Overview

This article delves into three pivotal practices for effective fan selection in electronics, underscoring the necessity of grasping fan fundamentals, assessing selection criteria, and executing best integration practices. It illustrates how critical factors—such as airflow, static pressure, efficiency ratings, and appropriate placement—are integral to achieving optimal cooling performance and reliability in electronic systems.

Introduction

Selecting the right fan for electronic applications represents a critical yet often overlooked aspect of engineering design. As electronic systems grow increasingly complex, a thorough understanding of fan fundamentals and specifications becomes essential for enhancing performance and reliability. However, engineers frequently encounter the challenge of navigating through a myriad of fan types and performance metrics to identify the optimal solution. To streamline this selection process and ensure effective integration of fans in electronic devices, it is vital to adopt key practices that will guide decision-making.

Understand Fan Fundamentals and Specifications

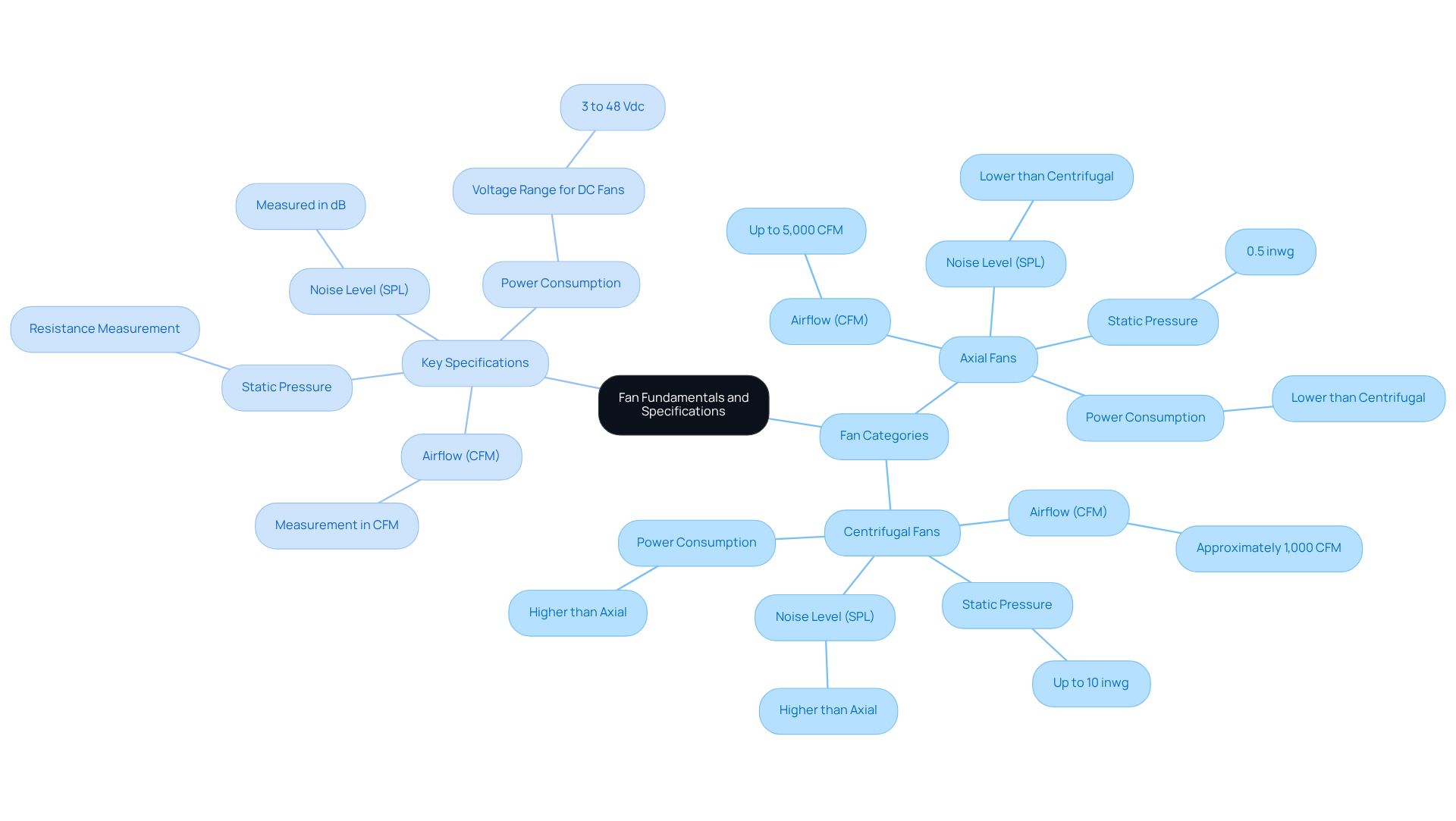

Selecting the right fan for electronic applications requires a comprehensive understanding of air movement, static pressure, and fan categories. Fans are fundamentally divided into axial and centrifugal types, each designed for specific operational requirements. Axial blowers excel in high air movement scenarios, making them ideal for temperature regulation in closely packed electronic components. In contrast, centrifugal devices are optimized for high-pressure environments, effectively overcoming resistance in systems equipped with filters or ducts.

Key specifications to consider include:

- Airflow (CFM): This metric quantifies the volume of air a fan can move, measured in cubic feet per minute (CFM). For instance, axial blowers can achieve airflow rates of up to 5,000 CFM, making them suitable for extensive cooling applications.

- Static Pressure: This parameter indicates the resistance a fan can overcome to maintain airflow, which is critical in applications involving ducting or filters. Centrifugal blowers can produce pressures up to 10 inches of water gauge (inwg), essential for ensuring airflow in constrained spaces.

- Noise Level (SPL): Expressed in decibels (dB), this figure reflects the operational loudness of the fan. Typically, axial units operate at compared to centrifugal counterparts, rendering them more appropriate for noise-sensitive environments.

- Power Consumption: Understanding the electrical requirements is vital for ensuring compatibility with the system’s power supply. For example, DC fans function efficiently within a voltage range of 3 to 48 Vdc, producing less electromagnetic interference (EMI) than AC fans.

By mastering these essential principles, engineers can make informed choices that align with their temperature management needs and system limitations, ultimately enhancing the performance and reliability of electronic systems.

