particular, present a multitude of benefits—ranging from enhanced airflow to the prolonged lifespan of electronic components. As technology advances and devices grow increasingly powerful, the challenge of effective thermal management intensifies. This raises a critical question: how can engineers and hobbyists alike harness the full potential of these small yet mighty devices to ensure peak performance in their projects?

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Engineering

Gagner-Toomey Associates stands at the forefront of delivering innovative tailored for the electronics engineering sector. Their unwavering commitment to advancing technology is evident in a diverse portfolio that showcases , including a and a comprehensive range of and centrifugal blowers. These devices are crucial for of electronic components.

By partnering with leading manufacturers, Gagner-Toomey provides engineers with access to the latest advancements in temperature regulation technologies, including liquid systems that can achieve heat fluxes exceeding 800 watts per square centimeter—one of the highest levels documented for this type of . Such are indispensable for regulating heat in , particularly as global energy consumption for temperature control is projected to more than double by 2030. This trend underscores the urgent need for more efficient temperature management solutions.

The integration of not only improves thermal management but also contributes to , making them essential in the evolving landscape of electronics.

Cooling Electronic Components: Utilizing Small Fan Blowers for Efficient Heat Management

Compact fan devices are essential for regulating the temperature of electronic components, as they enhance airflow and facilitate . These devices can , often by as much as 20°C, which is vital for preventing thermal accumulation that may lead to component failure.

By strategically placing within electronic assemblies, engineers can ensure that , thereby enhancing overall system reliability. For instance, the Delta Electronics AFB0412HH fan is particularly favored in industrial environments due to its performance, boasting a static pressure rating of 0.359 inchH2O, which ensures optimal temperature management in high-resistance conditions.

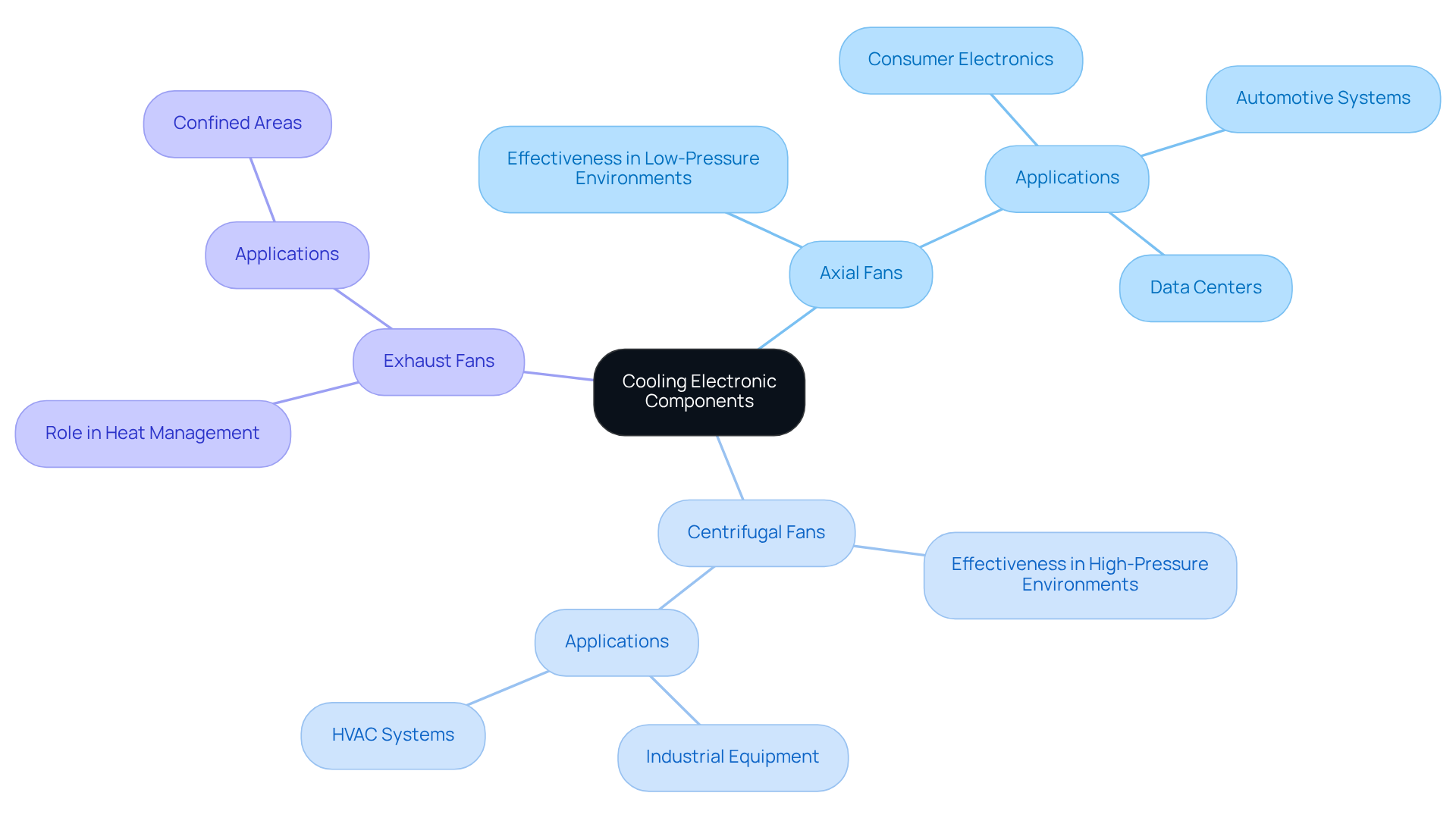

Furthermore, small ventilation fans are categorized into three primary types:

- Axial fans, effective in low-pressure environments

- Centrifugal fans, which excel in high-pressure situations

- Exhaust fans, each providing tailored solutions for various airflow requirements

Understanding airflow and static pressure is crucial for , as these factors influence the selection of the appropriate fan type for specific applications. The integration of these technologies not only enhances heat management but also , underscoring the importance of choosing the right fan type for particular applications.

Power Management: Enhancing Airflow with Small Fan Blowers for Optimal Performance

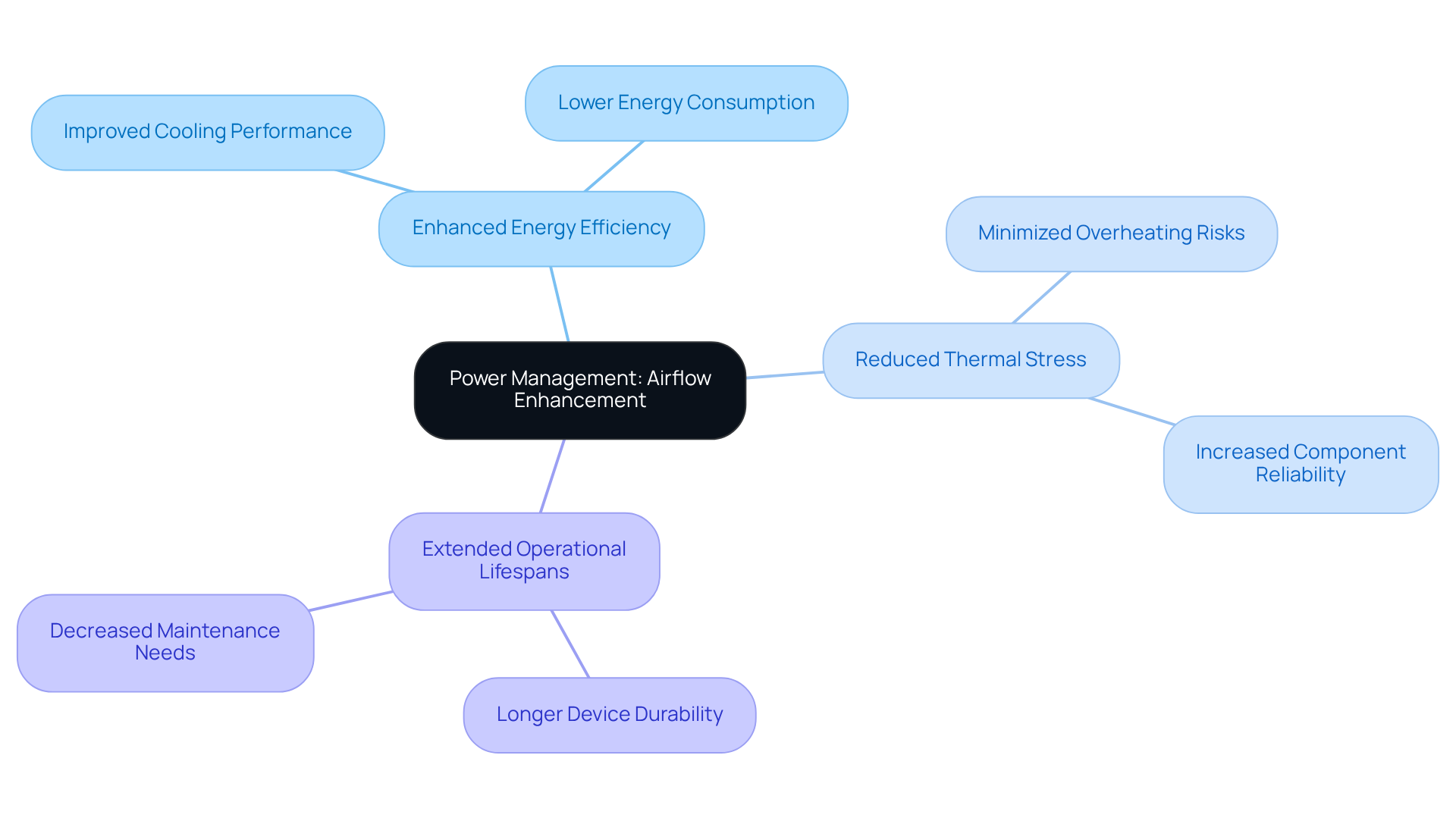

In , the role of small fan devices is critical in , which directly contributes to achieving optimal performance. These devices significantly improve the , thereby sustaining efficiency and preventing overheating—a crucial factor in high-density applications where heat generation is substantial.

By leveraging small fan devices, users can experience:

This underscores the necessity of aimed at maximizing performance and reliability.

Testing and Evaluation: Leveraging Small Fan Blowers for System Performance Assessment