Evaluate Key Selection Criteria for Optimal Performance

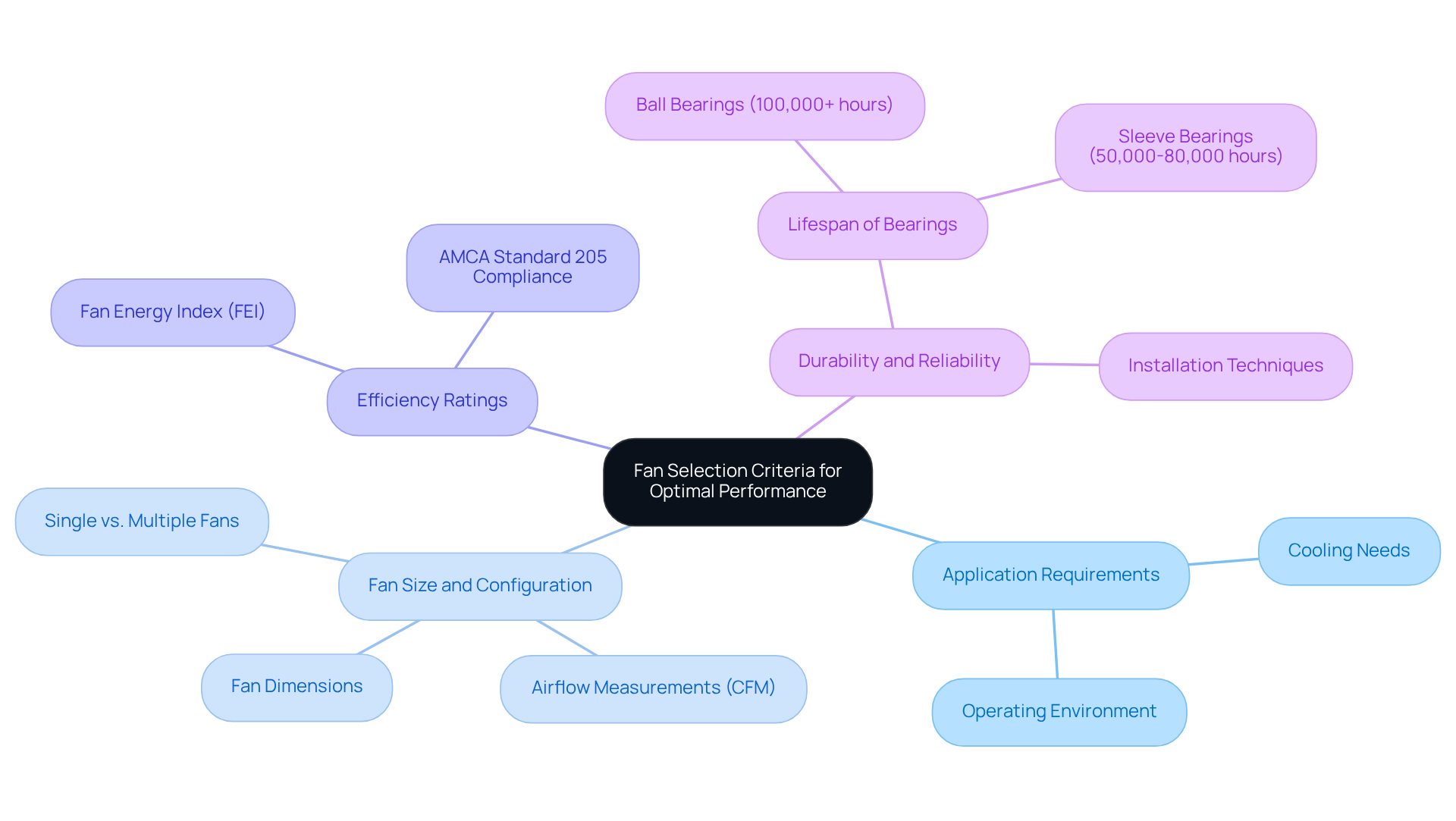

Selecting the appropriate fan for electronic devices necessitates a thorough evaluation of several key criteria to ensure optimal performance:

- Application Requirements: Recognizing the specific cooling needs dictated by the thermal load produced by electronic components is paramount. This assessment includes consideration of the operating environment, as indoor air quality can significantly differ from outdoor air, affecting . Gagner-Toomey Associates offers an extensive selection of DC input Tube Axial units and Centrifugal Blowers, designed for performance and efficiency, making them suitable for a variety of applications in electronics.

- Fan Size and Configuration: The physical dimensions of the fan must correspond with the design constraints of the device. For instance, small ventilators (≤92mm) are ideal for compact spaces but tend to generate less circulation and increased noise at higher speeds. Conversely, medium and large fans (120mm+) from Gagner-Toomey enhance ventilation efficiency at reduced speeds, leading to quieter and more energy-efficient operation. The configuration—whether employing single or multiple fans—also influences air movement dynamics; parallel setups improve air circulation, while series configurations boost air pressure for densely packed components. Airflow is quantified in cubic feet per minute (CFM), a critical measure for ensuring adequate cooling.

- Efficiency Ratings: High-efficiency units are vital for minimizing energy consumption while maximizing airflow, especially in battery-operated devices. The Fan Energy Index (FEI) serves as a valuable metric, with values exceeding 1 indicating superior efficiency compared to standard units. Furthermore, AMCA Standard 205 advises that a deviation of no more than 15 percentage points below the fan’s total peak efficiency is an acceptable range for selecting an efficient fan, guiding engineers in their pursuit of energy-efficient solutions. Gagner-Toomey’s products are engineered with these efficiency benchmarks in mind, ensuring optimal performance.

- Durability and Reliability: Evaluating the fan’s expected lifespan and its capacity to function under varying environmental conditions is crucial. For example, Gagner-Toomey’s models featuring ball bearings can last over 100,000 hours, making them ideal for heavy-duty applications, while sleeve bearings, with a lifespan of 50,000 to 80,000 hours, are more suited for low-load environments. Regular application of specialized lubricant to sleeve-bearing devices can extend their operational lifespan. Additionally, proper installation techniques, such as ensuring correct air movement direction and utilizing anti-vibration mounts, can further enhance durability and performance.