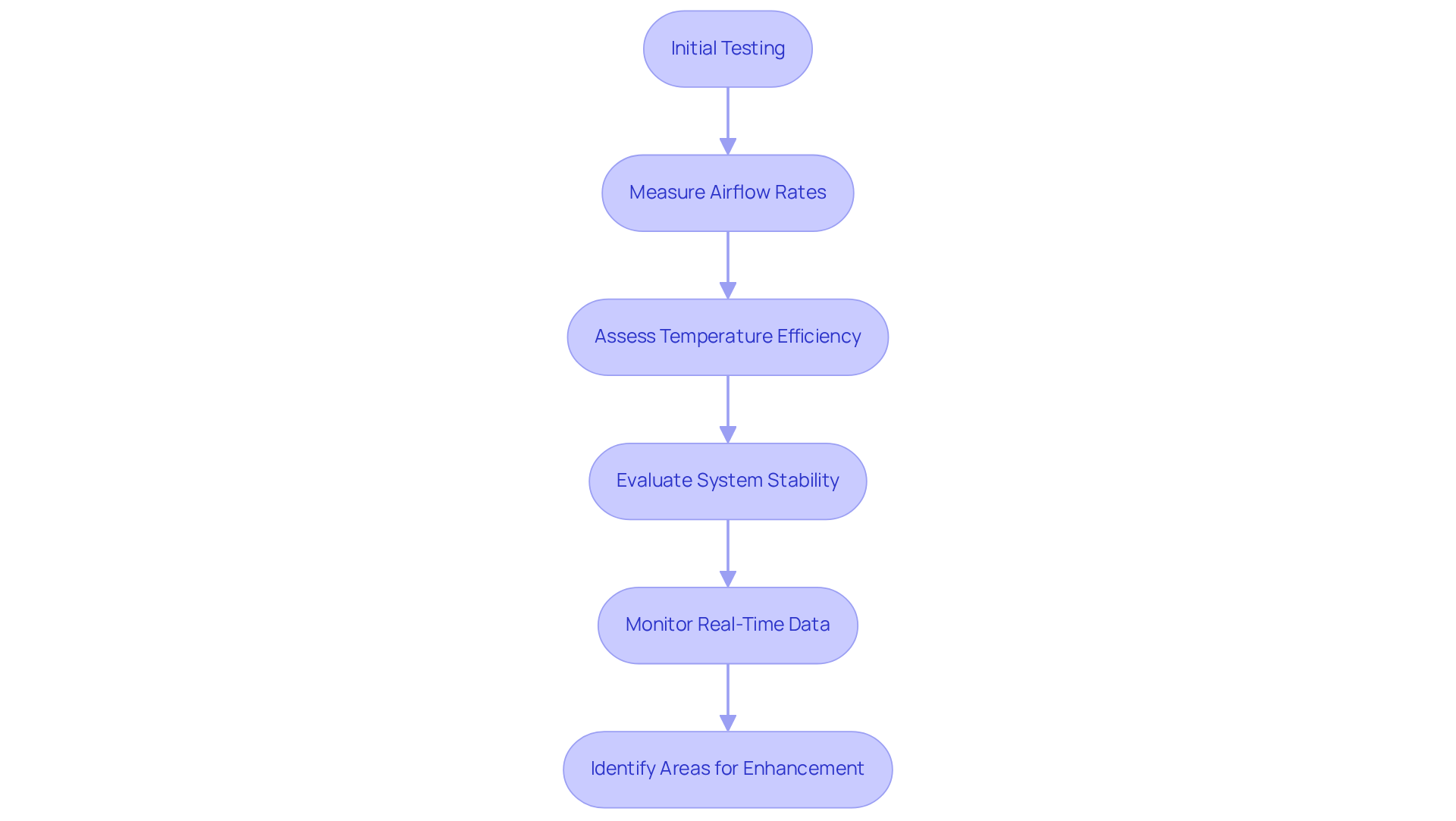

Comprehensive testing and evaluation are essential for measuring the performance of the in electronic devices. Engineers conduct thorough to assess airflow and , which involves measuring temperature differentials, , and overall system stability under various operating conditions.

For example, modern ventilation fans can achieve efficiencies exceeding 90%, making them vital for maintaining optimal performance in . These assessments not only verify that selected temperature regulation solutions meet the stringent requirements of contemporary electronic applications but also aid in pinpointing potential areas for enhancement.

By employing real-time monitoring and data analysis, engineers can promptly address inefficiencies, ensuring that airflow rates and align with the demands of evolving technologies. This proactive strategy is crucial as the need for continues to rise, particularly in applications related to artificial intelligence and high-performance computing.

Notably, products from companies such as SANYO DENKI can surpass 100 CFM (cubic feet per minute) airflow, underscoring the importance of evaluating in electronics.

RF Applications: Cooling Solutions with Small Fan Blowers for Enhanced Efficiency

In , maintaining optimal operating temperatures is crucial for performance. are essential for dissipating heat generated by RF components, which are especially sensitive to temperature fluctuations. Efficient temperature control methods not only but also greatly .

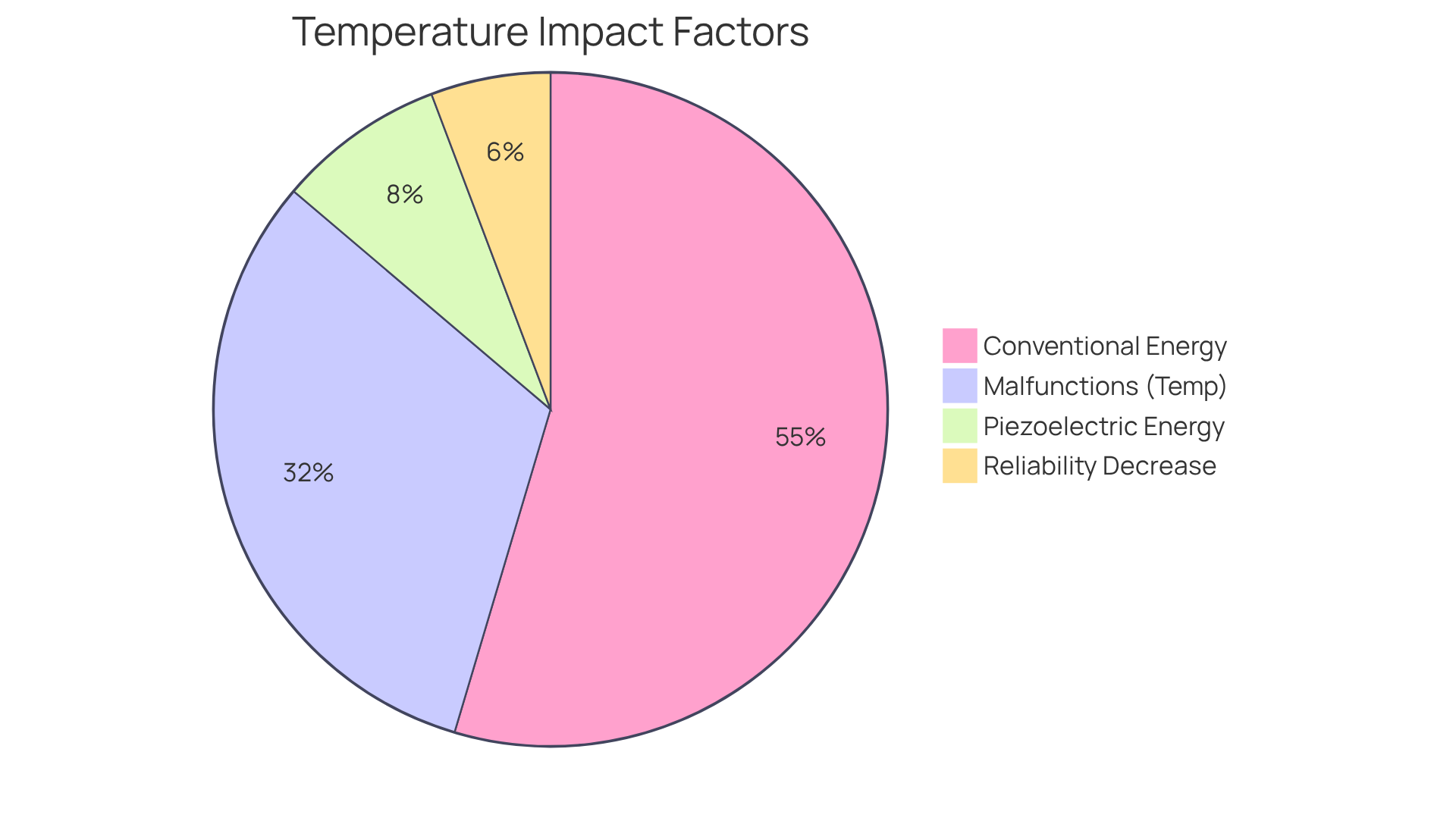

Research indicates that for every 2 °C rise in temperature, the reliability of electronic components decreases by 10%, underscoring the importance of . Furthermore, around 55% of electronic device malfunctions are linked to temperature-related problems, highlighting the necessity of robust .

By utilizing small fan blowers, can be achieved for RF devices, ensuring consistent performance in demanding applications such as telecommunications and broadcasting. Expert opinions emphasize that these temperature regulation solutions are essential for optimizing the functionality and longevity of RF components, ultimately resulting in .

Moreover, airflow energy represents around 30-80% of the overall energy usage for particular units, demonstrating the . The efficiency of small fan blowers is further illustrated by the , with piezoelectric devices consuming only 14 mW compared to 95 mW for conventional motor units. Additionally, when positioned at a suitable distance from the heat source, the heat transfer coefficient of a small fan blower can be 200% greater than that of traditional rotary fans, strengthening their efficiency in regulating RF components.