By meticulously assessing these criteria and considering Gagner-Toomey’s comprehensive range of temperature regulation solutions, including IP protection and various thermal management options such as heatsinks and liquid temperature control methods, engineers can make fans selection that not only meets performance expectations but also significantly enhances the durability and reliability of their electronic devices.

Implement Best Practices for Effective Fan Integration

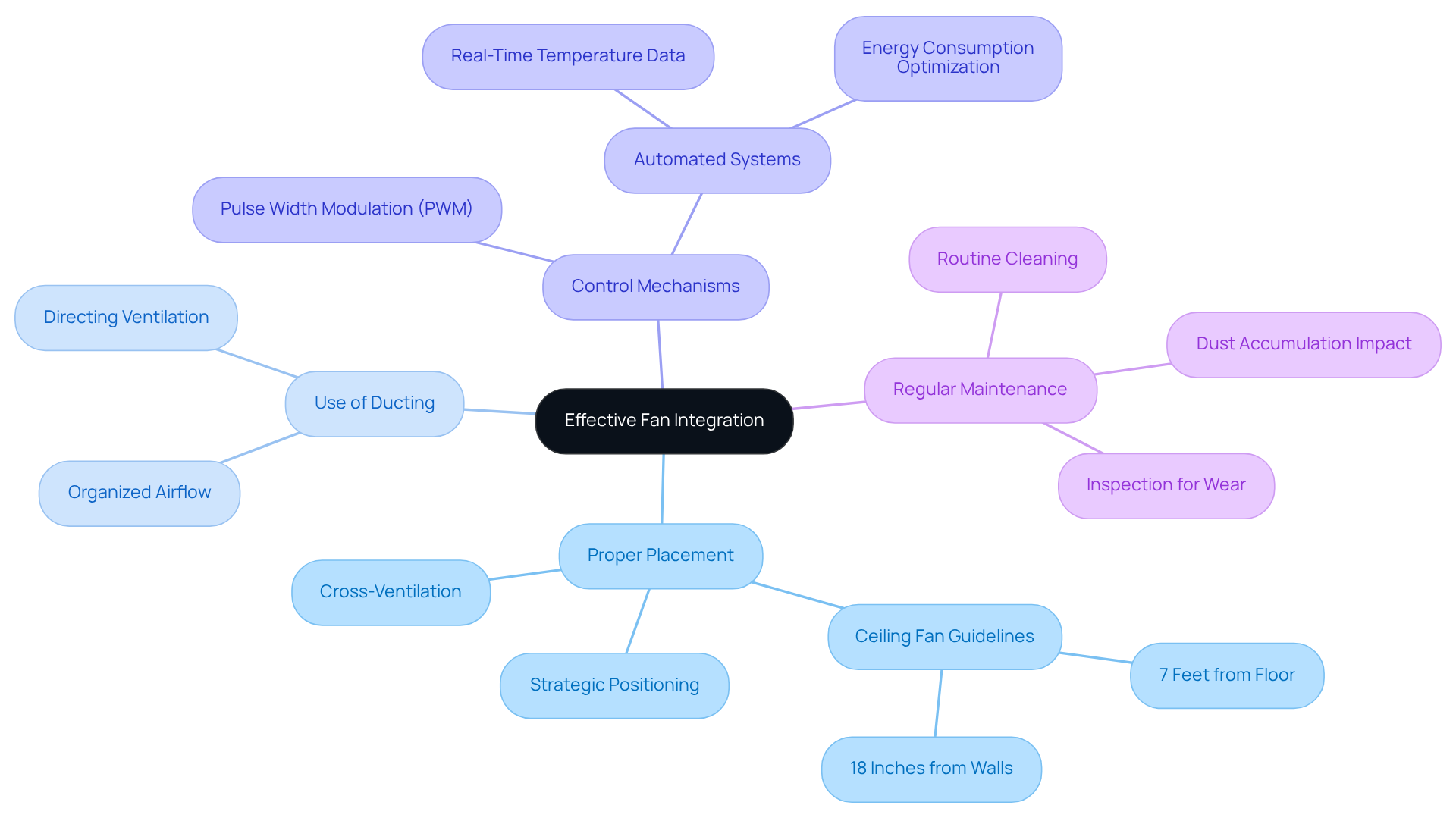

To achieve effective fan integration in electronic systems, it is essential to consider the following best practices:

- Proper Placement: Position fans strategically to optimize airflow across critical components. Unobstructed intake and exhaust paths promote . Experts emphasize that appropriate fan positioning can significantly enhance temperature management, with research indicating that inadequate temperature control may reduce equipment longevity by as much as 30%.