Interconnect Technologies: Ensuring Reliability with Small Fan Blowers

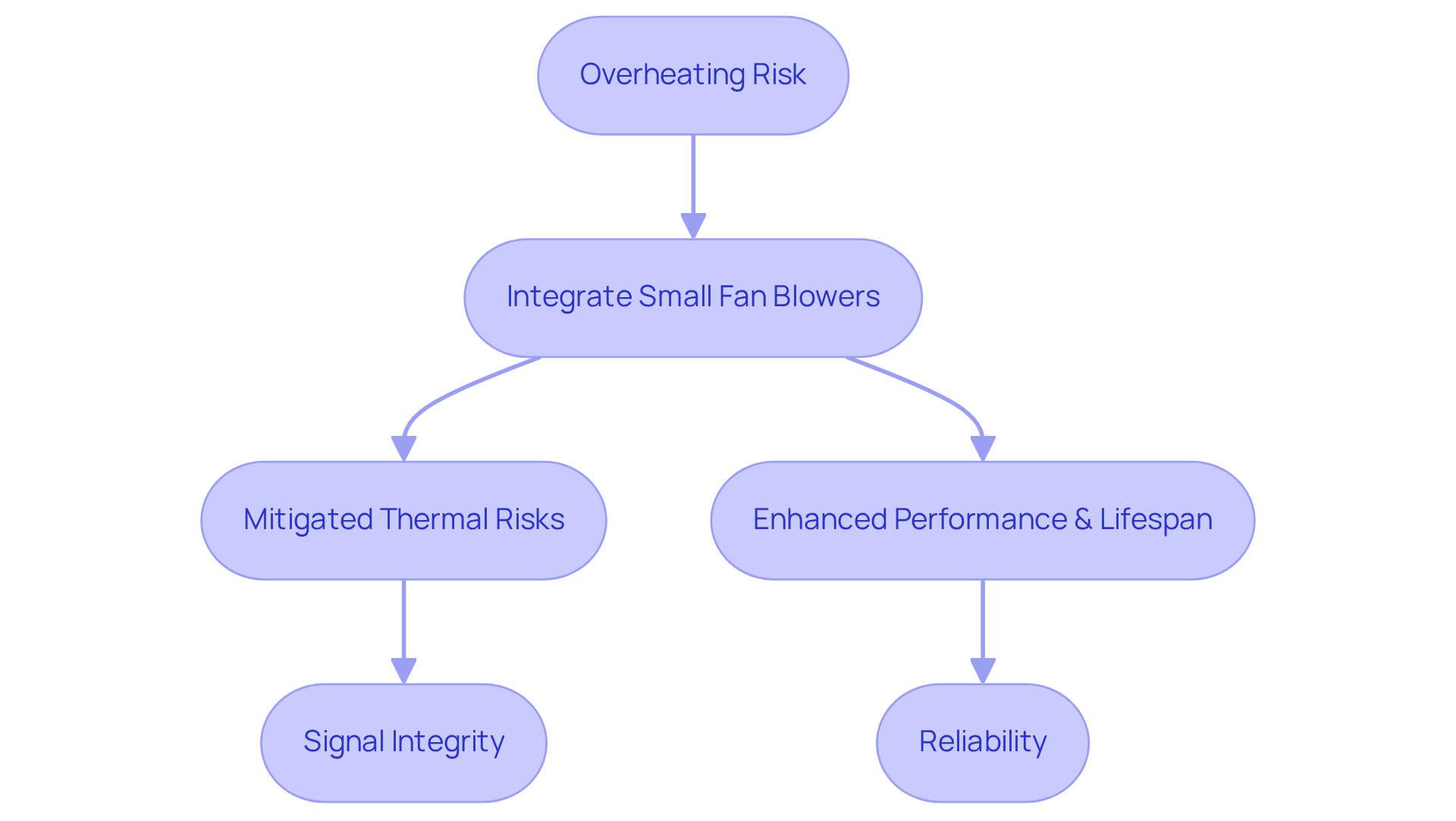

Compact fan devices are essential in ensuring the reliability of by effectively managing heat dissipation. Overheating poses a significant risk, leading to signal degradation and potential failure in interconnect systems. Therefore, is not just beneficial but crucial. By integrating small fan blowers into interconnect designs, engineers can significantly mitigate thermal risks, thereby of these critical components.

Furthermore, in connecting engineers with dependable distribution partners, facilitating access to such as CONEC and Delta. These partnerships are vital for and robust interconnect solutions.

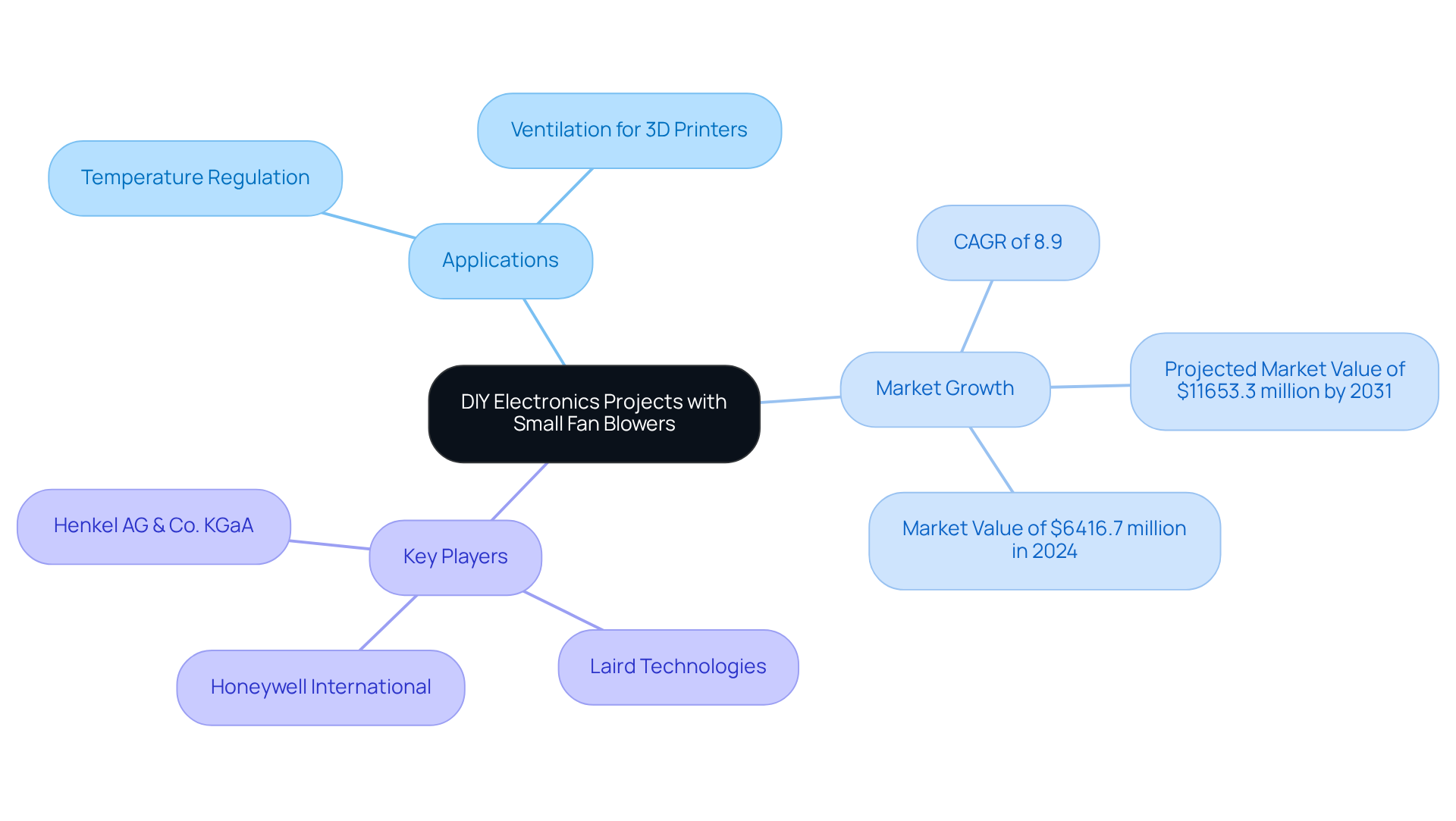

DIY Electronics Projects: Utilizing Small Fan Blowers for Creative Solutions

s are not solely intended for commercial uses; they can also be innovatively incorporated into . From temperature regulation setups for custom-built computers to , these devices provide flexible choices for hobbyists and engineers alike. By experimenting with different configurations and placements, users can develop of their projects while also addressing .

According to Laird Technologies, Inc., which focuses on , the incorporation of a small fan blower is essential for in various applications. Furthermore, the global Electronics Thermal Management Solutions market is projected to grow at a CAGR of 8.9% from 2024 to 2031, with a market value of $6416.7 million in 2024. This trend underscores the importance of , including the small fan blower, in DIY electronics, as highlighted by Honeywell International Inc., known for its advanced thermal management systems.

By leveraging the expertise of key players like Henkel AG & Co. KGaA and Laird Technologies, hobbyists can while effectively tackling thermal management issues.

Temperature Control: Protecting Electronics with Small Fan Blowers in Enclosures

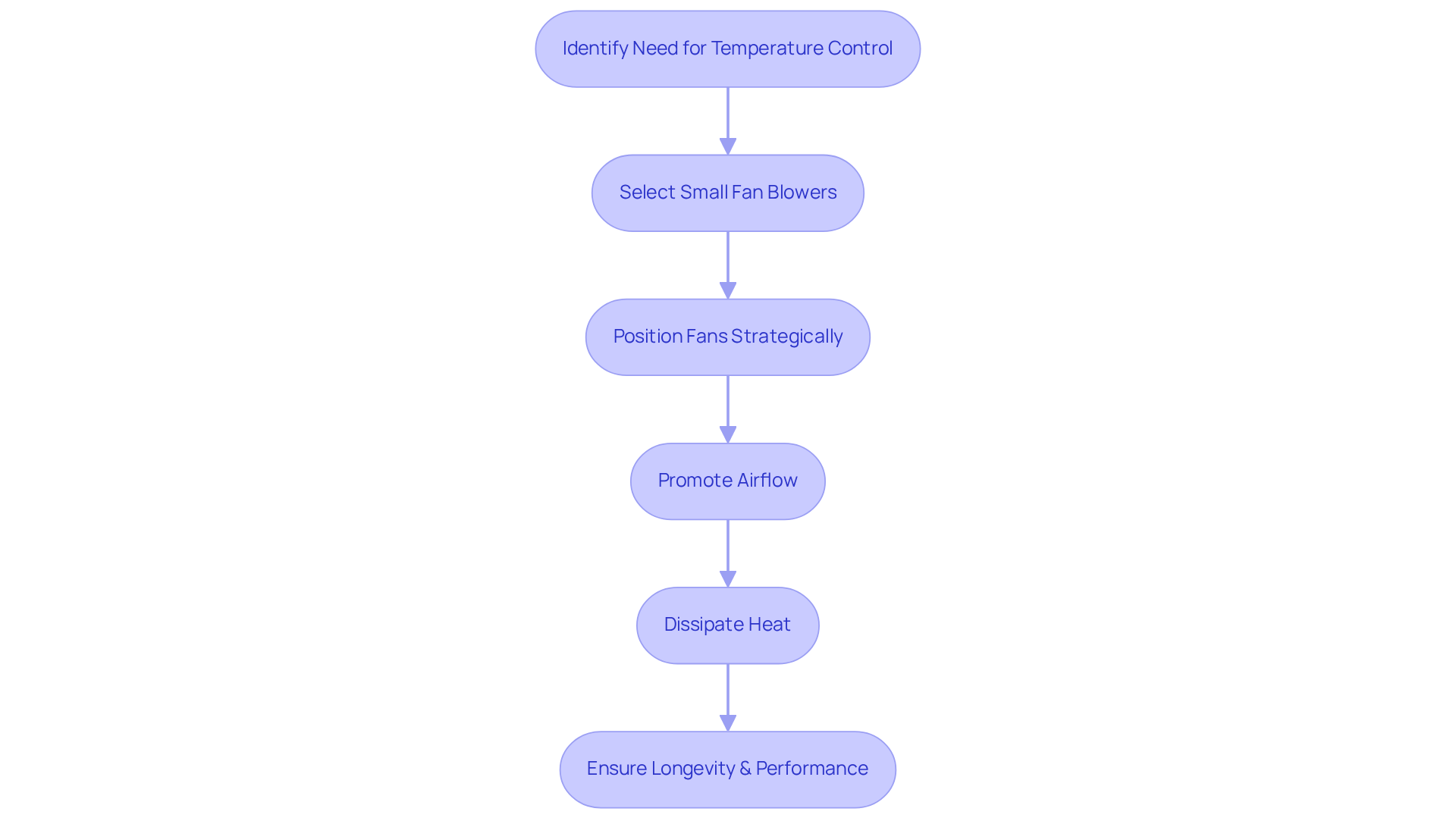

In electronic enclosures, maintaining is critical for protecting sensitive components from overheating. significantly enhance efficient by promoting airflow and dissipating heat within enclosed areas. By strategically positioning these fans in enclosures, engineers can effectively prevent . This proactive approach ensures that and efficiently, even in difficult environments. Ultimately, the implementation of well-placed small fan blowers is essential for the of electronic systems.