- Use of Ducting: In scenarios where space is limited, ducting can efficiently direct ventilation to specific locations, thereby improving temperature regulation. For example, ducting can channel air from a fan directly to heat-sensitive components, ensuring they remain within optimal temperature ranges. This method not only enhances temperature regulation but also contributes to a more organized airflow arrangement.

- Control Mechanisms: Implementing fan speed control mechanisms, such as Pulse Width Modulation (PWM), allows for the adjustment of fan speed based on thermal load. This strategy not only increases temperature regulation efficiency but also reduces noise levels, resulting in a more comfortable environment. Automated systems that respond to real-time temperature data can optimize energy consumption and extend the lifespan of refrigeration equipment.

- Regular Maintenance: It is crucial to schedule routine maintenance to clean fans and inspect for wear and tear. Dust accumulation can significantly impair fan performance and lifespan, making regular upkeep vital for sustained efficiency. By ensuring optimal fan performance, engineers can foster a healthier and more productive workspace.

By adhering to these best practices, engineers can ensure that their cooling solutions are not only effective but also sustainable over time.

Conclusion

Selecting the right fan for electronic applications is a critical task that necessitates a nuanced understanding of fan fundamentals, key specifications, and best practices for integration. Engineers who grasp the distinctions between axial and centrifugal fans can make informed choices that enhance performance and reliability in temperature management systems.

Essential factors such as airflow, static pressure, noise levels, and power consumption play a pivotal role in fan selection. Evaluating application requirements, fan size, efficiency ratings, and durability ensures that the chosen fan meets the specific demands of the electronic environment. Furthermore, implementing best practices for fan placement, ducting, control mechanisms, and regular maintenance optimizes cooling solutions, promoting long-term efficiency and sustainability.

Ultimately, effective fan selection and integration extend beyond immediate performance; they have far-reaching implications for the longevity and reliability of electronic devices. By prioritizing these practices, engineers can significantly enhance the functionality of their systems, ensuring efficient and effective operation across various applications. Emphasizing the importance of meticulous fan selection will lead to improved thermal management and a more robust electronic infrastructure.

Frequently Asked Questions

What are the main types of fans used in electronic applications?

The main types of fans used in electronic applications are axial and centrifugal fans. Axial fans excel in high air movement scenarios, while centrifugal fans are optimized for high-pressure environments.

What is the purpose of axial blowers in electronic systems?

Axial blowers are ideal for temperature regulation in closely packed electronic components due to their ability to achieve high airflow rates.

When are centrifugal fans preferred over axial fans?

Centrifugal fans are preferred in high-pressure environments where they can effectively overcome resistance in systems equipped with filters or ducts.

What does airflow (CFM) measure in fan specifications?

Airflow (CFM) measures the volume of air a fan can move, expressed in cubic feet per minute. Axial blowers can achieve airflow rates of up to 5,000 CFM.

Why is static pressure an important specification for fans?

Static pressure indicates the resistance a fan can overcome to maintain airflow, which is critical in applications involving ducting or filters. Centrifugal blowers can produce pressures up to 10 inches of water gauge (inwg).

How is noise level measured for fans, and which type is generally quieter?

Noise level is measured in decibels (dB). Typically, axial fans operate at lower noise levels compared to centrifugal fans, making them more suitable for noise-sensitive environments.

What should be considered regarding power consumption when selecting a fan?

Understanding the electrical requirements is vital for ensuring compatibility with the system’s power supply. DC fans typically operate efficiently within a voltage range of 3 to 48 Vdc and produce less electromagnetic interference (EMI) than AC fans.

How can engineers benefit from understanding fan fundamentals and specifications?

By mastering fan fundamentals and specifications, engineers can make informed choices that align with their temperature management needs and system limitations, ultimately enhancing the performance and reliability of electronic systems.