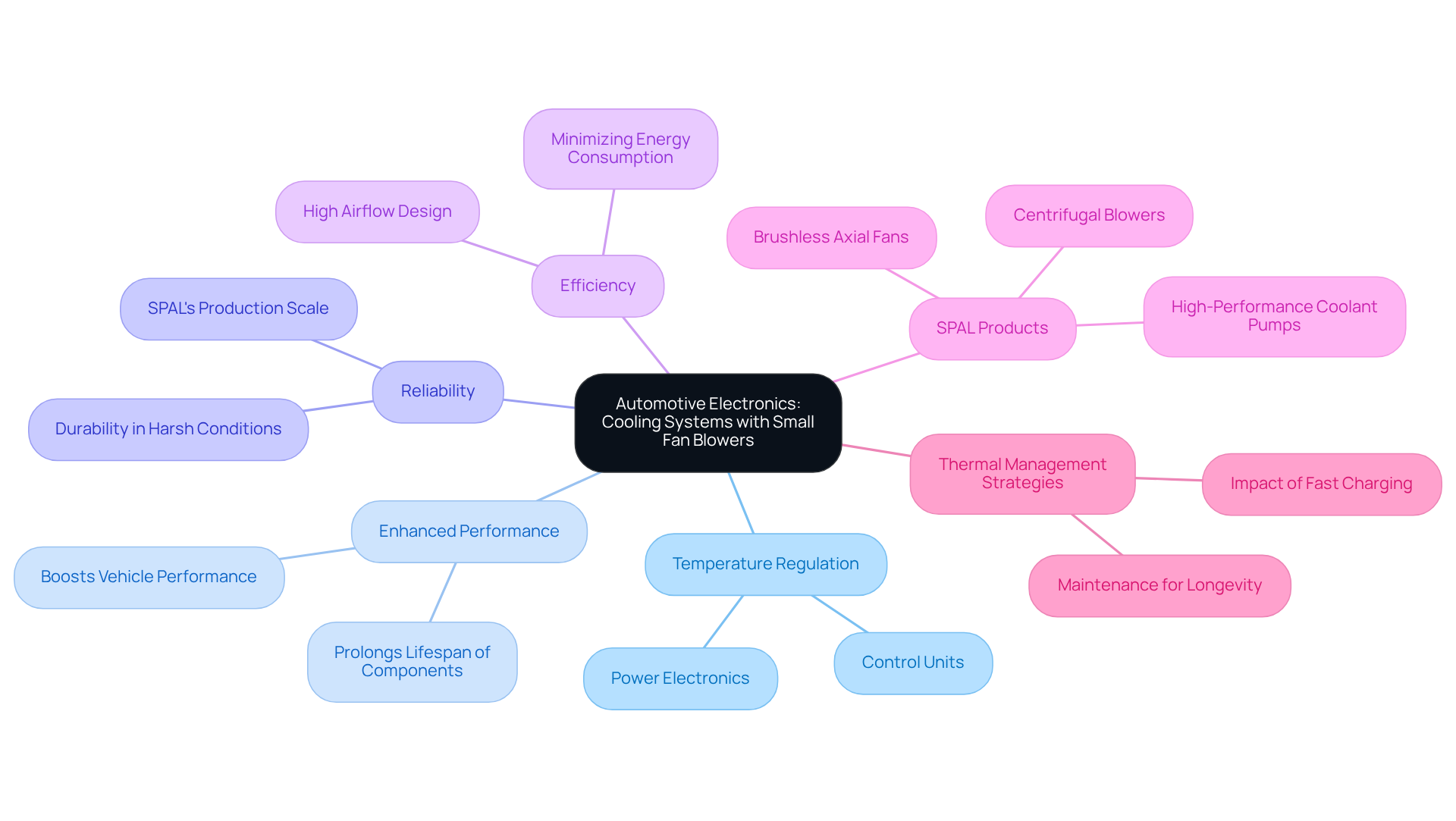

Automotive Electronics: Cooling Systems with Small Fan Blowers for Enhanced Performance

In the automotive industry, in regulating temperature for electronic components that endure . These devices effectively manage the heat produced by vital elements such as power electronics and control units, which is essential for and reliability.

By incorporating a into automotive designs, engineers can markedly . This integration not only but also of electronic components.

For instance, SPAL’s brushless axial devices are engineered to provide high airflow while minimizing energy consumption, making them ideal for modern automotive applications. SPAL produces millions of and centrifugal devices each year, underscoring their reliability and scale within the industry.

With over 60 years of expertise in heating and cooling products, SPAL’s knowledge fortifies the credibility of their solutions. As vehicles increasingly rely on advanced electronic systems, the importance of effective through the use of a small fan blower cannot be overstated. Their capacity to alleviate thermal stress directly affects the performance and durability of automotive electronics, ensuring that vehicles function efficiently even under challenging conditions.

Furthermore, the influence of fast charging on battery degradation underscores the necessity for robust thermal management strategies to preserve electronic performance in contemporary vehicles.

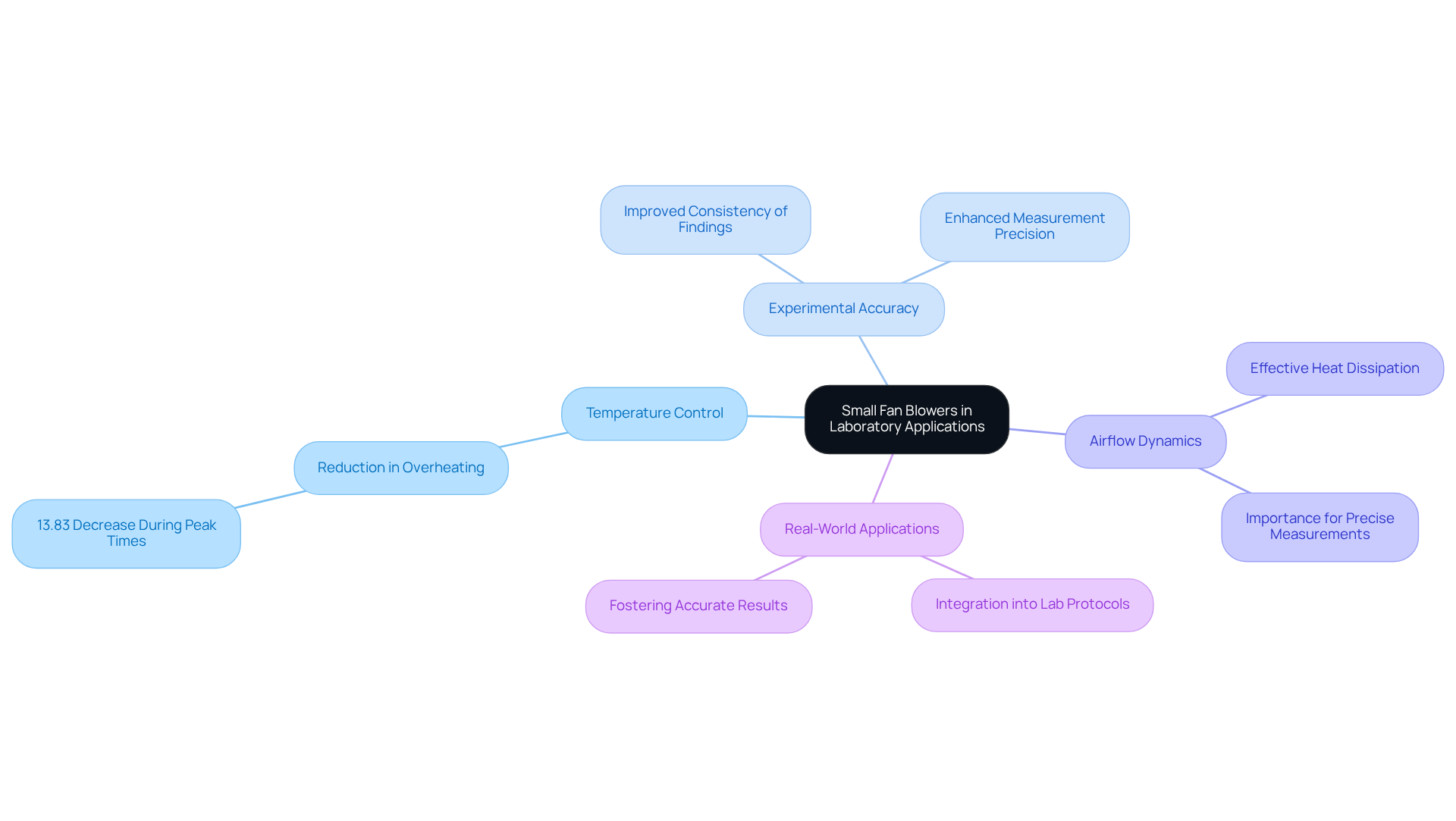

Laboratory Applications: Ensuring Precise Temperature Control with Small Fan Blowers

In laboratory environments, is paramount for ensuring experimental accuracy and prolonging equipment lifespan. s play a crucial role in achieving this objective by promoting . By incorporating these devices into lab configurations, researchers can keep delicate instruments and samples within ideal temperature ranges, greatly .

Research has demonstrated that the application of a small fan blower can decrease overheating by as much as 13.83% during peak operational times, thus alleviating discomfort and enhancing overall experimental conditions. Moreover, expert insights emphasize that these devices not only aid in better but also , which is crucial for precise measurements in different experimental arrangements.

Real-world applications illustrate that through a small fan blower can lead to more reliable data and . This underscores the necessity for researchers to integrate such devices into their protocols, thereby fostering an environment conducive to .

Conclusion

The integration of small fan blowers in electronics represents a pivotal advancement for enhancing performance and reliability across diverse applications. These compact devices are essential for managing heat, ensuring that electronic components function within safe temperature ranges. By efficiently dissipating heat, small fan blowers not only safeguard sensitive parts but also significantly contribute to the overall efficiency and longevity of electronic systems.

Key insights throughout the article underscore the necessity of selecting the appropriate fan type—whether axial, centrifugal, or exhaust—to satisfy specific airflow and pressure requirements. The advantages of small fan blowers span from power management and RF applications to automotive and laboratory environments, where precise temperature control is paramount. Additionally, the increasing trend towards DIY electronics illustrates the versatility of these devices, empowering hobbyists to innovate and enhance their projects.

Ultimately, the importance of effective thermal management cannot be overstated. As the demand for advanced electronics escalates, adopting innovative cooling solutions, such as small fan blowers, will be vital for ensuring optimal performance and reliability. It is essential for engineers, manufacturers, and enthusiasts alike to prioritize these technologies in their designs to address the challenges of modern electronics and promote a more efficient future.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates is recognized for delivering innovative temperature regulation solutions specifically tailored for the electronics engineering sector, including advanced cooling devices like small fan blowers and a variety of DC input tube axial fans and centrifugal blowers.

How do Gagner-Toomey’s cooling solutions benefit electronic components?

Their cooling solutions enhance the performance and reliability of electronic components by effectively managing temperature, which is crucial for preventing thermal accumulation and potential component failure.

What advancements in temperature regulation technologies does Gagner-Toomey offer?

Gagner-Toomey provides access to cutting-edge temperature regulation technologies, including liquid systems capable of achieving heat fluxes exceeding 800 watts per square centimeter, which are essential for high-performance electronics.

Why is efficient temperature management becoming increasingly important?

The global energy consumption for temperature control is projected to more than double by 2030, highlighting the urgent need for more efficient temperature management solutions in the electronics sector.

What are the benefits of using small fan blowers in electronic assemblies?

Small fan blowers enhance airflow and facilitate effective heat dissipation, significantly reducing temperatures by as much as 20°C, which is vital for maintaining safe operating conditions for critical components.

What types of small ventilation fans are available and what are their uses?

The three primary types of small ventilation fans are: – Axial fans, effective in low-pressure environments – Centrifugal fans, which excel in high-pressure situations – Exhaust fans, each designed for specific airflow requirements.

How do small fan devices contribute to power management applications?

Small fan devices enhance airflow, which directly improves the cooling of power electronics, sustaining efficiency, preventing overheating, and extending the operational lifespan of components.

What are the key advantages of integrating small fan devices into electronic designs?

Integrating small fan devices leads to enhanced energy efficiency, reduced thermal stress on components, and extended operational lifespans, which are essential for maximizing performance and reliability in electronic systems.